- Manuals

- Brands

- Aqua Manuals

- Water Pump

- HC150 Series

- Manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

PUMPS SERIES

HC150 / HC101

ADSP9500090

Rev. 3.1 del 05/10/2020

1

Related Manuals for Aqua HC150 Series

Summary of Contents for Aqua HC150 Series

-

Page 1

PUMPS SERIES HC150 / HC101 ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 2

HC150 / HC101 INTRODUCTION Analog solenoid driven dosing pump ENGLISH ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 3: Table Of Contents

HC150 / HC101 INTRODUCTION Analog solenoid driven dosing pump ENGLISH CONTENTS 1 INTRODUCTION ……………………4 1.1 Warnings …………………………..4 1.2 Models …………………………..5 1.3 Available flows …………………………5 1.4 Standards of reference ……………………….6 1.5 Technical features ………………………… 6 2.0 INSTALLATION AND TECHNICAL FEATURES …………..7 2.1 General regulations ……………………….

-

Page 4: Introduction

Analog solenoid driven dosing pump ENGLISH 1 INTRODUCTION Thank you for having purchased an Aqua product. The HC150 / HC101 series solenoid driven dosing pumps represent the ideal solution for dosing small amounts of chemical products. The pumps are regulated through analogue controls, including a two-colour LED and a regulating knob.

-

Page 5: Models

HC150 / HC101 INTRODUCTION Analog solenoid driven dosing pump ENGLISH There are 2 protection devices inside the pump: a varistor and a fuse. If it is necessary to remove the pump from the system, it is essential that the rubber discs are put back in so as to avoid liquid leaking out from the pump head.

-

Page 6: Standards Of Reference

HC150 / HC101 INTRODUCTION Analog solenoid driven dosing pump ENGLISH Flow Pressure Frequency (max) Flow Description cc per dose 0,28 HC101 Mod. 1 0,69 0,97 0,78 HC101 Mod. 2 0,89 1,11 0,33 HC101 Mod. 3 0,44 0,55 0,93 HC101 Mod. 4 1,11 1,30 0,44…

-

Page 7: Installation And Technical Features

HC150 / HC101 INSTALLATION Solenoid driven dosing pump ENGLISH 2.0 INSTALLATION AND TECHNICAL FEATURES 2.1 General regulations Pump installation must be carried out as follows: On a horizontal support (ex.: storage tank) or on the wall-mount bracket (optional) as long as the pumps remains in a vertical position +/- 15°.

-

Page 8: Pulse Emission Counter — Only For Model Pi

HC150 / HC101 INSTALLATION Solenoid driven dosing pump ENGLISH 2.3.3 Pulse Emission Counter – only for model PI HC150: Connect the red- BNC connector to the corresponding connector located at the bottom of the pump. HC150 PI Pulse water meter HC101: The pulse input is suitable for: …

-

Page 9: Hydraulic Connection

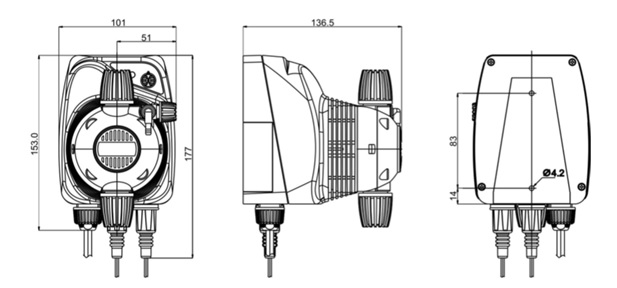

Overall dimensions HC150 series pump – wall-mounted (fig. 1) HC150 series pump – with base (fig. 2) HC101 series pump – with base (fig. 2a) Connections and exploded views …

-

Page 10: Programming The Pumps

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 3 PROGRAMMING THE PUMPS 3.1 HC150 / HC101 costant Programming the HC150 / HC101 costant pump or in constant mode is based on the setting, using the knob, regulating the number of pulses per minute that the pump must carry out. It is possible to regulate the number of pulses per minute, and therefore the flow of the pump, using two regulating scales: …

-

Page 11: Hc150 / Hc101 Ma

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 3.2 HC150 / HC101 mA The pump can operate in constant mode or in proportional current mode (mA). In constant mode it operates like model HC150 costant, whereas in proportional mode mA, the number of impulses is proportional to the current signal connected to the BNC — red connector.

-

Page 12: Scale Change Procedure

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 3.2.2 Scale change procedure The following procedure allows you to switch from one scale to the other. To perform this operation it is advisable to use a medium flat-tip screwdriver. …

-

Page 13: Hc150 / Hc101 Pi

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 3.3 HC150 / HC101 PI The pump can operate in constant mode as well as proportional mode to pulses sent from a counter. In constant mode it operates like model HC150 / HC101 costant whereas in proportional pulse mode the pump provides an injection for each “N”…

-

Page 14: Meaning Of Two-Colour Led

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 2 flashes => 101…200 3 flashes => 201…300 1 flash => 1…100 until you reach: 10 flashes => 901…1000 and then to 1 flash green => 1…10 (1xN) 3.3.2 Meaning of two-colour LED The colour of the LED immediately indicates the type of proportional pump operation, in fact: …

-

Page 15: How To Choose The Pump

HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH 3.3.4 How to choose the pump As the number of m of water to be treated in the system is known, and the quantity of product to be dosed, expressed in P.P.M.

-

Page 16: Maintenance

HC150 / HC101 MAINTENANCE Solenoid driven dosing pump ENGLISH 4 MAINTENANCE 4.1 General regulations Periodic maintenance is of fundamental importance to keep the pump in good running order and make it last over time. The tips provided below must be followed systematically and to the letter. It is extremely difficult to define the standard times required for maintenance beforehand, as the factors that determine the wear of the pump, and in particular the parts that are in contact with the liquid, are numerous.

-

Page 17: Troubleshooting

HC150 / HC101 MAINTENANCE Solenoid driven dosing pump ENGLISH 6. Re-insert the cartridge into the pump head. Changing sealing O-rings and the diaphragm Proceed as follows: 1. Remove the small round cover from the pump head using a small utensil to lever it off. 2.

-

Page 18: Chemical Compatibility Table

HC150 / HC101 WARRANTY Solenoid driven dosing pump ENGLISH 5 Chemical Compatibility Table Dosing pumps are widely used for dosing chemical products. It is important to select the most suitable material for the liquid to be dosed. The CHEMICAL COMPATIBILITY TABLE is a precious aid to that end. The following Table must be used as an indicative instrument.

-

Page 19: Return To The After-Sales Service

HC150 / HC101 WARRANTY Solenoid driven dosing pump ENGLISH Disclaimer The information included in these tables has been obtained from highly qualified sources which we deem reliable and they are provided without any guarantee, explicit or implicit, concerning their exactness. Conditions or methods for handling, storage and use of the material are beyond our control and/or knowledge.

-

Page 20: Dimensioni — Dimensions

8 Dimensioni – Dimensions “HC150” – W . 1: S ERIE A MURO ALL MOUNTING “HC150” – B . 2: S ERIE CON BASE ASE MOUNTING ADSP9500090 Rev. 3.1 del 05/10/2020…

-

Page 21

ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 22

“HC101” – B . 2A: S ERIE CON BASE ASE MOUNTING ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 23

– P . 3: C OLLEGAMENTI TUBI SUL CORPO POMPA UMP HEAD CONNECTIONS – – L . 4: S . 5: C PURGO MANUALE MANUAL PURGE OLLEGAMENTO SONDA DI LIVELLO OW LEVEL PROBE — OPTIONAL CONNECTION ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 24: Esploso / Exploded View

9 Esploso / Exploded view Fig. 6: HC150 Esploso / Exploded view ADSP9500090 Rev. 3.1 del 05/10/2020…

-

Page 25

VITE M 2.9×13 UNI 6954 (TCTC) INOX A2 ADSP9500130 ANELLO IDENTIFICAZIONE INGRESSI BNC ADSP9000002 COVER GIALLO RAL 1007 CORPO POMPA 1-14LT HC897 ADSP9000003 TARGHETTA NERA CON LOGO AQUA PER CORPO POMPA 1-14LT HC897 ADSP6000749 VITE M 2.9X9.5 UNI 6954 (AF-TCTC) INOX A2 ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 26

ADSP9500130 BNC INPUTS IDENTIFICATION RING ADSP9000002 COVER YELLOW RAL 1007 PUMP HEAD 1-14LT HC897 ADSP9000003 BLACK PLATE WITH AQUA LOGO FOR PUMP HEAD 1-14LT HC897 M 2.9X9.5 UNI 6954 (AF-SLOTTED PAN HEAD SCREW) STAINLESS STEEL A2 ADSP6000749 SCREWS ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 27

Fig. 6A: HC101 Esploso / Exploded view ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 28

CORPO POMPA 1-14 PP-GL-VT COMPLETO HC897/797 31 ADSP9000002 COVER GIALLO RAL 1007 CORPO POMPA 1-14LT HC897 32 ADSP9000003 TARGHETTA NERA CON LOGO AQUA PER CORPO POMPA 1-14LT HC897 ADSP6000835 CONNETTORE MASCHIO 4 VIE G4A5M CABLATO SERVIZI 1XPANDUIT 2 VIE ADSP9500090… -

Page 29

PUMP HEAD 1-14 PP-GL-VT COMPLETE HC897/797 31 ADSP9000002 COVER YELLOW RAL 1007 PUMP HEAD 1-14LT HC897 32 ADSP9000003 BACKPLATE WITH AQUA LOGO FOR PUMP HEAD 1-14LT HC897 ADSP6000835 MALE CONNECTOR 4-WAY G4A5M CABLED SERVIZI 1XPANDUIT 2-WAY ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 30

Fig. 7: Corpo pompa e valvole a sfera – Pump head and ball valves ADSP9500090 Rev. 3.1 del 05/10/2020… -

Page 31

Descrizione / Description Codice Descrizione Q.tà ADSP9000001P CORPO POMPA 1-14 PVDF HC897 ADSP9000001 CORPO POMPA 1-14 PP HC897 ADSP5007200 OR — RIF. 3143 — VITON NERO ADSP5007209 OR — RIF. 3143 — DUTRAL NERO ADSP5007049V OR — RIF. 2010 — VITON NERO ADSP5007055D OR — RIF. -

Page 32

Descrizione / Description Code Description Q.ty ADSP9000001P PUMP HEAD 1-14 PVDF HC897 ADSP9000001 PUMP HEAD 1-14 PP HC897 ADSP5007200 OR — REF. 3143 — VITON BLACK ADSP5007209 OR — REF. 3143 — DUTRAL BLACK ADSP5007049V OR — RIF. 2010 — VITON BLACK ADSP5007055D OR — RIF. -

Page 33

Note on environmental protection After the implementation of the European Directive 2002/96/EU in the national legal system, the following applies: Electrical and electronic devices may not be disposed of with domestic waste. Consumers are obliged by lak to return electrical and electronic devices at the end of their service lives to the public collecting points set up for this purpose. -

Page 34

PUMPS SERIES HC150 ADSP9500090 Rev. 3.1 del 05/10/2020…

- Manuals

- Brands

- Aqua Manuals

- Water Pump

- HC150 Series

Manuals and User Guides for Aqua HC150 Series. We have 2 Aqua HC150 Series manuals available for free PDF download: Operating And Maintenance Instructions Manual, Manual

Aqua HC150 Series Operating And Maintenance Instructions Manual (151 pages)

Brand: Aqua

|

Category: Water Pump

|

Size: 4.96 MB

Table of Contents

-

Italiano

2

-

Table of Contents

2

-

1 Introduzione

4

-

Modelli

4

-

Portate Disponibili

5

-

Avvertenze

5

-

Normative DI Riferimento

5

-

Caratteristiche Tecniche

6

-

-

2 Installazione E Caratteristiche Tecniche

7

-

Norme Generali

7

-

Accessori in Dotazione

7

-

Collegamenti Elettrici

7

-

Alimentazione

7

-

Sonda DI Livello

7

-

Contatore Lancia Impulsi — solo Per Il Modello PI

8

-

Segnale in Corrente — solo Per Il Modello Ma

8

-

-

Collegamento Idraulico

8

-

Principio DI Funzionamento

9

-

-

3 Programmazione Delle Pompe

10

-

HC150 / HC101 Costante

10

-

Procedura Cambio Scala

10

-

Significato LED Bicolore

10

-

-

HC150 / HC101 Ma

11

-

Significato LED Bicolore

11

-

Procedura Cambio Scala

12

-

Cambio Modo DI Funzionamento

12

-

-

Hc150 / Hc101 Pi

13

-

Procedura Cambio Scala DI Intervallo

13

-

Significato LED Bicolore

14

-

Cambio Modo DI Funzionamento

14

-

Come Scegliere la Pompa

15

-

-

-

4 Manutenzione

16

-

Norme Generali

16

-

Manutenzione Periodica

16

-

Come Intervenire

16

-

Sostituzione Parti DI Normale Usura

16

-

Risoluzione Dei Problemi

17

-

-

5 Tabella DI Compatibilità Chimica

18

-

-

English

20

-

1 Introduction

22

-

Models

22

-

Available Flows

23

-

Warnings

23

-

Standards of Reference

23

-

Technical Features

24

-

-

2 Installation and Technical Features

25

-

General Regulations

25

-

Accessories Included

25

-

Electrical Connections

25

-

Power Supply

25

-

Low Level Probe

25

-

Pulse Emission Counter — Only for Model PI

25

-

Current Signal — Only for Model Ma

26

-

-

Hydraulic Connection

26

-

Principle of Operation

27

-

-

3 Programming the Pumps

28

-

HC150 / HC101 Costant

28

-

Scale Change Procedure

28

-

Meaning of Two-Colour LED

28

-

-

HC150 / HC101 Ma

29

-

Meaning of Two-Colour LED

29

-

Scale Change Procedure

30

-

How to Change the Operating Mode

30

-

-

Hc150 / Hc101 Pi

31

-

Interval Scale Change Procedure

31

-

Meaning of Two-Colour LED

32

-

How to Change the Operating Mode

32

-

How to Choose the Pump

33

-

How to Set the «N» Parameter in 1/N Mode

33

-

-

-

4 Maintenance

34

-

General Regulations

34

-

Periodic Maintenance

34

-

How to Intervene

34

-

How to Change Parts after Normal Wear

34

-

Troubleshooting

35

-

-

5 Chemical Compatibility Table

36

-

6 Return to the After-Sales Service

37

-

7 Guarantee Certificate

37

-

-

Français

38

-

1 Introduction

40

-

Modèles

40

-

Portées Disponibles

41

-

Notice D’utilisation

41

-

Réglementations de Référence

41

-

Caractéristiques Techniques

42

-

-

2 Installation Et Caracteristiques Techniques

43

-

Règles Générales

43

-

Accessoires en Dotation

43

-

Branchements Électriques

43

-

Alimentation

43

-

Sonde de Niveau

43

-

Compteur Émetteur Impulsions — Seulement Pour Le Modèle PI

44

-

Signal en Courant — Seulement Pour Le Modèle Ma

44

-

-

Raccordement Hydraulique

45

-

Principe de Fonctionnement

45

-

-

3 Programmation des Pompes

46

-

HC150 / HC101 Constant

46

-

Procédure Changement D’échelle

46

-

Signification LED Bicolore

46

-

-

HC150 / HC101 Ma

47

-

Signification LED Bicolore

47

-

Procédure Changement D’échelle

48

-

Changement Mode de Fonctionnement

48

-

-

Hc150 / Hc101 Pi

49

-

Procédure Changement D’échelle D’intervention

49

-

Signification LED Bicolore

50

-

Changement Mode de Fonctionnement

50

-

Comment Choisir la Pompe

51

-

Comment Régler Le Paramètre «N» en 1/N Mode

51

-

-

-

4 Entretien

52

-

Règles Générales

52

-

Entretien Périodique

52

-

Comment Intervenir

52

-

Remplacement Parties Usure Normale

52

-

Solutions des Problèmes

54

-

-

-

Español

57

-

Índice

58

-

1 Introducción

59

-

Modelos

59

-

Caudales Disponibles

60

-

Advertencias

60

-

Normativas de Referencia

60

-

Características Técnicas

61

-

-

2 Instalación y Características Técnicas

62

-

Normas Generales

62

-

Accesorios Suministrados

62

-

Conexiones Eléctricas

62

-

Alimentación

62

-

Sonda de Nivel

62

-

Contador Lanza Pulsaciones — solo para el Modelo PI

62

-

Señal en Corriente — solo para el Modelo Ma

63

-

-

Conexión Hidráulica

63

-

Principio de Funcionamiento

64

-

-

3 Programación de las Bombas

65

-

HC150 / HC101 Constante

65

-

Procedimiento del Cambio de Escala

65

-

Significado del Led Bicolor

65

-

-

HC150 / HC101 Ma

66

-

Significado del Led Bicolor

66

-

Procedimiento del Cambio de Escala

67

-

Cambio del Modo de Funcionamiento

67

-

-

Hc150 / Hc101 Pi

68

-

Procedimiento del Cambio de Escala de Intervalo

68

-

Significado del Led Bicolor

69

-

Cambio del Modo de Funcionamiento

69

-

Cómo Elegir la Bomba

70

-

Cómo Configurar el Parámetro «N» en 1 / N Modo

70

-

-

-

4 Mantenimiento

71

-

Normas Generales

71

-

Mantenimiento Periódico

71

-

Cómo Intervenir

71

-

Sustitución de las Piezas Sujetas a Desgaste Normal

71

-

Resolución de Problemas

72

-

-

-

Deutsch

75

-

1 Einführung

77

-

Modelle

77

-

Verfügbare Förderleistungen

78

-

Hinweise

78

-

Bezugsvorschriften

78

-

Technische Eigenschaften

79

-

-

2 Installation und Technische Eigenschaften

80

-

Allgemeine Vorschriften

80

-

Mitgeliefertes Zubehör

80

-

Elektrische Anschlüsse

80

-

Versorgung

80

-

Niveausonde

80

-

Impulsgeberzähler — nur Beim Modell PI

80

-

Stromsignal — nur bei Modell Ma

81

-

-

Hydraulischer Anschluss

81

-

Funktionsprinzip

82

-

-

3 Programmierung der Pumpen

83

-

HC150 / HC101 mit Konstanter Flussrate

83

-

Vorgehensweise zum Skalenwechsel

83

-

Bedeutung Zweifarb-LED

83

-

-

HC150 / HC101 Ma (mit Proportionaler Flussrate)

84

-

Bedeutung Zweifarb-LED

84

-

Vorgehensweise zum Skalenwechsel

85

-

Änderung des Betriebsmodus

85

-

-

Hc150 / Hc101 Pi

86

-

Vorgehensweise zum Wechseln der Intervallskala

86

-

Bedeutung Zweifarb-LED

87

-

Änderung des Betriebsmodus

87

-

Wahl der Pumpe

88

-

Einstellung des Parameters „N» in 1/N Modus

88

-

-

-

Allgemeine Vorschriften

89

-

Periodische Wartung

89

-

Vorgehensweise

89

-

Ersetzen von Verschleissteilen

89

-

Problembehebung

90

-

-

4 Wartung

89

-

-

Русский

110

-

1 Введение

112

-

Moдели

112

-

Важно Знать

113

-

Нормативы И Сертификаты

113

-

Технические Характеристики

113

-

-

2 Монтаж

114

-

Основные Требования

114

-

Комплектность Изделия

114

-

Электрические Характеристики

114

-

-

3 Узлы Насоса И Элементы Управления

114

-

Рисунок — ПАНЕЛЬ УПРАВЛЕНИЯ НАСОСОМ

115

-

Рисунок ГИДРАВЛИЧЕСКАЯ ЧАСТЬ

115

-

Принцип Работы

115

-

Гидравлические Соединения

117

-

МОНТАЖ ТРУБОК ЗАБОРНОЙ /НАПОРНОЙ К ПАТРУБКАМ ЗАБОРНОМУ И НАПОРНОМУ

117

-

Монтаж Трубок Заборной/Напорной К Внешним Заборному/Напорному Клапанам

117

-

Монтаж Линии Стравливания Воздуха

118

-

-

Электрические Соединения

119

-

Датчик Уровня-Подключение

119

-

Импульсный Водомер — Подключение — Только Для Моделей НС101 PI

119

-

Токовый Вход- Только Для Моделей НС101 Ma

119

-

-

-

4 Производительность

119

-

Производительность Электромагнитных Насосов

119

-

Кривые Производительности И Доступные Модификации

119

-

-

5 Программирование Насоса

121

-

HC101 CST -Постоянный

121

-

Процедура Смены Шкалы

121

-

Значения Двух Цветов Индикатора

121

-

-

HC101 Ma

122

-

Значения Двух Цветов Индикатора

122

-

Процедура Смены Шкалы

123

-

Смена Режима Дозирования

123

-

-

Hc101 Pi

124

-

Выбор И Смена Шкалы Интервалов

124

-

Значения Двух Цветов Индикатора

125

-

Смена Режима Дозирования

126

-

Как Выбрать Насос

126

-

-

-

Advertisement

Aqua HC150 Series Manual (34 pages)

Brand: Aqua

|

Category: Water Pump

|

Size: 3.05 MB

Table of Contents

-

Table of Contents

3

-

Introduction

4

-

Warnings

4

-

Models

5

-

Available Flows

5

-

Standards of Reference

6

-

Technical Features

6

-

Installation and Technical Features

7

-

General Regulations

7

-

Accessories Included

7

-

Electrical Connections

7

-

Power Supply

7

-

Low Level Probe

7

-

Pulse Emission Counter — Only for Model PI

8

-

Current Signal — Only for Model Ma

8

-

Hydraulic Connection

9

-

Principle of Operation

9

-

Programming the Pumps

10

-

HC150 / HC101 Costant

10

-

Scale Change Procedure

10

-

Meaning of Two-Colour LED

10

-

HC150 / HC101 Ma

11

-

Meaning of Two-Colour LED

11

-

Scale Change Procedure

12

-

How to Change the Operating Mode

12

-

Hc150 / Hc101 Pi

13

-

Interval Scale Change Procedure

13

-

Meaning of Two-Colour LED

14

-

How to Change the Operating Mode

14

-

How to Choose the Pump

15

-

Maintenance

16

-

General Regulations

16

-

Periodic Maintenance

16

-

How to Intervene

16

-

How to Change Parts after Normal Wear

16

-

Troubleshooting

17

-

Chemical Compatibility Table

18

-

Return to the After-Sales Service

19

-

Guarantee Certificate

19

-

Dimensioni — Dimensions

20

-

Esploso / Exploded View

24

Advertisement

Related Products

-

Aqua HC150 costant

-

Aqua HC150 mA

-

Aqua HC150 PI

-

Aqua HC150 0

-

Aqua HC150 1

-

Aqua HC150 2

-

Aqua HC150 3

-

Aqua HC150 4

-

Aqua HC150 5

-

Aqua HC151

Aqua Categories

Water Pump

Water Filtration Systems

Indoor Furnishing

Lighting Equipment

Bathroom Fixtures

More Aqua Manuals

Operating And Maintenance Instructions Manual for Aqua HC150 Series Water Pump (151 pages)

Specifications:1517/1517040-hc150_series.pdf file (09 May 2023) |

Accompanying Data:

Aqua HC150 Series Water Pump PDF Operating And Maintenance Instructions Manual (Updated: Tuesday 9th of May 2023 05:50:18 AM)

Rating: 4.8 (rated by 57 users)

Compatible devices: HC 200, Simpool Pool-T, DET 1, TEXMO AHS 02/03, HC151 PH-RX, HC997-1, HC 1, ECO WASH.

Recommended Documentation:

Text Version of Operating And Maintenance Instructions Manual

(Ocr-Read Summary of Contents of some pages of the Aqua HC150 Series Document (Main Content), UPD: 09 May 2023)

-

69, HC150 / HC101 MANTENIMIENTO Bomba dosificadora electromagnética ESPAÑOL ADSP9500090 Rev.2.5 09.09.2015 69 1 parpadeo => 1…100 2 parpadeos => 101…200 3 parpadeos => 201…300 hasta llegar a: 10 parpadeos => 901…1000 y luego a 1 parpadeo verde => 1 … 1…

-

79, Aqua HC150 Series HC150 / HC101 EINFÜHRUNG Analoge elektromagnetische Dosierpumpe DEUTSCH ADSP9500090 Rev.2.5 09.09.2015 79 n° 2004/108/CE “ e s.m.i. n° 2006/95/CE “DBT Low Voltage Directive” e s.m.i. n° 2011/65/UE , 2002/96/CE “direttive RoHs e WEEE” e s.m.i. Dies vo…

-

20, HC150 / HC101 INDEX Analog solenoid driven dosing pump ENGLISH ADSP9500090 Rev.2.5 09.09.2015 20 CONTENTS 1 INTRODUCTION ……………………………………………………………………………………………………………………….. 22 1.1 Models …………………..…

-

82, HC150 / HC101 PROGRAMMIERUNG DER PUMPEN Elektromagnetische Dosierpumpe DEUTSCH ADSP9500090 Rev.2.5 09.09.2015 82 das Produkt injiziert werden soll, ein Verbindungsstück des Typs 1/2” Gf angebracht wurde, das Injektionsventil mit Teflon umwickeln und in die Rohrleitung stecken. Gewinder…

-

148, Aqua HC150 Series ADSP9500090 Rev.2.5 09.09.2015 148 Descrizione / Description / Description / Descripción / Beschreibung # Código Descripción Cant. 2 ADSP9000001P CUERPO DE LA BOMBA 1-14 PVDF HC897 1 ADSP9000001 CUERPO DE LA BOMBA 1-14 PP HC897 1 3 ADSP5007200 JUNTA TÓRICA — REF. 314…

-

28, HC150 / HC101 PROGRAMMING THE PUMPS Solenoid driven dosing pump ENGLISH ADSP9500090 Rev.2.5 09.09.2015 28 3 PROGRAMMING THE PUMPS 3.1 HC150 / HC101 costant Programming the HC150 / HC101 costant pump or in constant mode is based on the setting, using the knob, regulating the numbe…

-

Aqua HC150 Series User Manual

-

Aqua HC150 Series User Guide

-

Aqua HC150 Series PDF Manual

-

Aqua HC150 Series Owner’s Manuals

Recommended: ICF-CD855V, RX Series, HT702

-

Simer SIMER 2961

OWNER’S MANUALSubmersible Solids Handling PumpsNOTICE D’UTILISATIONPompes submersibles pour les matières solidesMANUAL DEL USUARIOBombas submergibles para elmanejo de líquidos con sólidosInstallation/Operation/PartsFor further operating, installation, or maintenance assistance: Call 1-800-468-7867E …

SIMER 2961 16

-

Sandpiper S30

Model S30 Non-Metallic Design Level 3A Unit of IDEX Corporation800 N. Main St., Manseld, Ohio 44902 USA Telephone 419.524.8388Fax 419.522.7867SANDPIPERPUMP.COM© Copyright 2017 Warren Rupp, Inc.All righ …

S30 24

-

Zehnder Pumpen ZKH 20

[de] Kondensatpumpe — Installations- und Wartungsanleitung für den Fachhandwerker [fr] Pompe à condensats — Notice d’installation et d’entretien pour le professionnel[en] Condensate pump — Installation and Maintenance Instructions for the Contractor [cz] Čerpadlo kondenzátu — Návod k in …

ZKH 20 16

-

Edelbrock 63-0303

©2010 Edelbrock Corporation Part #8810-8812, 88104, 88114, 88124, 8816, 8817, 8820-8822Rev. 3/10 — AJ/mc Page 1 of 3 Brochure #63-0303PLEASE study these instructions carefully before installing your new water pump. If you have any questions or problems, do not hesitate to contactour Technical Hotline …

63-0303 3

Popular Right Now:

Operating Impressions, Questions and Answers:

| МАТЕРИАЛ ИСПОЛНЕНИЯ | ||

|---|---|---|

| Насос AQUA HC 150 | Стандартное исполнение | По запросу |

| Головка насоса | PP | PVDF |

| Мембрана | PTFE | – |

| Шаровые клапаны | Pyrex | PTFE, Ceramica |

| Фитинги | PP | PVDF |

| Уплотнения | Viton | Dutral |

| Пружина инжкционного клапана | Hastelloy-Pyrex | Hastelloy-PTFE-Ceramica |

| Инжектор | PP | PVDF |

| Донные клапаны | PP | PVDF |

| ДОСТУПНЫЕ ВЕРСИИ | |

|---|---|

| Тип | Аналоговый |

| Регулировка производительности | Регулировка производительности (кол-во тактов) |

| Постоянное дозирование | • AQUA HC 150 CST |

| Пропорционально водосчетчику | • AQUA HC 150 PI |

| Пропорционлаьно сигналу 4-20 мА | • AQUA HC 150 MA |

| Подключение датчика уровня | • |

| Подключение датчика потока | no |

| Подключение датчика PH-RX | no |

| Подключение датчика CL | no |

| ГИДРАВЛИЧЕСКИЕ ХАРАКТЕРИСТИКИ | |||||||

|---|---|---|---|---|---|---|---|

| Модель | Производительность л/ч | Давление BAR | Количество тактов в минуту | Обьем впрыска мл | Потребление ВАТТ | Трубка мм | Головка насоса |

| 0 | 1,5 | 5 | 100 | 0,25 | 14 | 4×6 | PP 1/2″ |

| 2 | 3 | 0,33 | |||||

| 3 | 1 | 0,50 | |||||

| 1 | 2 | 8 | 120 | 0,28 | 14 | 4×6 | PP 1/2″ |

| 5 | 5 | 0,69 | |||||

| 7 | 2 | 0,97 | |||||

| 2 | 7 | 4 | 150 | 0,78 | 14 | 4×6 | PP 1/2″ |

| 8 | 2 | 0,89 | |||||

| 10 | 0 | 1,11 | |||||

| 3 | 3 | 12 | 120 | 0,42 | 16 | 4×6 | PP 1/2″ |

| 4 | 10 | 0,56 | |||||

| 5 | 8 | 0,69 | |||||

| 4 | 10 | 4 | 180 | 0,93 | 16 | 4×6 | PP 1/2″ |

| 12 | 2 | 1,11 | |||||

| 14 | 0 | 1,30 | |||||

| 5 | 2 | 20 | 75 | 0,44 | 16 | 4×6 | PP 1/2″ |

| 2,5 | 18 | 0,56 | |||||

| 3 | 15 | 0,67 |

| КОМПЛЕКТ ПОСТАВКИ | |

|---|---|

| Насос Aqua HC 150 | |

| ADSP6000001 | Донный клапан всасывания |

| ADSP6200007 | Инжекционный клапан |

| ADSP6000546 | Трубка всасывающая PVС (2м) |

| ADSP6000078 | Трубка подающая PE (2м) |

| ADSP6020221 | Кронштейн крепежный на стену |

| ADSP6000041 | Крепежная фурнитура |

| Инструкция |