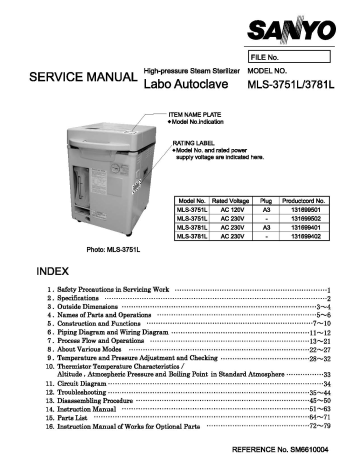

IFILE No.

SERVICE MANUAL

High-pressureSleamSlerilizer

MODEL NO.

Labo Autoclave

MLS-37S1 Ll3781 L

~--

ITEM NAME PLATE

• Model No.indication

R""N,r:; LABEL

+Model No. and rated power

supply voltage are indicated here.

Model No.

Rated Voltage

Plug

Productcord No.

MLS·3751L

AC 120V

131699501

MLS·3751L

AC230V

131699502

MLS·3781L

AC230V

131699401

MLS·3781L

AC230V

131699402

Photo: MLS-3751 L

INDEX

1. Safety Precautions in Servicing Work .................................................... ·············1

2. Specifications

...................................................... ·········································2

3. Outside Dimensions ...............................•...........•...........•........................... 3"""4

4. Names of Parts and Operations ...................................................... ··············5-6

5. Construction and Functions ....................................................................... 7 . . . . . 10

6. Piping Diagram and Wiring Diagram ...........•...........•...........•.................. ·····11~12

7. Process Flow and Operations .................................................................. ··13~21

8. About Various Modes .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. ···· .. · .. · .... · .. · .. · .. ·· .. 22 . . . . . 27

9. Temperature and Pressure Adjustment and Checking .................................... ··28 . . . . . 32

10. Thermistor Temperature Characteristics /

Altitude. Atmospheric Pressure and Boiling Point in Standard Atmosphere················ 33

11. Circuit Diagram ...................................................... ······································34

12. Troubleshooting ...................................................... ································35~44

13. Disassembling Procedure .............•...........•...........•...........•...................... ··45~50

14. Instruction Manual .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .... · .. · .. · .. ·· .. 51 . . . . . 63

15. Parts List .......................................................•...........•...................... ··64~71

16. Instruction Manual of Works for Optional Parts ··· .. · .. · .. · .. · .. · .. · .. · .. · .... · .. · .. · .. ·· .. 72 . . . . . 79

REFERENCE No. SM6610004

1. Safety Precautions in Servicing Work

Please read the "Safety Precautions" section carefully to prevent any accidents during service repair and provide a safe product.

• Loss or damage which may result from failing to heed these precautions and degree of their urgency, the precaution

have been classified ioto the three categories

&Danger

&Warning

&Caution

This indication shows the content of the result in the death or serious injure of the operator or

other persons.

This iodicates a potentially hazardous sitoation arisiog from the mishandliog or mis-operation

of the unit which, if not avoided, could result io the death orserious iojury of the operator or

other persons.

This iodicates a potentially hazardous sitoation arisiog from the mishandliog or mis-operation

of the unit which, if not avoided, may result io mioor iojury of the operator or other persons

and property damage .

• The figure sign classifies the contents that must be heeded, and is explaioed. (The followiog sign is an example.)

6.

1bis symbol calls attention to a danger, warning or caution, so please take care.

0

This symbol calls attention to an action which the operator is prohibited from performiog,

so take care .

•

This symbol calls attention to an action which must be performed or which the operator is

iostructed to perform, so tske care.

&

Warning

Always unplug thc;unit when carrying out inspection or repairs.

C

PI_pull 0lIl: a

Pl""=' fUIlPly phi'

• Always unplug the unit from. the outlet when assembling,

disassembling. inspecting, or replacing parts.Failure to

observe the above could lead to electric shock. or injury.

6)

Always return the wiring to its original condition after carrying

out inspection or repairs on the unit.

&

• Tighten the lead holden so that the lead wires do not

touch revolving parts, high-temperature parts,

high-pressure parts, or edges (sides) of parts. Contact

could lead to ma1fimctions, electric shock, or tire.

~

Take sufficient care of electric shocks.

c.utiowl of 1111

6)

• Take sufficient care of electric shocks from the charged

parts '" lead temllnals.

electric: shock

Always use specified parts when repairing.

0

0

• Parts marked with it are safety parts.These parts are

important in maintaining safety. While replacing, always

use the specified parts.

0

0

• Do not splice the power cord, plug it into an extension

cord. or use it with multiple plugs in a single outlet.

Failure to observe the above could result:in electric

shocks, heating '" fue.

• Always replace damaged or worn power cord or lead

wires.Failure to observe the above could result in electric

shock, beating or tire.

• Confirm that there is no dust and that the plug is secure,

inserting it all the way in. Dust or bad connection could

result in electric shock or tire.

Caution

Beware of burns due to high _perature.

• Take care, as after operation the chamber door, chamber,

and piping sections are extremely hot.

Always wear gloves when repejring or inspecting.

&

power cord, heating. or pulling it could result in damage.

• When repajring, always use the part listed on service parts table for the appropriate model and appropriate tools.

Also, under no circumstances are modifications to the unit to be carried out.

Failun: to observe the above could result in electric shock, heating or fire.

&

@

_,_

• Do not damage or change the power cord .This may lead

to electric shocks or fire.Placing heavy objects on the

• Use gloves to avoid injury from. the edge ofmeta11ic

surface.

&

&

-1-

• Measure the insulation resistance after repe:irs and

con:fum that is at least 5M (1 .

A problem in the insulation can lead to electronic

shock.

• Confirm that the position of attached parts, condition

of the wiring, and soldering, or crimp connections are

normal.An abnormality can lead to heating, :fire or

electric shock.

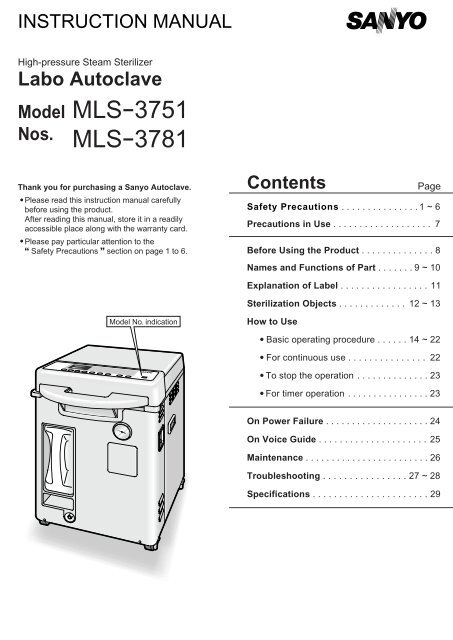

2. Specifications

Product Designation

Labo Autoclave (High-pressure Steam Sterilizer)

Model Designation

MlS-3751/3751 l

MlS-3781/3781l

Power supply

120V unit: 120VAC ( 50/60Hz ), 15.BA

220V unit: 220VAC (50/60Hz), 9.1A

230V unit: 230VAC ( 50/60Hz ), B.7A

220V unit: 220VAC ( 50/60Hz), lB.2A

230V unit: 230VAC (50/60Hz), 17.4A

Power Consumption

1.9kW ( 120V only), 2kW

4kW

External Dimensions

47B(W) x 632(D) x 74B(H) mm

47B(W) x 632(D) x 965(H) mm

Weight

Approx. 61 kg

Approx. 71 kg

Internal Capacity

57l

BOl

Effective Internal Capacity

50l

75l

Chamber Dimensions

370 (dia.) x 415(D)

(Effective depth including cover: 463) mm

370 (dia.) x630(D)

(Effective depth including cover: 6BB) mm

Chamber Material

SUS304 (Austenitic stainless steel)

Sterilization Temperature

115°C - 135°C

Melting Temperature

60°C - 114°C

Heat-retention Temperature

45°C - 60°C

Thermometer

Thermistor, digital display (25°C - 141°C)

Safety Valve Releasing Pressure

240kPa (34.Bpsi, 2.4bar)

Pressure Gauge Range

-0.1 - 0.4 MPa

Timer

Sterilization

1 min. - 5 hrs.

Melting

1 min. - 5 hrs.

Heat-retent

Timer

72 hrs. fixed

1 week (Designation: Year, month, day, hour and minute)

2 liter Polyethylene tank

Exhaust Tank

Warning and Safety Functions

Pressure safety valve, overheat prevention device, dry-scorch prevention,

cover interlock, excessive pressure prevention, earth leakage breaker

Max. 75dB (A)

Sound Pressure level

Stainless steel baskets - Large: 1, small: 1

Accessories

Stainless steel baskets - Large: 2, small: 1

Drain hose: 1

Exhaust tank (1), exhaust tank at rear side (1), tank mounting bracket (1) and tip-resistant metals (2)

Optional Accessories

Object temperature sensor, external temperature sensor,

printer, stainless steel basket (large), stainless steel basket (small),

punching basket, sterilization can

·Please consult us about the model number, price, delivery date, etc.

including other optional accessories than shown as above .

• The specifications may be subject to change for improvement without prior notice.

-2-

I Front Side I

Lateral Side

•

I

eN

-..j

0'1

<1~

oc::

en

o

1

CD

r

1

I

I

-

~

~

c-

r~ :a

I

1

II

100

=W

~

1159

420

678

=

=

=

=.

l:: II}

g

en

1

C/I

en

C/I

c)"

:::J

;..c:1

---,

.

.

·

.

~

426

607

673

689

766

:::J

o

CD

:::J

9

'-

100

CD

=

=

=

=

==

==

=

=

=

=

=

=

=

ill ·· 1c::::::J1

D

~

r-

~J

l

3

c:

1

I.

o

CD

3

1

I

75

t-

en

0..

632

~

......

......

1

478

oc

~

~

'"

""

""

g

71 66

~

3

3

~

:::J

I Front Side I

Lateral Side I

•

w

-4~

1;-1

632

D

=

=

=

1!1

['II

•

00

......

r

oc::

c:

CD

!if

I

I

I

75

..--

-..j

g

3

CD

::::I

CJl

c)'

::::I

CJl

=

=

=

=

=

=

=

==

==

=

·

· 1c:::::J1

r""

'--..J

=

=

=

=.

~~

.

.

·

~9

.

~

426

607

673

689

766

171 66

o.n

...,

...,

<=>

~

4. Names of Parts and Operations

»

Rear.lde

~"

~

+-__~~

~~=~~2r~~~~pno~'~U~~~~IW~~~+-______________________

Steam is discharged through

this port if pressure in the

chamber rises abnonnally.

•••

•

MOVIIbie handl.

pulling toward you.

---=c-::::-----,I

r

Handle

Use for opening/closing the

cover.

P.....UNa.ua.

Indicates the pressure inside

the chamber.

Exhaust tank

Exhaust tank ,---J~

on the rear side

•

•

. . / - 1- -....._ _ _ _- .

~

I

"

~j:-l::::;;:;;;::';'7V~/t11C;;;;;~;;;;;C~0YII~r;;;;;;;;,,"~

~r-~~

~

~

C' 0

-l / ~

CQllllllr to shut the chamber tight.

It is lined with silicon rubber

pecking.

~

mn

I~

~!

-

@

II

~

G~p

...

oH)~-~c-::~r'lch~

L rJ

f-Co-nd-e-'n."e"."'."'tea=m"e"m"';H'-ed--+-J.~

.l;"",J] J

from the chamber.

~

•

Control panel

Used for unlocking the cover.

The covar can be unlock8d by

pressing this handle down and

~

=

'8

If

~v

V

•

_

.

.,...

R""""" thO """,r to ",nnee! th.

optional printer to the product.

-••-......JI---C~~

Tankcua

Encases the exhaust tank.

•

'Ii

C ••tar

.

Exhau.thOH

Sends steam and air in the

chamber to the exhaust tank.

"

:

~J-</

C==~~~==~--Rtfr~4

~.~!.!

Packing.

Hose in tank

'

Ii.

f-::-------'====----c-+---t+

,,"f+; p.f!

Converts steam discharged

from the chamber Into water.

Exhu.t valve

Manually opening/cloeing valve

uaed for draining heating water

from Ihe Ohamber.

Drain outlet

~~

~

-5-

Heating water III drained from the

Ohamber Ihrough this outlet.

Connecl: the included drain hoee

to drain heating water.

Control panel

Cover lock lamp

II

IndicaN hi _ tim., rem .... ing

IndicaN hi nlu. of the currvnt

proce. with • flitbring bar.

tm., llerilizdon qd8, exhawt

U~ "" wIIIIn opI~on.aart.

with . . COlIer locked.

!D, cautionary m~ .rror

mMIIIIgIIl, dIIte IIIId voice ~id.

Mltting.

,bulla" .

WhIll1 the optlona' obfect

tlImperlltUre .,".or I, In.lalled

and thl' object templll'&lure

button '- preMed, the I~ IIglU

up and the llerlllzatlon tllTlllr II

controlled by !he ~rature of

Indicates Iha _18cIed lblrilizRliDn

cycle with • Iii limp.

I

...,.ratu. .,

IndicaN hi currtlnt

llerilizdon Nt I8mpendur.,

mIIlting MI temperature, IIIhBUII:

IIIIrling templill1llUre, date,

hourimllUlM and voice guide

MIttIng.

obfMD to be .....lIzed.

,lamp

LIghts up wh8l'l the chamber 'Intemally undlr prusure.

Thlllllmp Ilghtl up whln thll

button '- pl'UMd.

. IBBI

...

IBBB

I

v-~ ~

,-

fo :

lo, •

~-

BAtI'tD

~~

~~

~

''';

.:-:

Timer I

s_ thallma untiliha liar! of

operation.

' bUtton

Indates changa 01 MIllIngs and

MIllIngs 01 CUlTlll'lt op8l'llllDn on

II1II digital dilplays'lnd II.

lJMd Ibr IlItIIng and dlRnglng the

sIIIr1llz1lllon tempM'atul1l,

sItIr1llz1lllon 1m., nwllng

I8mpllllLlure, rnellng Ima, hINt....ntion tamperw.tul'8, 1IIChI.u.t

I8mperalure, sIIIrt timer and

..,.ust rate.

Stop I

Stope operdon and cancelli

tilnllr Htting. and hINd-l'lMntion.

lJMd In engage the cooling modi!

clnlng IIXhaulilng.

Start button

StarIti opaIW.tlon and IIm.._

operation.

Time I

Current Ilmlli5 DlICUld on

clgital dllplay I.

Model No.

SIIIIIca .ny 013 progran-.1IIId <4cydIII (toIII1 121111111c101ll).

-6-

r

5. Construction and Functions

_Names of parts and functions are common to Series 3751 U3781 L. The photo shows Model MLS-3781 L.

. Part name may be

I

I

list when you place an order.

1

2

3

7

4

,

No.

Part Name

1 Pressure gauge

2 Tank

3 Front panel

4

5

6

7

8

9

10

Richt side Danel

Side panel. R

Left side panel

Side panel, L

Safety valve cover

Back side Danel

Handle, frame

Function

Bourdon tube pressure gauge for displaying pressure in the chamber

Tank for exhausting air in the chamber

Front side frame constituting the appearance of the temperature

detector

Constitutina the richt side appearance of the unit cover

Right side frame constituting the appearance of the unit

Constitutin the left side appearance of the unit cover

Left side frame constituting the appearance of the unit

Plate to block steam blOW'ing out when the safety valve is actuated

Richt side frame constitutina the appearance of the unit

Handle for moving the unit

-7-

1

13

12

14

2

15

11

16

17

Right Side

No.

11

12

13

14

Part Name

Valve assembly, 1/28

Fan motor

Chamber set

Chassis

15

Caster

Function

Manual valve for draining the water for heating the chamber inside

Air blowin~ fan for coolina the chamber

Chamber to seal UD steam and Derform sterilization

Base plate to fIX the arrangement component parts and support

them

16 Pressure sensor

17 Thermistor assembly

Caster for moving the unit. 4 casters are used. Equipped with lock

function

Semiconductor sensor for detecting the pressure in the chamber

Sensor for temperature detection

-8-

20

21

18

22

19

23

24

25

26 (The operational

unit body is in

this unit.)

i i

II

-9-

27

28

No.

Part Name

27 Packina, chamber

28

29

30

31

32

33

34

Lid set, chamber

Heater cover

Packing, panel

Sheathed heater set

Lock shaft.

Panel

Circuit breaker

Function

Fitted to the lid by sealine oackina for sealing the chamber

Chamber see line lid which can be ooened and closed Quicklv

stand on which sterilization object to be put In the chamber Is placed

Packing to seal the gab between the dlamber and the panel

Heat source heater to generate sterilizing steam

Part for locking to seal and fix the chamber and the cover

Panel to vertically oartition the chamber and the cover

Electric pert to shut down the power supply circuit in case of an

over-current in the unit

-10 -

6. Piping Diagram and Wiring Diagram

• Piping Diagram

HOSE EXHAUST

I JOIN'[ L R1I4 x G1I4 FLARED

SAFETY VALVE

AS~

(560)

r::V~

PIPE

HOSE TANK

JOINT, ORIFICE ()1.8

/

AS~

SAFETY VAlVE

.~

HEATER

AS~

ELECTROMAGNETIC VALVE NC

PIPE, EXHAUST

PIPE COOLING

rs

PIPE ASSf,

PRESSURE GAUGE

'"

SENSOR, PRSSURE

NSK -BAOI OB -092

HOSE, IN TANK

PRESSUR GAUGE, 350P

PIPE ASSf,

PRESSURE SENSOR

JOINT T VACUUM

JOINT T CHAMBER

TANK, MLS -3781

VALVE, VC12B1-F

VALVE ASSY DRAIN 3781

PIPE ASSY,FREX .l250

- 11 -

• Wiring Diagram

11iERMOSTAT

HEATER

(MANUAL RE1IIRN)

=

51: Rl

16 C

3

P

---D

81: OJ

51:R2

81: Q2

J

lIiERMO

1

HEATER

PIISSURE

1 BREAKER

10

L,J

81 :Ql

I

-

U=:::J L----D ltj I

SW

Q

,--------~

I PS

3

gmj

un n;; lli®l:'":.ECT TEMP

81'~' ~ e!

SENSOR

51:'

14 ~13

LCNlLJ LOOfiJ

IDl'TIDNJ

J.d 13 r!d 1

~

3

~

2 NC ,

0--0 n-

51:W

,

81: V CN9

~

"

I

'~ RELAY ~

7 5

~ 8

3

4Wli

B

I

U~1

auo32

I

B.<m11Y

FOR COCK

I

P.C.B.ASSY ,CONTROL CE

~l9~f+tirB:3t1fCN7

~H 1 r

g

~.-----,'

CN5

A3781CE ~ ~

1378ICE

OPllONAL PRINTIR CONNECllON

WR

~n

,

- , - - - - - H CN3

,

2

'=5

~

~

[iiiii]

C-UD-:-~

F.~137~81~~~~tf~"l"

INC,

1 5

HANDLE LOCK SOLENOID

mt 1

NC

§]

EXHAUST VALVE

n--------n1

~SP

LOCK SHMT

cd

S"""R

C

51:Rl

SClENDID

CN201 Il=~SPPCB ,,JL,',f)"D7S1CE

P,C.O. Am, DISPlAY 3781

aRCUIT

3

D DS -PCB OS

CN103rl~~=

CN10l

DD

DD

TERM~L

BLOCK

"---_L--=~+I:TlI--t=

L=h

sLilllill

I

~II I

I

1

5

'~-

'1Qj!J 3 ,

MU'ER ~D-,~+t~f2~~~~;;~~tt"~~~'·~·IT17~"~=r5F~3n;'C~E-rIl-----~

"", •• ,.,

~c::Jl

~

22OY: 8220 3781

~vn

llIANSFORMER

~

.,

~-~~

~SA

~--~

COOLING FAN

FQ

l'1!.N:Bl2G 3751

22OY: IWG 3781

nov: Bl3Q 3781

I

51: P.C.8,ASSY, EM0l51 CE

81: P.C.8,ASSY, EMeJ781 CE

11OV: 03751 CE

11OV,13OV: N3781 CE

2A

37S1L(12OV),3781L(23OV ENTElA):

I

Cl7811N1RA

one! MOOEl5: (3781 CE

POWER

TRANSFORMER

*

Note) 51 in the figure shows MLS-3751 L, and 81 shows MLS-3781 L

- 12-

7. Process Flow and Operations

(OOperations and displays

IOperations and Process!

Digital Display I

Turn ON the power.

STAND-BY

I

Digital Display II

Bar display "- - -" is displayed for the

Boiling point setting temperature is

displayed for the first 4 sec. Thereafter,

first 4 sec. Thereafter, the display

the display changes to stand-by display. f - - changes to stand-by display.

~

Put sterilizing object

and close the cover.

Setting temperature is displayed.

f-However, The temperature in the

chamber is displayed by pressing the

"... " + "T" buttons at the same time. If

the temperature is lower than 25"C, "La"

is disolaved.

Setting time and cycle are displayed

alternately. However, the water heating

temperature is displayed by pressing the

"..... + "..... buttons at the same time. If

the temperature is lower than 25"C, "La"

is disolaved.

I

Press the start

button.

"COVER LOCK

" lights up and the process monitors flicker.

Temparature in the chamber is

f-displayed. However, if the temperature

is lower than 25"C, "La" is displayed.

HEAT

f--

STERI (MELT )

r--

Temperature in the chamber is

displayed.

r--

r--

Temperature in the chamber is

displayed.

r--

Kemalnlng smnllzatlon orne IS CISPISyeC. However,

I

EXHAUST

1""---------

Nothing is displayed. However, the water heating

temperature is displayed by pressing the ~ ... ~ + "....

buttons at the same tima. If the temperature is lower

than 25"C. ·Lo~ is displayed.

the water heating temperature is displayed by

pressing the""'~ + ..... ~ buttons at the same time.

NOlmng IS cisplaye~. nowever, me WSIer eaung

temperature is displayed by pressing the" ..... +

....... buttons at the same time.

_._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._----

KEEP WARM

Temperature in the chamber is

displayed.

f--

f--

Elapsed keep-warm time is displayed_ However, the

water heating temperature is displayed by pressing

the tt... w + ~ ...u buttons at the same time_ By pressing

the ttRESERV" + ~ .... at the same Ume, the elapsed

keep-warm time is displayed in minute_

STERI/KEEP WARM MELT/KEEP WARM

---------- -------------------------------------------------------------------------------------------------------COMPLETE

r--

Temperature in the chamber is

displayed. However, if the temperature

is lower than 25"C, "La" is displayed.

I

I

pen me cover ana

take out sterilized

obiectCs).

I

STAND-BY

~

"COVER LOCK

r--

Bar display"

" is displayed. However, the

water heating temperature is displayed by

pressing the .... " + MT" buttons at the same

time. If the temperature is lower than 25"C,

"Le" is displayed.

"goes out and the all process monitors light up and the "COMPLETE"

flickers.

Setting temperature is displayed_ However,

the temperature in the chamber is displayed

by pressing the ... " + MT" buttons at the

same time. If the temperature is lower than

25"C, "Lo" is displayed.

Setting time and cycle are displayed

alternately_ However, the water heating

temperature is displayed by pressing the ... +

"T- buttons at the same time_ If the

temperature is lower than 25"C, "Lo· is

D

f--

displayed.

- 13-

.....1 '0)

• Liqyid Sterilization (]-1 1-2 and 1-3)

Te

"". --

~

"",powLIW.

'"

IS.--

Sterilization settinlte~ Exhaustsettinlte~. -

~

~

....

'I

'I

Lid !ION

f------- - - - - - - - - -

•

~

-.

'I

...

~

,

Sterilization

,

Coolilll

OFF at boiling

r...J!.Ol!!!;+7'C __

.....

_

~

---------

CD

---------t

-=n

--------1-_

,

0'

:E

n

:::r

.,II....

~

--------~~

~f-----

• •••

Exhault valve (NO

Handesolenoid

(Unlocked bypower-ON)

F~

Dilital c:isplay 1

Dilital c:isplay 2

Processmonitor

,-

...,

~..

...

ShortBeep

... ~ I"

~"

I

~.,(1";m••

;

Rllmainilll starilizatian

,~

!

H..ti"lll

H. .ting2

Exh.uat 1

Sterilization

""

,-

...

Temp. in Chamber (Displayed lit hillher than 25'C)

"',-

n

1/1

1/1

Heater relay

Speaker

.,"tI

o

-to

i

.... ---__

i

.'

----------,

,,"

;,

." ..."..............-"- - - - - - - - - - -

••

~

,

SteriliZlltionutl:imll

- f----- --- ---------

HeaterTriack

'I

"',-

Udapen

------ --- ------f----- --- ---------

r-.

~

Corq,letion

R""chi..-

- - - - - - - - - - - - - - - f - -Imin.

---

65"C- - - - - - - - - - - - -

0""'"-

Heatilll

Boiling point

A

BoilinlPoint-

,

Airpurp=

Heatilll

"',-

i

!

~

Corq,Iet;ion

>

nStorilization/Koep Warm (2-1 2-2 and 2-3)

Heatin

1 'I

Temp.

Lid OIOM

•

•

,

'I

Start

•

Sterilization

'I

Reaohinl

set. temp.

Boilinl point

Press.

Sterilization settingtemp. --- ---------------

Heatin

•

,

•

,

,

Cooli

Compllftion

Stand-by

'I

,

Lid open

Ster1IIZ11tloneettlme

--------------- ----------------

== • • • • • • • • • • • • . ~:~~• • • • • • • ·.~~==:7~'~h~,:.===!1- -___

i"---------I-ot.I'.

--1------ __.+__

~~

i

----~~

....;...........

i

._.L ""------------------------- ------------------------ ------------------i----"r-t-----'--+---1

~

••

HeaterTriack

/

,~

••••

i

••••

Heater relay

Exhaust valve (NO)

Handesolenoid

(Unlocked bypower-ON)

Fon

___________~__.k_.'~~~~~~.i~~~i:~~~·~~~~~~~~~~~~~~~~~..~~~~~~~k"

Digital display 1

,,-

. nemaininl sterilization

...;.r-_"l

Digital diSPlay21....._ _...

...;."~...

Process monitor

i"(1'''m~

It Stand-by >

I...---...

-"-....;.r=--;--'TV'-----"T"-----"T"---"T"--T

..

...

...;.-._;"_"'

__

"""._'~(D_;..i-'...

;...d_"_h..

;;..._'_"_._"_25""..;.)...,-...,--------...,----~..T....----..;.-~"

I

Heatl1'll'2

Starlllzation

Keep-wann elapsed

time

Exhaust 1

I"

KellJlwann

Stand-by

Comph!ll:lon

>

• Melting/Keep Warm (3-1 3 - 2 and

3-3>

When the mettlna: temp ....ture II Ht at hl&her than l05"C, flXhault. aperatlan II performed for 8 mlm..t boIllna: pHrt + 5"C .fter heatlna:.

T.

m,.--

pJr_.

'"

p~ ss.--

Meltingsettingtemp. --

Keep-wannsettingtime ---

0 .... --

•

""-

He.tinl

Meltinl

~lhina:

'" ....

1 '1

Lid clo..

•

Start

•

,

•

"',,-

,

•

,

'I

•

""-

,

~

""""-

>

72 hra.

". r------------_._-----_._-----_._-----_._--- "',

-----------

••••••

-r-

------_._-----_._-----_._--

r------- --

............... J-.--

Heater relay

•

Meltinl Ht time

--------------- -------- ---_.- ----_._- ---_._-----_._-----_._-----_._---

Hem:erTrieck

Completion

Lid open

---------------- ------- ----------------

----- ---

Coolinl

•••••

Exhaust valve (NO)

Handesolenoid

(Unlocked bypower-ON)

Fon

....

.~

Speaker

Digital display 1

Digital display2

Proc8samonitor

""""-

I

....

....

~

ShortB.ep

• ."dBo,P

~

lieP(lOtim..>

T.....,. in Chaniler (Displayed at hilher then 25"C)

RemIIininl meltina: time

HtNrtina:l

W

Meltinl

Koap-warrn elapsed time

Elchauat 1

It

"'''-

W

Completion

>

.Instrument Sterilization (4=1 4-2 and 4=3)

T."" -Press. - -

.,L

a<

--

lJd~

•

:!..

•

Heating

Air pu ....

'I

•

,

H..ti

-.

Sterilization

'I

Boiling point

•

,

•

,

'I

Udopen

Reaohing

...

Sterilizationsettingtemp. -- ---------------- ------- ---------------- --------------OFF::ilinr

point +1"C

•

~Ietion

--

•

,

--

>

Sterilization_time

/i

---------.,.,li _________....

:

BoilinSpont--- --------------- --------

)--------- ....

/

OM.,

~

/'

:'

....

....

" ....

-+---+-+--,--£'. ~~~. ;:--+---------------.. ."'!----+---.-I

••

HeaterTriack

Heater relay

:

Exhaust valve (NC)

Handesolenoid

(Unlocked bypower-ON)

..

~,

Speaker

Digital display 1

1'--~-;;;;;~-.;;;,r--'II'----...,-----...,--~T.~m~'.,;;;"~c~..~""~w~(D~;-;;;;~.~d~.~'~h;;"',W~"";;;;"~"~"~};..._...-----T"----,/T.......---;;;;;~-~--.>"

I

Digital display 2

Processmonitor

~.ep('Otim",

1'-----;-1-

k

:

,. . ,---_.1....-""''',',....

momalnlna: sten IlAtion

St:.nd-by

Heatinl'

']

Heatinl 2

~

Sterilization

..

']

Exhaust ,

Exhaust 2

~Ietion

(3)Descriptions of process operation

G)Set the exhaust tank to the unit.

Fill the exhaust tank with water up to the "LOW" level and set the tank to the unit.

~Turn "ION" the power switch.

For the first 4 sec., the boiling point setting temperatura is displayed on the IDigital Display II and the bar

display "- - -" appears on the IDigital Display III ' and then the set temperature, set time or the cycle is

displayed.

Press down the handlij and pull the Imovable handleltoward you to open the cover. Fill the chamber with

water until the end of the water level metal of the heater cover is immersed in the water. Put object(s) to be

sterilized in the attached stainless-steel basket, set it in the chamber and close the cover.

@Heating process (Process monitor lamp: "Heating" flickers.)

After checking the detail of the cycle and settings, press the ISTART buttonl. Then, "Beep Beep" sound is

heard and the power to the ~terilization heate~ is turned ON to heat the heating water and generate steam.

At this time, the air in the chamber is driven out by steam. The steam at that time is discharged into the

exhaust tank where it is condensed to water. Also, excess steam which could not be condensed enough

flows into the back side exhaust tank at the back side of the unit.

After the completion of air exhausting process, closing of the c-x-;h:-:a-us-:-;t-v-::a~lvCle fills the chamber with steam

and raises the pressure. After starting, the COVER LOCK lam lights up and the cover can not be opened

due to interlock function.

@Sterilization process (Process monitor lamp: "Sterilization" flickers.)

When the temperature in the chamber reaches the sterilization temperature, the Isterilization time~ starts

working. During sterilization, the tern erature in the chamber is detected by the lateral thermistor (THI) and

the power supply to the sterilization heate is controlled by microcomputer. The temperature can be set

every i'C between 115'C and 135'C.

When the set sterilization time elapses, the sterilization process ends and goes to the next exhaust process.

@Melting process (Process monitor lamp: "Melting" flickers.)

This process is for melting culture medium, etc. The temperature in the chamber is detected by the lateral

thermistor (TH I) and the power supply to the ~terilization heate~ is controlled by microcomputer. The

temperature can be set every I'C between 60·C and 114"C.

@Exhaust process (Process monitor lamp: "Exhaust" flickers.)

<For INSUMENT STERI>

By shutting down the power supply to the ~terilization heate~ and opening the lexhaust valvij, steam in the

chamber is discharged into the exhaust tank to perform cooling.

This process is to be performed when the sterilization object is instrument, etc.

<For other than INSUMENT STERI>

Shut down the power supply to the ~terilization heate~ and keep the lexhaust valve ~Iosed so that the

temperature in the chamber is cooled naturally. When the tern erature in the chamber lowers down to the

preset exhaust temperature (initial value or boiling pint), th exhaust valv opens.

This process is performed when the sterilization object is liquid such as culture medium, etc. The

sterilization object is prevented from spilling out due to burst boiling.

(l)Keep-warm process (Process monitor lamp: "Keep Work" flickers.)

The temperature of sterilization object such as melted culture medium or sterilized culture medium can be

set and maintained every I·C between 45"C and 60·C and the sterilization object can be kept warm for 72

hours. (The keep-warm process can be completed by pressing the !lTOP buttonl.) The temperature in the

chamber is detected by the lateral thermistor (TH I) and the power supply to the Isterilization heate~ is

controlled by microcomputer.

@Completion process

<LIQUID STERI cycle/INSTRUMENT STERI cycle> (Process monitor lamp: "Completion" flickers.)

When the temperature in the chamber lowers down to a certain level, the buzzer sound "Beep" is issued ten

times, and the bar display"- - -" appears on the IDigital Display III to inform the completion of operation.

<Sterilization/Keep-warm cycle· Melting/Keep-warm cycle> (Process monitor lamp: "Completion" flickers.)

After the completion of keep-warm cycle, the buzzer sound "Beep" is issued ten times, and the bar display

"- - -" appears on thel Digital Display III to inform the completion of operation.

- 18-

(4)Descriptions of safety device actuation

eCaution sions

Caution Sian

Lid

Disolav Condition

Cover is not closed comDletelv.

When the START button is pressed, the

Cause/Checkina/Remedv

Press down the handle by force.

Press the START button after the temperature in

Hot

temperature in the chamber is higher than the

nreset temnerature.

Due to bending or clogging of the exhaust hose,

the chamber has lowered.

HOSE

abnormal pressure was detected more than 7

times durin" heatin"

(j)Operation is started without opening the cover

immediately after power-ON.

®Trouble with the lock shaft detection switch

door

Pull put the exhaust tank and correct

the bending of hose. Check the exhaust circun

for anv cloaaino.

(j)()nce open the cover and start the operation.

®Replace the lock shaft detection switch.

eError sians

El

Enror Sian

Lateral thermistor (TH1)

Open

E2

Bottom thermistor (TH3)

Open

E3

Lateral thermistor (TH1)

Abnormal temp.

E4

Object temp. sensor

Disolav Condition

Lower than 21"C Smin. after the bottom

thermistor becomes 90·C.

Lower than 21'C for 2min. after starting

and 2 min elapsing.

Higher than 139'C

Higher than 140'C

(TH2) Abnormal temp.

'

'

,

'

'

'

'

'

Cause/CheckinaiRemedv

Check the thermistor (TH1).

Check the thermistor (TH1) connector.

Check the thermistor (TH3).

Check the thermistor (TH3) connector.

Check the thermistor (TH1).

Check the Triack.

Check the thermistor (TH2).

Check whether or not the tip of the

object temp. sensor lips down into

the heater unit.

E5

Bottom thermistor (TH3)

Abnonnal tamp

• Higher than 110'C in heating I,

keep-warm process.

• Higher than 120'C in heating 2,

exhaust process.

E6

Unlocking of the movable

handle is impossible.

E7

Locking of the movable

handle' cover is

impossible.

E8

Abnormally high

pressure

E9

Low pressure

El0 EEPROM communication

error

• Higher than 140'C in heating 3, heating

4, sterilization process.

• Or, higher than set temp.+30·C

The detection switch is not turned OFF

even when the power supply to the

solenoid is turned ON and the solenoid is

unlocked.

• The detection switch is not turned ON

even when the power supply to the

solenoid is turned OFF and the

solenoid is locked.

• Lid detection switch is turned OFF

during operation.

• Lock shaft detection switch is turned

OFF durina oDeration.

• Pressure in the chamber is higher than

about O.33MPa.

• Pressure in the chamber is O.04MPa

higher than the saturated steam

pressure in the temperature of the

lateral thermistor at heating 4 and

sterilization processes.

• Pressure in the chamber is O.04MPa

lower than the saturated steam

pressure in the temperature of the

lateral thermistor at heating 3 ,heating

4 and sterilization processes.

Nothing can be read out or written from

or on EEPROM.

- 19-

• Check the thermistor (TH3).

• Check whether or not the exhaust port

is blocked with sterilization object.

• Isn't the amount of heating water

reduced and isn't the chamber is

heated wnhout water?

• Check for leakage of steam or water.

• Doesn't the lock pin catch?

• Check the cover swoch.

• Doesn't the lock pin catch?

• Check the cover swnch.

• Check the lock shaft switch.

• Sterilization object which makes the

exhaust difficult.

• Exhaust circuit is clogged.

• Exhaust port is blocked with the

sterilization bag.

• Deep sterilization can is used.

• Shortage of heating water.

• Exhaust circuit is blocked.

• Check and replace PCB.

-Hard limiter

When the temperature in the chamber which was detected by the lateral thermistor (TH1) rises to higher

than 140'C, the Triack and the relay control circuit is controlled directly by TH1 temperature detection and

the power supply to the heater is shut down.

This circuit is not controlled via micro-computer and it is reset automatically when the temperature lowers.

(Actuated in all processes.)

- Pressure safety valve

This valve opens to exhaust steam in the chamber and prevent abnormal pressure rise so that the pressure

in the chamber should not exceed O.25MPa.

(5) Functions of specific parts and cautions

<Deaver interlock

This is a safety device to prevent the user from opening the cover by mistake when the pressure in the

chamber is higher than the atmospheric pressure.

In order to check seating tightness between the lid and the chamber, micro-switches are mounted to their

lock shafts.

Also, 1 micro-switch is mounted for detection of the position of the solenoid for the movable handle lock and

2 micro-switches to the lid for detection of lid open/close status.

-When the cover is closed, the 2 micro-switches mounted to the lock shaft and the lid detects that the

solenoid is in the specified position, and "Beep" sound is issued and the operation turns to stand-by status.

- When the START button is pressed, the live solenoid becomes non-live and the end of the solenoid enters

the hole of the movable handle. By so doing, the movable handle is fixed and at the same time, the

micro-switch is pushed by the end of the solenoid and the position of solenoid is detected to start the

operation.

(Cautions)

If the START button is pressed with the cover lock being incomplete, the caution sign "Lid'"

appears on the digital display of the control panel and the buzzer sounds. This is to inform that the

lid is not closed up to the normal position. Therefore, the cover handle must be pushed down until

the buzzer sound "Short Beep" is heard .

• When the "Lid'" display appears, the following causes are taken account.

• Handle is not pushed down completely.

Since the temperature in the chamber is high, repulsive force (force to open the lid) of the

chamber lid packing is too strong to push down the handle .

• The chamber lid packing is removed and the lid bites a part of it.

®About the "door" display

Lock shaft is closed when the cover is open (detection switch "ON"), the lock shaft opens once as the cover

closes (detection switch "OFF"), and it closes again (detection switch "ON") when the cover closes.

In order to detect adherence to ON of the lock shaft switch, it is checked by microcomputer that the lock

shaft opens and then closes (detection switch turns OFF and ON.), and if it was not detected that the switch

is OFF, "door" is displayed.

(Cautions)

If the START button is pressed without opening the lid immediately after the power is turned ON,

the "door" display appears, but this is not due to any trouble. Close the cover once and then press

the START button to start the operation.

- 20-

@Back side exhaust tank

When the water temperature in the exhaust lank rises to make it impossible to condense steam to water,

the steam is exhausted into the back side exhaust lank.

It is the back side exhaust lank that recovers the steam.

(Cautions)

When connecting the exhaust hose to the back side exhaust lank, be sure to insert it so that its end

reaches near the bottom of the back side exhaust lank.

The water in the back side exhaust lank returns from the back side exhaust lank to the exhaust

lank. In case of incomplete connection of hose, water remains in back side exhaust lank and the

water may splash in all directions in the exhaust process.

@Thermostat

This is the final safety device to prevent abnormal temperature rise due to heating of empty chamber by

heater. The power supply is shut down when this device works. The thermoslat is of manual reset type. The

actuating temperature is 145°C±5°C.

The thermoslat is mounted to the bottom of the chamber. To reset it, remove the unit side panel and the

reset button must be pressed directly.

(Caution)

Since the thermoslat can not be rest at a high temperature, rest it when the chamber is cooled well.

@Chamber lid packing

Timing of the chamber lid packing replacement is 1 year as slandard. If deterioration of the edge, hardening,

remarkable deformation or lowering of elasticity is found, it must be replaced.

When replacing, tum OFF the power supply and then remove the chamber lid packing from the chamber

lid.

Make sure that no foreign matters such as dirt, etc. are sticking to the new lid packing and the lid before

mounting the packing to the chamber lid.

-21-

8. About Various Modes

Models MLS-3751 U3781 L are equipped with the following modes. As for the detail, refer to the pages of

respective modes.

Setting mode: Display of processing frequency, history of errors, etc. and settings. etc.

Test mode: Display of temperature and pressure in the chamber, adjustment of thermistors,

pressure sensors, etc.

Demonstration mode: Display of actual operation status and demonstration of operation, etc.

-How to enter into the setting mode

1. Tum ON the power switch.

2. When the ".A. "+ "SET/CONFIRM" buttons are pressed for

about 2 sec. while pressing the "START" button, "Short Beep

x 3" sound is heard and at the same time the decimal point on

sterilization

the Digital Display I flickers. (See the right figure.)

3. After the status has become such as in 2, when the "START"

button is pressed within 5 sec. while pressing the ".A."+ "T"

buttons, "Beep· sound is heard, and at the same time the

mode becomes the setting mode and model name and speech

language are displayed.

flicker

"c

1- 1

-How to cancel the setting mode

When the power switch is turned OFF, the setting mode is cancelled. Or, when the "STOP" button is

pressed to enter into the test mode and the operation in the "How to cancel the test mode· is performed,

the setting mode reset to the normal mode.

-How to enter into the test mode

Light-up Sterilization

A. In stand-by display

Enter into the setting mode according to the procedure in the Flicker

51e

"How to enter into the setting mode" and press the "STOP"

button. Then, "Beep" sound is heard and at the same the

mode changes to the test mode. The difference from the

normal mode is such that the decimal point on the Digital

Display I lights up. (See the right figure.)

B. In operation

When the procedure in the "How to enter into the setting

mode" is performed during operation, "Beep· sound is heard

and at the same time the mode changes to the test mode.

I

.lizati~

12 1

0:2'1

"c

Time

-How to cancel the test mode

When the power switch is turned OFF, the test mode is cancelled. Or, when the "START" button is pressed

for about 2 sac. while pressing the ".A."+ "SET/CONFIRM" buttons, "Short Beep X3" sound is heard and

at the same time the test mode returns to the normal mode.

-How to enter into the demonstration mode

1. Turn ON the power switch.

2. Start the reservation operation.

3. When the "Cycle selection" + "STOP" buttons is pressed within 5 sec. after starting the reservation

operation, "Beep Beep Beep· sound is heard and at the same time the stand-by is displayed and the

mode changes to the demonstration mode.

-How to cancel the demonstration mode

When the power switch is tumed OFF, the demonstration mode is cancelled.

- 22-

(1)About the setting mode

In the selling mode, product infonmation, factory setting, processing frequency, history of errors, boiling point

setting, exhaust setting, address, option I, option 2 and channel display frequency setting and checking can be

perfonmed.

II

Mode

II

II

Operation

II

I

Display

II

3 18

E n 9'

(j)Product

infonmation

Preset model name and

speech language is

I""""--==--"""""-:=::::-idisplayed.

(In factory. English has been

sel for 3751 or 3781.)

:::~[:::L~:~~r~:I'CLr"

I~FactOry setting

is displayed.

o...

@Processing

frequency

F'_',-,L""",-,L"""......,=alProcesSing frequency

is displayed.

'------""""

[email protected] of errors

@Boiling point

setting

When the "SELECT"

button is pressed,

the mode progress

(j)....~ ••• @)....(j).

IE

"""~

I:!.

01

_ _ _- - ' ' ' ' ' ' ' ' ' ' .

bP

100

RPe;

8 1

SR

[email protected]

IClJAddress

History of errors is

displayed.

Preset boiling point is

displayed. (In factory,

boiling point has been

set at 100"(;.)

Preset air purge time and

heater OFF temperature

are displayed. (In factory,

they have been set 8 min.

and 7"C, respectively.)

0

OP ,

1FbO

OP2

FFbO

[email protected] 1

[email protected]

[H

@)CH display

frequency

Preset CH frequency is

displayed. (In factory,

he frequency has

been set at 3000

imes.)

3000:

- 23-

(2) About sub-mode

(j»roduct information

Mode

II

II

Operation

II

II

Display

II

3 18

IQ)Model name and

speech language

display

II

"3781" or "3751" is

displayed. "JPn" or

r .......E

...i-n

"""'"-_

g

~·Eng. is displayed.

!

Time button

Preparation date

display (Note)

'

2001

"200703. 13" is

displayed. (March 13,

~~~~"""'"--3~2007) or fen is

!

Time button

3 ersion display

(Note)

O3•

U":-I.-""E..' r

f---....

!

operated.

"VEr 1.19" is

displayed.

,=-'-g=l (Version 1. 19)

Time button

"Model name can be changed by pressing the· ...·or "T" button during

CD the model name and speech

language display.

"Speech language can be changed by pressing the ·SET/CONFIRM" button and the" ...·or "T" button

during

CD the model name and speech language display. When the "SET/CONFIRM" buttons are

pressed again. the model name can be changed ...

"When the ·START" button is pressed while pressing the ·SET/CONFIRM" button, the content of the

change is written in non-volatile memory.

"When the "TIME· button is pressed, the mode changes in the order CD-+®[email protected]+CD"".

"When the "OBJECT TEMp· button is pressed during the product information display, all the LEOs are

light up.

«Note»

® Preparation date and @ Version display are altered depending on the specification charge.

~actory setting

"When the "START" button is pressed while pressing the "SET/CONFIRM" button, the alarm sound ·Beep

Beep Beep" is issued, and the setting is defaulted to the factory setting. When the "START" button is

pressed again while pnessing "SET/CONFIRM" button, the setting is defaulted to factory setting.

The following items ane subject to the factory setting:

(1 )Setting values for each cycle (sterilization temperature, sterilization time, etc.)

(2)Error information and frequency

(3)processing fnequency

(4)Boiling point and air purge settings

(S)Address

(6)CH display fnequency

- 24-

@Processing frequency

Total frequency

In the process frequency display, the total frequency of all cycles

and the processing frequency of each cycle are displayed.

• Each time when the "TIME" button is pressed, the processing

frequency of each cycle are displayed.

Processing

frequency

··ALL" stands for the total frequency, and "cSl" for LlQUD STERI,

"cS2" for STERI KEEP WARM, "cS3" for MERT/KEEP WARM

and "cS4" for INSTRUMENT STERI, respectively.

C cle-wise

·When the "START" button is pressed while pressing the

"--r--I~Cycl~e---.J1

·SET/CINFIRM" buttons, the total processing frequency and

1"""''--''......_..0.....,=1

operation frequency of each cycle are cleared.

R

S ,

C

--=''-' 'O.....,H ~~c:~~ I

L -_ _ _

@Hlstory of errors

Error No., error code and error occurring process No. are displayed.

The latest error data is displayed in the first place.

• The error No. is changed by pressing the" ...·or .... " button and

the history of errors can be checked.

The error No. can be recorded for 8 in number at the maximum.

If more than 9 errors occur, the oldest error is deleted and new

error is recorded instead.

·When the "START" button is pressed while pressing the

I Error code

·SET/CONFIRM" button, the error data is deleted.

(Total errors are not deleted.)

E

t

2 +-t

6 04--

Error No.

I

Error occurring

process No.

I

.Error Codes.

1 : Lateral thermistor (TH1) Open

6 : Movable handle Unlock impossible

2 : Bottom thermistor (TH3) Open

7 : Movable handle and lid Lock impossible

3: Lateral thermistor Abnormal temperature

8: Abnormally high pressure

4 : Object temperature sensor (TH2) Abnormal temperat 9: Low pressure

5: Bottom thermistor Abnormal temperatura

10: EEPROM communication error

< Error

occurring process Nos.>

Description

Process No Error Occurring Process

Process No Error Occurring Process

0

Stand-by

6

Heating 4

1

Reservation

SterilizationlMelting

2

Up to 90"C

3

Heating 1

Heating 2

7

8

From 90<>C to boiling poin1

9

Cooling 1

Cooling 2

4

Exhaust

10

Keep warm

11

Completion

5

Heating 3

THl

temp. rises up to

the preset temp.

Description

TH2 temp. rises up to

the preset temp.

Down to boiling point

Before cooling point

@Boiling Poing setting

Change the boiling point temperature according to the altitude of

the place for installation by pressing the" ...·or ..... button.

·When the 'START" button is pressed while pressing the

~OH Set temperature I

·SET/CONFIRM" button, the content of the change is written in

the non-volatile memory.

(The boiling temperature has been set at 100"C in the factory.)

• When setting the boiling point, refer to the table (P__ ) of the altitude and atmospheric pressure in the

standard atmosphere and the boiling point of water.

bP

,

- 25-

@Exhaust setting

-Heater OFF temperature can be changed by pressing the" ."

or "T" button.

(Heater ON temperature is fixed at the boiling point temp.+1 "C.)

-When the" ."or "T" button is pressed while pressing the

"SET/CONFIRM" button, the exhaust time can be changed.

-When the "START" button is pressed while pressing the

"SET/CONFIRM" button, the content of the change is written

in the non-volatile memory.

RP[j1

B 1

<!lAddress

-Address can be changed by pressing the" ."or "T" button.

This address is used for connection of the MTR system.

-When the "START" button is pressed while pressing the

"SET/CONFIRM" button, the content of the change is written

in the non-volatile memory.

@Option 1

-Change bit is selected by pressing the" • "or "T" button.

-Preset value can be changed by pressing the "TIMER" button

-When the "START" button is pressed while pressing the

"SET/CONFIRM" button, the content of the change is written

in the non-volatile memory.

SR

i

«Note» Do not set 9999.

- 26-

I Change bit I

OP2

FFbO

i

I Preset value I

@lCH display ferquency

CH display frequency is set. (CH is displayed when the total

processing frequency exceeds the CH display frequency.)

4 kinds of frequency of 1000 .. 2000 .. 3000 (Factory setting)

.. 9999.4 can be selected.

-When the "T" button is pressed, the frequency decreases and

when the"." button is pressed, the frequency increases.

-When the "START" button is pressed while pressing the

"SET/CONFIRM" button, the content of the change is written

in the non-volatile memory.

o

OP ,

lFbO

I Preset value I

@Optlon 2

-Change bit is selected by pressing the" • "or "T" button.

-Preset value can be changed by pressing the "TIMER" button

-When the "START" button is pressed while pressing the

"SET/CONFIRM" button, the content of the change is written

in the non-volatile memory.

Heater OFF temp.

11..)-_---,

IChange bit I

[H

3000

(3) Functions of test mode

1. Minute temperature display

When displaying the current temperature, the

value after the decimal point is also displayed.

1Displays 112.3"C. 1- ,

L

12°31

I

2. Expansion of temperature setting range

I

Temperature can be set from 20"C to 150"C.

Error is prohibited by the sterilization limiter.

Set value can be changed even after heating process.

3. Remaining time display in exhaust process

Exhaust remaining time is displayed on the Digital Display II. (in min.)

4. Pressure/Saturated steam pressure display

By pressing the "TIMER" button, the current pressure is the Digital Display I. (in kPa)

5. Forced exhaust

By pressing the "A" and 'STOP" buttons at the same time during stand-by, the exhaust valve opens.

The forced exhaust can be cancelled by pressing the "STOP" button.

6. TImer 60-time speed operation

While the "TIMER" and the "SET/CONFIRM" button at the same time, the reservation timer, process

timer and sterilization timer operate in 60-time speed. (It is preferable to perfonn the exhaust fast.)

7. sterilization process starUcompletion signal output

Buzzer sounds at the start and completion of the sterilization process.

(4)Functions of demonstration mode

1. Power is not supplied to the heater.

2. Process timer and sterilization timer operate in 60-time speed.

3. When the power is supplied to the heater, the temperature on the Digital Display rises automatically.

4. When the power is not supplied to the heater, the temperature on the Digital Display lowers automatically.

(For safety sake, however, the temperature does not lower than the actual temperature of TH1.)

5. Pressure Abnonnal is not detected.

- 27-

9.Temperature and Pressure Adjustment and Checking

(1)Adjustment of thermistors

The temperatures of the lateral thermistor, object temperature sensor and botlom thermistor can be

corrected manually. The temperature of the lateral thermistor has been corrected in the factory in advance.

Use the displays if the correction of temperature is necessary for validation,etc. The correction of

temperature is performed at 3 points, namely, 105"C, 121"C and 135"C.

For prevention of heating without water, check the heating water amount.

*Instrument to be prepared*

Thermometer that has been calibrated by temperature recording meter, etc.

Since the temperature is corrected on the basis of the temperature indicated by the thermometer, prepare

an accurate thermometer. The correction of temperature is performed as minute as 0.1 OC.

II

Operation

I

Enter into the test mode.

I

+

Select the instrument sterilization

cycle and set the sterilization

ISet the cycle, sterilization temp.

land time.

temp. to 105'C and set the

sterilization time at 1 hour.

t

Press the START button

Description

I

l

:like~

in the normal operation, heating,

and exhaust processes are

rmed.

I

I

I

II

~ EXSmple of normal diliPlay1

NO"

LEFT

0: ,yl

I

Release. ~

ISelect the thermistor you want to I

ladjust. (See the right figure.)

I

r

Press.

TIMER

IL

button

'-==

.....1.

Example of

oom>cIIon

The correction of temperature is

+

I tO 5EI~

Reaching 105'C and sterilization process

displayed only while the TIMER

I

Display

Lateral thermistor

button is pressed. When the

SELECT button is pressed while

pressing it, the display changes

in the order of -Lateral sensorObject temp. sensor-Bottom

sensor-Press. sensor. Select

the thermistor which you want to

adjust.

Obj ••, '.mp.

sensor

+

Press the •......or· A" button

while pressing the TIMER button,

and adjust the temperature so

I

Adjust at 105"C.

(Correction)

that it becomes the same

I

NO"

I

wi SELECT button I

to YBloc

001

TIMERI 3

temperature as the value

indicated on the thennometer.

+

When the START button is

pressed while pressing the

TIMER button. the corrected

Bottan

thermistor

Adjust at 105"C.

(Writing-in)

NO"

~

value is written in.

I

~ SELECT button

to 6 'Sloe

3) 001

EXHAUST: lateral thermistor

TIMER: Object temp. sensor

LEFT: Bottom thermistor

- 28-

I

3 : 105"c

4 : 121"c

5 : 135"c

1

Press the SETLCONF I RII button

to set the sterilization temp. at

121''c.

Set the sterilization temp.

Example of the lateral thermistor correction

display (in 121"C correction)

Reaching 121 "C and sterilization process

Perform the 121"C correction in

the same manner as the

correction at 105"C.

Press the SETLCONF I RII button

Adjust the temp. to 121 "C after

going to the 121 etc sterilization.

Set the sterilization temp.

to set the sterilization temp. at

135"C.

Reaching 135"C and sterilization process

Perform the 1350C correction in

the same manner as the

correction at 105"C.

Adjust the temp. to 135"C after

going to the 135"C sterilization.

- 29-

NO"

I

[2 IEloc

""'""111 021

(2) Adjustment of pressure sensors

Pressure correction of the pressure sensor can be performed manually.

Pressure correction is performed at 2 points, namely, in the status with the lid being opened and at 135 DC.

For prevention of heating without water, check the heating water amount.

I

Operation

I

I

Enter into the test mode .

I

..

I

Description

II

I

I

Display

Fix the 2 shafts found at the back

side of the cover by tape, etc.

and set it to ON status.

t

Close the lid once and then open

it.

..

Press the START button with

the cover being opened.

For adjusting the pressure when

the pressure is 0 (cover 'Open').

Normal display

The correction of pressure is

displayed only while the

reservation button is oressed.

When the cycle selection

button is pressed while pressing

it, the display changes in the

order of -Lateral sensor-Object

Selection of the pressure

correction display

(See the right figure.)

Release.

of ]

Raserv.

button

Press.

Example

nannal display

Cycle selection

button

temp. sensor-Bottom sensor-

~

Press. sensor. Select the

pressure correction display.

Lateral thermistor correction

display

( Cycle selection

button

Press the ~or "a" button

while pressing the reservation

buttu I and adjust the pressure

I Object temp. correction display

Pressure adjustment

(Correction)

[ Cycle selection

button

so that the pressure display valu

becomes 'P. 0'.

When the START button is

pressed while pressing the

reservatm buttu i, the

corrected value is written in.

1

J

Bottom thermistor correction

display

Pressure adjustment

Example of pressure

correction display

(Writing-in)

'-

e.1 rn

(j

Press the STOP butIpn and

Cycle selection

button

]

remove the tape from the shaft.

/

Pressure display value

- 30-

Corrected value

J

Select the instrument sterilization

cycle and set the sterilization

temperature at 135'C and the

sterilization time at 30 min. Close

the cover and press the STRAT

Set the cycle, sterilization temp.

and time.

~.

Reaching 135OC and sterilization process

Nonmal display

Release.

Press the "V"or ",6." button

while pressing the

SETlCONFIRM button

and

adjust the pressure so that the

pressure display becomes same

as the value on the pressure

gauge of the product.

When the START button is

pressed While pressing the

SET /DISPLA Y button the

corrected value is written in.

SET/COFIRM

Pressure adjustment

(Correction)

(See the Mght figure.)

The pressure gauge of the

product shows the pressure in

MPa and the pressure display

value in kPa.

button

Example of pressure

correction display

Pressure adjustment

(WMting-in)

Pressure

I

display value

-31-

Corrected

value

Press

(3)01ecklna the safety valve operation

'Checking procedure of the safety velve operation

I. Enter into the telt mo'" As for the .ntwirllllMlthod. _ ttl. PIIP d.scribirc th. wit mod •.

2. S.I.ct the in.tn.n.nt .t.iliution cycI.. ..t th • .twiliution w~nrtlnl .t 140"C .nd the .u.riliution tim.

at 10 min . ..,d ltart th. opwGon.

3. Wh.n th ........It p___ is owr. th • ..r.ty wI¥. i••ctu.t.d at.bout l4O"C1O.2tlMP. to b.lch.w.m from

*k

th,

IIidI.

4. Wh,n th, QOI'Ifimation if; cornplmd.•.t the ltlriliz.tion temp,r.tu ... at 135'C ..,d th, .t.ilization tim, .t

1 min.

5. Wh,n th, proeM, i. complil'tlld thelL,," the ,xhaLllt prac... IftIr ttl. complfiion of the ItlriliDiion pl'OCOlu.

tum OFF th, ~ to oomplm the confimlltion.

(4)Conformatlon of the THl and TH3 temperature.

When the '''''and ..... butlDns 818 pnIIIslKI at the same time,

the TH1 temperature ill displayed on the Digital Display I end

the TH3temperature ill displayed on the Digital Display II.

- 32-

-~NOW

12

12

I

I

I

I

"

10. Thermistor Temperature Characteristics /

Altitude,Atmospheric Pressure and Boiling Point in standard Atmosphere

-Thermistor temperature characteristics

Th1·Th3

Standard

Temp.

"C

Resistance

Standard

"C

Temp.

Resistance

Value M?

-10

-5

0

5

10

15

20

25

Temp.

"C

Value k?

9.71

7.17

5.33

4.01

3.03

2.32

1.78

1.39

1085

854

676

539

433

349

283

231

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

Standard

Resistance

Value k?

Standard

"C

Temp.

Resistance

Value k?

189.2

155.9

129

107.3

89.57

75.12

63.26

53.48

110

115

120

125

130

135

140

145

45.3t

38.6f

33.04

28.34

24.35

21.0f

18.2

15.84

- Altitude, atmospheric pressure and The Boiling point of water in standard atmosphere

Atmospheric Pressu ..

Altitude

(hPa)

-382

-300

-200

-100

o

100

200

300

400

500

61

1060

1049.0

1037.

1025.2

1013.

1001.4

989.5

977.6

966.

954.

943.

Altitude

(nmHg)

(

795.0

786.7

777.8

768.9

760.0

751.1

742.2

733.3

724.6

716.1

707.5

"C)

(m)

101.27

100.99

100.66

100.33

100.00

99.67

99.34

99.01

98.67

98.34

l8.

Atmospheric Pressu..

(hPa)

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

(nmHg)

805.2

795.0

785.4

775.8

766.2

756.6

746.9

737.

728.5

719.3

7'

MO

~.

603.9

596.3

589.1

581.9

574.7

567.5

560.2

553.3

546.4

539.5

532.'

IBoil!n_!! Point

( "C)

93.72

93.39

93.06

92.73

92.40

92.07

91.74

91.41

91.08

90.75

5

320

825.

815.

.5

l4.)5

4000

,.4

47 .

46..

46..

!7.

• Environmental conditions for use of equipment

Atmospheric pressure 701.1 - 1013.3hPa

-As for the conversion of the atmospheric pressure(hPa(mba) and mmHg), see the following formula:

1mmHg=13.5951 X980.665X1 O"'hPa(mba)

-As for the calculation of the boiling point, see the following formula:

Boiling point =100+0.0367(P-760)-0.000023(P-760)2

P: mmHg

- 33-

CD

~

I

®

nnnn

_

~

t~

=

®

@

-*-iY

I

-

~o--

uuuu

=

--

:1

limiter

I

CD Power cord

@Triac

® Tanninal block

® Power switch

® Power relay

0) Power transfonner

® Protective grounding tenninal

@Coil

®

I

I

I

-

EMCPCB

Current fuaa x 2

'5OV SA

----j Ud switch

Fan

I

AC power IlUpply ~

datecIIon circuit

I

;M

'!'i'

"''''''>A

...

Main relay

control circuit

MlcrocompulBr abno

detection circuit

12V

I

all Hard limiter

Fan control

circuit

I

I

IComm~onll

h

5

pea

Circuit

Sound

circuit

I

I

III Sol~'"

S<>Ieoo;d

control circuit

wlw

control circuit

1

DC88V

I

6: 120V

3: 110V

2: OV

II T_

_ II To~"""~

d'cult

circuit

I

Microcomputer & Control Section

-

8:23OV

4 :22OV

3 :200V

2: OV

TH3

I ILateral

temp. II Low temp.

sensor

sensor

L~ OV

~ I,

. - =1 Co~=on

·" ·"

kef'

I

CommutaUon

circuit

.- -

··, ··,

ITriKk~""'"

circuli

DCpower E'! 5V

IlUpply circuli

-'!.5V

I

Ud_h I

TH1

Heater detection

circuit

.-

--

PCB

--1

'-""<ow

Voltage drop

detection cirtlUit

7

•" •"

I

Display·Operation

-

0)"

22OV123OV

,-

I

I

1Commutation 1ComrTMJtation

circuit

circuit

I

I

Lid detection

circuit

l

Control PCB

I

I SolenoKj I I ~:st I

Commutation 1

circuit

Printer

0 ptio

n

~

I I PrMeurecircuit

dIlecIion

11

Tamp. dllectlon

circuit

"'all, I

'-""< SY!Ich

delecllon

'-""<

"all, I I Psensor

....,.. I I Objed tomp_

sensor

del8clion swim

Option

TH'

11.Citcuit Diagram

Sterilization heater

1900W : 3751 L(12OV)

2000W : 3751,3751 L(230V)

"~400OW:3781,3781L

12.Troubleshooting

is not

when the

is turned ON.

(1)

main power billa• .

If the breaker Is OFF, tum nON.

(2) Check the power cord for any breakage.

If broken, replace the power cord.

Checking point by

tea..,

i

the P0'NW5Upply.

Tum OFF the main power supply and turn ON the power

switch of the unit, and check the conductivity.

If not conductive, replace tha power switch.

(2) Check the lead wire for removal or looseness.

(1)

Check the conductivity

ENTERA (or CE).

F....

;

Check tha lead wire for breakaga.

• od<el of

housing set

- 35-

(2) iIIILid" appears on the dsplay and procesl doe. not start.

1) Check the 2 shafts mounted to the nd.

Shafts

2) Check the position of the both lock shah.

Lock shafts

Push the shafts to make sure that they slide In and out

smoothly.

If the shafts do not slide smoothly,

(1) Check the springs lItted to the shalls.

(2) Apply grease to the shaft sliding perl

When the cover is opened,

(1) Check if the shalls are in due position

On just about vertical position).

(2) Check if the lock shafts open when pushlld outward and

they retum to the original position by spring force when

relaased.

If they can not move normally,

(1) Remove any foreign matter which is pinched and jams the

.hall

(2) Replace the spring, etc. If In trouble.

(3) Apply grease to the shaft sliding perl

- 36-

i.,.,,;~ awIlch Is not conductive

housing set M.

ON, replace the

Detection switch

;

lead wire for breakage.

Socket of the

housing H1:

replace the

housing set OS.

Between Black 1 and 2

Conductivity checking

positions

• Detection switch 1

Between Black 1 and

2

• Detection switch 2

Between While 1 and

Black 3

• Wire Nos. are

Indicated on the

Between Black 3 and White 1

connectors.

- 37-

Check that the housings in the same color are connected.

Check. the

connection.

(3) "___ ..,.,..,.. on the _

even when the cover Is closed.

1) Check the Items 2) and 3) of "L.Jd" appears on the display

and

does not start

2) Check. the conductivity the switch when the both lock shafts

(5) _

is

Correct Kif In trouble.

Since the switch is turned OFF when the lock shafts open, the

switch Is not conductive.

If the switch is conductive, rwplace the housing set M.

not .. "".... to tho twater.

1) Check the exhaust hose.

2) Check the hose in the exhaust tank.

3) Check if the exhaust hole i, blocked with any sterilization

otfect or sterilization bag.

Check. if the hose is bent or clogged in the product when

exhaust 'lank Is Installed. Correct Kif bent or clogged.

Check if the hose is bent or clogged.

Correct Kif bent or clogged.

Remove it if the exhaust hole is blocked.

- 38-

(1) Since

does not operate in spite that the voltage

is applied, replace the exhaust valve.

If the voltage is OV,

(1) Check the connection of the housing set W or V.

(2) Replace the "PCB set, controlTH set".

7.6Qfor 3751 L (12OV), 13.2Qfor 3781L

26.5Qfor 3751L (230V) and 3751.

If not, replace the heeler.

Check the resistance

value bet¥Men the

terminal block 1 and

relay- 6.

..

(1) C;;eck.1~' ~)",;"g"' "'b'y I 3781 CE for connection and

breakage.

(2) Replace the relay.

OV.

''''''''

(1) Check the housing assemblyB120 3751

8230 3781 for conneclion or breakage.

(2) Replace the Triac.

(3) Replace the "PCB set, controlTH set".

1 and D.

chamber.

It can be restored If a "Click" sound Is heard.

,,-f-

Press hera.

(8) ''!me" "-""" on tho _ .

Check the Item. 1) - "') of ·Power is not not .upplied to the

heeler."

If any trouble, correct it

- 39-

or 8220 3781 or

(7) Steam leaks from the periphery of the chal'l"tter.