iMark

™

Microplate Absorbance Reader

Instruction Manual

iMark™

Microplate Absorbance Reader

Instruction Manual

Warranty Statement

This warranty may vary outside of the continental United States. Contact your local Bio-Rad office for the exact terms of your warranty.

Bio-Rad Laboratories warrants to the customer that the iMark Microplate Absorbance Reader will be free from defects in material and workmanship, and will meet all performance specifications for a period of one year from the date of shipment. This warranty covers all parts and labor.

In the event that the instrument must be returned to the factory for repair under warranty, the instrument must be packed for return in original packaging. Please contact your local Bio-Rad representative for the necessary return documents. The required documentation includes a decontamination certificate.

Bio-Rad shall not be liable for any incidental, special, or consequential loss, damage, or expense directly or indirectly arising from the use of the iMark Microplate Absorbance Reader. Bio-Rad makes no warranty whatsoever in regard to products or parts furnished by third parties, such being subject to the warranty of their respective manufacturers. Service under this warranty shall be requested by contacting your nearest Bio-Rad office.

The following items are considered customer-installable consumables: thermal printer paper and light bulbs. These parts are not covered by this warranty. All customer-installed parts are warranted only to be free from defects in workmanship. This warranty does not extend to any instrument or parts thereof that have been subject to misuse, neglect, or accident, or that have been modified by anyone other than Bio-Rad or that have been used in violation of Bio-Rad instructions.

The foregoing obligations are in lieu of all other obligations and liabilities including negligence and all warranties of merchantability, fitness for a particular purpose, or otherwise expressed or implied in fact or by law, and state Bio-Rad’s entire and exclusive liability and buyer’s exclusive remedy for any claims or damages in connection with the furnishing of goods or parts, their design, suitability for use, installation or operation. Bio-Rad will in no event be liable for any special, incidental or consequential damages whatsoever, and Bio-Rad’s liability under no circumstances will exceed the contract price for the goods for which liability is claimed.

i

Regulatory Notices

Electro Magnetic Compatibility:

This instrument is designed to meet the Class-A emissions and immunity levels of the EN 61326 product family standard for the CE mark. This rating requires that it only be used in a laboratory environment.

NOTE: These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his/her own expense.

Safety

This instrument is designed to meet EN 61010-1 requirements for the CE mark, which are internationally accepted safety standards for electrical equipment for measurement, control and laboratory use. EN 61010-1 applies to equipment which is used under the following conditions:

•Indoor use

•Altitude up to 2,000 m

•MAINS supply voltage fluctuations up to ±10%

This instrument has been tested, and its compliance has been confirmed under the following environmental conditions:

•Overvoltage category II

•Pollution degree 2

If the instrument is used in a manner not specified in this manual, the protection provided by the instrument may be impaired. This instrument should not be modified or altered in any way. Alteration of this instrument will result in the following:

•Void the manufacture’s warranty.

•Void regulatory compliance.

•Create a potential safety hazard.

Protective Ground

This instrument has a detachable, three-wire power cord for connection to both the power source and protective ground. The protective ground contact is connected to the accessible metal parts of the instrument. To prevent electrical shock, always use a power source outlet that has a properly grounded protective-ground contact.

ii

Table of Contents |

||

|

Introduction …………………………………………………………………………………….. |

1 |

|

|

Description …………………………………………………………………………………………… |

1 |

|

|

USB Interface ……………………………………………………………………………………….. |

1 |

|

|

Built-in Printer ………………………………………………………………………………………. |

1 |

|

|

External Features……………………………………………………………………………………. |

3 |

|

|

Keypad Guide ……………………………………………………………………………………….. |

4 |

|

|

Instrument Setup ……………………………………………………………………………….. |

5 |

|

|

Unpacking the Instrument…………………………………………………………………………. |

5 |

|

|

Initial Instrument Startup………………………………………………………………………….. |

5 |

|

|

Instrument Shutdown ………………………………………………………………………………. |

6 |

|

|

Software Overview…………………………………………………………………………….. |

7 |

|

|

Capabilities…………………………………………………………………………………………… |

7 |

|

|

Quick Guide to Reading a Plate …………………………………………………………………. |

7 |

|

|

Instrument Functions ………………………………………………………………………….. |

8 |

|

|

Calculations ………………………………………………………………………………………….. |

8 |

|

|

Security password…………………………………………………………………………………… |

8 |

|

|

Memory Back-Up…………………………………………………………………………………… |

8 |

|

|

Limits ………………………………………………………………………………………………… |

9 |

|

|

Report Types ………………………………………………………………………………….. |

10 |

|

|

End-point Protocol Reports……………………………………………………………………… |

10 |

|

|

1. |

Raw data report……………………………………………………………….. |

10 |

|

2. |

Absorbance report ……………………………………………………………. |

10 |

|

3. |

Limit report ……………………………………………………………………. |

10 |

|

4. |

Matrix report ………………………………………………………………….. |

10 |

|

5. |

Cutoff report…………………………………………………………………… |

11 |

|

6. |

Curve Fit Report ……………………………………………………………… |

12 |

|

7. |

Concentration Report………………………………………………………… |

12 |

|

8. |

Difference Report…………………………………………………………….. |

12 |

|

9. |

TeSeE Screening Report ……………………………………………………. |

13 |

|

Kinetic Protocol Reports ………………………………………………………………………… |

15 |

|

|

1. |

Absorbance Report …………………………………………………………… |

15 |

|

2. |

Kinetic Plots Report …………………………………………………………. |

15 |

|

3. |

Linear Regression Report…………………………………………………… |

15 |

|

4. |

GALT Report …………………………………………………………………. |

15 |

iii

|

Screen by Screen Procedures………………………………………………………………. |

17 |

|

Initial Startup ………………………………………………………………………………………. |

17 |

|

Configuring the System………………………………………………………………………….. |

18 |

|

Printing Reports and Protocol information…………………………………………………… |

20 |

|

Memory Recall Operation ………………………………………………………………………. |

21 |

|

Editing the Kinetic Protocol…………………………………………………………………….. |

22 |

|

Checkmark Value Setting (Administrator only)…………………………………………….. |

24 |

|

Editing End Point Protocol ……………………………………………………………………… |

25 |

|

Cutoff Setting Procedure ………………………………………………………………………… |

26 |

|

Standard Setting Procedure……………………………………………………………………… |

29 |

|

Mode Setting Procedure …………………………………………………………………………. |

32 |

|

Plate Map Setting Procedure……………………………………………………………………. |

33 |

|

Instrument Maintenance…………………………………………………………………….. |

36 |

|

Installing Interference Filters …………………………………………………………………… |

36 |

|

Changing the Lamp ………………………………………………………………………………. |

36 |

|

Troubleshooting and Error Messages…………………………………………………….. |

37 |

|

Instrument Specifications…………………………………………………………………… |

39 |

iv

iMark Microplate Absorbance Reader Instruction Manual

Introduction

Description

The iMark™ Microplate Absorbance Reader (catalog #168-1130) is an eight-channel, vertical pathlength photometer that measures the absorbance of the contents in the wells of a 96-well microtitration plates. It can perform single or dual wavelength measurements and can report absorbance values to three decimal places.

The iMark reader can be programmed by entering commands through the membrane keypad to define plate reading and data analysis parameters as testing protocols and select report types. Hard copy reports can be produced by an optional on-board thermal printer or external printer.

The iMark reader can also be controlled by the Windows-based Microplate Manager® software (catalog # 168-9520) program, through its built-in USB 2.0 interface device. Microplate Manager software provides a complete, user-friendly solution for protocol programming as well as data analysis, for all microplate absorbance readers from Bio-Rad Laboratories.

USB Interface

The iMark Microplate Reader has a built-in USB interface. This allows external computers to control the instrument. When an external computer is in control of the microplate reader, the printer and the membrane keys, except for the Start/Stop and Open/Close keys, are automatically deactivated, and the LCD display appears as below.

Remote mode

The reader will remain in remote control mode until it is released or until the Start/Stop key is pressed on the reader.

Built-in Printer

The iMark Microplate Reader has a built-in printer. It can generate all types of reports, including graphs and kinetic plots.

1

iMark Microplate Absorbance Reader Instruction Manual

|

Catalog # |

Description |

|

168-1130 |

iMark Microplate Absorbance Reader with built-in printer |

|

168-1135 |

iMark Microplate Absorbance Reader with built-in printer, |

|

including Microplate Manager 6 software |

|

|

168-6940 |

Checkmark Absorbance Reader Performance Validation Kit |

|

Accessories |

|

|

Catalog # |

Description |

|

168-1011 |

405 nm filter |

|

168-1013 |

415 nm filter |

|

168-1020 |

450 nm filter |

|

168-1028 |

490 nm filter |

|

168-1038 |

540 nm filter |

|

168-1040 |

550 nm filter |

|

168-1044 |

570 nm filter |

|

168-1049 |

595 nm filter |

|

168-1054 |

620 nm filter |

|

168-1056 |

630 nm filter |

|

168-1061 |

655 nm filter |

|

168-1080 |

750 nm filter |

|

168-1006 |

Replacement lamp for iMark Microplate Absorbance Reader |

|

168-2007 |

Replacement printer paper, package contains 3 rolls |

Custom filters between 400 and 750 nm may be ordered. Corresponding catalog numbers can be found on www.bio-rad.com, or you can order by specifying the wavelength and the model number of the reader.

Checkmark Absorbance Reader Performance Validation Kit (catalog item 168-6940) consists of a plate with absorbance standards and software to calculate the accuracy and precision of the iMark Microplate Absorbance Reader.

2

|

iMark Microplate Absorbance Reader Instruction Manual |

|||

External Features |

Release latch for rear cover |

Rear cover |

|

|

Power button |

Printer slot |

Liquid crystal display (LCD)

Keypad

Reading chamber door

Cooling vents and fan

|

USB 2.0 interface |

Serial number label |

Power cord receptacle |

3

iMark Microplate Absorbance Reader Instruction Manual

Keypad Guide

|

Main |

Returns to MAIN SCREEN. |

|

Start/Stop |

Initiates plate reading using current active protocol. |

|

Stops plate reading and printing. |

|

|

Paper Feed |

Advances paper strip in internal printer. |

|

|

Prints out the plate data and protocol information. |

|

Edit |

Enters the Edit Menu, and sets up the instrument. |

|

Memory Recall |

Reads out protocol and plate data. |

|

Open/Close |

Opens or closes the reading chamber door. |

|

Open/Close |

Memory |

Edit |

|

|

Recall |

|||

|

START |

|||

|

/ |

|||

|

STOP |

|||

|

Main |

Paper Feed |

|

|

Up Arrow |

Moves the cursor upward. |

|

Selects the alphabet or the symbol. |

|

|

Left Arrow |

Returns to the previous screen. |

|

Moves the cursor to the left. |

|

|

Down Arrow |

Moves the cursor downward. |

|

Selects the alphabet or the symbol. |

|

|

Right Arrow |

Moves the cursor to the right. |

|

Changes or selects the value and type. |

|

|

Enter |

Completes or seals a field entry. |

A => Z

+−••

ENTER

Back Change

Z => A

|

Dot/Function |

Inputs the dot. |

||||||||||||||||||

|

Changes the input mode. |

|||||||||||||||||||

|

Ten Keys |

Inputs numbers or well type in plate mapping. |

||||||||||||||||||

|

CP |

CN |

CW |

|||||||||||||||||

|

0 |

/ EMP |

: Empty |

|||||||||||||||||

|

7 |

8 |

9 |

|||||||||||||||||

|

5 |

/ QC |

: QC control |

|||||||||||||||||

|

1 |

/ SMP |

: Sample |

CO |

QC |

CAL |

||||||||||||||

|

6 |

/ CAL |

: Calibrator |

4 |

5 |

6 |

||||||||||||||

|

2 |

/ BLK |

: Blank |

|||||||||||||||||

|

SMP |

BLK |

STD |

|||||||||||||||||

|

7 |

/ CP |

: Positive Control |

|||||||||||||||||

|

1 |

2 |

3 |

|||||||||||||||||

|

3 |

/ STD |

: Standard |

|||||||||||||||||

|

8 |

/ CN |

: Negative Control |

|||||||||||||||||

|

EMP |

FUNC |

||||||||||||||||||

|

4 |

/ CO |

: Cutoff control |

0 |

0 |

|||||||||||||||

|

9 |

/ CW |

: Weak Positive Control |

4

iMark Microplate Absorbance Reader Instruction Manual

Instrument Setup

Unpacking the Instrument

The shipping carton contains the following items:

•iMark™ Microplate Reader, with 415 nm, 450 nm, 490 nm, 595 nm, 655 nm, and 750 nm interference filters installed on the filter wheel

•Power cord

•USB cable

•Dust cover

•Instruction manual

•Warranty card

•One roll of thermal printer paper

Inspect the exterior of the instrument for any signs of shipping damage. Contact your local Bio-Rad representative if any of these items are damaged or missing.

Initial Instrument Startup

1.Place the instrument on a clean, sturdy table or bench. It is important to keep the instrument in a clean, relatively dust free environment to ensure optimal performance.

2.Connect the power cord to the back of the instrument. Before connecting the instrument to the main electrical supply, check that the AC voltage is appropriate for the instrument.

3.To turn the power on press the green power button on the top of the instrument. The LCD will display the version number of the on-board firmware. After about three seconds, the instrument will perform an initial self-diagnosis that requires about fifteen seconds. The login screen displays for you to choose your user level (administrator or common user), and enter the password (initial password: 00000). Please allow three minutes for the instrument to warm up (reach thermal equilibrium) before reading plates.

System Login

User: Administrator

Password:*****

Press ENTER

Change password

Select “Change Password” in the Security Menu.

Enter the current Password then move the cursor to the 3rd line and enter a new password. Press Enter to complete the field entry. The system will return to the previous Security Menu.

Change user mode

Select “Change user” in the Security Menu.

Select a desired user mode by pressing the Right Arrow key. Enter the appropriate password for the selected user mode. Press Enter to complete the field entry. The system will return to the previous Security Menu.

5

iMark Microplate Absorbance Reader Instruction Manual

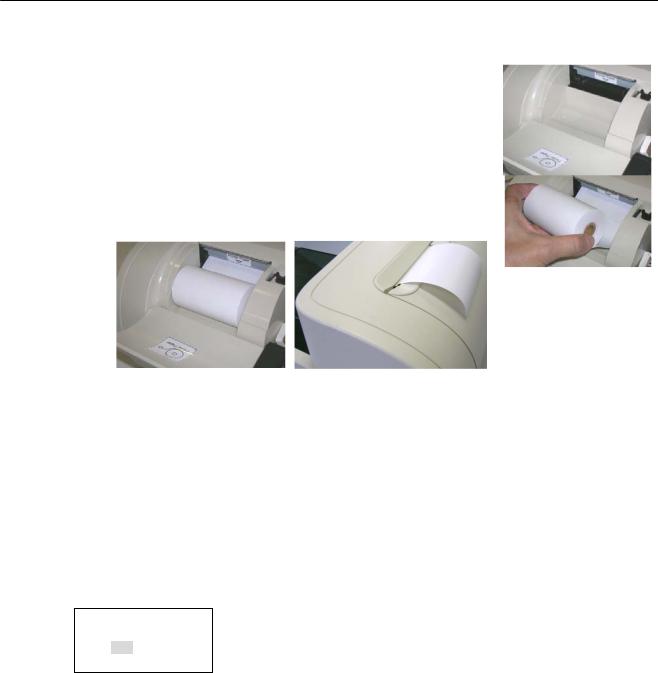

4.Install the printer paper. The thermal printer paper is printable on one side only and must be properly installed for the printer to function. The outside of the roll is the printable side.

a.Open the rear cover of the instrument.

b.Tear off a small piece at the beginning of a new roll at an angle to form a point.

c.Place the roll of paper in the small pan-like holder positioned below the printer. The roll should be positioned so that it will feed from the bottom.

d.While pressing the PAPER FEED key, feed the pointed end of the paper into the paper feed slot in the underside of the printer until the printer grabs the paper and feeds it through the slot in the top of the instrument.

e.Securely close the rear compartment.

Multi-language support

The iMark LCD can produce text in three languages; English, Russian and Chinese. To switch to English from Russian or Chinese, press the Main button, then the Edit button to get to the configuration screen. Press the downward-pointing arrow on the key pad six times to navigate to the language options line. Press Enter twice to select English, and then press Enter a third time to shut down the reader. When restarted, the iMark will display in English.

Instrument Shutdown

To shut down the instrument, press the green power button on the top of the instrument for a few seconds. Then the LCD will display a Power off, Yes or No screen. Select “Yes” to shut down the instrument.

Power off

>>Yes No

6

iMark Microplate Absorbance Reader Instruction Manual

Software Overview

Capabilities

The iMark Microplate Reader has on-board software that allows the user to set the plate reading and data analysis conditions, to save these settings as a test protocol, to read a microplate under this protocol, and to print reports from the built-in printer. The software communicates through the 4-line, 20-character LCD and is controlled through the instrument’s membrane keypad.

The software has three different protocol types: End-point analysis, Kinetic analysis, and Checkmark validation. The Checkmark validation function is used only by the administrator to verify quality control.

The display shows the current mode. The user can choose between these protocol types, or can press the Memory Recall key to use the current protocol type.

Quick Guide to Reading a Plate

1.Turn on the instrument. Allow about 30 seconds for self-diagnosis. The instrument needs to warm up for about three minutes prior to reading a plate.

2.Upon power up, the login screen will appear. Enter the login password (initial password: 00000), press Enter.

3.Program a protocol for your assay. See page 22 for information on Editing a Kinetic protocol, or page 25 for Editing an End Point Protocol. Make sure filters installed correlate with information entered in reader firmware.

4.Select the protocol of choice, if programmed. See the Memory Recall section on page 21 for detailed operation.

5.Review or print parameters set in the protocol. See the Editing End Point Protocol section on page 25 for details.

6.Verify settings on Cutoff, Report, Limit, STDs, Mode, Mapping, and kit name parameters are as desired.

7.Protocol setting can be printed; see the Printing Reports and Protocols section on page 20 for information.

8.All reports other than the raw data report require plate mapping. Set the plate map with instructions from the Plate Map Setting Procedure section on page 33.

9.The Matrix and Limit reports require assignment of upper and lower limits. Set the upper and lower limits in the Editing End Point Protocol Limit setting window.

10.The Cutoff report requires definition of the cutoff setting. Refer to the Cutoff Setting Procedure section on page 26.

11.The Curve fit and Concentration reports require that standard concentration and locations must be defined. Refer to page 29 for details on how to define the standards and the curve fit parameters.

12.Set the general reading mode (single or dual wavelength reading, plate shaking, read mode) following the instructions in the Mode Setting Procedure section on page 32.

After warm-up is complete:

13.Press the “Main” key. The main screen appears on the LCD.

14.Carefully place the microplate in the reading chamber. Press the “Start/Stop” key to read.

7

iMark Microplate Absorbance Reader Instruction Manual

Instrument Functions

Calculations

The Microplate Reader uses Beer’s Law to calculate the absorbance value of each well. Beer’s Law states that absorbance is equal to the log10 of the ratio of the baseline measurement intensity (Io) to the sample measurement intensity (I).

Beer’s Law: Absorbance = Log10 (Io/I)

Before measuring the plate, the reader takes a reading for all eight photodiode channels. These values are recorded as the baseline measurement (Io) values for each channel, respectively. The reader then records the sample measurement (I) value for each well, and calculates the absorbance using these values. Channel-to-channel error is significantly reduced because the Io value for a given channel is used only in determining the absorbance of the wells of that channel.

Security password

The iMark Microplate Reader requires a user login with password. This security feature helps to prevent any unwarranted modifications to the analysis conditions/protocols and data stored in the instrument, and identifies the operator on reports. The reader has two user settings, the Administrator and the Common user. Each user level has its own security password.

Memory Back-Up

The battery back-up provides memory even after the reader is turned off.

The following information will be saved in the memory until new reading parameters are set by the user or a new plate is read by the instrument. Note that if a run is aborted before it is finished, all the previous plate reading data remain in memory and none of the data from the aborted reading is stored.

•The ten latest sets of End-point protocol plate reading results

•The two latest sets of Kinetic plate reading results (max. 30 series of readings for each Kinetic Protocol)

•64 End-point Protocol settings and 2 Kinetic Protocol settings

•A set of Checkmark reference data and the one latest set of Checkmark reading result

•A set of standard curve data for the storage of standard curves and graphs

•Eight wavelength values for filters

•Laboratory name

•Two security passwords (for the Administrator and the Common user)

•Instrument serial number

In addition to the battery back-up memory, the instrument has a small amount of non-volatile memory to keep the system information after the battery is dead. The serial number is stored in this memory. The average battery life is 5 years.

8

iMark Microplate Absorbance Reader Instruction Manual

The first time the instrument is turned on, or after a battery failure, the following default information is held in the memory.

1.Both Administrator and Common user security passwords are set to «00000».

2.Laboratory name is «Bio-Rad Laboratories».

3.All wavelength values of the filters are set to «—» nm.

4.The date and time of the calendar chip are set to 1 day, 1 month, 00 year, 0 hour and 0 minute.

5.No plate reading data is available.

6.End-point protocol is chosen and the protocol number is set to #1.

7.No standard curve data for the storage of standard curves and graphs is available.

Limits

The Microplate Reader displays absorbance readings with absolute values as 3.500. Out-of-range absorbance values, (those with absolute values greater than 3.500) are displayed as either «*.***» or «-*.***». For example, if the absorbance is 4.500, then the display will read «*.***», and if the absorbance is -4.500, the display will read «-*.***».

9

Bio-Rad Laboratories (США) – глобальная компания, производитель оборудования, питательных сред, антител, расходных материалов, а также программного обеспечения для исследований в области геномики и протеомики и безопасности пищевых продуктов. За более полувековую историю компании удалось стать одним из лидеров рынка в производстве современного оборудования для молекулярно-биологических исследований, с каталогом, насчитывающим более 8 000 наименований, штатом сотрудников в 6 тыс. человек, работающих в том числе в России, Казахстане и Украине. Большое внимание компания уделяет поддержке пользователей, организовывая регулярные практические семинары по протеомному анализу и применению ПЦР «в реальном времени», проводя сервисное обслуживание на территории России и стран СНГ и многое другое.

-

Life Science Group

Model 680 and 680 XR Microplate Reader

Service Manual

Part Number 100-2414 Revision E

-

100-2414E 02/06 i

PROPRIETARY NOTICE

Information contained in this manual is copyrighted by Bio-Rad

Laboratories, Inc. None of the contents may bereproduced in full or

in part by any person without the prior written approval of Bio-Rad

Laboratories, Inc. Thismanual is intended to provide information to

assist the qualified field or instrument service technician to

repair,maintain, and order replace parts for the instrument

supplied. Every reasonable effort has been made to keepthe

information in this manual current and accurate as of the date of

publication or revision. However, no guar-antee is given or implied

that the manual is error-free or accurate about any

specification.Copyright 2002-2006 by Bio-Rad Laboratories, Incorporated. All

rights reserved.Bio-Rad Laboratories Inc, Life Science Group

2000 Alfred Nobel Drive

Hercules, California 94547

Telephone: 1-800-424-6723

-

ii 100-2414E 02/06

About this manual This document is part of Life Science Groups

commitment to provideyou, the service professional, with adequate

information to effectivelysupport Bio-Rad instruments. Additional

copies of this service documentmay be ordered using part number

100-2414.We welcome and appreciate any suggestions you may have to

improveour service documentation. Please address your comments or

sugges-tions to:Technical Editor, Global Service Support Dept.

Bio-Rad Laboratories, Life Science Group

2000 Alfred Nobel Drive

Hercules, CA 94547

FAX Number: 510 741-5802

-

100-2414E 02/06 iii

Revision Control List

Document: Model 680 and 680 XR Microplate Reader Service

ManualPart Number: 100-2414Date of Latest Revision: February

2006Each page of this manual has the catalog number, revision level

and revision date for that page. Subsequentrevisions to a page will

be indicated by changes to the revision level and revision date for

that page. A sum-mary of changes for all revisions is listed in the

following table.RevisionPage

NumberDescription

ChangedBy

Date

A — Initial Release A. Gandy Feb. 2002

B 4-11 to 4-12 Updated Checkmark Plate procedure A. Gandy June

20025-1 to 5-4 Added optics cleaning procedure

6-1 to 6-25 Added part numbers to sections; Updated Figure

6-96-16 Added check of plate position

7-1 to 7-2 Added Checkmark Plate; Updated Figure 7-3

7-4 Added Section AdjustingPlate Carrier Belt Tension

7-6 Added Section Alignment of Plate Carrier

8-5 Added Table 8-4 Checkmark Plate Failures

C Sec 1 thru 10 Manual Updated to Add Model 680XR A. Gandy Mar

20045-1 Added Note

6-3 Added 6.3.3 Model 680 XR Lamp

6-12 Added Table 6-1

6-15 to 6-16 Added 6.3.11 Model 680 XR Lamp Control PCB

6-22 Added 6.3.17 Model 680 XR Light Balancing Filter

7-8 Added Table 2 Firmware History

8-1 Updated Table 8-1

9-3 to 9-11 Updated parts information

App D Added Appendix D

D 6-12 Added Backlit LCD to Table 6-1 A. Gandy Sept 2005

7-6 Updated to reference Section 7.7

7-9 Updated Firmware Table 7-2 and added 7.6.3

7-10 to 7-11 Added Section 7.7 QC Software

9-5 to 9-11 Updated parts

E 7-8 to 7-9 Updated Firmware version 1.71; Table 7-2 update A.

Gandy Feb 20067-11 to 7-15 Updated 7.6.4 Firmware Downloading

7-17 Added Section 7-8 External Printer Setup

8-1 Updated troubleshooting printer

9-11 Added Shield Cover

-

Table of Contents

Section 1 Introduction 1.1 General Inforation . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . 1-11.2 Service Philosophy . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11.3 Safety and Precautions . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-11.4 Conventions . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 1-1Section 2 System Overview 2.1 Introduction . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 2-12.2 Product Description . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12.3 Product Configurations . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-22.4 Regulatory Notices . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-22.5 Product Overview . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-32.5.1 Calculations . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32.5.2 Limits . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-32.5.3 Memory Backup . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32.5.4 Reports . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-42.5.5 RS-232 Interface . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42.6 Instrument Specifications . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-52.6.1 Features . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52.6.2 Optical . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-52.6.3 Performance . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52.6.4 Thermal . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-62.6.5 Electrical . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-62.6.6 Physical . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6Section 3 Installation 3.1 Introduction . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . 3-13.2 Visual check . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 3-13.3 Installation Procedure . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-23.4 Install Paper Roll (Optional Internal Printer) . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23.5 Computer Interface (Optional). . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3Section 4 System Checkout 4.1 Introduction . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 4-14.2 Tools and Materials . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14.3 Summary of Tests and Specifications . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24.4 System Checkout Procedure . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34.4.1 General. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-34.4.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-34.4.3 Preparing Yellow Dye Test Plate . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 4-3 -

Table of Contents

4.4.4 Startup . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-34.4.5 Touch Pad/Mixing Function . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 4-34.4.6 Verify Printer . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44.4.7 Start Microplate Manager. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 4-44.4.8 Air Read . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-54.4.9 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74.4.10 Channel-to-Channel Variation . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 4-84.4.11 Stability and Drift . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-94.4.12 Verify Incubator Temperature (Optional) . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 4-104.5 Checkmark Validation Program (Optional Method) . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 4-114.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-114.5.2 Procedure. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11Section 5 Preventative Maintenance5.1 Introduction . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . 5-15.2 Tools and materials

5.3 Preventative Maintenance. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15.3.1 Firmware . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15.3.2 Inspection of Instrument . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 5-15.3.3 Perform System Checkout . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 5-1Section 6 Removal and Replacement 6.1 Introduction . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 6-16.2 Tools and Materials . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-16.3 Removal and Replacement Procedures . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 6-16.3.1 Interference Filters . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16.3.2 Model 680 Lamp . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16.3.3 Model 680 XR Lamp . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 6-36.3.4 Top Cover . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46.3.5 Printer Assembly . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56.3.6 Keypad Membrane. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 6-76.3.7 Inlet Assembly . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-86.3.8 Plate Carrier Assembly and Analog Board (#282) . . . . . .

. . . . . . . . . . . . . . . . . . 6-96.3.9 CPU Board (#281) . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-126.3.10 Incubator Control Board . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-136.3.11 Model 680 XR Lamp Control PCB . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 6-156.3.12 Power Supply, 12 Volt . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-176.3.13 Power Supply, 24 Volt . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-186.3.14 Photo Sensor (Analog Board) . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 6-19 -

Table of Contents

6.3.15 Photo Sensor (Filter Wheel) . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 6-206.3.16 Model 680 Light Balancing Filter . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 6-216.3.17 Model 680 XR Light Balancing Filter . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 6-226.3.18 Plate Carrier Motor . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-236.3.19 Optical Fiber Assembly . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-256.3.20 Filter Wheel/Filter Wheel Motor . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 6-276.3.21 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-286.3.22 Lithium Battery . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-29Section 7 Adjustment and Calibration 7.1 Introduction . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . 7-17.2 Tools and Materials . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-17.3 Electronics Adjustment . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-17.3.1 Setting of Jumper on the CPU Board . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . 7-17.3.2 Setting of Jumpers on the Printer Control Board . . . . .

. . . . . . . . . . . . . . . . . . . . 7-27.3.3 Incubator Electronics Adjustment . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 7-37.4 Adjusting Plate Carrier Belt Tension . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-47.5 Plate Carrier Alignment . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-67.5.1 Checking of Plate Alignment . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 7-67.5.2 Adjusting Plate Alignment — Y Direction . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 7-77.5.3 Adjusting Plate Alignment — X Direction . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 7-77.6 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 7-87.6.1 General . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-87.6.2 Firmware History . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-97.6.3 Integration of English and Chinese Firmware Version . . .

. . . . . . . . . . . . . . . . . . 7-107.6.4 Downloading Firmware. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 7-117.7 QC Software . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 7-167.7.1 Entering QC Software . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 7-167.7.2 Monitor Mode . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-167.7.3 Plate Positioning. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-177.8 External Printer Setup . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-17Section 8 Troubleshooting 8.1 About this Section . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 8-18.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1Table 8-1 General Problems . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1Table 8-2 Error Codes. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2Table 8-3 Firmware Downloading . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 8-4 -

Table of Contents

Section 9 Parts Information9.1 About this Section . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . 9-19.2 Parts Orders . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 9-19.2.1 US Domestic Operations . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 9-19.2.2 International Subsidiaries . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 9-19.3 Returning Defective Parts . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-19.3.1 US Domestic Operations . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 9-19.3.2 International Subsidiaries . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 9-29.4 Service Parts . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 9-3Table 9-1 Replaceable Parts for the Model 680 Microplate Reader

. . . . . . . . . . . . . . . . 9-3Table 9-2 Consumables . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-119.5 Filters . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . 9-12Table 9-3 Filters . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-129.6 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 9-13Table 9-4 Special Service Tools . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-139.7 Manuals . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 9-14Table 9-5 Manuals . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-14Section 10 Drawings 10.1 About this Section . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . 10-110.2 Drawings . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 10-1Block Diagram Wiring Diagram

AppendixAppendix A Model 680 System Checkout Report . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . A-1Appendix B Model 680 XR System Checkout Report . . . . . . . . .

. . . . . . . . . . . . . . . . . . . B-1Appendix C Checkmark Check Plate . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . C-1Appendix D Error Flow Diagrams . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . D-1 -

Introduction

100-2414C 03/04 1-1

Section 1Introduction

1.1 General Information

This manual is the reference to be used for troubleshooting,

repair, and maintenance of the Model 680 andModel 680 XR Microplate

Readers. It is intended to be used by trained technicians and

engineers familiar withsafety precautions relative to working with

instrumentation. The procedures in this manual assume that

thereader is familiar with the operation of the Model 680 and 680

XR Microplate Readers. Complete operatinginstructions are contained

in the Model 680 and 680 XR Microplate Reader instruction manual.

Informationpresented in the instruction manual is not repeated in

this Service Manual unless there is a compelling reasonto do

so.1.2 Service Philosophy

This manual is designed to support mail in products. Regional

service centers are the first level of service,where faulty

assemblies can be most effectively repaired at a central repair

facility. The second level of serviceis performed at our factory

instrument service facility in Richmond, California, where

additional service proce-dures requiring resources not available at

regional service centers are performed.1.3 Safety and Precautions

The Model 680 and 680 XR Microplate Reader contains the

following Hazards:Hazardous voltages

Thermally hot components

The following should be observed when servicing this unit:

When power is required, the unit should be plugged into an

outlet with a properly grounded receptacle.The use of 2-prong plug

adapters is not recommended and will void the safety certification

of thisproduct.The use of extension cords may compromise the safety of the

operator and is not recommended.Ensure that fuses installed in the unit are of the correct

rating.Ensure that none of the ventilation openings in the unit are

blocked. Excessive heat buildup in the unitmay cause failures.Bio-Rad is not responsible for any injury or damage caused by

the use of this instrument for purposes otherthan for which it is

intended or by modifications of the instrument not performed by

Bio-Rad or an authorizedagent.1.4 Conventions

The following conventions are used throughout this manual.:

Left and right sides of the unit are as viewed from the front,

operators position, unless otherwise stated.Dimensions are in millimeters, unless otherwise stated.

-

System Overview

100-2414C 03/04 2-1

Section 2System Overview

2.1 Introduction

The Model 680 and Model 680 XR Microplate Readers are an

eight-channel, vertical pathlength photometerthat measures

absorbance of the contents of 96 well mictotitration plates. They

can perform single or dualwavelength measurements, and can report

absorbance values to three decimal places.The Model 680 and 680 XR Microplate Readers can be programed by

entering commands through the keypadto define plate reading

conditions and data analysis conditions as a protocol data, and

select report types. Aprinted report is produced by an optional

on-board thermal printer or external printer. An optional incubator

isalso available.The Model 680 and 680 XR Microplate Readers feature a built-in

RS-232C serial interface device for conve-nient computer

interfacing. The Microplate Manager software for personal computers

offers a complete analy-sis program. Microplate Manager supports

Windows 95, Windows NT and Windows 2000.Microplate Manager Version 5.2.1 added support for the Model

680XR reader.2.2 Product Description

Figure 1: Model 680/680 XR Microplate Reader

The following items are included with the Model 680/680 XR

Microplate Reader system:Microplate Reader with 415 nm, 450 nm, 490 nm and 655 nm

interference filters installedPower Cord

Spare Fuse

Dust Cover

Instruction Manual

Warranty Card

-

System Overview

2-2 100-2414C 03/04

2.3 Product Configurations

The Model 680 Microplate Reader is available in four

configurations.2.4 Regulatory Notices

This instrument is designed to meet Class A emissions and

immunity levels of EN61326 product family stan-dard for CE mark.

This rating requires that it only be used in a laboratory

environment.This instrument is designed and certified to meet EN61010

requirements which are internationally acceptedelectrical safety

standards. Certified products are safe to use when operated in

accordance with the InstructionManual. This instrument should not

be modified or altered in any way. Alteration of this instrument

will result invoiding of the manufacturers warranty, void

regulatory certification and create a potential safety hazard.This equipment has been tested and found to comply with the

limits for Class A digital device, pursuant to Part15 of FCC rules.

These limits are designed to provide a reasonable protection

against harmful interferencewhen the equipment is operated in a

commercial environment. This equipment generates, and can

radiateradio frequency energy and if not installed and used in

accordance with the Instruction Manual, may causeharmful

interference to radio communications. Operation of equipment in a

residential area is likely to causeharmful interference in which

case the user will be required to correct the interference at their

expense.Table 1: Product Configurations

Catalog Number Description

168-1000 Model 680 Microplate Reader No Temperature Control and

No Internal Printer168-1001 Model 680 Microplate Reader With Temperature Control

and No Internal Printer168-1002 Model 680 Microplate Reader No Temperature Control and

With Internal Printer168-1003 Model 680 Microplate Reader With Temperature Control

and With Internal Printer168-1100 Model 680 XR Microplate Reader No Temperature Control

and No Internal Printer168-1101 Model 680 XR Microplate Reader With Temperature Control

and With Internal Printer -

System Overview

100-2414C 03/04 2-3

2.5 Product Overview

2.5.1 Calculations

The Model 680 and 680 XR Microplate Readers uses Beers Law to

calculate the absorbance value of each well. Beers Law states that

absorbance is equal to the Log10 of the ratio on the baseline

measurement intensity (Io) to the Sample measurement intensity

(I).Beers Law: Absorbance = Log10 (Io/I)

Before measuring the plate, the reader takes a reading for all

eight photodiode channels. These values are recorded as the

baseline measurement (Io) values for each channel, respectively.

The reader then records the sample measurement (I) value for each

well, and calculates the absorbance using these values.

Chan-nel-to-channel error is significantly reduced because the Io

value for a given channel is used only in deter-mining the

absorbance of the wells of that channel.2.5.2 Limits

The Model 680 and 680 XR Microplate Readers display absorbance

readings with absolute values up to 3.500. Absolute values greater

than 3.500 are out of range and are displayed as either *.*** or

-*.***.2.5.3 Memory Backup

The battery backup provides memory even after the reader is

turned off. The following information will be saved in memory until

new reading parameters are set by the user or a new plate is read

by the instrument. Note: If reading a new plate is aborted before

it is finished, all the previous plate reading date will remain in

memory and none of the new data from the new plate is retained.1. 10 latest plate reading data for End point protocol

2. 2 latest sets of Kinetic plate reading data (maximum 30

series of readings for each Kinetic)3. End Point and kinetic protocol data

4. A set of Checkmark protocol data and the latest set of

Checkmark read data5. 8 wavelength values for filters

6. Laboratory name

7. 2 security passwords (Administrator and Common user)

The first time the instrument is turned on, or after a battery

replacement, the following default information will hold in

memory:1. Both Administrator and Common user security password are set

to 000002. Laboratory name is Bio-Rad Laboratories

3. All wavelength values of the filters are set to — nm

4. The date and time of the calendar chip are set to 1 day, 1

month, 00 year, 0 hour and 0 minutes5. None of the plate reading data is available

6. End Point protocol is chosen and the protocol number is set

to #1 -

System Overview

2-4 100-2414C 03/04

2.5.4 Reports

Eight types of reports for End Point protocol can be generated

by the Model 680 Microplate Reader:1. Raw Data Report2. Absorbance report3. Limit Report4. Matrix

Report5. Cut Off report6. Curve Fit Report7. Concentration Report8.

Difference report2.5.5 RS-232 Interface

The Model 680 Microplate Reader has a built-in RS232C interface

(9 pin D-sub connector). This allows external computers to control

the instrument. When an external computer is in control of the

microplate reader, the printer and the keypad keys (except

Start/Stop) are automatically deactivated and the display will

indicate Remote Mode.The reader will remain in the remote control mode until it

receives RL command from the host computer or until the Start/Stop

key is pressed.RS-232 communication parameters are as follows:

Signals: TDX: Transmit DataRXD: Receive DataDTR: Data Terminal

ReadyDSR: Data Set ReadyCTS: Clear to SendRTS: Ready to SendTransmission: Baud Rate 9600, Data Width 8, Stop Width 1, Parity

NoneData: ASCII (no distinction between upper and lower case)

Signal Assignment:

Host Computer9 Pin D-sub

Model 680 Reader9 Pin D-sub

Receive Data 2 ———————— 3 Transmit Data

Transmit Data 3 ———————— 2 Receive Data

Data Terminal Ready 4 ———————— 6 Data Set

ReadySignal Ground 5 ———————— 5 Signal Ground

Data Set Ready 6 ———————— 4 Data Terminal

ReadyRequest to Send 7 ———————— 8 Clear to Send

Clear to Send 8 ———————— 7 Request to Send

-

System Overview

100-2414C 03/04 2-5

2.6 Instrument Specifications

The Model 680 and 680 XR Microplate Reader specifications are as

follows:2.6.1 Features

Operating Panel: Membrane pad with 4 arrow keys, 7 function keys

and 11 numeral keysDisplay: LCD, 4 Lines x 20 Alphabet Characters

Computer Interface: Bi-directional RS-232C serial communication

port, 9 pin D-sub receptacleExternal Printer Port (only when internal printer option is not

installed): Centronics interface with ASCIIcharacter code; 25 pin

D-sub receptacle; 80 characters output per lineReport Types: Raw, absorbance, matrix, limit, cutoff,

concentration, curve fit, difference, kineticApplicable Plates: Standard 96 well microtitre plate of

polystyrene — flat, U, V rigid bottomMixing: 3 speeds (low, medium, high); Programmable time period

0-999 secondsWarm-up Time: 3 minutes

2.6.2 Optical

Photometric Methods: Single and dual wavelength

Photo detectors: 8 silicon diodes for measurement and 1 silicon

photodiode for referenceLight Source: Tungsten halogen lamp, 20 Watts with 3000 hours

average lifetimeModel 680 Spectral Range: 400 nm to 750 nm

Model 680 XR Spectral Range: 340 nm to 800 nm

Interference Filters: Wavelength Tolerance +/- 3 nm; Band Width:

10 nm typicalFilter Capacity: 8 filters

Model 680 Standard Filters: 415, 450, 490, 655 nm

Model 680 XR Standard Filters: 340, 405, 415, 655 nm

Optional Filters: 340 through 800 nm (in 5 nm increments)

Fast Reading Speed: 6 seconds with single wavelength reading; 10

seconds with dual wavelengthreadingStandard Reading Speed: 15 seconds with single wavelength

reading; 30 seconds with dual wave-length readingIndication Range: 0.000 to 3.5 OD

2.6.3 Performance

Resolution: 0.001 OD

Accuracy: +/- 1.0% (or 0.010 from 0 to 3.0 OD at 490 nm)

Linearity: +/- 1.0% (from 0 to 2.0 OD); +/- 2.0% (from 2.0 to

3.0 OD)Reproducibility: 1.0% (or 0.005 from 0 to 2.0 OD); 1.5% (from

2.0 to 3.0 OD)Inter-Channel Variation: 1.5% (or 0.005 from 0 to 3.0 OD)

Stability and Drift: 0.010 OD at OD=1 with single wavelength

reading -

System Overview

2-6 100-2414C 03/04

2.6.4 Thermal

Incubator (Optional): Temperature Set Point: 25oC to 45oC (at

least 5oC above ambient)Set Point Accuracy: +/- 0.5oC (set point = 37oC and room

temperature = 25oC)Well-to-Well Uniformity: 0.5oC (set point = 37oC and room

temperature = 25oC)Warm-up Time: 5 minutes (set point = 37oC and room temperature =

25oC)2.6.5 Electrical

Line Voltage: Universal Input: 100-120 VAC, 200-240 VAC, 50/60

HzFuse: T3.15 Amp, 250 Volts, 20mm x 5mm

Power Consumption: 100 VA maximum

Battery: Lithium, CR2032, 3 Volts; average lifetime 5 years

2.6.6 Physical

Dimensions: 340 x 330 x 152 mm

Weight: 5.5 kg

Operating Environment: 5oC to 35oC, 0 to 95% RH, non

condensingStorage Environment: -20oC to 50oC, 0 to 95% RH, non

condensing -

Installation

100-2414C 03/04 3-1

Section 3Installation

3.1 Introduction

The Model 680 and 680 XR Microplate Readers are easy to install.

Prior to installation, verify that all systemcomponents have been

received.3.2 Visual Check

1. Check this instrument for any signs of damage which may have

occurred during shipping.2. Check the filters: Open the rear cover by pushing the release

latch on the top. Check that the filters are installed into the

proper positions per Table 1:Table 1 — Filter Installation

3. Check to insure filters are properly seated (Figure 1).

Figure 1: Filter Check

Filter Position Model 680 Model 680XR

1 415 nm 340 nm

2 450 nm 405 nm

3 490 nm 415 nm

4 655 nm 655 nm

5 User User

6 User User

7 User User

8 User User

-

Installation

3-2 100-2414C 03/04

3.3 Installation Procedure

1. Place the instrument on a clean, sturdy table or bench. It is

important to keep the instrument in a clean, relatively dust free

environment to ensure maximum performance.2. Connect the power cord to the connection on the back if the

instrument.3. Turn ON the power switch on the rear panel. The LCD will

display the version number of the on board firmware. After about

three seconds, the instrument will perform a self test diagnosis

that takes about fifteen seconds.4. When prompted by the Log In screen, enter the password

(password = 00000). Press Enter.5. Allow three minutes for the instrument to warm up prior to

reading plates.3.4 Install Paper Roll (Optional Internal Printer)

1. Open the rear cover by pushing the release latch on the

top.2. Tear off a small piece of paper to form a diagonal point on

the end of the paper roll.3. Place the paper roll in the holder positioned below the

printer and orient the roll so that it will feed from the bottom

(Figure 2).Figure 2: Orientation of Paper Roll

4. While pressing the Paper Feed key, direct the pointed end of

the paper into the paper feed slot in the underside of the printer

until the printer grabs the paper and feeds it through the slot in

the top of the instrument. -

Installation

100-2414C 03/04 3-3

3.5 Computer Interface (Optional)

1. Some customers may utilize the system with a computer and

microplate software such as Microplate Manager (or Checkmark).2. Set up computer as required and install software.

3. Install serial cable from computer to Model 680 oe 680

XR.4. Turn on instrument, enter password.

5. Verify communication with instrument using Microplate

Manager.Note: Microplate Manager version 5.2.1 is required for Model

680XR support. -

System Checkout

100-2414C 03/04 4-1

Section 4System Checkout

4.1 Introduction

This section provides the system checkout procedure for the

Model 680 and 680 XR Microplate Reader. Suc-cessful completion of

the tests in this section represent the Operational Qualification

of the instrument. A Sys-tem Checkout Report is available in

Appendix A and B.The system checkout procedures for the Model 680 and 680 XR

Microplate Readers require the use of aremote computer using

Microplate Manager software.The Model 680 and 680 XR Microplate Reader contains an on board

checkout procedure, Checkmark Valida-tion Program, which requires

the use of a special Checkmark test plate.4.2 Tools and Materials

Microplate Manager Software, 170-9520

RS-232 Cable, 931-0184

Printer

Digital Temperature Multi-meter with 0.1 mm diameter bead type K

thermoprobe (minimum +/- 0.5 C temperature meter accuracy)96 Well Microtitre Plate, Flat Bottom, 224-0096

Micro Pipette, 50L

Pipette Tips

50 ml beaker

Acid Yellow 99, Fisher AC19178-100

Distilled Water

Tween 20, 170-6531

Checkmark Reader Performance Check Plate, 170-6940

(Optional) -

System Checkout

4-2 100-2414C 03/04

4.3 Summary of Tests and Specifications

The following is a summary of the tests and specifications for

the Model 680 and 680 XR Microplate Readers.Table 1: Summary of Tests and Specifications

Test Parameter Specification

Firmware Firmware Version Record Version

Instrument Function Keypad and Display Proper Function

Internal Printer (optional feature) Proper Function

Startup and Self Diagnosis Proper Function

RS-232 Communication Proper Communication

Mixing Feature Proper Function

Incubator Set Point 37 C (optional feature) 37 C +/- 0.5 C

System Checkout Air Read < 0.005 OD

Accuracy CV < 5%

Channel-to-Channel CV < 5%

Stability and Drift < 0.010 OD

-

System Checkout

100-2414C 03/04 4-3

4.4 System Checkout Procedure

4.4.1 General

1. All system checkout procedures in this section will be

performed with Microplate Manager via PC computer.2. The Checkmark Validation Program, if available, may be used

for system checkout as an alternate method (paragraph 4.5).4.4.2 Setup

1. Setup computer.

2. Install Microplate Manager.

3. Install HPK protection key.

4. Connect RS-232 cable from computer to reader.

4.4.3 Preparing Yellow Dye Test Plate

1. System checkout requires the preparation of a yellow dye

pipetted into a microtitre plate. Pipetting must be of extreme

accuracy as the Model 680 reader is sensitive enough to detect

pipetting errors.2. Prepare the yellow dye as follows:

Mix: 2 mg Acid Yellow 9950 ml Distilled Water0.01 ml Tween

203. Pipette 200 microliters yellow dye into each well of the

microtitre plate (96 total).4. The value of the prepared test plate is 0.424 — 0.444 OD.

4.4.4 Startup

1. Turn ON the reader power switch. The LCD will display the

version number of the on board firmware. Record Firmware

Version.2. After about three seconds, the instrument will perform a self

test diagnosis that takes about ten sec-onds.3. When prompted by the Log In screen (Administrator), enter the

password 00000. Press Enter.4.4.5 Touch Pad/Mixing Function

1. Open chamber door (leave open for this test).

2. Press Memory Recall button.

3. Select Protocol and press Enter.

4. Select End Point and press Enter.

5. Select End Point 01 and press Enter twice.

6. Press the Start button.

7. Observe that plate carrier vibrates for 3 seconds prior to

read. -

System Checkout

4-4 100-2414C 03/04

4.4.6 Verify Printer (Optional Feature)

1. After completion of the above End Point 01 test, press the

Print button.2. Select Reports and press Enter.

3. Verify the printer is functioning properly.

4.4.7 Start Microplate Manager

1. Start Microplate Manager.

2. Select File…Select Reader. Select Model 680 or Model 680 XR

and click OK.3. Select New Endpoint Protocol. The Microplate Manager window

will appear (Figure 1).Figure 1: Microplate Manager — Endpoint Protocol

4. The instrument will be placed in remote mode. Remote Mode

will appear on display and touch keys will become

nonfunctional. -

System Checkout

100-2414C 03/04 4-5

4.4.8 Air Read

1. This test is performed without the use of a microtiter

plate.2. Press Show Template button.

3. Click the Turn Off Autofill Icon.

4. Click the Format as Unknowns Icon.

5. Using the curser, click and drag highlighting all rows (A1 to

G12).6. All wells on the template should be squares filled with 1s

(see Figure 2).Figure 2: Plate Template

7. Minimize the plate template.

8. Click on Reports.

9. Check the Raw Data Report. Click OK. (See Figure 3).

Figure 3: Raw Data Report Setup

-

System Checkout

4-6 100-2414C 03/04

10. Check the Reading Parameters Single box.

11. Select Measurement filter: 490.

12. Click the Run button.

13. Plate will take a few moments to read and display the Raw

Data Report.14. Ensure that all values are < 0.005. Reference Figure

4.Figure 4: Raw Data Report

-

System Checkout

100-2414C 03/04 4-7

4.4.9 Accuracy

1. This test is performed with the use of the yellow dye test

plate.2. Use the formatted plate template from the Air Read above.

3. Click on Reports.

4. Check the Raw Data Report and Unknown Concentrations. Click

OK. See Figure 5.Figure 5: Report Selection

5. Check the Reading Parameters Single box.

6. Select Measurement filter: 490.

7. For Mix Time (sec) enter 3.

8. Click the Run button.

9. Ensure the CV is < 5% on the Unknown Concentrations Report

(Figure 6) and target values are within expected ranges (Mean

OD).Figure 6: Unknown Concentrations Results

-

System Checkout

4-8 100-2414C 03/04

4.4.10 Channel-to-Channel Variation

1. This test is performed with the use of the yellow dye test

plate.2. Press Show Template button.

3. Click the Turn Off Autofill Icon.

4. Click the Format as Unknowns Icon.

5. Using the curser, click and drag highlighting rows A1 to A12.

The number 1 should appear in each box. Repeat highlighting rows B1

to B12. The number 2 should appear in each box. Repeat for the

remaining rows C1 to C12, D1 to D 12, etc. All wells on the

template should appear as shown in Fig-ure 7.Figure 7: Channel to Channel Setup

6. Minimize the plate template.

7. Use the same format for reports (Raw Data Report and Unknown

Concentrations), filter (490) and mix time (3).8. Click the Run button.

9. Plate will take a few moments to read and display the Raw

Data Report and Unknown Concentra-tions Report.10. Ensure the CVs are < 5% on the Unknown Concentrations

Report (Figureand target values are within expected ranges

(Mean OD). -

System Checkout

100-2414C 03/04 4-9

Figure 8: Unknown Concentrations Report

4.4.11 Stability and Drift

1. This test uses the same setup as specified in 4.4.11

Channel-to-Channel Variation above.2. Rerun the Channel-to-Channel variation test 3 times allowing

10 minutes between tests.3. Compare the data from the three tests. The average mean from

each row shall be within 0.010 OD of each other. -

System Checkout

4-10 100-2414C 03/04

4.4.12 Verify Incubator Temperature (Optional Feature)

1. Place checkmark in Incubator On box. Insure set point is 37

C.2. Place a standard 96 well microtitre plate filled with 200

microliters water in wells A1, A6, A12, D6, D9, H1, H6, and H12 in

the plate carrier. See Figure 9.Figure 9: Designated Temperature Test Points

3. Allow microtiter plate to warm for 30 minutes.

4. After 30 minutes, immerse the thermoprobe in the designated

well filled with the 200 microliters of water without touching any

portion of the inner well wall. The immersed probe must be in the

middle of the well and immersed in water. See Figure 10.Figure 10: Well Temperature Measurement

5. Verify that the actual well temperature is 37 C +/- 0.5 C for

each well (A1, A6, A12, D6, D9, H1, H6, and H12). -

System Checkout

100-2414C 03/04 4-11

4.5 Checkmark Validation Program (Optional Method)

4.5.1 General

Figure 11: Checkmark Check Plate

1. The Checkmark program is used with the Checkmark Reader

Performance Check Plate for validat-ing the performance of the

Model 680 Microplate Reader. It will test the following

parameters:Default Measurements

Accuracy

Precision

Linearity

Optional Measurements

Plate Positioning

Cross-talk

Filter Check

0 OD and Overflow

IR Spectral Blocking

2. The Checkmark program resides in the Model 680 Microplate

Reader programs.4.5.2 Procedure

Entering Checkmark Plate Reference Data

1. Turn on Model 680 Reader and enter password.

2. Press Memory Recall button.

3. Select Protocol and press Enter.

4. Select Checkmark and press Enter. Press any key if

instructed.5. Press the Edit button.

6. Select Protocol and press Enter.

-

System Checkout

4-12 100-2414C 03/04

7. Select Serial/Report and press Enter

8. Enter serial number of Checkmark plate. Select report type

Simple or Full. Press Enter.9. Select Linearity and press Enter.

10. Enter appropriate data from Checkmark reference plate data.

Press enter when complete.11. Select Max CV and press Enter.

12. Enter appropriate data from Checkmark reference plate data.

Press enter when complete.13. Select Filter Check Reference and press Enter.

14. Enter appropriate data from Checkmark reference plate data.

Press enter when complete.Running the Test

1. Open chamber door, insert Checkmark Reader Performance Check

Plate, and close door.2. Press Memory Recall button.

3. Select Protocol and press Enter.

4. Select Checkmark and press Enter. Press any key if

instructed.5. Press the Start button.

6. Test will take about 3 minutes to read plate.

-

Preventative Maintenance

100-2414C 03/04 5-1

Section 5Preventative Maintenance

5.1 Introduction

This section provides the preventative maintenance procedure for

the Model 680 and 680 XR MicroplateReader. Preventative maintenance

is recommended at least once a year.5.2 Tools and Materials

Small Hand Tools

Cleaning Materials (Lint Free Cloth, Lens Tissue, Isopropyl

Alcohol)5.3 Preventative Maintenance

5.3.1 Firmware

1. Connect the power cord to the connection on the back if the

instrument.2. Turn ON the power switch on the rear panel. The LCD will

display the version number of the firm-ware.3. Record firmware version.

4. Turn OFF instrument.

5. Update to latest firmware if applicable (see Section

7.6).5.3.2 Inspection of Instrument

1. Remove top cover.

2. Visually inspect for cleanliness of plate carrier. Clean

plate carrier and rails with lint free cloth and isopropyl

alcohol.Note: Do not use grease on the plate carrier or rails.

3. Visually inspect for cleanliness of lenses. Clean as required

with lens tissue and isopropyl alcohol (see Section 5.3.3).4. Reassemble instrument.

-

Preventative Maintenance

5-2 100-2414C 03/04

5.3.3 Optics Cleaning

1. Remove top cover.

2. To access top lenses, remove the two screws securing the

fiber optics to the cover (Figure 5-1).Figure 5-1: Remove Screws Securing Fiber Optics

3. Remove two hex standoffs securing top lens block.

4. To remove lenses, remove ten securing screws (Figure

5-2).Figure 5-2: Top Lens Block

5. Clean lenses with lint free cloth and isopropyl alcohol.

6. Reassemble lenses into holder and remount.

Note: Check for proper orientation when remounting.

-

Preventative Maintenance

100-2414C 03/04 5-3

7. To access bottom lenses, remove cover (Figure 5-3).

Figure 5-3: Bottom Lenses

8. Clean lenses as required. If removal of bottom lenses is

required for cleaning, remove plate carrier and analog board (see

Section 6.3.12).9. Remove bottom lens block (Figure 5-4).

Figure 5-4: Bottom Lens Block Screws

-

Preventative Maintenance

5-4 100-2414C 03/04

10. Remove lenses from holder to clean (Figure 5-5).

Figure 5-5: Bottom Lens Holder

11. Clean with lint free cloth and isopropyl alcohol.

12. Reassemble instrument. Note proper orientation of bottom

lens holder upon resaaembly.5.3.4 Perform System Checkout

1. Perform system checkout per Section 4.0 of this Service

Manual. -

Removal and Replacement

100-2414D 09/05 6-1

Section 6Removal and Replacement

6.1 Introduction

This section provides the parts removal and replacement

procedures for the Model 680 and 680 XR MicroplateReader.6.2 Tools and Materials

Standard Hand Tools

Voltmeter

6.3 Removal and Replacement Procedures

6.3.1 Interference Filters

1. Open the rear cover by pushing the release latch on the

top.2. Rotate the filter wheel until the desired filter is in top

position. Grasp top of filter frame to and pull up to remove

filter.3. To install filter, insert into desired slot until filter

locks into place.6.3.2 Model 680 Lamp (1681006)

1. Open the rear cover by pushing the release latch on the

top.Caution: Surface of Cover may be Hot!

2. Remove the two screws that hold the black plastic cover in

place (Figure 6-1) and remove cover.Figure 6-1: Screws Securing Cover

-

Removal and Replacement

6-2 100-2414D 09/05

3. Remove the screw which holds the metal cover in place (Figure

6-2) and remove cover.Figure 6-2: Screw Securing Metal Cover (Caution: Hot)

4. Carefully pull the lamp free and remove (Figure 6-3).

Figure 6-3: Lamp Removal

5. Install new lamp in reverse order of the above steps.

-

Removal and Replacement

100-2414D 09/05 6-3

6.3.3 Model 680 XR Lamp (1681104)

1. Open the rear cover by pushing the release latch on the

top.Note: Surface of Cover may be Hot! Allow to cool before

replacing lamp.2. Remove the two screws (arrows) that hold the black plastic

cover in place (Figure 6-4) and remove cover assembly.Figure 6-4: Screws Securing Cover

3. Remove the lamp (Figure 6-5).

Figure 6-5: Lamp Removal

4. Install new lamp.

Note: Do not tough new lamp with fingers. Oil on lamp may reduce

lamp life.5. Reassemble in reverse order of the above steps.

-