Dalian Forklift owner’s, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

| Title | File Size | Download Links |

| Dalian CPCD 30 / CPQD 30 / CPCD 35 Forklift Spare Parts Catalog [PDF] | 4.6Mb | Download |

| Dalian CPCD10 / CPCD15 / CPCD18 / CPQD18 Spare Parts Catalog [PDF] | 4.1Mb | Download |

| Dalian CPCD20 / CPCD25 / CPQD20 / CPQD25 Forklift Spare Parts Catalog [PDF] | 5Mb | Download |

| Dalian CPQD / CPCD 10-15-2025-30 Technical Specifications Sheet [PDF] | 467.7kb | Download |

| Dalian CRS450Z5 (Z-CCZ5, Z-DCZ5) Operation and Maintenance Manual [PDF] | 3.5Mb | Download |

Dalian Forklift, established in 1946, is one of China’s most prestigious forklift and loader producers today. Certificates of conformity to international standards attest to the fact that the company’s output is of the highest quality.

Different variants, including diesel and electric ones, are available, each with its design, performance, and utility-related quirks. The machinery is organized into 30 series, each corresponding to a specific combination of motor type and load.

The following salient characteristics distinguish this brand’s loader apparatus:

- The most recent controller technology is used in electric models and state-of-the-art automatic transmissions in diesel versions. This makes changing gears quickly and effortlessly possible.

- Devices that show the current status of unique machinery.

- A mast that was meticulously planned and constructed to provide the pilot with a complete spherical perspective.

- The unloading height may be adjusted by swapping out the mast at the customer’s request, and there is also the option of installing a protective screen for the operator.

- Relax in the warm and customizable interior with a heater and safety belt. The operator’s cabin for high-output variants is permanently sealed for safety reasons.

- A large variety of mounting accessories make the method practically ubiquitous. For example, a Dalian forklift may now be purchased with a crane boom, a bucket, rotating forks, etc.

Dalian Forklifts Capacity Classification

The production’s gear may be broken down into the following groups according to their load capacities:

- Machines that can handle weights between one and three tons are considered minor.

- To move loads between 4 and 10 tons, go for a medium-sized model.

- The third category consists of heavy loaders carrying weights of 10-16 tons.

Electric models are often in the small to medium range and hence is not suited to handling substantial loads.

So, look closely at one of the most well-known models in each category.

Mini light loader CPCD15 CB/FB

The versatile equipment is in great demand since it is simple to use and is powered by a diesel engine. Its low emissions and fuel efficiency make it useful in outdoor settings and huge interior storage facilities. The CPCD15 CB/FB stands out for its versatility, ease with which it can be used and maintained, and ability to carry out its duties regardless of the weather.

Features of the Model:

- Up to 1.5 tons of cargo may be carried.

- Height of lift: 2.7-6 m.

- Power comes from a 2600 kW diesel XINCHANG NC485BPG-1 engine.

- The gearbox is fully automatic.

- One might expect to go at a rate of 14.5/19 kilometers per hour (with and without load, respectively).

- There’s a 20-degree load-bearing limit on the maximum ascent angle.

- There may be up to 52 liters of gas in the tank.

Electric Medium-Duty Truck CPD25 CA

A crucial medium-duty version that may greatly ease product loading and unloading in any storage facility. It has a lot of uses since it combines great mobility with stability in the best possible way. Moreover, because of its strong electric motor and inability to emit toxic gases, this machine may be safely employed in confined areas.

Features of the Model:

- The maximum allowable weight is 2.5 tons.

- The furthest height that may be raised is 3 meters.

- The whole mass is 4.1 metric tons.

- The average rate of load ascent is 31 centimeters per second.

- It can go at 13 kilometers per hour when empty.

- Easily understandable settings and buttons.

- This vehicle has an ergonomically designed interior that is both comfortable and relaxing.

- Specifically, the length of the fork is 1 meter.

- 1.45 meters is the wheelbase length.

Powerful loader CPCD90 A/F

Large businesses and warehouses that handle a lot of goods will find the machine to be an invaluable helpmate. It can keep working for a whole shift without showing any signs of overheating and is distinguished by outstanding performance and long service life. In addition, the method requires nothing in the way of upkeep and is straightforward.

Features of the Model:

- The utmost weight it can carry is 9 tons.

- There should be a maximum lifting height of between three and six meters.

- There is a 39/41 cm/sec lifting speed (with and without cargo, respectively).

- When fully laden, the furthest degree of lifting is 25%.

- As for the fuel tank, it can hold up to 140 liters.

- 92 kW, diesel-powered YUCHAJ YC6B125 engine mated to a fully automated gearbox.

- 11.9 tons is the total weight.

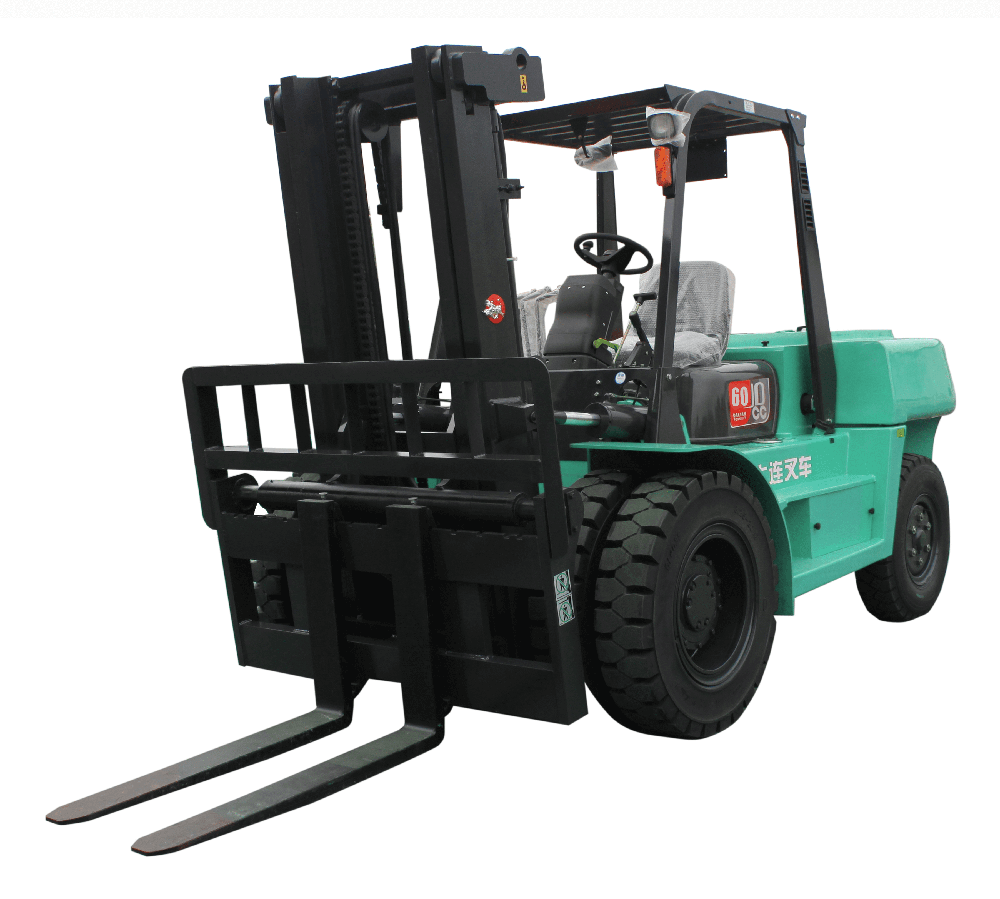

Dalian CPCD60AD

Dalian CPCD CPQD 30 35 Forklift Truck Parts Catalog & Wiring Diagrams PDF

Dalian CPCD CPQD 30 35 Forklift Truck Parts Catalog & Wiring Diagrams PDF

Dalian CPCD CPQD 30 35 Forklift Truck Pa

Adobe Acrobat Document

2.0 MB

Dalian CPCD CPQD 20 25 Forklift Truck Parts Catalog & Wiring Diagrams PDF

Dalian CPCD CPQD 20 25 Forklift Truck Parts Catalog & Wiring Diagrams PDF

Dalian CPCD CPQD Forklift Truck Parts Ca

Adobe Acrobat Document

3.2 MB

Some DALIAN Forklift Truck Service Parts Manual PDF & Wiring Diagrams above the page.

TCM and Dalian are very similar, both are the oldest manufacturers.

Dalian as a company has existed since 1946, and has been producing loaders since 1958. The first Chinese forklift was released just by Dalian in 1958.

Chinese companies do not reinvent the wheel; they either borrow leading technologies or, roughly speaking, steal. As for Dalian, they use Mitsubishi technology in their forklifts with ICE. And in electric forklifts they use Nissan technology.

Dalian is a lawmaker in the China handling equipment industry. And therefore its development went from small to large. Today Dalian has the largest range of

manufactured equipment, from 1 to 45 tons.

In addition to forklifts, the company also produces diesel and electric tractors.

At the same time, Dalian produces the entire line equally well: electric forklift from 1 to 3 tons; electric tractors from 2 to 10 tons; diesel engines from 2.5 to 8 tons;

fork gas gasoline forklifts from 1 to 3 tons; diesel loaders from 1 to 45 tons.

Dalian occupies in its domestic market the lion’s share of the production of heavy loaders up to 45 tons, including reach stackers.

As mentioned earlier, Dalian uses Mitsubishi technology, and officially,

unlike the competitors who steal these technologies.

Therefore, in terms of legality, Dalian has such formal agreements, so many Dalian forklifts are very similar to the old Mitsubishi forklifts. As for Nissan, a license for a full range of products was purchased.

The Dalian factory is old with great traditions, but according to the program of modernization of the production capacities of China in

2003, the Dalian factory completely moved from its old premises to the new factory with completely new equipment.

That is, no old machine was transported to a new place. The recognition of the high technology of this production was that after the opening of the plant, almost 10 years Mitsubishi forklifts were manufactured for the domestic market.

As part of the interaction, Mitsubishi rented space from Dalian, there was a

separate conveyor line where Mitsubishi forklift were manufactured.

Therefore, Dalian experts spied on the process of organizing production, to implement and in their own.

Dalian Forklifts operator’s, workshop, service and repair manuals, spare parts catalogs, error codes in PDF download

|

Title |

File Size |

Download Links |

|

Dalian CPCD 30 / CPQD 30 / CPCD 35 Forklift Spare Parts Catalog |

5Mb |

Download |

|

Dalian CPCD10 / CPCD15 / CPCD18 / CPQD18 Spare Parts Catalog |

4.4Mb |

Download |

|

Dalian CPCD20 / CPCD25 / CPQD20 / CPQD25 Forklift Spare Parts Catalog |

5.3Mb |

Download |

|

Dalian CPQD / CPCD 10-15-2025-30 Technical Specifications Sheet |

490.6kb |

Download |

|

Dalian CRS450Z5 (Z-CCZ5, Z-DCZ5) Operation and Maintenance Manual |

3.5Mb |

Download |

Dalian is a manufacturer of fork loaders, together with Hangzhou and Heli, which is included in the top three most famous and demanded manufacturers of Chinese lifting equipment.

Dalian, founded in 1946, until recently was a state -owned enterprise and was called Dalian General Truck Works. It was this company that laid the foundation for the production of twist Chinese

loaders, for the first time releasing the equipment of this type in 1958.

To date, the Dalian company is the only specialized research and production center in China, making a full model range of reach stakers, as well as loaders of container and fork -type type. The

assortment of the company presents about 30 episodes and 130 models with a carrying capacity of 1 to 45 tons. The annual volume of equipment produced by the company exceeds 8 thousand units per

year.

Dalian Forklift Co., Ltd develops rapidly and successfully introduces modern technologies into production. All Dalian technique meets international requirements and has the

necessary quality certificates. That is why the company’s products have repeatedly been awarded the prestigious national awards “The Best Consumer Product” and “The famous brand”, and the company

itself was one of the 500 strongest enterprises in China Engineering and the AAA ClassofCredible Enterprise rating.

Dalian Forklift Co., Ltd. Actively cooperates with well-known Japanese manufacturers of lifting and transport equipment. In 1984, the company began to use Mitsubishi technology in the production of diesel loaders with a carrying capacity of 10 to 42 tons, and in 1998 the achievements of the world

famous company Nissan.

1

F-Series

CPCD20/25/30/35F

CPQ(Y)D20/25/30/35F

Internal Combustion Counterbalanced Forklift Truck

2-3.5T

OPERATION & SERVICE MANUAL

KION Baoli (Jiangsu) Forklift Co., Ltd.

PREFACE

F-series balance weight type forklift trucks with engine are designed on the base of the advanced features available from both local and foreign designs. These trucks are suitable to handle, transport and stack goods in factories, mines, stations, ports, freight yards, warehouses and used widely in food processing, textiles and other light industries.

The use of forklift trucks fitted with kinds of attachments will become extensive.

F-series forklift trucks feature a wide-vision mast system, full hydraulic steering unit, self-boost brake, stepless speed control, parking brake device with foot pedal, integral overhead guard and high quality large screen combination meter, so they have a lot of advantages such as good performance, easy operation, wide vision, flexible steering, reliable braking, powerful and aesthetic appearance.

This manual states the specifications, operation, maintenance, main assemblies’ constructions and working principles of F-series forklift trucks so as to help operators to use the trucks correctly and attain the highest functions. It is necessary to read over the manual before operating or maintaining the forklift trucks. The rules and notices in this manual should be abided seriously by all relative persons to enable these trucks in optimized working state for long period and bring the highest efficiency.

The relevant content in this manual might not correspond with the actual condition because of technical improvement. Our products are subject to improvements and changes without notice.

CONTENTS

Ⅰ. About F-series forklift truck…………………………………………………………… 1

1. External view and technical parameter………………………………………………… 1

2. Characteristic……………………………………………………………………………… 3

3. Main system

……………………………………………………………………………… 3

4. Main components………………………………………………………………………… 4

5. Operation device and instrument panel………………………………………………… 5

Ⅱ. Safety instruction and operation of forklift truck………………………………… 10

1. Handling a new forklift truck……………………………………………………………… 10

2. Inspection before operation……………………………………………………………… 10

3. Start and stop of the engine……………………………………………………………… 11

4. Parking and storing……………………………………………………………………… 12

5. Shipping, loading and unloading, slinging and towing of forklift truck……………… 13

6. Information of safety operation…………………………………………………………… 15

7. Caution plate……………………………………………………………………………… 19

Ⅲ. Periodic inspection and servicing…………………………………………………… 24

1. General rules on inspection and maintenance………………………………………… 24

2. Inspection content………………………………………………………………………… 25

3. Periodic replacement table……………………………………………………………… 30

4. Lubrication c hart…………………………………………………………………………… 31

5. Weekly maintenance……………………………………………………………………… 32

6. Self service………………………………………………………………………………… 34

7. Recommended oil and grease for forklift truck………………………………………… 36

Ⅳ. Construction, principle, adjustment and maintenance of forklift truc……………… 38

1. Power system

…………………………………………………………………………… 38

1.1 General description

4

1.2 Engine parameter and appropriate truck model

……………………………………… 38

1.3 Inspection and adjustment of engine

0

1.4

Precautions of cooling system…………………………………………………………

2. Hydraulic drive unit

…

39

2.1 General description

……………………………………………………………………… 40

2.2 Reducer and differential………………………………………………………………… 42

2.3 Torque converter

………………………………………………………………………… 43

2.4 Hydraulic circuit

0

2.5 Towing disabled truck

…………………………………………………………………… 44

2.6 Troubleshoot

……………………………………………………………………………… 45

3. Drive system

……………………………………………………………………………… 47

3.1 General description

……………………………………………………………………… 47

3.2 Assembly of wheel hub

………………………………………………………………… 47

3.3 Troubleshoot

……………………………………………………………………………… 50

4. Brake system

…………………………………………………………………………… 51

4.1 General description

……………………………………………………………………… 51

4.2 Master cylinder

…………………………………………………………………………… 51

4.3 Wheel brake

……………………………………………………………………………… 52

4.4 Operating device of parking brake

……………………………………………………… 54

4.5 Inspection of wheel brake

……………………………………………………………… 55

4.6 Troubleshoot

……………………………………………………………………………… 56

5. Steering system

………………………………………………………………………… 57

5.1 Hand wheel

……………………………………………………………………………… 58

5.2 Cycloid gear type powered steering unit

……………………………………………… 58

5.3 Inspection after reassembling the steering system

…………………………………… 59

5.4 Troubleshooting of steering system

…………………………………………………… 59

5.5 Steering axle

……………………………………………………………………………… 60

6. Hydraulic system

………………………………………………………………………… 63

6.1 General description

……………………………………………………………………… 63

6.2 Hydraulic oil pump

……………………………………………………………………… 63

6.3

Control valve & flow divider…………………………………………………………… 63

6.4 Hydraulic oil circuit

……………………………………………………………………… 67

6.5 Lift cylinder

……………………………………………………………………………… 68

6.6 Flow regulator valve

……………………………………………………………………… 69

6.7 Tilt cylinder

……………………………………………………………………………… 70

6.8 Troubleshoot

……………………………………………………………………………… 71

7. Lifting system

…………………………………………………………………………… 73

7.1 General description

……………………………………………………………………… 73

7.2 Maintenance and adjustment

…………………………………………………………… 75

8. Electric system

…………………………………………………………………………… 78

8.1 General description……………………………………………………………………… 78

8.2 Brief explanation for operation………………………………………………………… 79

8.3 Instructions of meter panel

……………………………………………………………… 80

8.4 Principle diagram of electrical system

………………………………………………… 85

8.5 Diagram of harness

……………………………………………………………………… 85

Note

…………………………………………………………………………………………… 93

EC DECLARATION OD CONFORMITY

………………………………………………… 94

Ⅰ. About F-series forklift truck

1. External view and technical parameter

Fig1.1 External view

1

Technical parameter

Manufacturer

Model

Power type

Rated capacity

Load center

Overall dimension

Length to fork face

Overall width

Mast lowered height

Mast extended height

Overhead guard height

Lift height

Free lift height

Fork size

Mast tilt angle

Front overhang

Turning radius

Self weight

Tyre

Front

Rear

Tread

Front

Rear

Wheelbase

Ground clearance

(full load/no load)

Mast

Frame

KION Baoli kg mm

L1 mm

CPCD20F

CPQ(Y)D20F

CPCD25F

CPQ(Y)D25F

CPCD30F

CPQ(Y)D30F

CPCD35F

CPQ(Y)D35F

2000

Diesel/Gasoline/LPG

2500 3000

500

3500

2564 2634 2775 2814

1236 B1 mm

H1 mm

H3 mm

H2 mm

1150

2050

4040

2150

2080

4273

2180

2230

H mm 3000

H4 mm 140 145

L×W×T mm 1070×120×40 1070×120×45 1070×125×45 1075×130×45

α/β deg

6 / 11

X mm

R mm kg

484

2220

3510

489

2290

3810

7.00-12-12PR

494

2400

500

2490

4320 4620

28×9-15-12PR 28×9-15-14PR

B2 mm

B3 mm

Y mm

M

F mm

6.00-9-10PR

970

1650

85 / 105

140 / 145

970

6.50-10-10PR

1000

1700 1760

110 / 135

170 / 175

F-series forklift trucks mentioned in this manual correspond in different engines, please refer to the following table.

Model of forklift truck Model of engine

CPCD20F

CPCD25F

XINCHANG BPG490,ISUZU C240,YANMAR 4TNE92

XINCHANG BPG490,DACHAI CA498,ISUZU C240,ISUZU 4JG2PE,YANMAR

4TNE92

Diesel

CPCD30F

XINCHANG BPG490,XINCHANG BPG495,XINCHANG BPG498,DACHAI

CA498,ISUZU C240,ISUZU 4JG2PE,YANMAR 4TNE98

CPCD35F

XINCHANG BPG495,XINCHANG BPG498,DACHAI CA498,ISUZU 4JG2PE,

YANMAR 4TNE98

Gasoline

CPQ(Y)D20/25F MITSUBISHI 4G64-31ZG,NISSAN K21,NISSAN K25

CPQ(Y)D30/35F MITSUBISHI 4G64-31ZG,NISSAN K25

Notice: Please refer to AD sheet of F-series forklift truck about other technical parameters or new engine configuration not mentioned in this manual.

2

2. Characteristic

(1) The hydraulic steering device and transverse steering axle makes steering flexible and the turning radius minor.

(2) The braking system employs hydraulic brake, makes it possible to manipulate conveniently and brake reliably.

(3) Hydraulic transmission type forklift trucks are provided with a drive unit including a hydraulic torque converter and an electron transmission box. They feature the following:

·Hydraulic torque converter can change the speed automatically with no limitation and output torque makes the forklift truck have good performance of drawing.

·The inching device makes it easy for the drivers to aim the fork to the cargo.

·The use of hydraulic transmission ensures the engine operate smoothly for the sudden increase of load. At work, the forklift truck that needs starting and shifting frequently, electron transmission device can achieve smooth shift and raise working efficiency, simplify operation, reduce the driver’s labor intensity and reduce requirement of the driver’s operation skill.

(4) The mast is high intensity and wide vision for the use of two stage CC extension type mast and hidden-type tilt cylinder device. The forklift truck can be fitted with 2-stage or 3-stage full free lift mast having different lifting height, even all kinds of the attachments according to the needs of the clients.

(5) The forklift truck can be chosen different height mast and driver’s cab according to the operating into container or out container.

(6) Specific outline adopts streamline design, wider operating vision and larger driving space. It has advantages such as low noise, vibration damping, dustproof, comfortable operation, safety and reliability.

3. Main system

No. Name

1 Power system

2

Transmission system

3 Drive axle

4 Brake system

5 Steering system

6 Hydraulic system

7 Electric system

8 Lifting system

Contents engine mounting, fuel, exhaust and cooling system(inc. torque converter oil cooler) etc. torque converter, gear box, transmission shaft, gearshift etc. axle housing, half shaft, brake, front wheel etc. wheel brake and parking brake etc. steering wheel, cycloid gear type powered steering unit etc. pump, valve, HP oil pipe, LP oil pipe, connectors etc. lamps and lanterns, battery, meter, harness etc. mast, fork, lift bracket, load backrest, tilt cylinder, lift cylinder, lift chain, mast roller etc.

3

4. Main components

Fig1.2

1. Outer mast

4. Lift cylinder

2. Inner mast

5. Load backrest

3. Lift chain

6. Fork location pin

7. Lift bracket 8. Fork 9. Driving wheel

10. Tilt cylinder 11. Turning wheel 12. Engine hood

13. Refueling lid 14.

Operator’s seat

15. Counter weight

16. Flasher (option) 17. Rear combination lamp 18. Overhead guard

19. Head lamp 20. Front combination lamp 21. Steering wheel

Size & slinging parameter of the main parts that can be disassembled

Counter weight

Max. outline size (mm)

1130

×739×955

Min. slinging capacity

(Kg)

1700

Standard mast

1935×854×600

730

Lift bracket

(with load backrest)

1200×1197×260

170

Fork

1150×660×125

80

Notice: The above-mentioned size and capacity is only for a reference, which may be adjusted because of configuration difference or technology optimization.

4

5. Operation device and instrument panel

Fig1.3

1. Direction control lever 2. Steering wheel 3. Horn button

4. Integrated light and turn signal switch

6. Tilting lever

9. Tool kit

12. Ignition switch

5. Lifting lever

7. Operating lever, attachment 8. Combination meter

10. Accelerator pedal 11. Brake pedal

13. Release lever, parking brake 14. Inching pedal

15. Adjust lever, steering wheel 16. Parking brake pedal

18. Cover, refuel and check brake fluid

17. Adjust lever, parking brake

5

5.1 Switch (Fig.1.3)

No.

1

2

Name

Ignition switch

Integrated light and turn signal switch

(1) Left turn

(2) Right turn

Operation and attention

O (OFF): Engine stop position. Key insertion and withdraw are performed in this position.

I (ON): Engine operation position. Locate one position clockwise from O (OFF) position.

The intake heater is preheated before starting the diesel forklift.

START: Engine start position. Locate one position clockwise from the I (ON) position.

After engine start, release the key and it will return to the

I(ON) position automatically.

Caution:

.Never operate the ignition switch before sitting on the seat.

.For the sake of safety it is recommended to always start the engine with the transmission gear shift lever shifted in the neutral position.

.Do not turn the switch to the START position while the engine is running.

.Do not leave the switch in the ON position when the engine is stopped. It may cause over discharge of the battery.

.Do not operate the starter motor for more than 15 seconds continuously. Return the switch to the OFF position and wait at least 30 seconds prior to attempting restart.

This switch serves as both two-position light control and turn signal switch.

Light control switch

Lamp name Step1 Step2

Head lamps

— ○

Side clearance lamps

○ ○

Caution:

Do not keep lamps such as head lamps kept on for a long time when the engine is stopped. It may cause over discharge of the battery to make engine starting impossible.

Turn signal switch

Make the turn signal lamps blink.

Left turn…………………..Push forward

Right turn…………………Pull backward

Caution:

The signal switch will operate when the ignition switch is

ON.

6

5.2 Control components (Fig.1.3)

No.

1

Name

Direction control lever

(Fig. 1.3-1)

(1) Forward (2) Reverse

2 Horn button

(Fig. 1.3-3)

(1) Press

Operation and attention

Lever for shifting between forward and reverse.

Forward……………………Push forward

Reverse……………………Pull backward

The neutral position is halfway between the forward and reverse position.

Caution:

The engine can’t be started unless the control lever is at the neutral position.

Stop the vehicle before shifting between forward and reverse.

Press the button in the center of the steering wheel to sound this horn.

The horn will sound even when the ignition switch off.

3

4

Lifting lever

(Fig. 1.3-5)

(1) Lower (2) Raise

Tilting lever

(Fig. 1.3-6)

(1) Forward tilting

(2) Backward tilting

Raise and lower the forks.

Raise…………………….Pull backward

Lower……………………Push forward

The lifting speed can be adjusted by the degree of accelerator pedal depression and lever operating stroke.

The lowering speed can be adjusted only by the degree of lever operating stroke.

Caution:

Always operate the lifting lever while correctly seated.

Tilt the mast forward and backward.

Forward……………………..Push forward

Backward……………………Pull backward

The forward or backward tilting speed can be adjusted by the degree of accelerator pedal depression and lever operating stroke.

Caution:

Always operate the tilting lever from a seated position.

7

5 Steering wheel adjustment lever

(Fig. 1.3-15)

1. The steering wheel position may be adjusted back and forth.

2. Lowering the directional lever at the proper position fixes the steering wheel at that position.

3. After the adjustment, try to move the steering wheel back and forth to see that it is fixed.

Caution:

The steering wheel position must be adjusted before starting the vehicle. Adjustment during traveling must be avoided.

(1) Raised

6 Accelerator pedal (Fig. 1.3-10)

Brake pedal (Fig. 1.3-11)

Inching pedal (Fig. 1.3-14)

From the right: accelerator pedal, brake pedal and inching pedal.

Note:

When control lever is shifted to forward-reverse, the vehicle will move even the accelerator pedal stays neutral.

7 Parking brake pedal

(Fig. 1.3-16)

Parking brake release lever

(Fig. 1.3-13)

(1) Press down

(2) Release lever

Use the parking brake pedal when parking or stopping.

1. When engaging the parking brake, while stepping on the brake pedal, fully press down on the parking brake pedal.

2. To disengage the parking brake pedal, while stepping on the brake pedal, pull the release lever toward you.

Warning:

.Before operating the parking brake pedal, step on the brake pedal and always confirm that the vehicle has come to a stop.

.When parking on a slope, apply wheel chocks to the wheels.

.Traveling without releasing the brake will spoil the brake performance.

8

5.3 Body components (Fig. 1.2)

No.

1

Name

Operator’s seat (Fig. 1.2-14)

Operation and attention

The operator’s seat and seat belt are provided for your safety.

The seat can be moved back and forth for position adjustment while the adjust lever is pulled right.

2 Engine hood (Fig. 1.2-12)

(1) Engine hood lock release lever

(1) Push

3 Fork (Fig. 1.2-8)

4

(1) Fork stopper

Draw bar

Opening:

1. Pulling up on the engine hood lock release lever will release the engine hood lock, and the engine hood will pop up slightly.

2. Lift the engine hood.

3. Open the engine hood all the way, then shake the hood slightly to check that the hood damper has been securely fastened before letting go.

Closing:

1. Lifting up the engine hood and press the hood damper lock to release the lock.

2. Close the engine hood quietly, and press down on the hood until you hear a clicking sound.

Caution:

Operating the vehicle without firm locking of the engine hood is very dangerous. Be sure to check firm locking before operating the vehicle.

Lift each fork stopper and turn to release so that forks can be moved left and right. Adjust the forks in the position most appropriate for the load.

When adjusting the forks, make sure that the center of gravity of the load corresponds to the center of the vehicle.

After adjustment, turn the stoppers to lock the forks in place.

Warning:

Make the forks are locked before carrying load.

The draw bar is located at the back of the counterweight, and is used to pull the vehicle when its tyres drop into a gutter. It can also be used for loading the forklift onto a truck or another vehicle.

Caution:

The draw bar should not be used for towing the forklift truck or for towing another vehicle using the forklift truck.

9

Ⅱ. Safety instruction and operation of forklift truck

It is important for drivers and managers to remember the principle of

“first safety” and ensure the safety operation as the description of Operation & Service Manual. Please read this manual thoroughly. This will give you a complete understanding of Baoli forklift truck and you will operate them correctly and safely.

1. Handling a new forklift truck

The performance and service life of the forklift truck depends heavily upon the way you handle it during the break-in period. Drive with special caution while becoming familiar with a new forklift truck.

(1) Always warm up your vehicle before putting it to work irrespective of season.

Don’t run engine at high rpm without load needlessly. Operate the vehicle under the light load, avoid suddenly speeding and braking.

(2) Replace gear oil in the differential and reducer after the new forklift truck working for 100 hours.

(3) Renew the oil in engine oil pan, transmission, driving axle and hydraulic oil tank; check and readjust the clearance of the driving and driven gear in the reducer after the new forklift truck working for 200 hours.

2. Inspection before operation

Please pay attention to the following items in order to make the vehicle working with high efficiency and lengthen its service life.

(1) The forklift truck adopts the home or imported engine, please read the manual accompanied with the engine carefully when using and maintenance.

(2) Check the tyre inflation pressure, if doesn’t enough, charge air in time. Check the bolts of all wheels for tightness.

(3) Check the amount of oil in the working oil tank for sufficiency, the position of lubrication should be lubricated. The oil level should be at the middle position between the upper and lower scale marks of oil level meter. The contamination level of the hydraulic oil should be lower than grade 12.

(4) Check the radiator, and add antifreeze if necessary.

(5) Check hydraulic oil and brake fluid for leakage. Check if any leak or damage found on the oil pipes, water hoses, vent-pipes and the piping joints, pumps and valves etc.

(6) Check for all the terminals and plugs in normal state. Check the meters, lamps, switches and electric circuit if they are running properly.

(7) Check every pedal for free stroke and the levers for looseness and smooth

10

operation. Check lifting system, actuate the lifting and tilting levers to be certain that the lift bracket moves up and down properly and the mast can be tilted smoothly. Check brake system and steering system for flexibility and reliability.

(8) Check the traveling brake: the free stroke of brake pedal is 4-8 mm, when achieving effective brake, the clearance between the front floor and the pedal should be more than 20mm.

(9) Check the parking brake: the unload truck can park on 20% slope, when the parking brake is locked.

(10) Check all connectors and fasteners for looseness.

3. Start and stop of the engine

(1) Start of the engine

(a) First set the shift lever at the neutral position and the parking brake at the braking position.

(b) When starting, put the key into the start switch, turn it in the counter clockwise, preheat 10-15 seconds, and th en turn it in the clockwise to “START” so the starting motor works. When hand is away from the key, it automatically returns to

“ON” by spring force.

Every starting time shouldn’t be morn than 15 seconds. Restarting should be after 30 seconds

. As the engine doesn’t work after some times starting, should check and remove the trouble, do not keep the starting motor engaged for a long time.

(c) Follo wing the start of the engine, it’s necessary to set the engine on idle running for five minutes. Full load operation can’t be started until water temperature of the engine rises above 60

℃.

When the engine is on idle running, you must check water thermometer, oil manometer, ammeter, fuel measurer, and so on for the data, whether to meet the specification, and check each pedal for free stoke, braking performance for its reliability, steering operation for its flexibility, tyre pressure for its conformance to the standard. If there is no trouble, operation may be allowed.

(2) Stop the engine

First set the engine on idle running for five minutes, so as to cool the engine gradually, and then turn off the ignition switch, so the engine is stopped to work.

Notice:

.

While the engine running, does not turn the start switch to “START” position, since there is a danger of damage to the starting motor.

.Do no t keep the start switch at the “ON” position while the engine is shut down. This will result in battery discharge.

11

4. Parking and storing

(1) Safe parking

(a) Park your forklift truck on a level ground preferably in a wide area. If parking on a slope is unavoidable, press down the parking brake device and block the wheels to prevent accidental roll. The truck is forbidden parking on a steep slope.

(b) Park your forklift truck in the area where designated or traffic conditions permit. If necessary, put a signpost or signal lights around the truck.

(c) Park your forklift truck on the solid ground. Avoid soft ground, deep mud or slippery surfaces.

(d) If you can not lower the forks on the ground due to break-down of the lifting system, put a warning flag to the fork end and park in the traffic conditions permitting.

(2) Storing

.Before storing

Before storing your forklift truck, clean it thoroughly and perform inspection using the following procedures.

(a) Wipe away grease, oil, etc. adhering to the body of the truck with waste cloth and water, if needed.

(b) While washing the body of the truck, check general condition of the truck.

Especially check the truck

’s body for recess or damage and tyres for wear and nails or stones in the tread.

(c) Fill the oil tank up with the appointed fuel.

(d) Check for leakage of hydraulic oil, engine oil, fuel or coolant.

(e) Apply grease where needed.

(f) Check for looseness of hub nuts and cylinder piston rod joints. Check the surface of piston rod for damage.

(g) Check mast rollers to see that they rotate smoothly.

(h) Full oil into the lift cylinders by lifting the lift cylinders at the full stroke.

(i) In cold weather, don’t draw off long antifreeze, if there is cooling water, run it away.

.Daily storage

(a) Park the forklift truck at a specified place and block the wheels.

(b) Place the shift lever in the neutral position and press the parking brake pedal.

(c) Put the key switch in

“OFF” position and turn off the engine, operate the lever of the control valve several times and release the residual pressure of the cylinder or pipes.

(d) Remove the key and keep it in a secure place.

.Long time storage

12

Perform the following service and checks in addition to the

“Daily storage” service:

(a) Taking the rainy season into consideration, park the truck at a higher and hard ground.

(b) Avoid parking on soft grounds such as asphalted road in summer.

(c) Apply antirust oil to the exposed parts such as piston rods and shafts which tends to rust.

(d) Cover components which may be caught with humidity.

(e) The truck should be operated at least once a week. Fill the cooling system, if cooling water is discharged. Remove grease from the piston rods and shafts. Start the engine and warm up thoroughly. Move the truck slowly forwards and backwards. Operate the hydraulic controls several times.

.Operate the forklift truck after long time storage

(a) Remove antirust oil from the exposed parts.

(b) Discharge the engine oil in crankshaft case of the engine, discharge the gear oil or hydraulic transmission oil in differential and gear box, after cleaning up then renew oil.

(c) Discharge foreign matter and water from the hydraulic reservoir and fuel tank.

(d) Remove the cylinder cap, check the valves and the rocker shafts for the clearance in normal data.

(e) Add cooling fluid to specified level.

(f) Perform pre-operation checks carefully.

(g) Warm up the engine before operation.

Warning:

If at any time your forklift truck is found to be in need of repair, defective, or in any way unsafe, the condition should be reported to the supervisor, and the truck should be taken out of service until it has been restored to safe operating condition.

5. Shipping, loading and unloading, slinging and towing of forklift truck

(1) Ship the forklift truck

(a) Apply the parking brake when shipping the forklift trucks by container or freight car.

(b) Fix the mast and the balance weight with steel wire and use jacks to prevent the forklift trucks from moving in the cabin.

(c) Pay attention to the overall length, width, height when loading, unloading and shipping and conforming the regulations is necessary.

(d) Single transporting if necessary after disassembling the mast and balance weight.

(2) Load and unload the forklift truck

13

(a) Use the plate with enough length, width and strength.

(b) Pull the parking brake and use jacks to stop the wheel.

(c) Fasten the plate on the center of the cabin, there must be no grease on the plate.

(d) The left and right height of the plate must be equal to make the loading and unloading smooth.

(e) Don’t change the direction on the plate to prevent the danger.

(f) Reverse the truck slowly when loading the forklift truck on the freight car.

(3) Sling the forklift truck

(a) Only the specially trained personnel can sling the truck.

(b) Sling points should be always at the positions specified in sling nameplate.

(c) The slinging cable must be enough to hang the forklift truck.

(d) Disassembled parts of forklift truck must be slung in the appointed position.

Notice:

Dismantling and slinging the component shall not be performed without the approval of our company. Under special circumstances, the appointed sling position should be used. The balance weight, fork and mast of the truck all have their

appointed sling position.

(4) Towing of forklift truck

(a) The draw bar is installed below the counter weight. When operating the draw bar, first extract it and fasten a steel wire, then install the draw bar.

(b) When towing the forklift truck, release the parking device.

(c) The draw bar only used for following situation, while the truck can’t move or while transporting the truck.

(d) Fasten the towing steel wire at the appointed position.

(e

) Don’t apply capacity abruptly when towing the truck.

(5) Repair the broken-down truck

If the truck broken-down suddenly during using, drag it away and repair in time to avoid hindering other vehicles or workers.

6. Information of safety operation

(1) The forklift truck belongs to special equipment. Only trained and authorized operator shall be permitted to operate and service the truck.

(2) Wear the safety guards, such as clothing, shoes, helmet and gloves while operating the truck.

(3) When operating the truck, observe and follow all nameplates stuck on the truck.

The nameplates must be replaced if lost or damaged.

14

(4) Daily maintenance should be done before or after using the truck. Anytime you find that the truck is not functioning normally, operation of the truck should be halted and check or repair at once.

(5) When the distance between the gravity center of loads and the fork arms is

500mm, the max. capacity is the rated capacity. When the distance exceeds 500mm, the capacity shall be reduced according to the load chart. Overloading is strictly prohibited.

(6) Operate your forklift truck on a hard ground. Operate on other ground, the lift capacity and travel speed must be decreased. Wipe off the oil and grease from the floor.

(7) If the forklift truck is equipped with attachment, its usage sphere will be wider, but its allowable load and stability is reduced. The attachment and special device is not to be diverted to any other purpose. It’s very dangerous to rebuild the attachment. Please read the additional instruction we supplied and operate the truck following it strictly.

(8) Users select

“Lengthening fork” in order to carry widening loads. Pay much attention not to overload and observe the allowable load and the capacity chart stuck on the truck. Careful driving should be taken when traveling and turning.

(9) The unloaded forklift truck with attachment should be operated as a loaded truck.

(10) Connect the power and turn on the key switch, select the position of direction switch, check the truck for normal operation by turning steering wheel, depress the accelerator pedal softly to keep proper acceleration.

(11) During operation, pay attention to the performance and condition of the system of machinery, hydraulic, electric etc.

(12) When operate one lever, pay attention not to shift another lever. Don’t operate the lever at any position out of the driver

’s seat.

(13) The shift distance of control valve lever can control the speed of the lifting or descending of the goods. When the goods are lifted or descended, the initial speed shouldn’t be too fast in either case.

(14) When tilting the mast forward or backward to the limit or lifting the fork to the maximum height, return the directional lever to neutral.

(15) The starting, turning, driving, braking and stopping of the truck should be done smoothly. When turning on the humid or slippery road, the truck should be decelerated.

(16) Because the forklift truck turns by the rear wheels, the end counterweight may swing widely when turning. Use care in narrow aisles and other workplaces.

(17) Operate the forklift truck smoothly, don’t jerk the steering wheel. Avoid sudden stop, acceleration, stop or turn. In the case of improper operation, the truck will turn over.

In case of this, the driver must keep calm, don’t jump off the truck. The driver must hold

15

tightly the control wheel with two hands; meanwhile, his body must incline in opposite direction of truck’s turning over.

(18) Turning, lateral or deflective traveling shall not be taken on a slope. It could cause overturning of the truck, it is very dangerous. On a slope, drive the truck with load forward to ascend and backward to descend. When the truck goes down on a slope, drive slowly with the brakes on. Make sure that the engine should not be shut down when traveling on a slope.

(19) The stability of the truck is influenced by the wind-force during outside operation, you must notice specially.

(20) Be careful and slow driving over a dock or temporary paving slab.

(21)

Insert forks deeply under goods. Adjust fork’s distance according to the dimension of goods. Make the loads distribute on the forks evenly to avoid tilt and slide of goods.

(22)

Don’t pick the loads with single fork. Fork can not be used to pull out any embedded goods, if necessary, the pulling force should be estimated.

(23)

Don’t handle unfixed or loose goods. Be careful to handle bulky goods. To prevent the collapse of stacked goods, tighten them. Forbid loading loose or little volume goods without pallet.

(24) When loading the goods, lower the forks to the floor. After the fork inserting stacked goods, the fork arms should be in contact with the goods. Drive the truck with mast tilting back for stabilizing the load. Before traveling, raise the forks for

200mm-300mm from the floor.

(25) When handling bulky loads which block your view, operate the forklift truck in reverse or have a guide.

(26)

While mast’s lifting and lowering, anyone is absolutely prohibited from standing under the lift bracket or being lifted with forks. Never permit anyone to stand or walk under upraised forks.

(27) When lifting the load, according to the weight of the load, accelerate properly and then pull the lifting lever.

(28) The load descends for the gravity, at this time, the engine must be in idle position, and the lever must be pulled slowly to prevent the load from sudden falling.

(29) When loading and unloading goods, keep the mast vertical and the truck is in braking state.

(30) Load should cling to the load backrest. Do not handle the load which exceeds height of the backrest, or else there is a danger of load’s falling against operator.

16

(31) W hen travel with load, don’t tilt mast forward, don’t do handling. Don’t brake abruptly to prevent goods from slipping off the forks.

(32)

It is necessary to brake before tilting the mast forward or backward. It’s also necessary to decelerate and tilt forward slowly so as to prevent the goods from slipping off the forks.

(33)

Don’t make a sudden braking when the truck traveling with loads.

(34) Drive the forklift truck to the stacked goods at a low speed, at the same time, pay much attention to sharp and hard objects near the goods, otherwise, the tyres will be pricked.

(35) Pay attention to pedestrian, obstacle and bumpy road when driving. Pay attention to the clearance over the forklift truck.

(36) Keep your head, hands, arms, feet and legs within the confines of the cab.

Never allow other persons on the forklift truck.

(37) Tilt the mast of the high lift forklift truck as backward as possible when operating the truck. Use minimum forward and backward tilt when loading and unloading. It is dangerous to travel or turn when lifting the goods at high levels.

(38) It is noted that the goods will fall down when the forks of the truck with lifting height more than 3m lift, take the protection measures if necessary.

(39) Before the truck decelerating and stopping, d on’t change gear to reverse shift, so as to ensure the safe loading.

(40) When the truck stops and the engine is on idle position, the mast must be tilted backward.

You shouldn’t leave the truck with idling engine or hanged goods unattended.

(41) When adding fuel, make the driver leave the truck and the engine flameout.

Don’t ignite when checking the level of fuel tank.

(42)

Don’t open the radiator cap when the engine is very hot.

(43) After one day’s working, the fuel tank should be added oil to prevent the humidity in the fuel tank from becoming the blob and then interfusing the fluid.

(44) When leaving, engage the parking brake, lower the forks on the ground and let the shift lever to neutral, make the engine flameout or cut down the electric supply. If parking on a slope with smaller gradient, apply the parking brake and block the wheels.

The truck is forbidden parking on a slope with bigger gradient.

(45)

Don’t adjust the control valve and relief valve at will to prevent the damage of hydraulic system and its components because of excessive pressure passing them.

(46) Tyres should be inflated according to the pressure value specified in the nameplate of

“Tyre Pressure”.

17

(47) Check the chains periodically to make sure that good lubrication condition exists between the chain elements, the degree of tightness between left and right chain is identical. If the variation value of the chain pitch exceeds 2% standard value, it indicates that the chains have been worn excessively, replace it immediately.

(48) The overhead guard is main part which is strong enough to meet safety standard, and protect the operator from falling materials. It’s very dangerous to dismantle or rebuild the overhead guard, because these conditions could lead to an accident.

(49) A load backrest shall be used as protection against back falling objects on the fork. It’s very dangerous to dismantle or rebuild the load backrest, because these conditions could lead to an accident.

(50)

You can’t change or add other working equipments on the truck without our company’s permission, or the rated capacity and safety operation will be affected.

(51) Keep safety when serving on high position.

(52) The forklift truck must be operated under the following environment: below an elevation of 1000 meters and temperature between -20

℃and 40℃, relative humidity is

95%. Careful operation must observe under other adverse circumstances.

(53) Because of the danger for the people, the forklift is forbidden operating in airtight space, or you may be choked by the tail gas. The tail gas’s exhausting standard shouldn’t be lower than the no-load mechanical vehicle exhaust standard ruled by the nation that users are in. If in Europe nation, the adopted tail gas’s exhausting index should be applied

Europe StageⅢA standard.

(54) According to the Directive 2000/14/EC and based on EN12053 standard,the noise pressure level at the operator’s position and the measured sound power level and the guaranteed sound power level is referred to the following table. But the noise of the forklift truck may fluctuate due to different operation and the influence of the external environment.

(55) The driver feels the vibration of the forklift truck when operating and traveling the forklift truck.. According to ISO3691 and based on EN13059 standard. The vibration of the forklift truck fluctuates according to environment condition. In normal working condition, the vertical direction acceleration mean value from the seat to the operator by testing is in the following table. But the vibration frequency felt by the driver depends on the working condition (etc. road, operation method), so the actual vibration frequency must be determined according to environment condition when necessary.

(56) To prevent the fire, accident or other unpredictable event, prepare the fire extinguishers in advance and operate them according to the instructions.

18

Model

CPCD20F

CPCD25F

CPQD20F

CPQD25F

CPCD30F

CPCD35F

CPQD30F

CPQD35F

The noise pressure level at the operator’s

The measured sound power level position

EN12053 EN12053

The vertical

The guaranteed direction sound power level acceleration mean

2000/14/EC value from the seat to the operator

85 dB(A)

86 dB(A)

85 dB(A)

85 dB(A)

87 dB(A)

86 dB(A)

86 dB(A)

87 dB(A)

105 dB(A)

104 dB(A)

103 dB(A)

103 dB(A)

105 dB(A)

104 dB(A)

103 dB(A)

104 dB(A)

107 dB(A)

107 dB(A)

105 dB(A)

105 dB(A)

107 dB(A)

107 dB(A)

105 dB(A)

105 dB(A)

0.76 (m/s

2

)

0.72 (m/s

2

)

0.86 (m/s

2

)

0.84 (m/s

2

)

0.91 (m/s

2

)

0.84 (m/s

2

)

0.85 (m/s

2

)

0.87 (m/s

2

)

7. Caution plate

The caution plates stuck on the vehicle indicate the operating method and instructions. Before driving it, be sure to read them thoroughly. If the caution plate drops, stick it again. When maintaining, check if the caution plate is complete and the writing is legible, if necessary, please replace them.

(1) Safety mark (People are forbidden to stand on or down the fork.)

(2) General information when operating

19

(3) Nameplate of forklift truck

(4) Lubrication system

(5) Capacity chart

(6) Inspections before starting

(7) Adjust parking brake

20

(8) Use parking brake

(9) Add hydraulic oil

(10) Add fuel (gasoline)

(11) Add fuel

(12) Add antifreeze

(13) Tyre safety (charging tyre)

21

(14) Tyre pressure decal (charging tyre)

2-2.5t forklift truck

3-3.5t forklift truck

(15) Sling point indication

(16) Sling decal

(17) Forbid entering into the space behind the mast

22

(18) Forbid conveying person

(19) Hand caution

(20) Fan hurting hand

(21) Hood crushing hand

(22) Belt pulley thumb hand decal

(23) Overturn caution

23

Ⅲ. Periodic inspection and servicing

During operating the forklift truck, it is necessary to operate carefully, service and maintain periodically to make the forklift truck keep in good condition.

1. General rules on inspection and maintenance

(1) Only use genuine parts when replacing critical parts.

(2) Only use genuine or recommended oil when replacing or adding.

(3) Clean oil fillers and grease fittings with a brush or waste cloth before adding oil or grease.

(4) Checking oil level and adding oil should be made with the truck parked on a level ground.

(5) Preventive maintenance should be done in an orderly manner and due care taken not to injure yourself.

.Regular inspection

(1) Check the seal and the reliability of the hydraulic system.

(2) Check the reliability of the steering and braking system.

(3) Check the reliability of mast, driving axle and steering axle connecting with the frame.

(4) Check all wheels for tightness.

.Irregular inspection etc.

(1) Check the reliability of each welding joints of the mast, frame and so on.

(2) Check the reliability of connecting joints of steering cylinder, joint plate and gimbal

(3) Check all pipes and hoses for any leakage and breakage.

(4) Check the performance of the traveling brake and the parking brake.

Caution:

.Only trained and authorized serviceman shall be permitted to service and

repair the truck.

. If any damage or fault is found, stop the truck and report the condition to the

manager. Do not operate the truck until it has been repaired completely.

.When checking and maintaining the truck, do not use the mast or the load

backrest instead of a ladder, these actions will lead to a dangerous condition unexpectedly.

24

2. Inspection content

Walk around inspection

Vehicle uprightness

Beneath the vehicl e

Tyre inspection

Hub nut inspection

Does the vehicle lean to one side or the other? If it, check for a tyre puncture or a problem with the undercarriage.

Check for any oil or water leakage on the ground or floor where the vehicle was parked. Check for loose parts or damage.

If any unusual condition is found, have the vehicle inspection by a professional serviceman.

Tyre inflation pressure

1. Use a tyre pressure gauge and measure the inflation pressure. Adjust it to the proper level.

The tyre pressure is referred to the corresponding section in the manual or according to the decal of the vehicle.

2. After the adjustment, check if air is not leaking from the valve.

Damage, crack and wear of tyres and rims

Check the tyres for damage and wear, and the rims for bending.

If the tyres are damaged, or there is a marked difference in the wearing of tyres between the front and rear or between the left and right is perceived, or bent rims are found, ask a professional serviceman for inspection.

Check the tightness of the hub nuts.

Avoid uneven torque and tighten all of the nuts uniformly. Refer to the corresponding section for proper torque.

Lamp inspection

Are the filaments intact? Is there any lens damage?

Always keep the lenses clean to insure proper forward vision.

25

Engine compartment inspection

Engine coolant level check and supply

Level check and supply of engine coolant shall be performed while the coolant is cool.

1. With the engine off, open the engine hood and check the engine coolant level in the reservoir tank.

Note:

The reservoir tank equipped to the radiator automatically supplies the engine coolant when the coolant quantity in the radiator becomes insufficient.

2. The coolant level is proper if it is between the upper and lower limits. If the level is below the lower limit, supply coolant to the upper limit.

3. The concentration of the long life coolant (LLC) in the engine coolant must be higher than 30% (or 50% in a frigid zone.)

Note:

If no engine coolant remains in the reservoir tank, be sure to check the coolant level in the radiator, too.

(1) Reservoir tank

Checking the engine coolant level in radiator

(1) Radiator cover

Checking hydraulic oil level

1. Remove the radiator cover.

2. Remove the cap and check the coolant level from the filler port.

3. If the engine coolant is not visible through the filler port, fill appropriately diluted coolant (LLC) to the port.

Note:

To close and tighten the radiator cap, match the pawl on the reverse side of the cap with the notch on the filler port and turn the cap fully clockwise while applying a downward force.

Warning:

When the engine is hot, it is very dangerous to remove the cap.

Coolant level check must always be performed when the engine is cold.

Always stop the engine and lower the fork to the ground before checking the level of the hydraulic oil, while the vehicle is on level ground.

1. Open the engine hood and remove the hydraulic oil cap.

2. Wipe the level gauge attached to the oil cap with clean cloth, insert it again into the tank and screw tightly.

Note:

Inspect the oil level by placing the level gauge on the opening of the oil supply inlet, without screwing the hydraulic oil cap tightly.

3. Extract the level gauge gently and check if the hydraulic oil adhesion is up to the level line.

4. If the hydraulic oil level is insufficient, add oil. Spilled and splashed oil must be wiped off thoroughly.

26

Engine oil inspection

Adding engine oil

Leakage inspection

1. Park the vehicle on a flat ground. If the vehicle is inclined, the indicated level may be incorrect.

2. The oil level must be checked before starting the engine or at least 3 minutes after the engine is stopped.

3. Extract the oil level gauge and wipe it with clean cloth. Insert it again and check if the oil level is between the F and L levels.

4. If the oil level is below the L line, add oil to the F line.

1. To supply oil, remove the filler cap and pour oil through the filler port. Never let the oil level exceed the F line.

2. The oil to be supplied must be appropriate for the season.

SAE40 Ambient temperature higher than 30

℃

SAE30 Ambient temperature 0

℃ to 30℃

SAE20 Ambient temperature -10

℃ to 0℃

Caution:

Always use the same brand of oil if possible.

Select the brand number of the engine oil according to the request of the engine or the corresponding section of the manual.

Check the engine compartment for any oil or fuel leakage.

Check the radiator if it is clogged and check if there are any foreign objects, such as paper or other, onto the radiator grill.

On board vehicle inspection

Brake fluid inspection

(1) Reservoir tank

With the engine off, check the level of the brake fluid in the reservoir tank. If the level is below the lower limit, add brake fluid up to the proper level. If the decrease in brake fluid is excessive, the brake system may be leaky. Ask a professional serviceman for inspection as early as possible.

Warning:

.Never use any oil other than brake fluid.

.Do not allow dirt to get into the reservoir tank. Even a small amount of dirt in the brake fluid can prevent proper braking.

.Check the small vent hole in the reservoir tank cap frequently to make sure that it is not clogged with dirt.

27

Brake pedal inspection

(1) Brake pedal

(2) Brake pedal floor clearance

Parking brake inspection

(1) Parking brake pedal

(2) Parking brake release lever

1. Depress the brake pedal fully, and check the floor clearance

(clearance between the pedal and floor is not fewer than

110mm)

2. Make sure that the pedal does not go any further when it is kept depressed.

3. Also check that no abnormality is observed with pedal depression and return.

4. Manually depress the brake pedal to check the play until a resistance is felt.

The value of brake pedal play: 5 mm to8mm.

Warning:

Ask a professional serviceman inspection if the play is excessive, pedal movement is abnormal or brake performance is improper.

1. Fully press down on the parking brake pedal and inspect that the brake is functioning normally.

2. After fully pressing the parking brake pedal, pull the parking brake release lever toward you and confirm that the parking brake is released.

Warning:

Ask a professional serviceman for inspection if any abnormality is found.

Inching and brake pedal inspection

(1) Inching and brake pedal

Instrument inspection

Fuel level check and supply

(1) Fuel tank cap

1. Manually depress the inching and brake pedal to check the play until a resistance is felt.

The value of inching and brake pedal play:5~8mm

2. Depress the inching and brake pedal and check that there is no depression or abnormal resistance.

Caution:

Ask a professional serviceman for inspection when any abnormality is found.

Start the engine and see that they operate properly.

1. Observe the fuel meter to see if the fuel is sufficient.

Note: After the end of daily operation, fill the tank with fuel to prevent the moisture in the air in the tank from mixing into the fuel.

2. When supplying fuel, stop the engine, remove the fuel tank cap by turning it counterclockwise, and pour fuel through the fuel filler neck.

3. After fueling, be sure to tighten the fuel tank cap.

Caution:

.Always stop the engine and keep any fire source away before and during the fueling operation.

.Carefully prevent entrance of water and dirt into the tank during fueling.

28

Engine inspection

Loading handling system

Steering wheel inspection

While moving slowly

Brake effectiveness

Steering inspection

Start the engine and warm it up sufficiently.

1. Check each meter and warning lamp to see there is no abnormality.

2. Check if the engine is generating abnormal sound or vibration.

3. Check the exhaust gas color to see it is normal.

Colorless or light blue exhaust indicates complete combustion; black exhaust, incomplete combustion; and white exhaust, burning oil as a result of oil getting into the cylinders.

Warning:

.The exhaust gas is harmful. If you must start the engine inside a building or enclosure, insure sufficient ventilation.

.The gasoline engine carburetor is equipped with the automatic chock that keeps the engine running at a relatively high speed a while. Do not be bothered, however, because the engine resumes a normal speed upon warming enough.

1. Check the fork installation state, for cracks and bending.

2. Check for mast distortion, chain tension and oil leakage from cylinders and piping.

3. Operate the lift and tilt levers to check their operating state.

If anything unusual is found, have the vehicle inspected by a professional serviceman.

Perform the inspection after starting the engine.

1. Check the steering wheel play with the rear wheel set in the straight traveling direction.

The standard play of steering wheel when idling: 20~50mm

2. Turn the steering wheel in the circumferential direction and also move it up and down to check there is no looseness.

3. Push the horn button to check if the horn sounds normally.

4. If any abnormality is found, ask a professional serviceman for inspection.

Inspect to see if there is anything unusual when the brake pedal is pressed or if the brakes only work on the side.

Effect the parking brake and insure that the vehicle can be stopped and that a parked condition can be maintained.

Caution:

If anything feels even slightly unusual, stop vehicle operation immediately and have the vehicle inspection by a professional serviceman.

While moving the vehicle slowly in a safe location, turn the steering wheel to the left and right and check for any unusual movement.

29

Before garaging the vehicle

Remove dirt from all vehicle components and then perform the following.

1. Inspect for oil or water leakage.

2. Inspect each component for warping, scratches, dents or cracks.

3. Clean the air filter element and lubricate parts as required.

4. Raise the forks all the way up and down to lubricate the inside of the lift cylinder.

Caution:

Even a small malfunction can cause a serious accident.

Do not operate the vehicle until repairs have been completed.

If you sensed anything unusual during operation, notify the supervisor.

3.

Periodic replacement table

Replacement period (Accumulate hours of operation or monthly periods of operation, whichever comes sooner.)

Engine oil

Engine oil filter

Cooling water

(except LLC, LLC is every 2 years)

Air cleaner element

Fuel filter

Torque converter oil

Torque converter oil filter

Manual transmission oil

Differential gear oil

Hydraulic oil

Hydraulic oil filter

Wheel bearing grease

Spark plugs

Master cylinder, wheel cylinder cap and

Power steering hose

Power steering rubber parts

Hydraulic hose

Fuel hose

Torque converter rubber hose

Chain

Hydraulic oil pump seal

Every

Every

6 Weeks

250

●

●

●

●

Every 2 years

●

●

●

Every 2 years

Every 2 years

Every 2 years

●

●

●

Every 2 years

Every 3 years

Every 3 years or 6000 hours

3 6 12 Months

500 1000 2000 Hours

←

●

←

←

←

←

● ← ←

←

●

●

←

←

●

←

←

●

←

●

←

Note: In case of the hard operating condition, the service interval of 170 hours or 1 month may be recommendable.

30

4. Lubrication chart

1. Chain

2. Differential gear

3. Front wheel bearing

4. Brake fluid cup

5. Transmission case

6. Rear wheel bearing

7. Steering knuckle king pin

8. Oil tank

9. Engine crankcase

10. Pump transmission device

11. Foot operating assy

Ⅰ) Inspect every 8 hours (daily)

Ⅱ) Inspect every 40 hours (weekly)

Ⅲ) Inspect every 250 hours (6 weeks)

Ⅳ) Inspect every 1000 hours (6 months)

Ⅴ) Inspect every 2000 hours (annually)

○: Inspect and service

●: Replace

A) MP grease

B) Engine oil

C) Hypoid gear oil

D) Hydraulic oil

12. Direction column locking mechanism E) Hydraulic transmission oil

13. Mast support bushing F) Brake fluid

14. Tilt cylinder pin

15. Propeller shaft

16. Tie rod end pin

17. Steering cylinder rear pin

Note: In case of the hard operating condition, the service interval of 170 hours or 1 month may be recommendable.

31

5.

Weekly maintenance

Inspect the items below in addition to the preoperation items. Please inspect the vehicles thoroughly every week to insure safety and pleasant working conditions.

Weekly (40-hour) inspection items

Air cleaner

Fan belt clean inspect

Torque converter oil level check

Bolts and nuts retighten

Mast and steering linkage grease

Chain lubrication lubrication oil

Frame serial number

The frame serial number is stamped on the front cross plate.

Please refer to the frame serial number when making inquiries about your vehicle.

(1) Frame serial number location

Air filter cleaning

Element cleaning

(1) Element

How to wash the element

(1) Evacuator valve

The element can be taken out after removing the three catches fixing the element.

1. Tap the element filter paper lightly without causing any damage or blow dust off with compressed air (7kg/cm

2

or less) from inside.

2. After element cleaning, remove any dust in the evacuator valve (optional).

Note:

.Always replace the element if the filter paper is torn or damaged.

.Wash the element if heavily contaminated.

1. Soak the element in water containing neutral detergent for approximately 30 minutes and then wash. Use care not to scratch the filter paper.

2. After washing, rinse the element with clean water (water pressure less than 2.8 kg/cm

2

).

3. Allow to dry naturally or use a dryer (cold air). Never use compressed air or flame.

Note:

The element should be replaced after washing six times or after it is used for one year.

32

Fan belt inspection

Torque converter oil inspection

(1) Toe board

Retightening of bolts and nuts

Greasing mast and steering linkage

Fuel tank check

Inspect the fan belt for cracks, fraying and tension.

If any abnormalities are found, have the belt replaced or adjusted by a professional serviceman.

1. Park the vehicle at a safe and level ground, and stop the engine.

Caution:

Inspect with the parking brake pedal is effected and the forks are lowered to the ground.

2. Open the engine hood and remove the toe board.

3. Exhaust the level gauge and wipe it with clean cloth.

4. Insert the level gauge back to the hole from which it is removed, and extract it again to check if the oil level is among the gridding lines on the level gauge.

Retighten each bolt and nut on the chassis and load handling system.

Grease in accordance with the lubrication table.

Caution:

·Clean the grease fitting tips thoroughly prior to greasing.

·After greasing, wipe off excess grease.

Check fuel tank, tank covering, fuel inlet, and drain plug against possible fuel leak. Follow the steps below.

1. Try to smell leak.

2. Look for leak.

3. Touch possible leak.

See the nearest Baoli dealer upon finding leak and have them repair tank immediately.

Caution:

Never perform do-it-yourself welding or other repair work for it might cause explosion or fire.

33

6. Self service

Replacing or repairing tyre

Adding antifreeze

Prepare tools and jack necessary for replacing or repairing tyres.

1. Front wheel

.Stop the vehicle on a level, hard surface and shut down the engine. All loads should be unloaded from the vehicle.

.Press the parking brake pedal and block the wheels. Put the jack under the vehicle frame.

.Jack up the vehicle to the extent that the tyre still remains on the ground. Loosen the hub nuts. Do not remove them.

.Again jack up the truck until the tyre leaves off the ground.

Remove the hub nuts, and detach the wheel.

.The wheel should be reinstalled in the reverse order: the hub nuts should be tightened in the diagonal order evenly.

.After reinstallation, check the tyre for pressure and make it achieve standard value.

2.Rear wheel

Use the same manner as with the front wheel tyre repair or replacement except for the position of the jack which goes under the counterweight.

If the vehicle is left in an area where the temperature is less than

0

℃, the cooling water will freeze and may damage the radiator and/or cylinder block. In such cases, antifreeze coolant must be used.

When long-life coolant (LLC) is used, it must be changed once every two years.

Freezing temperature varies depending on the amount of antifreeze added.

Freeze protection temperature

(

℃)

Antifreeze (%)

Caution:

-12

25

-15

30

-24 -35

40 50

The antifreeze fluid is flammable, so be particularly careful to avoid flame. Prior to adding antifreeze, inspect the radiator, water pump, piping and cylinder block for leaks.

The procedures for adding antifreeze are as follows.

1. Remove the radiator cap. Loosen the drain cock on the radiator and cylinder block and drain the cooling water.

2. Flush out the radiator and cylinder block by adding clean water through the radiator inlet.

3. After the water has drained out of the radiator and cylinder block, tighten the radiator and cylinder block, tighten the radiator and engine drain cocks.

4. Add the proper amount of antifreeze to the radiator inlet and fill up the remaining space with clean water.

5. When warm weather arrives and there is no longer any danger of freezing, drain the cooling water containing the antifreeze (except LLC, LLC is every 2 years in replacement).

Flush out the radiator and engine block and fill with clean water.

34

Fuse replacement

Air purge of the fuel system

Draining the sedimenter

(1) Priming pump

(2) Drain plug

(3) Drain hose

Cleaning the radiator fin

If a lamp does not come on or an electrical device does not function, the corresponding fuse may be blown. Check the fuse for each device. The lighting location on the fuse box is blown fuse when electrified. The fuse box is located in the front left as seen from the opened engine hood.

The fuse check and replacement procedures are as follows:

1. Set the ignition switch to the OFF position.

2. Remove the fuse box cover and check the fuse.

3. If the fuse is blown, replace it with a spare fuse.

Caution:

Use the fuse having the same capacity as that of the installed one.

When fuel has been completely depleted or when maintenance has been performed on the fuel system, be sure to perform air purge in the following sequence.

1. Open the engine hood.

2. Operate the priming pump up and down to perform air bleeding.

The sedimenter separates the water contained in the fuel. It is integrated with the fuel filter.

If the sedimenter warning lamp comes on, immediately drain water according to the following procedure because the accumulated water in the sedimenter is above the specified level:

1. Place a water receiving container under the open end of the drain hose under the fuse filter.

2. Turn around the drain cock a time or two to loose it and operate the priming pump up and down to drain the water in the sedimenter.

3. When fuel starts to flow out after the end of water draining, firmly tighten the drain cock.

Caution:

Wipe the fuel clearly from the adjacent area.

Clean the radiator and radiator fin, if debris is trapped therein, this may cause over-heating.

Caution:

. After stopping the engine, confirm that the engine has sufficiently cooled down before cleaning. Taking inadequate precautions may result in burns.

.When cleaning the radiator fin, take care not to cause it to become deformed.

.When performing cleaning, always wear safety goggles and dust mask.

35

Maintaining the battery

(1) Grease

When the battery is dead

(1) Dead-battery vehicle

(2) Engine hanger

(3)To frame

(4) Booster cable

(5) Rescue battery

Terminals:

1. A loose or corroding terminal causes failure in connection.

Eliminate white powder, if noticed on the terminal, by pouring warm over it to disable and then grease the terminal.

2. Remove the terminal, if it is extremely corroded, from the battery to brush off the corrosion using a wire brush or sandpaper. Then connect the terminal tightly to the battery and grease the terminal.

Note:

Remove the negative terminal (-) first, then replace the other terminals.

Caution: