Контроллеры Eliwell линейки ID Next — это устройства нового поколения, подходящие для статических и вентилируемых установок при нормальных и низких температурах.

Линейка IDNext подходит для использования с установками, в которых используются легковоспламеняющиеся хладагенты, такие как R290 или R600.

Контроллеры ID Next имеет функцию глубокого цикла охлаждения (усовершенствованный алгоритм, позволяющий быстро снижать температуру). Функция Easy Map предлагает несколько предварительно загруженных конфигураций машины, а функция перегрева компрессора контролирует температуру нагнетания компрессора, уведомляя о любых плохих рабочих условиях.

Диапазон ID Next совместим с приложением Eliwell AIR и облачным решением TelevisAir.

| Источник питания | 12 В переменного тока/постоянного тока |

| Потребляемая мощность | 5 ВА — 2,5 Вт |

| Диапазон отображения | -99,9…+99,9 °C -999…+999 °C |

| Аналоговые входы | 2 x PTC или NTC или Pt1000 |

| Цифровые входы | 1 x SELV |

| Цифровые выходы | 1 x SPST 2 л. с. 12(8)230 В переменного тока 1 x SPDT 0,5 л. с. 8(4)230 В переменного тока 1 x SPST 5(2)230 В переменного тока |

| Дисплей | Светодиодный индикатор 3 цифры + знак |

| Разрешение (0,1°C с десятичной запятой) | 0,1°C |

| Диапазон измерений | NTC: -50,0…+110,0 °C PTC: -55,0…+140,0 °C Pt1000: -55,0…+150,0 °C |

| Точность | NTC: лучше чем 0,5% от полной шкалы + 1 цифра РТС: лучше чем 0,5% от полной шкалы + 1 цифра Pt1000 в [-55,0…+70,0°С]: лучше чем 0,5% от полной шкалы + 1 цифра Pt1000 в [+70,0…+150,0°С]: лучше, чем 1% от полной шкалы + 1 цифра |

| Связь | Порт TTL для подключения к устройству мониторинга Unicard или TelevisSystemModBus |

| Последовательные порты | 1 x TTL |

| Установка | Панель, 71×29 мм |

| Аксессуары | USB-ключ Unicard/TTL BTLE/TTL |

| Вес нетто | 190 г |

| Ширина | 81 мм |

| Высота | 35 мм |

| Глубина | 60 мм |

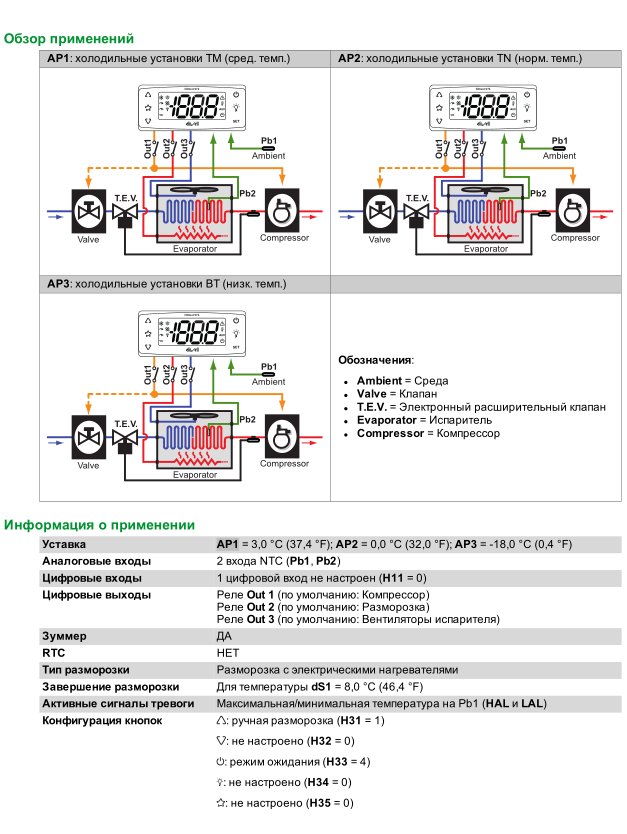

В каждом контроллере имеется 3 предопределенных приложения AP1, AP2, AP3 которые задают предварительную настройку контроллера для использования в 3-х реальных ситуациях, сокращая время, необходимое для установки, поскольку они требуют только изменения отдельных параметров.

Изменение рабочих параметров контроллера не влияет на значения предопределенных приложений. При первом включении прибора рабочие параметры такие же (в плане значений и видимости), как в приложении AP1.

Приложения AP1, AP2 и AP3 нельзя изменить с прибора. Приложения AP2 и AP3 могут быть изменены только с помощью Device Manager – программного обеспечения, разработанного Eliwell.

Приложение AP1 не может быть изменено никаким образом (даже с помощью Device Manager), чтобы позволить восстановить контроллер, используя приложение с гарантированной работоспособностью.

При первом пуске:

1. Выберите и загрузите предопределенное приложение AP1, AP2 или AP3 которое наилучшим образом подходит вашим рабочим потребностям.

2. Проверьте и при необходимости настройте значения основных параметров контроллера, чтобы привести выбранное приложение в соответствие с вашей системой.

3. Убедитесь в отсутствии активных сигналов тревоги.

USER INTERFACE

The user has a display and four keys for

controlling status and programming of the

instrument.

KEYS AND MENUS

UP key

Scrolls through the menu

items Increases the values

Activates manual def. function

DOWN key

Scrolls through the menu items

Decreases the values

Programmable by parameter

fnc key

ESC function (exit)

fnc

Programmable by parameter

set key

Accesses the setpoint

set

Accesses the menus

Confirms the commands

Displaying the alarms (if present)

At start-up the instrument performs a

Lamp Test; for few seconds the display and

the leds blink, in order to verify their inte-

grity and correct operation. The instru-

ment has two main menus: the «Machine

Status» and «Programming» menu.

ACCESSING AND USING MENUS

Resources are arranged in a menu, which

can be accessed by pressing and quickly

releasing the «set» key («Machine Status»

menu) or by holding down the «set» key

for more than 5 seconds («Programming»

menu).

To access the contents of each folder, indi-

cated by the relevant label, just press the

«set» key once.

You can now scroll through the contents

of each folder, modify it or use its func-

tions.

If you do not use the keyboard for over

15 seconds (time-out) or if you press the

«fnc» key once, the last value shown on

the display is confirmed and you return to

the previous screen mask.

LED

Position

Related Function

Compressor or relay 1

Defrost

Alarm

Fans

ID 974

electronic controllers for «forced air» refrigerating

units

MACHINE STATUS MENU

To access the «Machine Status» menu

Press and quickly release the «set» key.

If alarms are not present, the label «SEt»

appears. By using the «UP» and «DOWN»

keys you can scroll through the other fold-

ers in the menu:

-Pb1: probe 1 value folder;

-Pb2: probe 2 value folder

-SEt: Setpoint setting folder.

Set Setting

Access the «Machine Status» menu by

pressing and quickly releasing the «set»

key. The label of the «SEt» folder appears.

To display the Setpoint value press the

«set» key again.

The value appears on the display.

To change the Setpoint value, use the «UP»

and «DOWN» keys within 15 seconds.

If the parameter is LOC = y the Setpoint

cannot be changed.

Alarm on

If alarm condition exists, when accessing

The «Machine Status» menu the «AL» fold-

er label appears (see the «Diagnostics»

section).

Displaying Probes

By pressing the «set» key when the appro-

priate label appears, the value of the pro-

be associated to it is displayed.

PROGRAMMING MENU

To enter the «Programming» menu, press

the «set» key for more than 5 seconds.

If specified, the access PASSWORD will be

requested, (parameter «PA1»), and the

label of the first folder will follow.

To scroll through the other folders, use

the «UP» and «DOWN» keys.

To enter the folder, press «set». The label

of the first visible parameter appears. To

scroll through the other parameters, use

the «UP» and «DOWN» keys; to change the

parameter, press and release «set», then

set the desired value using the «UP» and

«DOWN» keys, and confirm with the «set»

key to move to the next parameter.

Status

ON when the compressor is started up; blinking in case of delay,

protection or blocked enabling

ON when defrosting; blinking in case of manual

enabling

ON when the alarm is enabled; blinking when the alarm is silenced

ON when the fan is working

PASSWORD

The password allows access to program-

ming parameters. In the standard configu-

ration password is not present.

To enable and assign it the desired value,

access the «Programming» menu, within

the folder with the «diS» label. If pass-

word is enabled, you will see it at the

entrance of the «Programming» menu.

MANUAL ACTIVATION OF THE

DEFROSTING CYCLE

To manually activate the defrosting cycle,

press the «UP» key for 5 seconds.

If defrosting conditions are not present,

(for example the evaporator probe

temperature is higher than defrost stop

temperature), the display

will blink three (3) times, in order to

indicate that the operation will not be

performed.

COPY CARD

The Copy Card is an accessory connected

to the TTL serial port which allows pro-

gramming quickly the instrument parame-

ters. The operation is performed as fol-

lows:

Format

This command allows copy card formatting,

an operation recommended in case of first

use.

Warning: if the copy card has been pro-

grammed, using the «Fr» the data entered

are erased. This operation cannot be can-

celled.

Upload

This operation loads the programming

parameters from the instrument.

Download

This operation downloads to the instru-

ment the programming parameters.

The operations are performed accessing

the folder identified by the «FPr» label and

selecting, according to the case, «UL», «dL»

or «Fr» commands; the operation is con-

firmed by pressing the «set» key. If the

operation is successful an «y» is displayed,

on the contrary, if it fails a «n» will be dis-

played.

Tab. 1

Parameter Table

DESCRIPTION

PAR.

COMPRESSOR REGULATOR (folder with «CP» label)

diFferential. Relay compressor tripping differential. The compressor stops on reaching the

diF

Setpoint value (as indicated by the adjustment probe), and restarts at temperature value

equal to the Setpoint plus the value of the differential.

Note: the value 0 cannot be assumed.

Higher SEt. Maximum possible setpoint value.

HSE

Lower SEt. Minimum possible setpoint value.

LSE

COMPRESSOR PROTECTIVE DEVICE (folder with «CP» label)

On time (compressor). Compressor activation time in the event of faulty probe. If set to

Ont

«1» with Oft at «0» the compressor is always on, while at Oft >0 it functions always

in duty cycle mode.

OFF time (compressor). Compressor in disabled state time in the event of a faulty probe.

OFt

If set to «1» with Ont at «0» the compressor is always off, while at Ont >0

it functions always in duty cycle mode.

delay (at) On compressor. Delay time in activating the compressor relay after switch-on

dOn

of instrument

delay (after power) OFF. Delay after switch off; the indicated time must elapse between

dOF

switch-off of the compressor relay and the successive switch-on.

delay between power-on. Delay between switch-ons; the indicated time must elapse

dbi

between two successive switch-ons of the compressor.

delay Output (from power) On. Delay time in activating the outputs after switch-on of

OdO

the instrument or after a power failure.

DEFROSTING REGULATOR (folder with «dEF» label)

defrost type. Type of defrosting.

dty

0 = electric defrost;

1 = reverse cycle defrost (hot gas);

2 = Free defrost (compressor hot).

defrost interval time. Interval between the start of two successive defrosting operations.

dit

dCt

defrost Counting type. Selection of count mode for the defrosting interval.

0 = compressor operating hours (DIGIFROST® method);

1 = Real Time – appliance operating time;

2 = compressor stop.

defrost Offset Hour. Start-of-defrosting delay time from start up

dOH

of instrument.

defrost Endurance time. Defrosting time-out; determines duration of

dEt

defrosting.

defrost Stop temperature. Defrost stop temperature (defined by the evaporator

dSt

probe).

defrost (at) Power On. Determines if at the start-up the instrument must enter defrosting

dPO

(if the temperature measured by the evaporator allows this operation).

y = si; n = no.

FANS REGULATOR (folder with «FAn» label)

Fan Stop temperature. Fan lock temperature; if the value, read by the evaporator probe,

FSt

is higher than the set value, fans stop.

Fan differential. Fan starting differential (see par. «FSt» and «Fot»).

FAd

Fan delay time. Delay time in activating fans after a defrost operation.

Fdt

drainage time. Dripping time.

dt

defrost Fan disable. Allows to select the evaporator probes exclusion

dFd

during defrost. y = yes; n = no.

Fan Compressor OFF. Allows to select compressor fans lock

FCO

OFF (switched off).

y = fans activated (with thermostat; based on the value read by the defrost probe,

see parameter «FSt»);

n = fans off;

d.c. = duty cycle (by parameters «Fon» and «FoF»).

ALARMS (folder with «AL» label)

Alarm Fan differential. Alarm differential.

AFd

Higher ALarm. Maximum temperature alarm. Temperature value (with regard to Setpoint)

HAL

which if exceeded in an upward direction triggers the activation of the alarm signal.

Lower ALarm. Minimum temperature alarm. Temperature value (with regard to Setpoint),

LAL

which if exceeded in a downward direction, triggers the activation of the alarm signal.

Power-on Alarm Override. Alarm exclusion time after instrument switch on,

PAO

after a power failure.

defrost Alarm Override. Alarm exclusion time after defrost.

dAO

temperature Alarm Override. Temperature alarm signal delay time.

tAO

DISPLAY (folder with «diS» label)

(keyboard) LOCk. Keyboard locking. However, you can enter parameter programming

LOC

modify them along with the status of this parameter in order to allow keyboard locking.

y = yes; n = no

PAssword 1. When enabled (value other than 0) it constitutes the access key for

PA1

level 1 parameters.

ndt

number display type. View with decimal point. y = yes; n = no

CAlibration 1.Calibration 1. Positive or negative temperature value added to the value

CA1

read by probe 1, based on «CA» parameter settings.

CAlibration 2.Calibration 2. Positive or negative temperature value added to the value

CA2

read by probe 1, based on «CA» parameter settings.

defrost display Lock. Modalità di visualizzazione durante lo sbrinamento.

ddL

0 = visualizza la temperatura letta dalla sonda cella;

1 = blocca la lettura sul valore di temperatura letto dalla sonda cella all’istante di entra-

ta in sbrinamento e fino al successivo raggiungimento del valore di Setpoint;

2 = visualizza la label «deF» durante lo sbrinamento e fino al successivo raggiungimento

del valore di Setpoint.

dro

display read-out. Selezione °C o °F per la visualizzazione temperatura letta dalla sonda.

0 = °C, 1 = °F.

ID 974 LX

RANGE

DEFAULT

VALUE*

0.1…30.0

2.0

LSE..302

99.0

-55.0…HSE

-50.0

0…250

0

0…250

1

0…250

0

0…250

0

0…250

0

0…250

0

0/1/2

0

0…250

6

0/1/2

1

0…59

0

1…250

30

-50.0… 150

8.0

n/y

n

-50.0..150.0

2.0

1.0…50.0

2.0

0…250

0

0…250

0

n/y

y

n/y/d.c.

y

1.0…50.0

2.0

LAL…150.0

50.0

-50.0…HAL

-50.0

0…10

0

0..999

0

0…250

0

n/y

n

0…250

0

n/y

y

-12.0…12.0

0

-12.0…12.0

0

0/1/2

1

0/1

0

LEVEL**

U.M.

1

°C/°F

1

°C/°F

1

°C/°F

1

min

1

min

1

sec

1

min

1

min

1

min

1

flag

1

hours

1

flag

1

min

1

min

1

°C/°F

1

flag

1

°C/°F

1

°C/°F

1

min

1

min

1

flag

1

flag

1

°C/°F

1

°C/°F

1

°C/°F

1

hours

1

min

1

min

1

flag

1

number

1

flag

1

°C/°F

1

°C/°F

1

flag

1

flag

3/4