Emerson

Универсальные контроллеры перегрева Emerson серии EC3-X33 с дисплеем ECD-002 для работы с электрическими регулирующими клапанами Emerson с шаговым двигателем серии EX4…EX8 и FX5…FX9. Руководство по эксплуатации.

Скачать

Pdf 1.57 Mb

Язык: RU

G e n e r a l i n f o r ma t i o n :

EC3-X33 is a universal superheat controller in conjunction with EMERSON

Electrical Control Valves EX4…EX8 and FX5…FX9.

Note: This document contains short form instructions for experienced users.

S a f e t y i n s t r u c t i o n s :

• Read operating instructions thoroughly. Failure to comply can result in

device failure, system damage or personal injury.

• According to EN 13313 it is intended for use by persons having the

appropriate knowledge and skill.

• Do not exceed the specified maximum ratings for pressure, temperature,

voltage and current.

• Before installation or service disconnect all voltages from system and device.

• Do not operate system before all cable connections are completed.

• Entire electrical connections have to comply with local regulations.

Note: The EC3-X33 series contains

lead-acid battery.

The battery must NOT be disposed of with other commercial

waste. Instead, it is the user’s responsibility to pass it to a designated collection

point for the safe recycling of batteries (harmonized directive 2012/19/EU). For

further information contact your local environmental recycling center.

M o u n t i n g p o s i t i o n :

The EC3-X33 is designed to be mounted onto a standard DIN rail. Mounting

position: on vertical walls, with stepper motor connector on top side only.

M o u n t i n g o f E C D — 0 0 2 :

• ECD-002 can be installed at any time also during operation.

• ECD-002 can be mounted in panels with

71×29 mm cutout.

• Push controller into panel cut-out.(1)

• Make sure that mounting lugs are flush with

outside of controller housing

• Insert Allen key into front panel holes and turn

clockwise. Mounting lugs will turn and gradually

move towards panel (2)

• Turn Allen key until mounting lug barely touches

panel. Then move other mounting lug to the same

position (3)

• Tighten both sides very carefully until keypad is

secured. Do not over tighten as mounting lugs

will break easily.

!

E l e c t r i c a l I n s t a l l a t i o n :

• Refer to the electrical wiring diagram for electrical connections.

• Do not apply voltage to the controller before completion of wiring.

• Ground the metal housing with a 6.3 mm spade connector.

• Keep controller and sensor wiring well separated from mains wiring. Minimum

recommended distance 30 mm.

• Use a class II category transformer for 24 VAC power supply. Do not ground the

24 VAC lines. We recommend using individual transformers for EC3

rd

controller(s) and for 3

party controllers to avoid possible interference or

grounding problems in the power supply.

• Connecting any EC3 inputs to mains voltage will permanently damage the EC3.

• The use of the relay is essential to protect the system in case of power failure if

the communications interface or the ECD-002 are not utilized.

• If the output relay is not utilized, the user must ensure appropriate safety pre-

cautions are in place to protect the system against damage caused by a power

failure.

• In order to provide system protection in the event of power loss, it is

recommended to change the battery annually.

Digital input status is dependent to operation of compressor/thermostat

Commander

Operating condition

Compressor

Compressor starts

Compressor stops

Thermostat

Demand (compressor must be ON)

No demand

Emerson Climate Technologies GmbH

Am Borsigturm 31 I 13507 Berlin I Germany

EC3-X33 Superheat Controller and ECD-002

Keypad / Display Unit

a VRLA battery = valve regulated rechargeable

Digital input (I)

Closed / 24 V (Start)

Open / 0 V (Stop)

Closed / 24 V (Start)

Open / 0 V (Stop)

www.emersonclimate.eu

Operating instruction

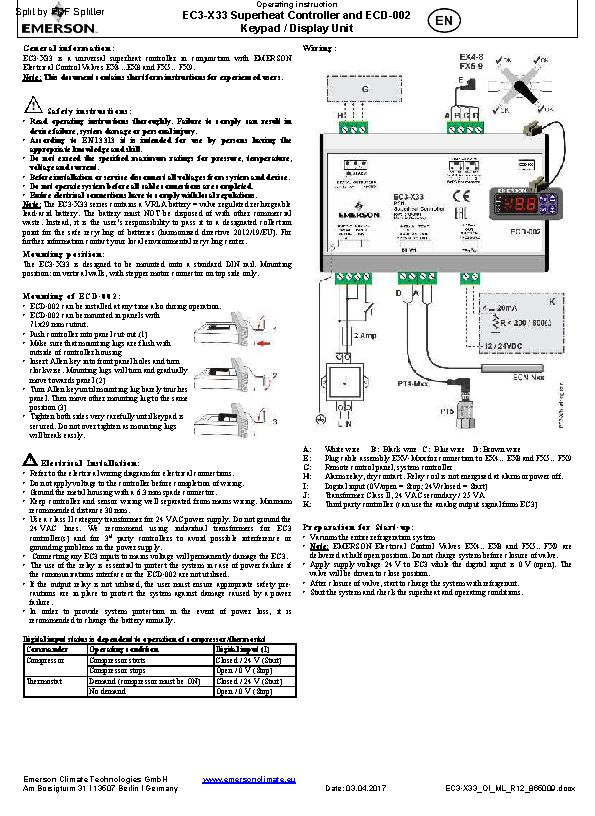

W i r i n g :

A:

White wire

E:

Plug cable assembly EXV-Mxx for connection to EX4…EX8 and FX5…FX9

G:

Remote control panel, system controller

H:

Alarm relay, dry contact. Relay coil is not energized at alarm or power off.

I:

Digital input (0V/open = Stop; 24V/closed = Start)

J:

Transformer Class II, 24 VAC secondary / 25 VA

K:

Third party controller (can use the analog output signal from EC3)

P r e p a r a t i o n f o r S t a r t — u p :

• Vacuum the entire refrigeration system

• Note: EMERSON Electrical Control Valves EX4…EX8 and FX5…FX9 are

delivered at half open position. Do not charge system before closure of valve.

• Apply supply voltage 24 V to EC3 while the digital input is 0 V (open). The

valve will be driven to close position.

• After closure of valve, start to charge the system with refrigerant.

• Start the system and check the superheat and operating conditions.

Date: 03.04.2017

B: Black wire C: Blue wire D: Brown wire

EC3-X33_OI_ML_R12_865009.docx

Бренд: Emerson

Категория для инструкций: Автоматика, регуляторы, модули, термостаты

Алфавит (англ.): E

Описание: Универсальные контроллеры перегрева Emerson серии EC3-X33 с дисплеем ECD-002 для работы с электрическими регулирующими клапанами Emerson с шаговым двигателем серии EX4 EX8 и FX5…FX9. Руководство по эксплуатации

Размер файла: 1935829 байт

Инструкция на контроллеры перегрева Emerson серии EC3-X33 с дисплеем ECD-002

E C D — 0 0 2 d i s p l a y / k e y p a d u n i t : ( L E D s a n d b u t t o n f u n c t i o n s )

Blinking: valve is opening

ON: valve is fully open

Blinking: valve is closing

ON: valve is fully close

ON: demand

OFF: no demand

ON: alarm

Prg&Sel (5 sec)

OFF: no alarm

Manual reset for

blinking alarm codes

S e t u p o f ma i n p a r a me t e r s u s i n g E C D — 0 0 2 :

(need to be checked/modified before start-up)

• Make sure that digital input is 0V (open). Turn the power supply ON.

• Important: Three main parameters i.e. refrigerant type (u0), pressure sensor type

(uP) and valve type (ut) can be set only when digital input is open (0V) while the

power supply is ON (24 V). This feature is for added safety to prevent accidental

damage of compressors and other system components.

• For easy setting of main parameters, follow the pictorial procedure of «Quick

start-up» on the attached individual paper.

• Once the main parameters have been selected/saved the EC3 is ready for

startup. All other parameters can be modified at any time during operation

or standby if it is necessary.

P r o c e d u r e f o r p a r a me t e r s m o d i f i c a t i o n u s i n g E C D — 0 0 2 :

• The parameters can be accessed via the 4-button keypad. The configuration

parameters are protected by a numerical password. The default password is «12».

To select the parameter configuration:

• Press the PRG button for more than 5 seconds. A flashing «0» is displayed

• Press

or

until «12» is displayed; (password)

• Press SEL to confirm password

• Press

or

to show the code of the parameter that has to be changed;

• Press SEL to display the selected parameter value;

• Press

or

to increase or decrease the value;

• Press SEL to temporarily confirm the new value and display its code;

• Repeat the procedure from the beginning «press

• To exit and save the new settings: Press PRG to confirm the new values and

exit the parameters modification procedure.

• To exit without modifying any parameters: Do not press any button for at least

60 seconds (TIME OUT).

R e s e t a l l p a r a me t e r s t o f a c t o r y s e t t i n g :

• Make sure that digital input is 0V (open).

• Press

and

together for more than 5 seconds. A flashing «0» is displayed.

• Press

or

until the password is displayed (Factory setting = 12).

If password was changed, select the new password.

• Press SEL to confirm password

«0» is displayed.

• Press SEL to reset all parameters to factory setting

• Press PRG to activate the function and leave the special function mode.

C o n t r o l ( v a l v e ) s t a r t — u p b e h a v i o r : ( P a r a me t e r u u a n d u 9 )

EX4/5/6 ≤ 1.5 seconds

EX7 ≤ 3.2 seconds

uu

EX8 ≤ 7.2 seconds

≤ 7.3 seconds

FX5-8

FX9 ≤ 9.7 seconds

Emerson Climate Technologies GmbH

Am Borsigturm 31 I 13507 Berlin I Germany

EC3-X33 Superheat Controller and ECD-002

Keypad / Display Unit

Parameters setting/saving

Next parameter/

value (higher)

Selecting/confirming

or

to show…»

%

Sec.

u9

www.emersonclimate.eu

Operating instruction

M a i n p a r a me t e r s :

(must be checked and modified if necessary)

Code

Parameter description and choices

H5 Password

u0 System refrigerant

0 = R22 1 = R134a

5 = R410A

8 = R407A

12 = R449A

uP Installed pressure sensor type

0 = PT5-07x (for R22 / R134a / R507 / R404A / R407A / R407C /

1 = PT5-18x (for R410A/ R32)

2 = PT5-30x (for R410A / R744 / R32)

Next parameter/

3 = PT5-50x (for R744)

value (lower)

ut

Installed valve type

1 = EX4

5 = EX8

9 = FX7

O p t i o n a l p a r a me t e r s :

(recommended factory setting for majority of applications)

Code

Parameter description and choices

uu Start valve opening (%)

u9 Start opening duration (second)

uL Low superheat alarm function

0 = disable (for flooded evaporator)

1 = enable auto reset

Cut-out at 0.5K (if it maintains 1 min.); Cut-in immediately at 3K

u5 Superheat set-point (K)

If uL enabled (auto or manual)

If uL disabled

u2 MOP function

0 = disable 1 = enable

u3 MOP set-point (°C) saturation temperature

**) Factory setting is according to selected refrigerant (u0):

+13°C — R22

+7°C — R404A

+50°C — R124

+10°C — R407F

+12°C — R449A

+24°C — R1234ze

*) Min. and Max. setting values are dependant to selected type of

refrigerant

┌┘

5 Units conversion (only for u3, u5,

0 = °C, K, bar 1 = °F, R, psig

(Psig values are divided by 10. Example: Display 12.5 is 125 psig)

┌┘

1 Value to show

0 = Measured superheat (K) 1 = Measured evaporating pressure, (bar);

2 = Valve opening (%)

4 = Calculated evaporating temperature (°C) from the pressure

u4 Superheat control mode

0 = Standard,

2 = intermediate control

b1 Battery error management, when battery is

defective, see below

value

0

1

2

3

When setting b1 to option 0 or 1, the user must ensure appropriate

!

safety precautions are in place to protect the system against damage

caused by a power failure.

uF Control range valve %

*) Notes for R32: R32 is classified as low flammable refrigerant in Europe. EC3-

X33 is designed under consideration of European safety standards and directives

for none flammable refrigerants. The use of EC3-X33 with R32 is for

systems/regions which it does not require consideration of additional safety

standards as for flammable refrigerant.

After selecting the parameters the EC3-X33 is fully functional without

keypad/display unit. ECD-002 may be removed or connected at any time.

Date: 03.04.2017

2 = R507 3 = R404A

6 = R124 7 = R744 (subcritical application)

9 = R407F

10 = R32*

13 = R450A

14 = R513A

R407F / R124 / R448A /R449A / R450A / R513A /

R1234ze)

2 = EX5

3 = EX6

6 = FX5

7 = FX6

10 = FX7.5

11 = FX8

2 = enable manual reset

+15°C — R134a

+15°C — R407C

-5°C — R744

+10°C — R32

+19°C — R450A

┌┘

1)

3 = Measured coil-out temperature (°C)

1 = Slow

Alarm

display

Alarm relay

Valve

—

—

Regulating

Ab

—

Regulating

Ab

Signalling

Fully close

Ab

Signalling

Fully close

(blinking)

EC3-X33_OI_ML_R12_865009.docx

Factory

Field

Min Max

setting

setting

1

199

12

0

16

1

4 = R407C

11 = R448A

15 = R1234ze

0

3

0

1

12

5

4 = EX7

8 = FX6.5

12=FX9

Factory

Field

Min Max

setting

setting

0

100

50

0

120

5

0

2

1

3

30

6

0.5

30

6

0

1

1

*

*

**

+7°C — R507

+15°C — R410A

+10°C — R407A

+12°C — R448A

+13°C — R513A

0

1

0

0

4

0

0

2

0

0

3

2

Reset possibility after

recovery/replacement

—

—

Auto

Manual

5

100

100

Specifications:1588/1588914-ec3x33.pdf file (17 Mar 2023) |

Accompanying Data:

Emerson EC3-X33 Controller, Monitor PDF Operating Instruction (Updated: Friday 17th of March 2023 09:50:56 PM)

Rating: 4.4 (rated by 25 users)

Compatible devices: DIXELL XR77CHC, PMAC II Solo, Dixell Wing XW263L, Bettis G10 Series, DSM314, TESCOM 44-1300 Series, EC3-751, Unidrive M400.

Recommended Documentation:

Text Version of Manual, Operating Instruction

(Ocr-Read Summary of Contents of some pages of the Emerson EC3-X33 Document (Main Content), UPD: 17 March 2023)

-

11, Instructions de service EC3-X33 Contrôleur de surchauffe et afficheur déporté ECD-002 Emerson Climate Technologies GmbH www.emersonclimate.eu Am Borsigturm 31 I 13507 Berlin I Germany Date: 03.04.2017 EC3-X33_OI_ML_R12_865009.docx Messages d’erreur: Code alarme Description Paramètre…

-

20, Emerson EC3-X33 Instruzioni operative Controllo del surriscaldamento EC3-X33 e Unità Display ECD-002 Emerson Climate Technologies GmbH www.emersonclimate.eu Am Borsigturm 31 I 13507 Berlin I Germany Date: 03.04.2017 EC3-X33_OI_ML_R12_865009.docx Dati Tecnici: Alimentazione 24 VAC ±10%; 50/60 Hz;…

-

24, Emerson EC3-X33 Руководство по эксплуатации Контроллер перегрева EC3-X33 и дисплей ECD-002 Emerson Climate Technologies GmbH www.emersonclimate.eu Am Borsigturm 31 I 13507 Berlin I Germany Date: 03.04.2017 EC3-X33_OI_ML_R12_865009.docx Тех�…

-

5, Betriebsanleitung EC3-X33 Überhitzungsregler mit ECD-002 Anzeige- / Einstelleinheit Emerson Climate Technologies GmbH www.emersonclimate.eu Am Borsigturm 31 I 13507 Berlin I Germany Date: 03.04.2017 EC3-X33_OI_ML_R12_865009.docx Beschreibung: EC3-X33 sind universelle Überhitzungsregler…

-

25, EC3-X33 Superheat Controller and ECD-002 Keypad / Display Unit Emerson Climate Technologies GmbH www.emersonclimate.eu Am Borsigturm 31 I 13507 Berlin I Germany Date: 03.04.2017 EC3-X33_OI_ML_R12_865009.docx 0 1 1a 1b 1c 1d 1e 2 2a…

-

Emerson EC3-X33 User Manual

-

Emerson EC3-X33 User Guide

-

Emerson EC3-X33 PDF Manual

-

Emerson EC3-X33 Owner’s Manuals

Recommended: C711WT, QD-4240, NSVS1151

-

UPS ZINTO A Series

Benutzerhandbuch ONLINE ZINTO A-Serie Deutsch: Seite 3 — 62English: Page 63 — 120Italia: Pagina 121 — 181 Deutschland Italien Schweiz ONLINE USV-Systeme AG Dreimühlenstr. 4 D-80469 München Phone +49 (0) 89 / 2423990-10 Fax +49 (0) 89 / 2423990-20 www.online-usv.de ONLINE UPS-Systems S …

ZINTO A Series 181

-

Danfoss FC 300

FC 300 Design GuideContents! How to Read this Design Guide ………………………………………….. 5″ How to Read this Design Guide ………………………………………………………… 5″ Approvals ………………………………………………………………… …

FC 300 309

-

Trane Tracer UC210

SAFETY WARNINGOnly qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualif …

Tracer UC210 72

-

Philips Dynalite DRC810DT

WMGD Pty Limited trading as Dynalite ABN 33 097 246 92 Unit 6, 691 Gardeners Road Mascot NSW 2020 Australia t +61 8338 9899 f +61 2 8338 9333 [email protected] dynalite-online.com DRC810DT SPDT Dry Contact Relay Controller Installation Manual contents Warning…… …

Dynalite DRC810DT 10

Additional Information:

Popular Right Now:

Operating Impressions, Questions and Answers: