Новости

11июл

С 2023 года ООО «Айпиком системс» стала дистрибьютором компании PAL Electronics Systems Ltd, производящей самые лучшие и функциональные GSM-модули в мире.

Подробнее

26янв

В продажу поступил GSM модуль «ДОМОВОЙ».

Подробнее

24янв

С 24 января произошло анонсируемое повышение цен на продукцию FAAC.

Подробнее

10янв

Информируем Вас о планируемом повышении цен на продукции FAAC c начала 2022 года.

Подробнее

ВНИМАНИЕ! Цены, указанные на сайте, действуют только при оформлении заказа на сайте. Система скидок, акции, бонусы не применяются при заказе по телефону. Менеджеры отдела продаж выставляют счета и предложения на основании розничного прайс-листа отдела продаж. Информация о наличии товаров указана ориентировочно. Точную информацию о наличии и сроках сообщает менеджер после оформления заказа (перед оплатой).

Производитель: FAAC

Модель: KIT746ERZ16

Артикул: KIT746ERZ16

Бонусные баллы: 8137

Наличие: На заказ 6 — 8 недель

Поставляется по запросу. Возможность поставки уточняйте у менеджера.

Отправить запрос:

Файлы для скачивания:

- Буклет — приводы для откатных ворот 2012г. (365.73KB)

- Каталог продукции FAAC полный 2012г. (7.08MB)

- Каталог продукции FAAC Россия 2015г. (8.08MB)

- Инструкция — привод FAAC серии 746 ER для откатных ворот (2.3MB)

- Запасные части FAAC привод отканых ворот 746 ER каталог чертежи (2.43MB)

- Каталог запасных частей FAAC полный 2017 г (1.8MB)

Автоматика для откатных ворот, комплект привода для откатных ворот FAAC 746ER Z16 самоблокирующийся. Привод для откатных ворот FAAC 746 ER со встроенным блоком управления 780 D, 230В. В комплекте с приводом ведущая шестеренка Z16 — 16 зубьев с модулем М4. Скороть движения полотна откатных ворот 9,5 м/мин. Магнитные концевые выключатели, масляная ванна. В комплект привода для откатных ворот FAAC 746 ER включена монтажная пластина (арт. 737816).

- Максимальная защита пользователя от механических травм обеспечивается двухдисковым сцеплением в масляной ванне и электронным энкодером.

- Самоблокирующийся привод для откатных ворот FAAC 746ER Z16 не требует установки электрозамков.

- Защищенный крышкой рычажный механизм разблокировки электро привода с помощью ключа.

- Магнитный концевой выключатель, упрощенная процедура установки магнитов в конечных положениях.

- Возможность регулировать горизонтальное и вертикальное положение крепления привода откатных ворот.

- Защищенная корпусом плата управления с упрощенной процедурой программирования функций с помощью дисплея.

Комплектация привода для откатных ворот 746 ER Z16 с пластиной для монтажа:

- привод со звездочкой и платой управления 780D (арт. 109776)

- магниты концевых выключателей

- ключ для разблокировки привода

- заглушки для крепежных отверстий.

- монтажная пластина (арт. 737816)

Дополнительное оборудование и аксессуары смотрите во вкладке Рекомендуемые

Характеристики привода для откатных ворот FAAC 746ER Z16 смотрите в разделе Характеристики

Характеристики встроенной платы управления 780D привода откатных ворот FAAC 746ER Z16:

- Напряжение электропитания ……………………………………………………………………… ~230 В (+6% -10%), 50 (60) Гц

- Потребляемая мощность ………………………………………………………………………….. 10 Вт

- Макс. мощность привода ………………………………………………………………………….. 1000 Вт

- Макс. потребление тока аксессуарами ………………………………………………………… 0,5 A

- Диапазон рабочих температур ……………………………………………………………………. -20°C ? +55°C

- Плавкие предохранители …………………………………………………………………………… 2

- Режимы работы ……………………………………………………………………………………….. Автоматический / Автоматический + Пошаговый / Полуавтоматический / Полуавтоматический + Пошаговый / Безопасность / Полуавтоматический B / Присутствие оператора C / Смешанный B/C

- Время работы ………………………………………………………………………………………….. (от 0 до 4 мин)

- Время автоматического закрывания …………………………………………………………….. (от 0 до 4 мин)

- Толкающее усилие …………………………………………………………………………………… Регулируется, 50 уровней

- Входы на клеммной колодке ………………………………………………………………………. Открыть — Частично открыть — Устройства безопасности при открывании — Устройства безопасности при закрывании — Стоп — Профиль безопасности — Электропитание + Земля

- Гнездовые разъемы …………………………………………………………………………………… Концевые выключатели открывания и закрывания / Конденсатор привода

- Выходы на клеммной колодке ……………………………………………………………………… Сигнальная лампа / Привод / Электропитание аксессуаров =24 В / Лампа-индикатор =24 В / Запрограммированный по времени контактный выход / Управление электрозамком / Светофор — Failsafe (Тест фотоэлементов)

- Разъем …………………………………………………………………………………………………….. 5-штыревой разъем для плат Minidec, декодера или радиоприемников RP

- Средство программирования ………………………………………………………………………… 3 кнопки (+, -, F) и дисплей, основные и дополнительные настройки

- Функции, программируемые в основных настройках …………………………………………. Режим работы — Время автоматического закрывания — Толкающее усилие — Направление движения ворот — Закрывание

- Функции, программируемые в дополнительных настройках ………………………………… Пусковой крутящий момент — Торможение — Failsafe (Тест отоэлементов) — Предварительное включение сигнальной лампы — Лампа-индикатор / Запрограммированный по времени контактный выход / Электрозамок при открывании и закрывании — Режим работы устройств безопасности при открывании и закрывании — Энкодер / Чувствительность устройства защиты от механических травм

- Замедление — Время частичного открывания — Время работы — Требование выполнить техническое обслуживание — Счетчик рабочих циклов

- Сигнализация состояния системы ………………………………………………………………….. Дисплей

| Общие характеристики | |

| Категория | Откатные компл. |

| Питание | ~230 В, 50 (60) Гц |

| Интенсивность использования | 70 процентов |

| Потребляемая мощность | 300 Вт |

| Потребляемый ток | 1,5 А |

| Класс защиты | IP 44 |

| Рабочая температура | -20°C ÷ +55°C |

| Характеристики приводов | |

| Максимальная ширина створки | 8 м |

| Максимальный вес створки | 600 кг |

| Скорость ворот | 9.5 м/мин |

| Максимальное усилие | 62.5 даН |

| Питание двигателя | ~220 В |

| Термозащита | 120°C |

| Тип масла | FAAC HP OIL |

| Передаточное отношение | 1:30 |

| Скорость вращения двигателя | 1400 об/мин |

| Тип привода | Масляная ванна |

| Тип концевых выключателей | Магнитные |

| Характеристики откатных приводов | |

| Зубчатая рейка | мод 4 |

Написать отзыв

Ваше имя:

Ваш отзыв:

Примечание: HTML разметка не поддерживается! Используйте обычный текст.

Оценка: Плохо

Хорошо

Введите код, указанный на картинке:

Каталоги и буклеты FAAC. Автоматика для ворот, шлагбаумы, болларды, автоматические двери

…»

Руководства FAAC по монтажу и эксплуатации приводов откатных ворот. Инструкции по настройке и эксплуатации блоков управления откатных ворот и аксессуаров.

…»

Совместимость аксессуаров с блоками управления, автоматикой, шлагбаумами и барьерами FAAC. Совместимость радиоприемников и пультов, сигнальных ламп, фотоэлементов FAAC.

Совместимость радиоприемников, блоков управления и автоматики FAAC

…»

Каталог запасных частей для автоматических шлагбаумов FAAC 620 RPD. Запчасти для автоматических шлагбаумов FAAC 620 RPD.

*Для получения более детальной информации скачайте каталог запасных частей автоматического шлагбаума FAAC 620 RPD с чертежами по ссылке в конце страницы.

Сборочный чертеж ав …»

- Home

- Инструкции

- Автоматика для ворот

- FAAC

- 746

FAAC 746 инструкция

Язык: Русский

Размер : 1.8 Mb

Формат файла: pdf

Добавлен: 04.06.2013

Руководство по установке и использованию

Предварительный просмотр

Информация, описание, технические характеристики изделия

Описание и информация о технических характеристиках по данному изделию пока что отсутствует. Содержание во всех разделах сайта периодически обновляется. Попробуйте зайти на страницу позже.

Отзывы по оборудованию и комментарии к материалу

Здесь можно оставить свои отзывы по оборудованию «FAAC 746 — Откатные ворота», а также написать комментарии к материалу.

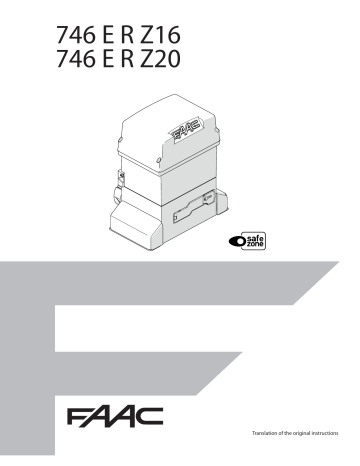

746 E R Z16

746 E R Z20

Translation of the original instructions

© Copyright FAAC S.p.A. dal 2018. Tutti i diritti riservati.

Nessuna parte di questo manuale può essere riprodotta, archiviata, distribuita a terzi

né altrimenti copiata, in qualsiasi formato e con qualsiasi mezzo, sia esso elettronico,

meccanico o tramite fotocopia, senza il preventivo consenso scritto di FAAC S.p.A.

Tutti i nomi e i marchi citati sono di proprietà dei rispettivi fabbricanti.

I clienti possono effettuare copie per esclusivo utilizzo proprio.

Questo manuale è stato pubblicato nel 2018.

© Copyright FAAC S.p.A. from 2018. All rights reserved.

No part of this manual may be reproduced, archived, distributed to third parties nor

copied in any other way, in any format and with any means, be it electronic, mechanical

or by photocopying, without prior written authorisation by FAAC S.p.A.

All names and trademarks mentioned are the property of their respective manufacturers.

Customers may make copies exclusively for their own use.

This manual was published in 2018.

© Copyright FAAC S.p.A. depuis 2018. Tous droits réservés.

Aucune partie de ce manuel ne peut être reproduite, archivée ou distribuée à des tiers

ni copiée, sous tout format et avec tout moyen, qu’il soit électronique, mécanique ou

par photocopie, sans le consentement écrit préalable de FAAC S.p.A.

Tous les noms et les marques cités sont la propriété de leurs fabricants respectifs.

Les clients peuvent faire des copies pour leur usage exclusif.

Ce manuel a été publié en 2018.

© Copyright FAAC S.p.A. ab dem 2018. Alle Rechte vorbehalten.

Kein Teil dieses Handbuchs darf reproduziert, gespeichert, an Dritte weitergegeben

oder sonst auf eine beliebige Art in einem beliebigen Format und mit beliebigen

Mitteln kopiert werden, weder mit elektronischen, noch mechanischen oder durch

Fotokopieren, ohne die Genehmigung von FAAC S.p.A.

Alle erwähnten Namen und Marken sind Eigentum der jeweiligen Hersteller.

Die Kunden dürfen nur für den Eigengebrauch Kopien anfertigen.

Dieses Handbuch wurde 2018 veröffentlicht.

© Copyright FAAC S.p.A. del 2018. Todos los derechos están reservados.

No puede reproducirse, archivarse, distribuirse a terceros ni copiarse de ningún modo,

ninguna parte de este manual, con medios mecánicos o mediante fotocopia, sin el

permiso previo por escrito de FAAC S.p.A.

Todos los nombre y las marcas citadas son de propiedad de los respectivos fabricantes.

Los clientes pueden realizar copias para su uso exclusivo.

Este manual se ha publicado en 2018.

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Tel. +39 051 61724 - Fax +39 051 09 57 820

www.faac.it - www.faacgroup.com

© Copyright FAAC S.p.A. van 2018. Alle rechten voorbehouden.

Niets uit deze handleiding mag gereproduceerd, gearchiveerd, aan derden openbaar

gemaakt of op andere wijze gekopieerd worden, in om het even welke vorm en

met geen enkel middel, noch elektronisch, mechanisch of via fotokopiëren, zonder

schrfitelijke toestemming vooraf van FAAC S.p.A.

Alle vermelde namen en merken zijn eigendom van de respectievelijke fabrikanten.

De klanten mogen kopieën maken die enkel voor eigen gebruik bestemd zijn.

Dez handleiding werd in 2018 gepubliceerd.

The Manufacturer

(2006/42/EC ANNEX II P.1, B)

Company name:

FAAC S.p.A. Soc. Unipersonale

Manufacturer and person authorised to prepare the relevant technical documentation

Address:

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Company name:

FAAC S.p.A. Soc. Unipersonale

hereby declares on his sole responsibility that the following products:

Address:

Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Description:

Gearmotor for sliding gates

hereby declares that for the partly completed machinery:

Models:

746 E R Z16, 746 E R Z20

Description:

Gearmotors for sliding gates

Model:

746 E R Z16, 746 E R Z20

comply with the following applicable EU legislations:

The essential requirements of the Machinery Directive 2006/42/EC (including

all applicable amendments) that have been applied and fulfilled are as follows:

1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.3, 1.2.5, 1.2.6, 1.3.1, 1.3.2,

1.3.4, 1.3.6, 1.3.9, 1.4.1, 1.4.2.1, 1.5.1, 1.5.2, 1.5.5, 1.5.6,

1.5.7, 1.5.8, 1.5.10, 1.5.11, 1.5.13, 1.6.1, 1.6.4, 1.7.1,

1.7.2, 1.7.3, 1.7.4.2, 1.7.4.3

and that the relevant technical documentation has been compiled in compliance

with part B of Annex VII.

Furthermore, the following harmonised standards have been applied:

EN 12100:2010

EN 13849-1:2015

EN 13849-2:2012

2014/30/EU

2011/65/EU

Furthermore, the following harmonised standards have been applied:

EN 61000-6-2:2005

EN 61000-6-3:2007 + A1:2011

Bologna, Italy, 01-04-2018

CEO

A. Marcellan

Other standards applied:

EN 12453:2017

And also undertakes to transmit, in response to a reasoned request by the national authorities, relevant information on the partly completed machinery by mail or e-mail.

Finally, the manufacturer declares that the above-mentioned partly completed

machinery must not be put into service until the final machine in which it is to be

incorporated has been declared compliant with the requirements of the abovementioned Machinery Directive 2006/42/EC.

Bologna, Italy, 01-04-2018

746 E R

3

CEO

A. Marcellan

732099 - Rev.D

ENGLISH

DECLARATION OF INCORPORATION FOR PARTLY

COMPLETED MACHINERY

Translation of the original instructions

EU DECLARATION OF CONFORMITY

CONTENTS

EU Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Declaration of incorporation for partly completed machinery3

1. INTRODUCTION TO THIS INSTRUCTION MANUAL . . . . . . . . . . 5

1.1 Meaning of the symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Translation of the original instructions

ENGLISH

2. SAFETY RECOMMENDATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Installer safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Unpacking and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vent closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Disposal of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

6

6

7

7

7

3. 746 E R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Limitations of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Unauthorised use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Emergency use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Component identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Components supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Components supplied separately. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9 Manual operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Releasing the gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Restoring operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Mechanical requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Example system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Installation dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

12

12

13

14

5. MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Installing the foundation plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Installing the gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open the vent hole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Installing the rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steel rack - Weld-on fastenings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steel rack - Screw-on fastenings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nylon rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Adjusting and checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Fastening the gearmotor permanently . . . . . . . . . . . . . . . . . . . . . . .

5.6 Installing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

15

15

16

16

17

17

18

19

20

20

21

746 E R

24

25

25

25

26

26

8. START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Installing the limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Programming the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restoring factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Operating logics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Adjusting the anti-crushing system . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limiting the static force. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obstacle detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

27

28

29

29

30

31

31

31

31

9. PUTTING INTO SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.1 Final operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Flashing light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Photocells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Sensitive edges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 LED/timed lamp, traffic light control, electric lock . . . . . . . . .

32

32

33

34

34

11. DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Connection status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Status of the automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Request assistance alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

35

35

35

12. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

12.1 Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

13. INSTRUCTIONS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Safety recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Emergency use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Releasing the gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restoring operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

38

39

39

39

39

TABLES

1 Symbols: notes and warnings on the instructions. . . . . . . . . . . . . 5

2 Symbols: safety signs and symbols (EN ISO 7010) . . . . . . . . . . . . . 5

3 Symbols: personal protective equipment . . . . . . . . . . . . . . . . . . . . . . 5

4 Symbols: warnings on packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Technical data (referring to 230 V~ 50 Hz/115 V~ 60 Hz) . . . . . 9

6 Symbols: tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Board technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Basic programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9 Advanced Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 LEDs on the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11 Status of the automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

12 Scheduled maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6. OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Release lock with personalised key . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7. ELECTRONIC INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Removing the cover from the board . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Board 780D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic limit stop sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control devices and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radio receiver/decoder board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earthing the gearmotor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Installing the cable glands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Installing the board cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

22

22

22

22

23

23

23

23

23

23

23

ADDENDUM

1 Foundation for leaves of max weight and width . . . . . . . . . . . . . 40

4

732099 - Rev.D

1. INTRODUCTION TO THIS INSTRUCTION MANUAL

This manual provides the correct procedures and requirements for

installing 746 E R and maintaining it in a safe condition.

When drafting the manual, the results of the risk assessment conducted by FAAC S.p.A. on the entire product life cycle have been taken

into account in order to implement effective risk reduction measures.

The following stages of the life cycle of the product have been considered:

- Delivery/handling

- Assembly and installation

- Set-up and commissioning

- Operation

- Maintenance/troubleshooting

- Disposal at the end of the product’s life cycle

Risks arising from installation and using the product have been taken

into consideration; these include:

- Risks for the installation/maintenance technician (technical

personnel)

- Risks for the user of the automation system

- Risks to product integrity (damage)

In Europe, the automation of a gate falls under the Machinery Directive

2006/42/EC and the corresponding harmonised standards. Anyone

automating a gate (new or existing) is classified as the Manufacturer

of the Machine. They are therefore required by law, among other

things, to carry out a risk analysis of the machine (automatic gate in

its entirety) and take protective measures to fulfil the essential safety

requirements specified in Annex I of the Machinery Directive.

FAAC S.p.A. recommends that you always comply with the EN 12453

standard and in particular that you adopt the safety criteria and devices indicated, without exception, including the dead-man function.

This manual also contains general information and guidelines, which

are purely illustrative and not exhaustive, in order to facilitate the activities carried out by the Manufacturer of the Machine in all respects

with regard to carrying out the risk analysis and drafting the instructions for use and maintenance of the machine. It should be clearly

understood that FAAC S.p.A. accepts no liability for the reliability and/

or completeness of the above instructions. As such, the manufacturer

of the machine must carry out all the activities required by the Machinery Directive and the corresponding harmonised standards on the

basis of the actual condition of the locations and structures where the

product 746 E R will be installed, prior to commissioning the machine.

These activities include the analysis of all the risks associated with

the machine and subsequent implementation of all safety measures

intended to fulfil the essential safety requirements.

This manual contains references to European standards. The automation of a gate must fully comply with any laws, standards and

regulations applicable in the country where installation will take place.

1.1 MEANING OF THE SYMBOLS USED

RECYCLING AND DISPOSAL - The materials used in manufacturing, the batteries

and any electronic components must not be sent to landfill. They must be

taken to authorised recycling and disposal centres.

FIGURE E.g. 1-3 see Figure 1 - item 3.

TABLE E.g. 1 see Table 1.

§

CHAPTER/SECTION

E.g. §1.1 see Section 1.1.

STATUS OF THE LEDS ON THE BOARD

LED off LED on LED flashing

2 Symbols: safety signs and symbols (EN ISO 7010)

GENERIC HAZARD

Personal injury hazard or risk of damage to components.

ELECTROCUTION HAZARD

Risk of electric shock from live parts.

CRUSHING HAZARD

Risk of crushing to the hands/feet due to the presence of

heavy parts.

CUTTING/AMPUTATION/PUNCTURE HAZARD

Cutting hazard due to the presence of sharp components or the

use of pointed/sharp tools (drill).

SHEARING/TRAPPING HAZARD

Risk of fingers and hands being sheared or trapped due to

moving parts.

BURNING OR SCALDING HAZARD

Risk of burns due to the presence of high-temperature parts.

otherwise specified, the measurements provided in the instructions

Unless

are in mm.

3 Symbols: personal protective equipment

Personal protective equipment must be worn to protect against hazards (e.g. crushing,

cutting, shearing etc.):

Obligation to wear mask/goggles to protect the eyes from the risk of fragments due to the use of drill or welder.

Obligation to wear work gloves.

Obligation to wear safety footwear.

746 E R

5

ENGLISH

F

!

Symbols: notes and warnings on the instructions

WARNING ELECTRIC SHOCK HAZARD - The operation or step described must

be carried out following the instructions provided and according to the safety

regulations.

WARNING, personal injury hazard or risk of damage to components - The

operation or step described must be carried out following the instructions

provided and according to the safety regulations.

WARNING - Details and specifications which must be respected in order to

ensure that the system operates correctly.

732099 - Rev.D

Translation of the original instructions

1

2. SAFETY RECOMMENDATIONS

2.2 TRANSPORT AND STORAGE

This product is placed onto the market as “partly completed machinery”, therefore it cannot be commissioned until the machine in which

it will be incorporated has been identified and declared to conform

to the Machinery Directive 2006/42/EC by the actual Manufacturer.

Translation of the original instructions

ENGLISH

!

!

Follow the instructions on the package

4 Symbols: warnings on packaging.

Incorrect installation and/or incorrect use of the product might cause serious

harm to people. Read and comply with all the instructions before starting

any activity on the product. Keep these instructions for future reference.

Perform installation and other activities adhering to the sequences provided

in the instructions manual.

Always comply with all the requirements contained in the instructions and

warning tables at the beginning of the paragraphs. Always comply with

the safety recommendations.

Only the installer and/or maintenance technician is authorised to work on

the automation components. Do not modify the original components in

any way.

Close off the work site (even temporarily) and prevent access/transit. EC

countries must comply with the legislation that transposes the European

Construction Site Directive 92/57/EC.

Handle with care. Presence of fragile parts.

Up indication.

Keep away from water and moisture.

3

Maximum number of stacked packages.

CE marking.

The installer is responsible for the installation/testing of the automation and for completing the Register of the system.

The installer must prove or declare to possess technical and professional proficiency to perform installation, testing and maintenance

activities according to the requirements in these instructions.

PALLETISED SUPPLY

RISKS

PERSONAL PROTECTIVE EQUIPMENT

!

2.1 INSTALLER SAFETY

Installation activities require special work conditions to reduce to the

minimum the risks of accidents and serious damage. Furthermore,

the suitable precautions must be taken to prevent risks of injury to

persons or damage.

!

The installer must be in good physical and mental condition, aware of and

responsible for the hazards that may be generated when using the product.

The work area must be kept tidy and must not be left unattended.

Do not wear clothes or accessories (scarves, bracelets, etc.) that may get

caught in moving parts.

Always wear the personal protective equipment recommended for the type

of activity to be carried out.

The required level of workplace lighting must be equal to at least 200 lux.

Operate CE marked machinery and equipment in compliance with the

manufacturer's instructions. Use work instruments in good conditions.

Use the transport and lifting equipment recommended in the instructions

manual.

Use safety-compliant portable ladders of adequate size, fitted with anti-slip

devices at the top and bottom, equipped with retainer hooks.

Follow the instructions on the packaging

during handling.

Use a forklift or pallet truck, following safety

regulations to avoid the risk of impacts or

collisions.

SINGLE PACKAGE

RISKS

PERSONAL PROTECTIVE EQUIPMENT

!

Follow the instructions on the packaging during

handling.

For manual lifting, there should be one person for every

20 kg to be lifted.

STORAGE

Store the product in its original packaging, in closed and dry premises,

protected from the sun and free from dust and aggressive substances.

Protect from mechanical stress. If stored for more than 3 months,

regularly check the condition of the components and the packaging.

- Storage temperature: 5°C to 30°C.

- Percentage of humidity: 30% to 70%.

746 E R

6

732099 - Rev.D

2.3 UNPACKING AND HANDLING

RISKS

PERSONAL PROTECTIVE EQUIPMENT

A

1. Open the package and remove the contents.

- Do not lift the gearmotor by the cover or the electronic

board. Grip the body of the gearmotor using the handholds A

(1).

2. Check that all components are present and intact (See § Component

identification).

ENGLISH

1

The packaging materials (plastic, polystyrene etc.) must not be left within

reach of children as they are potential sources of danger.

When you have finished with them, dispose of the packaging in the appropriate containers, as per applicable waste disposal regulations.

2

VENT CLOSURE

!

The 746 E R is supplied with the vent hole closed with a screw and washer

(2). Whenever the gearmotor is handled, the vent must be closed to

prevent oil leaking out.

4

1

2

3

4

3

Gearmotor 746 E R

Gearmotor bracket guards and Hardware/accessories

Limit switches

Instruction manual

1

2.4 DISPOSAL OF THE PRODUCT

After having dismantled the product, dispose of it in compliance with

the current waste disposal regulations.

Components and structural materials, batteries and electronic components

must not be disposed of together with household waste. They must be taken

to authorised disposal and recycling centres.

The oil must be gathered in a watertight container and given to an authorised

disposal and recycling centre. Do not mix with other substances such as

antifreeze or transmission fluids. Keep the used oil away from sources of

heat and out of the children's reach. The fluid is not hazardous to health. In

case of contact with eyes, skin or clothing, wash and rinse the affected parts.

The technical data sheets of the fluids are available on request.

7

2

746 E R

7

732099 - Rev.D

Translation of the original instructions

!

A

3. 746 E R

3.1 INTENDED USE

3.3 UNAUTHORISED USE

Translation of the original instructions

ENGLISH

FAAC746 E R series gearmotors are designed to operate horizontal

sliding gates for residential buildings / apartment complexes.

Only one gearmotor must be installed for each leaf. The system

requires a special foundation plate, supplied separately, which is

embedded in a plinth. The gate must be moved via a rack.

The 746 E R is intended for installation on gates in areas that are accessible by people, the main purpose of which is to provide access

for goods, vehicles and people.

To move the gate manually, follow the instructions in section § Manual

operation.

!

- Uses other than the intended use are prohibited.

- It is prohibited to install the automation system outside of the

limits specified in the Technical Data and Installation Requirements sections.

- It is forbidden to use 746 E R in a constructional configuration

other than the one provided by the manufacturer.

- No component part of the product may be modified.

- It is prohibited to install the automation system on escape routes.

- It is prohibited to install the automation system to create fire

doors.

- It is prohibited to install the automation system in environments

in which there is a risk of explosion and/or fire: the presence of

flammable gases or fumes is a serious safety hazard.

- It is prohibited to power the system with energy sources other

than those specified.

- It is prohibited to integrate commercial systems and/or

equipment other than those specified, or use them for purposes

not intended and authorised by their respective manufacturers.

- Do not allow water jets of any type or size to come into direct

contact with the gear motor.

- Do not expose the gear motor to corrosive chemicals or atmospheric agents.

- It is prohibited to use and/or install accessories which have not

been specifically approved by FAAC S.p.A.

- It is prohibited to use the automation system before performing

commissioning.

- It is prohibited to use the automation system in the presence of

faults which could compromise safety.

- It is prohibited to use the automation system with the fixed and/

or mobile guards removed or altered.

- Do not use the automation system unless the area of operation

is free of persons, animals or objects.

- Do not enter/remain in the area of operation of the automation

system while it is moving.

- Do not try to prevent the movement of the automation system.

- Do not climb on, hold onto or let yourself be pulled by the

leaf. Do not climb onto the gear motor.

- Do not allow children to approach or play in the area of operation

of the automation system.

- Do not allow the control devices to be used by anyone who is

not specifically authorised and trained to do so.

- Do not allow the control devices to be used by children or persons

with mental and physical deficiencies unless they are supervised

by an adult who is responsible for their safety.

Any other use that is not expressly specified in these instructions is prohibited

and could affect the integrity of the product and/or represent a source of

danger.

3.2 LIMITATIONS OF USE

The maximum force required to move the leaf by hand over its entire

length of travel must be 225 N for residential areas and 260 N for

industrial or commercial areas.

The maximum force required to start the movement must be less

than the maximum torque at initial thrust of the operator indicated

in the technical data.

The leaf must fall within the dimensional and weight limits indicated

in the technical data.

The presence of weather conditions such as snow, ice and strong wind,

even occasional, could affect the correct operation of the automation,

the integrity of the components and be a potential source of danger

(see § Emergency use).

746 E R is not designed to be a security (break-in protection) system.

If there is a pedestrian access gate integrated in the leaf of the gate,

the motorised movement must be disabled when the pedestrian gate

is not in a safe position.

The installation must be visible during the day and at night. If it is

not, appropriate solutions must be provided to make the fixed and

moving parts visible.

Implementing the automation requires the installation of the necessary safety devices, identified by the installer through an appropriate

risk assessment of the installation site.

!

During manual operation, gently guide the leaf the whole way, do not push

it and let it slide freely.

3.4 EMERGENCY USE

In emergencies or if there is a fault, turn off the power supply to the

automation. If the leaf can be moved safely by hand, use the MANUAL

OPERATION mode; otherwise place the automation out of service until

it has been reset/repaired.

In the case of a breakdown, the automation must be reset/repaired

exclusively by the installer/maintenance technician.

746 E R

8

732099 - Rev.D

3.5 PRODUCT IDENTIFICATION

The product can be identified by the plate (3).

Italy

tttttt

FAAC S.p.A. Soc. Unipersonale

Via Calari, 10 - 40069 Zola Predosa BOLOGNA

Italy

PRODUCT WARNINGS

tttttt

746 E R Z16

The adhesive sign must be placed on the casing by the installer. It indicates

the risk of trapping fingers / hands due to the rotation of the pinion.

Adhesive sign on the casing. It indicates the breather screw that must be

removed before start-up.

tttttt

tttttt

tttt

tttt

FAAC tt

HP OIL

tttttt

tttt

Sale code

Product name

Month/year of production + Progressive number

for the month of production

Example:

0117 0001

* REFERS TO 230 V ~ - 50Hz

made in:

January 2017

Cod.

... MMYY PROG

tttttt

3.6 TECHNICAL SPECIFICATIONS

IDENTIFICATION NUMBER

3

5 Technical data (referring to 230 V~ 50 Hz/115 V~ 60 Hz)

746 E R Z16

Power supply voltage

220-240 V~ 50/60 Hz

Max power

400 W

Max thrust force

810 N

Max torque at initial thrust

345 N

Pinion

Z16 Module 4

Start-up capacitor

12.5 µF V~

Thermal protection

120°C automatic rearming

Max leaf length

40 m

Max leaf weight

600 kg

Leaf speed

9.6 m/min

Stopping space

40 mm

Type of use

Residential buildings/Apartment

complexes

Ambient operating temperature

-20 °C to +55 °C

Continuous use time (ROT)

90 min at 25°C 50 min at 55°C

Use frequency

70% at 25°C 50% at 55°C

Protection rating

IP44

Dimensions (LxDxH)

275x191x336 mm

Gearmotor weight

14 kg

Oil

FAAC HP OIL

9

746 E R Z20

220-240 V~ 50/60 Hz

400 W

650 N

275 N

Z20 Module 4

12.5 µF V~

120°C automatic rearming

50 m

400 kg

12 m/min

45 mm

Residential buildings/Apartment

complexes

-20 °C to +55 °C

90 min at 25°C 50 min at 55°C

70% at 25°C 50% at 55°C

IP44

275x191x336 mm

14 kg

FAAC HP OIL

746 E R Z20 [115 V]

115 V~ 50/60 Hz

400 W

650 N

275 N

Z20 Module 4

50 µF V~

120°C automatic rearming

50 m

400 kg

12 m/min

45 mm

Residential buildings/Apartment

complexes

-20 °C to +55 °C

90 min at 25°C 50 min at 55°C

70% at 25°C 50% at 55°C

IP44

275x191x336 mm

14 kg

FAAC HP OIL

732099 - Rev.D

Translation of the original instructions

ENGLISH

Electromechanical oil-bath gearmotor, supplied with a pinion for the

rack. Available in versions:

- 746 E R Z16 with pinion Z16

- 746 E R Z20 with pinion Z20

Irreversible system In order to be operated manually, the gearmotor

has to be released using the special key.

Magnetic encoder The encoder determines the position of the leaf

and the speed of movement.

Adjustable sensitivity obstacle detection The electronic board detects the

presence of an obstacle via the encoder. If an obstacle is detected

during opening or closing, the gate reverses for 1 s and then the

automation stops.

Force limitation The maximum force exerted by the gearmotor is

adjusted by means of the mechanical twin-disk clutch in oil-bath.

Magnetic limit switches To be fixed to the rack to set the opening and

closing stop positions.

End of travel slowdown Adjustable electronic slowdown near to the

open and closed positions.

Board 780D The built-in electronic board is equipped with a display,

programming buttons and a protective plastic cover.

Equipment required The following must be purchased:

- foundation plate

- rack (module 4)

746 E R

progressive:

0001

3.7 COMPONENT IDENTIFICATION

Translation of the original instructions

ENGLISH

COMPONENTS SUPPLIED

Gearmotor

1 Casing

2 Start-up capacitor

3 Transformer

4 Electronic board 780D with protective cover

5 Limit switch sensor

6 Pinion (Z16/Z20 Module 4) with hand guard

7 Anti-crushing clutch adjustment screw

8 Oil filler plug

9 Earth connector

10 Gearmotor body

11 Key release

12 Fastening brackets

1

7

8

2

3

Hardware/accessories

13 Gearmotor bracket guards

14 Cable glands to install in the board compartment

15 Casing screws with screw caps, terminal boards, cable lug for earth cable and

adhesive hazard warning sign

16 Closing and opening magnetic limit switches (magnets, spacers, mounting

hardware and screws)

4

9

5

10

6

11

12

COMPONENTS SUPPLIED SEPARATELY

The installation requires the following FAAC components that are

supplied separately:

17

Steel rack with spacers (to be screwed or welded on)

or

18

Nylon rack with mounting hardware - for leaves having a max weight of 400 kg

19

Foundation plate with mounting hardware

DANGER, AUTOMATIC MOVEMENT warning sign

13

14

17

15

18

16

19

5

746 E R

4

10

732099 - Rev.D

3.8 DIMENSIONS

Centre distances

243

82

ENGLISH

336

275

6

3.9 MANUAL OPERATION

Releasing the gearmotor

In order to operate the leaf manually, the gearmotor has to be released

using the key provided.

!

Disconnect the power supply from the automation before releasing the

gearmotor.

During manual operation, gently guide the leaf the whole way. Do not push

it and let it slide freely.

Do not leave the gearmotor in the released mode: restore automatic operation

after moving it manually.

RELEASING THE GEARMOTOR

90°

1. Open the lock cover.

2. Insert the key and turn it clockwise by 90°.

3. Open the release lever by 90° (7).

Restoring operation

RESTORING OPERATION

1. Close the release lever. Turn the key to the vertical position and

remove it (7).

2. Close the lock cover.

3. Move the leaf manually to make sure that the mechanical system

meshes correctly.

!

Make sure that the gate is at its opening or closing end of travel position (the

relative limit switch must be engaged) before turning the power back on and

operating the automation.

7

746 E R

11

732099 - Rev.D

Translation of the original instructions

191

4. INSTALLATION REQUIREMENTS

If the area of installation gives rise to the risk of impact by vehicles, provide

an appropriate protective structure to protect the gearmotor.

4.1 MECHANICAL REQUIREMENTS

The mechanical structural components must comply with the requirements of EN 12604. Before installing the automation, the suitability

of the mechanical requirements must be established and any work

that is necessary in order to meet them carried out.

The essential mechanical requirements are as follows:

Translation of the original instructions

ENGLISH

!

746 E R

4.2 ELECTRICAL SYSTEM

Solid ground to support the weight of the gate, the structures present and

the gearmotor. Flat, horizontal paving in the area of movement of the

leaf. There must be no chance of water accumulating in the installation area.

The structure (columns, guides, mechanical stops, leaf and counterweights)

must be solid and there must be no risk of detachment or collapse (considering

the weight of the leaf and the forces applied by the gearmotor and wind

action). Perform structural calculations where necessary.

The structure must show no signs of corrosion or cracking.

The leaf must remain vertical throughout the entire length of travel, with a

regular, smooth and uniform movement. The path along which the leaf slides

must be perfectly horizontal (the leaf must not have a tendency to open or

close spontaneously when it is released).

Appropriate devices must be installed to prevent the leaf from falling.

There should be a solid surface on the leaf sufficiently large to attach the

rack to.

The sliding guides must be in good condition; they must be straight and not

deformed, they must be fastened securely and there must be no obstacles

along their entire length. The diameter of the guide wheels must be

appropriate for the weight and length of the leaf and their profile section

must coincide with that of the sliding guide. The number and position of

the wheels must ensure an adequate and constant distribution of the weight.

A solid guide system for the suspended leaf in the case of a cantilever gate.

Presence of upper containing guide to prevent vertical oscillation of the

leaf. The leaf must not under any circumstances come out from its guides

and fall. Wheels, rollers and bearings in good condition, lubricated and

free from play or friction.

Presence of external mechanical limit stops to limit the travel of the leaf

when opening and closing. The stops must be suitably sized and solidly

fastened so that they resist any impact of the leaf in the event of improper

use (leaf pushed and left to slide freely). The mechanical limit stops must

be positioned at 50 mm beyond the stop position of the leaf, and must ensure

that the leaf remains inside its sliding guides.

The thresholds and protrusions of the paving must be appropriately shaped

in order to prevent the risk of sliding or slipping.

For the creation of detection loops, refer to the specific instructions.

Presence of a safety area between the wall (or other fixed element) and the

furthest protruding part of the open leaf, to protect against the risk of persons

becoming trapped/crushed. Alternatively, check that the opening force

required falls within the maximum permissible limits according to applicable

standards and legislation.

Presence of safety areas between the fixed and moving parts, to protect

against the risk of hands being trapped. Alternatively, apply protective

elements that prevent fingers from being introduced.

Presence of a safety area between the paving and lower edge of the leaf, along

its entire path, providing protection from the risk of feet becoming caught in

and crushed beneath the wheels. Alternatively, apply protective elements

preventing the introduction of feet.

No sharp edges or protruding parts should be present to ensure there are no

cutting, hooking or perforation hazards. Alternatively, eliminate or protect

any sharp edges and protruding parts.

No slots or openings should be present on the sliding leaf or the fencing to

prevent the creation of a shearing hazard. Alternatively, apply protective

mesh to any such openings. The mesh should be sufficiently fine to prevent

introduction of body parts requiring protection, in relation to the distance

between the fixed and moving parts.

For the minimum dimensions to prevent crushing/shearing of body parts,

refer to EN 349. For the safety distances required to prevent danger zones

being reached, refer to ISO 13857.

F

!

12

Always shut off the power supply before performing any work. If the

disconnect switch is not in view, apply a warning sign stating “WARNING Maintenance in Progress”.

The electrical system must comply with applicable legislation in the country

of installation.

Use components and materials with CE marking which are compliant with the

Low Voltage Directive 2014/35/EU and EMC Directive 2014/30/EU.

The power supply line for the automation must be fitted with a multi-pole circuit breaker, with a suitable tripping threshold, a contact opening distance of

at least 3 mm and a breaking capacity that complies with current regulations.

The power supply for the automation must be fitted with a 30 mA differential

switch.

The metal parts of the structure must be earthed.

Check that the protective earthing system complies with applicable regulations in the country of installation.

The electrical cables of the automation system must be of a size and insulation

class that is compliant with current legislation and laid in appropriate rigid

or flexible conduits, either above or below ground.

Use separate conduits for the power supply and the 12-24 V control devices

/ accessories cables.

Check buried cable plans to ensure that there are no other electrical cables

in proximity to the planned digging/drilling locations to prevent the risk of

electrocution.

Check that there are no pipes in the vicinity as well.

The conduit fittings and the cable glands must prevent the entry of moisture,

insects and small animals.

Protect extension connections using junction boxes with an IP 67 protection

rating or higher.

It is recommended to install a flashing light in a visible position to indicate

when it is moving.

For the creation of detection loops, refer to the relative instructions.

The control accessories must be positioned in areas that are always accessible

and not dangerous for the user. It is recommended to position the control

accessories within the field of view of the automation. This is mandatory in

the case of hold-to-run controls.

If an emergency stop button has been installed, it must be EN13850 compliant.

Comply with the following heights from the ground:

- control accessories = minimum 150 cm

- emergency buttons = maximum 120 cm

If the manual controls are intended to be used by disabled or infirm persons,

highlight them with suitable pictograms and make sure that these users are

able to access them.

732099 - Rev.D

4.3 EXAMPLE SYSTEM

Translation of the original instructions

ENGLISH

The example is an illustration only and is just one of the possible applications of the 746 E R (8).

1

Mains power supply

3G 1.5 mm2

2

Circuit breaker

3

Junction box

4

Gearmotor 746 E R

5

Photocell TX

6

Photocell RX

7

Key button

8

Flashing light

9

Mechanical stop

8

9

4

5

2

7

3

6

1

1

8

746 E R

13

732099 - Rev.D

4.4 INSTALLATION DIMENSIONS

■ FOUNDATION PLATE

Opening to the left

Opening to the right

50

50

144

60

60

275

0 … 50

0 … 50

■ RACK

Steel rack

275

12.5…28

50

50

77 (Z16)

85 (Z20)

60

113 (Z16)

121 (Z20)

Nylon rack

60

Translation of the original instructions

90°

90°

12.5…28

ENGLISH

144

9

746 E R

14

732099 - Rev.D

5. MECHANICAL INSTALLATION

!

The installation must comply with standard EN 12453. Mark off the work

site and prohibit access/transit.

Installation must be carried out when it is not raining. In case of rain, a

suitable shelter for the gearmotor must be provided until the mechanical and

electronic installation has been completed.

Never handle the gearmotor by the electronic board.

TOOLS REQUIRED

The tools required are indicated below ( 6).

!

Use appropriate tools and equipment in working environments which comply

with applicable legislation.

6 Symbols: tools

Drill bit for metal

3

M8

5, 6.5

Level

Angle grinder

Screw clamp

Welder

(for weld-on steel rack)

Threading tap

(for screw-on steel rack)

Wire strippers

Electrician's scissors

Flat-head screwdriver

PHILLIPS SCREWDRIVERS

2.5, 6

TORQUE WRENCH - if necessary for safety, a torque wrench and the TIGHTENING TORQUE will be specified

ENGLISH

Hex key

3, 8

E.g.: SPANNER 7 set at 2.5 Nm

x.x Nm

2.5 Nm

7

5.1 INSTALLING THE FOUNDATION PLATE

RISKS

19

PERSONAL PROTECTIVE EQUIPMENT

F

!

Carry out the work with the power supply disconnected.

70

- The 746 E R must be installed with the foundation plate.

- The characteristics of the foundation, indicated in the schematic diagram in

the appendix to this manual, are provided as a guideline only. The schematic

considers the 746 E R applied within the maximum limits indicated in this

manual and under the most arduous conditions. The installer is responsible

for the evaluation of the foundation materials and dimensions on the basis of

the characteristics of the ground and place of installation. Perform structural

calculations where necessary.

10

1. Assemble the foundation plate (10).

2. Make the hole in the ground. Fill it with concrete, making sure that

the cable conduits protrude in the correct position with respect

to the gearmotor. Place the plate at the centre of the foundation,

leaving its surface uncovered (11).

3. Clean any concrete from the surface of the plate and the nuts with

washers so that they can be subsequently adjusted. Check the

plate is horizontal using a spirit level.

4. Wait for the concrete to set.

~ 15 cm

pinion side

mechanical release side

11

746 E R

15

732099 - Rev.D

Translation of the original instructions

Spanner

7, 10, 13, 19

5.2 INSTALLING THE GEARMOTOR

RISKS

H = 20

PERSONAL PROTECTIVE EQUIPMENT

Translation of the original instructions

ENGLISH

F

Carry out the work with the power supply disconnected.

1. Make sure that the concrete of the plinth has set completely, then

adjust all the support nuts to the height H indicated (12).

2. Place the washers on the nuts.

3. Remove the cover from the gearmotor. Position the gearmotor in

correspondence with the 4 fasteners (13).

- Pass the electric cables through the hole on the base and as far

as the board.

!

12

Be careful not to damage the electrical cable tubes.

4. Make sure that the gearmotor is level. Position the washers and

nuts (14).

- Do not tighten the nuts so that the height can be adjusted when

the rack is being installed.

OPEN THE VENT HOLE

Open the vent hole by removing the breather screw and washer (15).

of oil may leak out after the vent hole has been opened, even

Aduefewtodrops

the initial movements.

Keep the screw and washer as they will have to be reinstalled if the gearmotor

has to be removed and subsequently transported.

13

keep the screw and

washer

746 E R

7

19

15

14

16

732099 - Rev.D

5.3 INSTALLING THE RACK

RISKS

!

PERSONAL PROTECTIVE EQUIPMENT

!

- DO NOT weld the spacers onto the racks.

- DO NOT weld the elements of the rack together.

- DO NOT apply grease or other lubricants to the racks.

!

ENGLISH

Mounting the rack involves moving the leaf manually several times.

Comply with the safety information § Manual operation.

STEEL RACK - WELD-ON FASTENINGS

!

Welding must be carried out in a workmanlike manner.

affected if it is carried out badly.

Safety may be

16

Translation of the original instructions

thickness:

Rack

8 mm for leaves weighing up to 400 kg max

12 mm for leaves weighing more than 400 kg

1. Prepare all the elements of the rack that are required for the length

of the leaf (16):

- screw 3 spacers onto each element of the rack

- position the spacers so that they touch the top of the slots,

this will allow future adjustments if the guide were to move

downwards

- if an element of the rack needs to be shortened, cut it with an

angle grinder away from the slot.

2. Open the leaf manually.

3. Rest an element of the rack on the pinion. Make sure that it is level

using a spirit level and secure it to the leaf using a screw clamp.

4. Weld the first spacer to the leaf (17), then move the leaf with the

rack resting on the pinion. Make sure that it is horizontal and weld

on the other spacers.

!

17

Protect the gearmotor from weld spatter. DO NOT connect the earth of the

welder to the gearmotor.

5. Move the leaf. Rest the next element of the rack on the pinion so that

it touches the previous element.

- Line up the teeth by resting them on an element of the rack and

assemble temporarily using screw clamps (18).

6. Make sure that it is horizontal using a spirit level. Weld the spacers

(as in step 4). Remove the screw clamps.

7. Repeat from step 5 for all elements of the rack.

18

746 E R

17

732099 - Rev.D

STEEL RACK - SCREW-ON FASTENINGS

thickness:

Rack

8 mm for leaves weighing up to 400 kg max

Translation of the original instructions

ENGLISH

12 mm for leaves weighing more than 400 kg

The rack installation accessories contain screws for aluminium or steel

leaves. Use specific screws for other materials.

!

1. Open the leaf manually.

2. Rest an element of the rack on the pinion.

3. Place a spacer between the rack and the leaf. Make sure that it is

horizontal using a spirit level. Mark the hole to be drilled on the

leaf (19).

- Position the spacers so that they touch the top of the slots, this will

allow future adjustments if the guide were to move downwards.

4. Drill the hole and make a thread in it (20).

5. Fasten using the screw and washer (21).

6. Move the leaf with the rack resting on the pinion. Repeat steps 3 ...

5 for the other fixing points.

7. Move the leaf. Rest the next element of the rack on the pinion so that

it is touching the previous element.

- Line up the teeth by resting them on an element of the rack and

assemble temporarily using screw clamps (22).

8. Repeat steps 3 ... 6 for the other fixing points. Remove the screw

clamps.

9. Repeat from step 7 for all elements of the rack that are required for

the length of the leaf.

- If an element of the rack needs to be shortened, cut it with an

angle grinder away from the slot.

19

6.5

M8

20

13

22

746 E R

21

18

732099 - Rev.D

NYLON RACK

Rack thickness: 20 mm for leaves weighing up to 400 kg max.

5

1. Close the leaf manually.

2. Rest an element of the rack on the pinion (23). Make sure that it

is horizontal using a spirit level.

3. Drill holes at the centre of the slots (1). Fasten using suitable screws

and washers.

Use fixing screws that are specific for the material from which the leaf is

made. Self-tapping screws and washers are available for aluminium or steel

and should be ordered separately (2).

4. Move the leaf manually. Assemble the next interlocking element at

the end of the previous one and rest it on the pinion (24). Make

sure that it is horizontal using a spirit level.

5. Drill holes at the centre of the slots. Fasten using suitable screws

and washers.

6. Repeat steps 4 and 5 for all elements of the rack that are required for

the length of the leaf.

- If an element needs to be shortened, cut it with an angle grinder

away from the slot.

ENGLISH

!

5

Translation of the original instructions

1

2

TE 6.3 x 25 UNI 6950

6.5 x 18 x 2 UNI 6953

23

10

24

746 E R

19

732099 - Rev.D

5.4 ADJUSTING AND CHECKING

1. In order for it to work correctly, the rack must never rest on the

pinion. Turn all the support nuts clockwise by half a turn (25)

in order to lower the gearmotor. In this way, a constant distance

between pinion and rack is obtained for the entire length of

travel (26-A). Make sure that the gearmotor is level by using

a spirit level.

2. Check: when the distance between rack and pinion is correct, with

the gearmotor stopped, it is possible to rock the leaf manually to

the left and right by a few millimetres.

3. Make sure that the rack is centred on the pinion (26-B).

Move the leaf manually to repeat the checks along the entire length

of travel for all the elements of the rack.

ENGLISH

!

19

Comply with the safety information § Manual operation.

5.5 FASTENING THE GEARMOTOR PERMANENTLY

1. Tighten the upper nuts to the fastening torques indicated in the

figure (27).

2. Press the guards onto the brackets (28).

180°

Translation of the original instructions

25

3 mm

=

=

A

!

B

!

26

80

Nm

28

746 E R

19

27

20

732099 - Rev.D

5.6 INSTALLING THE COVER

!

1

The cover protects the electronic components and prevents access to moving

parts. Never leave the gearmotor unattended without the cover fitted until

installation has been completed.

8

Install the cover once the gearmotor has been set-up.

29

6. OPTIONAL EQUIPMENT

6.1 RELEASE LOCK WITH PERSONALISED KEY

1. Open the release lever using the key. Remove the screw and the

locking lever, then remove the nut and the existing lock (30).

2. Install the new lock and fasten it using the nut. Insert the locking

lever vertically and fasten it using the screw (31).

3. Make sure that the release lever works, using the new keys.

8

8

24

24

31

746 E R

30

21

732099 - Rev.D

Translation of the original instructions

ENGLISH

With reference to 29, apply the adhesive sign 1 to the cover: risk

of fingers and hands being trapped due to the rotation of the pinion

and the movement of the rack. Install and fasten the cover. Press

the screw caps on.

7. ELECTRONIC INSTALLATION

RISKS

PERSONAL PROTECTIVE EQUIPMENT

7.1 REMOVING THE COVER FROM THE BOARD

Remove the casing cover and lift the board cover (33). Temporarily

remove the thrust capacitor in order to make this easier.

33

7.2 BOARD 780D

L N

CAP

60 W max

MOT2

MOT1

MOT COM

N

L

M

L AM P

+

J5

F

J8

J9

L N PE 17 16 15 14 13

J7

-

J6

8.8.

F1

display

SAFE

Led

STOP

J1

FC1

FC2

FSW CL

J2

F2

J4

FSW OP

OPEN B

OPEN A

J3

1 2 3 4 5 6 7 8 9 10 11 12

L

N

PE

Translation of the original instructions

Only remove the board cover in order to work on electrical connections. Disconnect the power supply to the automation before removing the cover of the

electronic board. Only reconnect the power supply after having reinstalled

the cover.

The board must be programmed with the board cover installed.

W.L.

TX-FSW

{

ENGLISH

F

24 V

500 mA

max

SAFE

STOP

FSW CL

FSW OP

OPEN B

OPEN A

32

COMPONENTS

STATUS LEDS

Removable terminal board for control devices and accessories (provided in the

hardware/accessories)

J2

Connector (5-pin) for radio/decoder boards (as indicated in the FAAC catalogue)

J3-J4 Transformer connectors

J5

Rapid connector for start-up capacitor

J6

Removable terminal board for motor and flashing light

Removable terminal board for mains power supply (provided in the hardware/

J7

accessories)

J8

Rapid connector for inductive limit switch

J9

Rapid connector for magnetic limit switch

F1 Fuse for mains power supply F 5 A (230 V~) F 10 A (115 V~)

F2 Fuse for accessories power supply T 0.8 A

+ - F Programming buttons

FC1 FC2

SAFE

STOP

FSW CL

FSW OP

OPEN B

OPEN A

ENCODER

J1

746 E R

22

Opening/closing limit switch (depending on the opening direction)

Sensitive edges

STOP command

Closing photocells

Opening photocells

Partial opening/closing command

Total opening command

Encoder

732099 - Rev.D

7 Board technical data

Power supply voltage

Max power

Max. motor power

Max accessories load 24 V "

Ambient operating temperature

Flashing light

780D [230 V~]

220-240 V~ 50/60 Hz

10 W

1000 W

500 mA

-20°C to +55°C

230 V~ - 60 W

780D [115 V~]

115 V~ 50/60 Hz

10 W

1200 W

500 mA

-20°C to +55°C

115 V~ - 60 W

7.3 CONNECTIONS

M

Do not exceed the maximum load of the outputs.

The connection to terminal board J6 is carried out at the factory (34).

DO NOT modify the factory connection. If the direction of rotation of the

motor has to be reversed, modify function d l in basic programming.

TERMINAL BOARD J6

15

COM

Common

16

MOT 1 Phase

17

MOT 2 Phase

J6

(grey or blue)

(black)

(brown)

Translation of the original instructions

L AM P

MOTOR

!

ENGLISH

60 W max

Carry out the work with the power supply disconnected.

MOT2

MOT1

MOT COM

N

L

F

!

17 16 15 14 13

magnet

FLASHING LIGHT

Connect the flashing light to terminal board J6 (34).

MAGNETIC ENCODER

The magnetic encoder sensor detects the rotation of the magnet on

the shaft (34).

The sensor is integrated in the board and does not need to be connected.

START-UP CAPACITOR

Connected at the factory: rapid connector J5 (35).

34

TRANSFORMER

The transformer is factory installed (connectors J3-J4) (35).

J5

transformer

J9

MAGNETIC LIMIT STOP SENSOR

Connected at the factory: rapid connector J9 (35).

J3

J4

35

746 E R

23

732099 - Rev.D

ENGLISH

- Multiple contacts on the same NC input must be connected in series.

- Multiple contacts on the same NO input must be connected in parallel.

TERMINAL BOARD J1

Connect a push button or another type of NO device.

1

OPEN A

When the contact closes, the leaf opens completely.

Connect a push button or another type of NO device.

When the contact closes, the command is activated according to the

OPEN B programmed operating logic:

2

CLOSE

- in logic A, AP, S, E, or EP: partial opening (OPEN B)

- in logic B, C, or B/C: closing (CLOSE)

NC contact. Connect the opening photocells (§ Accessories chapter).

3

FSW OP

Bridge with the negative (TX-FSW) if not used.

1 2 3 4 5 6 7 8 9 10 11 12

J1

Connect the control devices and the accessories to terminal board

J1 (36).

W.L.

TX-FSW

2.5

{

CONTROL DEVICES AND ACCESSORIES

24 V

500 mA

max

SAFE

STOP

FSW CL

FSW OP

OPEN B

OPEN A

NC contact. Connect the closing photocells (§ Accessories chapter).

4

FSW CL

Bridge with the negative (TX-FSW) if not used.

Translation of the original instructions

Connect a push button or another type of NC device.

5

STOP

Bridge with the negative (–) if not used.

When the contact opens, it stops the leaf and locks the gearmotor

(which remains locked until the button is reset).

NC contact. Connect the sensitive edges.

6

SAFE

Bridge with the negative (TX-FSW) if not used.

When the contact opens, it causes the leaf to reverse for 2 s and then

locks the gearmotor.

7, 8 –

Accessories power supply negative and common contacts.

9, 10 +

Accessories power supply positive 24 V (500 mA max.).

Open collector negative for the functional test (failsafe) on inputs

3, 4 and 6.

11 TX-FSW Connect the photocell transmitter/sensitive edges negative to terminal 11 (§ Accessories).

Do not exceed the max load of the output: 24 V

", 100 mA.

Open collector negative configurable for lamp or electric lock (§

Accessories).

12

W.L.

Example of NO contacts connected in parallel

Do not exceed the max load of the output: 24 V " ,

100 mA. If necessary, use a relay and a power supply that

is external to the board.

Example of NC contacts connected in series

746 E R

24

36

732099 - Rev.D

RADIO RECEIVER/DECODER BOARD

!

J2

Example: RP2

Always disconnect power from the board before installing/removing the

receiver/decoder board.

a FAAC 5-pin radio receiver board or a decoder board that is compatible,

Install

in terms of frequency and coding technology, with the FAAC radio controls

that are used:

- a single-channel system only enables the OPEN A radio command

- a two-channel system enables the OPEN A and OPEN B/CLOSE radio commands (according to the programmed operating logic).

Insert the radio receiver or the decoder board into the quick insertion

connector J2. The connector is polarised, therefore make sure that

it is inserted the correct way round (37).

ENGLISH

37

EARTHING THE GEARMOTOR

F

L N

Cut the power to the system before making the connections.

L

N

PE

POWER CABLE

F

Translation of the original instructions