-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

4008 S

Hemodialysis device

Service Manual

Software version: 11.40 and higher

Edition: 7/01.13

Part no.: M49 985 1

0123

Related Manuals for Fresenius Medical Care 4008 S

Summary of Contents for Fresenius Medical Care 4008 S

-

Page 1

4008 S Hemodialysis device Service Manual Software version: 11.40 and higher Edition: 7/01.13 Part no.: M49 985 1 0123… -

Page 3: Table Of Contents

Supply mains ……………………..4-5 Guidance and manufacturer’s declaration for EMC (IEC 60601-1-2)……………………… 4-8 4.8.1 Electromagnetic emissions………………….4-8 4.8.2 Electromagnetic immunity ………………….4-8 4.8.3 Recommended separation distances between portable and mobile RF Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 4

Setting the digital outputs of CPU 1 …………….5-48 5.1.4.10 Setting the digital outputs of CPU 2 …………….5-54 5.1.4.11 Setting / reading the digital outputs of CPU 1 …………5-57 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 5

Positive pressure test (positive pressure holding test) ………….. 7-11 7.1.14 UF function test ……………………. 7-14 7.1.15 Conductivity test ……………………7-15 7.1.16 DIASAFE plus test/ HPU test ………………..7-16 Device error during cleaning programs …………….7-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 6

Part 12.3: Calibrating the concentrate pump stroke …………..9-22 9.1.27 Part 12.4: Measuring the volume of the concentrate pump in liters……….. 9-23 9.1.28 Part 12.5: Calibrating the bicarbonate pump stroke …………..9-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 7

Assignment of the hydraulic processing unit (HPU) …………..10-9 10.4 Assembly of components………………… 10-10 10.4.1 Self-cutting screws ……………………10-10 10.4.2 Torques ……………………… 10-10 10.5 Housing and cart ……………………10-11 10.5.1 Tilting the device……………………10-11 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 8

10.8.16 Filter holder for DIASAFE plus ………………..10-41 10.9 Extracorporeal Blood Circuit Module (EBM)…………… 10-42 10.9.1 Opening and closing the EBM, service position …………..10-42 10.9.2 Pneumatic unit contamination………………..10-43 10.9.3 BPM (option)……………………..10-44 viii Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 9

HPU wiring diagram (hydraulic processing unit)…………..11-47 11.2.6 CAN communication connection diagram …………….11-49 11.2.7 P.C.B. LP 450-2 Air detector control (LD) …………….11-50 11.2.8 P.C.B. LP 493 Blood leak detector ………………11-52 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 10

11.2.24 P.C.B. LP 1629 EBM display ………………..11-71 11.2.25 P.C.B. LP 1631 CPU 1 ………………….11-72 11.2.26 Heater board (4008 power supply unit) ………………. 11-74 11.2.27 Power board (4008 power supply unit) ………………11-75 12 Appendix Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 11

Error messages 7-1 Hydraulic unit, description 11-30 CALIBRATION menu structure 9-2 Error messages after turning Hydraulics unit 9-42 power on 7-28 CAN communication connection diagram 11-49 Error messages during dialysis 7-29 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 12

Tools (service equipment) 8-1 P.C.B. LP 632: DIP switch (array 2) 5-69 Traffic light (operation status indicator) 10-22 P.C.B. LP 634: DIP switch (array 1) 5-70 Transportation of hemodialysis unit 3-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 13

– Edition, e.g., 4/03.11 means, 4th edition, March 2011 – The page identification 1-3, for example refers, to chapter 1, page 3. Organization of the To facilitate the use of documents from Fresenius Medical Care, the chapters organization of the chapters has been standardized in all manuals. -

Page 14: Significance Of The Note

A T1 test and a check of the electrical safety must be performed after working on the device working on the device. The current Operating Instructions must be enclosed with the device. If necessary, additional operator training is required. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 15: Technical Documentation

Touching live parts will cause an electric shock. Disconnect the power plug before opening the device. Actuating the On / Off switch stops operation of the device, but does not disconnect the device from the supply voltage! Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 16: Addresses

Phone: +49 6172 609-0 www.fmc-ag.com International Fresenius Medical Care service Deutschland GmbH Service Support International Hafenstrasse 9 97424 Schweinfurt Germany Phone: +49 9721 678-333 (hotline) Fax: +49 9721 678-130 Local service Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 17: Installation

ESD precautions When repairing the device and when replacing spare parts, observe the applicable ESD precautions. TSC/ MA intervals The TSC/MA procedures on this device are to be performed after 24 months. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 18: Important Information For Use In A Domestic Environment

Moving within a domestic (see Transportation of hemodialysis unit page 3-28) environment Initial start-up report See the following pages. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 19

Arterial zero point: 0 mmHg (±10 mmHg) CALIBRATION Yes No Venous zero point: 0 mmHg (±10 mmHg) CALIBRATION Yes No Check of the blood leak detector Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 20

Run the disinfection program. Cleaning / – – disinfection 14.4 Operating Instructions and accessories package complete and match the – – device. 14.5 Attach TSC inspection label. – – Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 21

The device has been released for further use Yes (attach inspection label). No Date of next inspection: Remarks: Date: Signature: Stamp: Warning On completion of these procedures it is imperative to run a disinfection. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 22: Explanations For The Initial Start-Up Report

Re 1.2 The following closing plugs have to be removed: – on the overflow tube of the heater block – on the disinfectant connector – on the water inlet plate Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 23

Re 2.1 Labels and identifications are present and legible (with illustrations below). 2 x label «Type label complete device“ Check device specification: Serial number Equipment code 1 x label «Made in Germany» Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 24

(monitor / chassis unit) 1 x label «Type label monitor unit / chassis unit“ 1 x label «Hot surface“ 1 x label «Power supply unit type label“ 1 x label «Hydraulic unit type label“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 25

Chapter 3: Installation 1 x label «Type label EBM“ 1 x label «Insert dialyzer lines here“ 1 x label «Refer to instruction manual/booklet“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 26

Chapter 3: Installation ® 1 x label „Hot rinse“ (DIASAFE plus) 1 x label „Hot rinse“ (overflow tube) 1 x label „Hot rinse“ (shunt interlock) 1 x label „Hot rinse“ (disinfection solution) 3-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 27

Chapter 3: Installation 1 x label „Potential equalization“ 1 x label «To / from dialyser“ 1 x label «CDS warning label“ (option) 1 x label «Water input / drain, max. 6 bar“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-11… -

Page 28

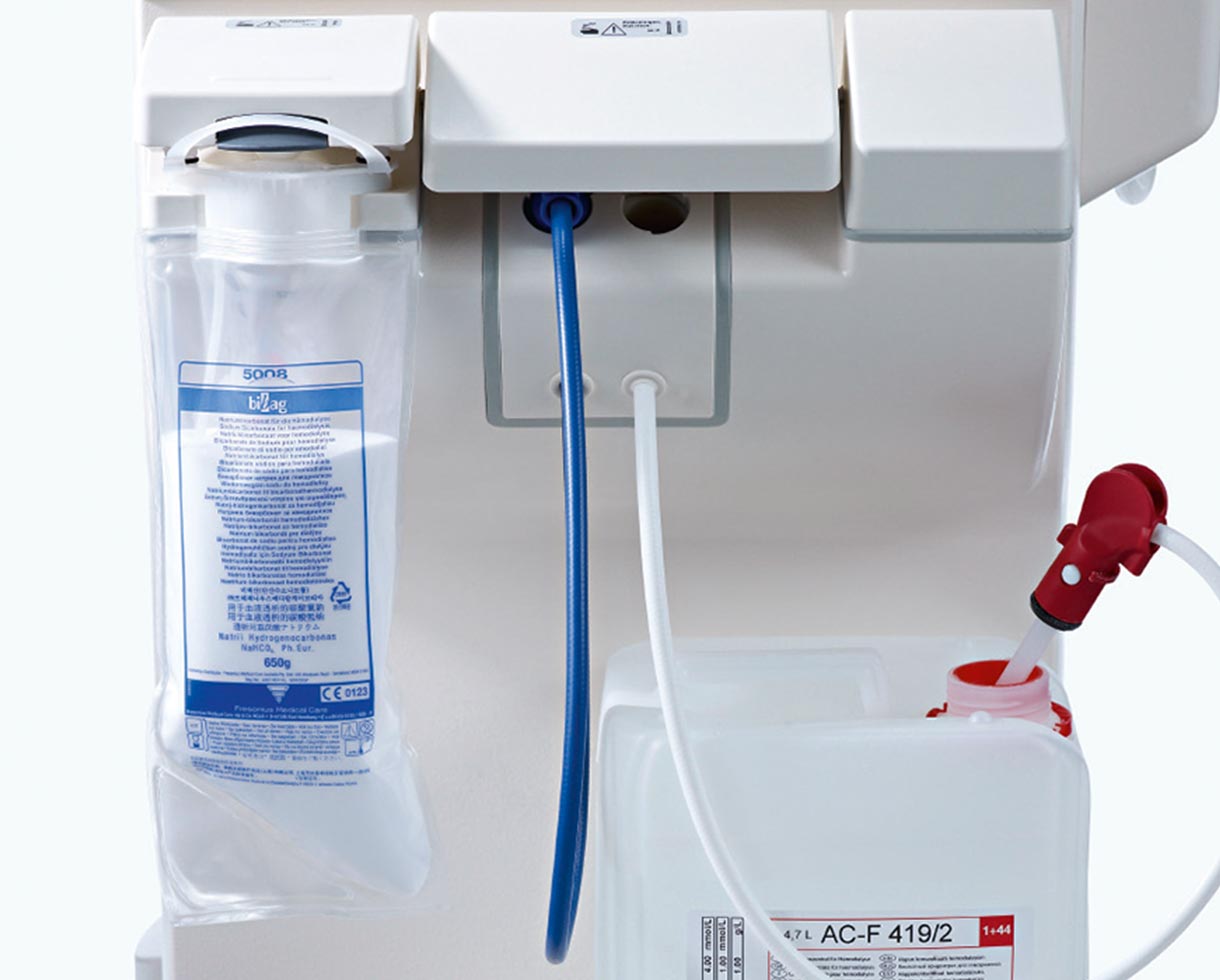

1 x label „max. 5 kg“ (IV pole) ® 1 x label „Hot rinse“ (bibag connector, on the outside) ® ® 1 x label „bibag “ (bibag connector, on the inside) 3-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 29

1 x label „Hot rinse“ (sealing cap, on the outside) 2 x Label «Warning label risk of hand injury» (EBM hinge bracket on the left and on the right) 1 x label „Warning“ (BPM connection) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-13… -

Page 30

Chapter 3: Installation 2 x labels «Tipping hazard» (housing left and housing right) Bed-Side-Link (option): 2 x label: „LAN“ and „CardBox“ 3-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 31

To be checked: – Tubings and cuff of BPM (option) Re 2.3 The power cable shows no signs of damage. Re 2.4 Blood pump emergency crank attached to housing rear. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-15… -

Page 32

(switch 3, 4, 5 to OFF and switch 7 depending on the heater rod) LP1631 – Without Central Delivery System: P.C.B. LP 1631: Array 2, switch 7 on ON LP1631 3-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 33

Rinse to remove any preservatives. Operating condition: Cleaning / rinsing – Turn the hemodialysis device on – Wait until the device is completely booted up. Then set the service switch (1) to ON (top). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-17… -

Page 34

Operating condition: Service mode / CALIBRATION Re 5 Check of the zero point of the pressure display (art./ven.) Re 5.1 Arterial zero point: 0 mmHg (±10 mmHg) Operating condition: Service mode / CALIBRATION 3-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 35

10 cm above the shunt interlock. CAL. DIAL. PRESSURE Conf Conf DIALYSATE Pressure see Part 14.1 Conf TMP-Check see Part 14.2 Conf PDIAL2 press-check see Part 14.3 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-19… -

Page 36

Operating condition: Service mode / CALIBRATION Re 9 Check of the extracorporeal components Re 9.1 Blood pumps: Check the blood pump rate. (see chapter 9.1.8 page 9-9). Operating condition: Service mode / CALIBRATION 3-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 37

The exact measuring points are indicated in the figures. – Heater rod — outward measurement point (screw head) (1) on the bottom right on the rear side of the device Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-21… -

Page 38

Chapter 3: Installation – Screw head (2) / monitor rear – Screw head (3) / power supply unit 3-22 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 39

Differential current measurement according to figure 5: Direct measurement according to fig. 4 The unit under test must be insulated when installed. All earth connections (e.g. potential equalization, …) have to be removed. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-23… -

Page 40

Last measured value: 390 µA 470 + (470 – 390) = 470 + 80 = 550 (-> not passed!) Re 11 Functional test Re 11.1 T1 test performed. Operating condition: T1 Test 3-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 41

– Use the syringe to generate a pressure of approx. 2 bar (see Checking the venous occlusion clamp page 9-51). – The pressure may not drop by more than 0.1 bar within 3 minutes. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-25… -

Page 42

Check the desired temperature of 36.5 °C (±0.2 °C) using a reference measuring instrument connected between the dialyzer couplings. – Optical detector = dark (NTC 109 is active) – Flow = 500 ml/min 3-26 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 43

Date of next inspection: The next inspection date has to be entered in the report. The intervals prescribed by the manufacturer must be observed. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-27… -

Page 44: Transportation Of Hemodialysis Unit

Risk of tilting when pushing the device or leaning against it If lateral force is exerted it may result in tilting or slipping of the device. Check transportation conditions are as stated. 3-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 45

After transportation – After moving the device, bring the hemodialysis device back into service (see Restarting after removing 4008 from Service). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 3-29… -

Page 46

Chapter 3: Installation 3-30 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 47: Specifications

Empty weight incl. all options: approx. 86 kg Safe working load: approx. 39 kg Maximum total weight: approx. 125 kg (Empty weight incl. all options + safe working load = maximum total weight) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 48: Type Label (Identification Of The Device)

Manufacturer with date of manufacture as year digit Operating temperature range Power requirements (voltage / power consumption) Maximum total weight (empty weight + safe working load) Serial number Type identification Equipment code (EC) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 49: Operating Environment

Degree of protection Defibrillator-protected applied part of type CF against electric shock (blood pressure cuff) Degree of protection drip-proof against ingress of liquids Leakage currents according to IEC 60601-1 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 50: Electrical Supply

1 x T 3.15 A; power supply unit, fuse in housing foot (rear) / SI5 Power board T 3.15 A Safety fuse Axial FF 10 A Safety fuse Heater board T 2.5 A Safety fuse T 6.3 A Safety fuse T 16 A Safety fuse Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 51: Supply Mains

Recommendation: one residual-current device for each device (or outlet) (RCD less than or equal to 30 mA). – Overvoltage / lightning protection in the main and emergency power supply. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 52

(B / BF / CF) Housing leakage currents of all types 10 times higher than ”CF” Via the blood and patient leakage current! the dialysate, the patient is electrically connected to the earth potential. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 53

Additionally, the room must comprise a potential equalization. For further information see IEC 60364-7-710. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 54: Guidance And Manufacturer’s Declaration For Emc (Iec 60601-1-2)

±1 kV differential ±1 kV differential Mains power quality should be that of a IEC 61000-4-5 mode mode typical commercial and / or hospital ±2 kV common mode ±2 kV common mode environment. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 55

Interference may occur in the vicinity of equipment marked with the following symbol. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 56: Recommended Separation Distances Between Portable And Mobile Rf

(W) according to the transmitter manufacturer. Note: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people. 4-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 57: Operating Conditions

*AL = Action Level. ISO 13959:2009: Concentration from which on steps should be taken to interrupt the trend towards higher, unacceptable values. The value usually is about 50% of the alarm limit. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 4-11…

-

Page 58: Consumption Data / Energy Data

Other data is available from the manufacturer on request. Average water Dialysis: approx. 30 liters consumption Disinfection: approx. 14.5 liters Heat disinfection: approx. 10.5 liters Mean acid concentrate Dialysis (mixing ratio 1+44 ACF): approx. 0.7 liters consumption 4-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 59: Storage Conditions

IEC or ISO standards (e.g., IEC 60950-1 for information technology equipment). Furthermore, all device configurations shall comply with the requirements for medical electrical systems (see Chapter 16 and Appendix I to EN 60601-1:2006). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 4-13…

-

Page 60: Override Conditions

Mute alarm time: adjustable in the SETUP MENU from 1 minute to 2 minutes (factory setting: 1 minute) Any new alarm reactivates the silenced audible alarm. Blood leak override Override time: 2 minutes 4-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 61: Materials Used

4.14 Materials used Plastics Description Use in the dialysis circuit EPDM PA (PA 6.6) PBT / ABS GF 20 PC+ABS PE (soft) PEEK Polyester PP-H PP(E) PPSU Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 4-15…

-

Page 62

CM/ EPDM-L EPDM Metals / glass Description Use in the dialysis circuit Graphite Glass Aluminum Sheet copper Steel sheet Aluminum sheet St37K 1.4300 1.4301 1.4305 1.4401 1.4404 / 1.4435 4-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 63

Synchroflex (toothed belt) Sirex PU foam (insulating boards), open-pored, adhesive on one side Ceramics Miscellaneous – adhesives Description Use in the dialysis circuit Loctite Scotch-Weld DP 460 Scotch-Weld V 23 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 4-17… -

Page 64

Dilution: Type FS 225 Screening lacquer: Elektro DAG 438/ Fa. Acheson Screwlock Loctite 243 Miscellaneous – packaging Description Use in the dialysis circuit Ethafoam (polystyrene) Corrugated cardboard Cellular rubber Wooden pallet 4-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 65

Potting compound PU 151/20, UP resin, Iron core Copper + tin, Plug connectors glassfiber enforced thermoplast P.C.B. base material, epoxy fiberglass Electronic components Ferrite cores, lithium batteries, lead-acid battery Copper, PVC, Teflon Cables Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 4-19… -

Page 66

Chapter 4: Specifications 4-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 67: Setup / Service Program

Setting the service switch to ON while the treatment or the cleaning program is in progress will turn off the heater relay. 5.1.1 Service mode overview CALIBRATION DIAGNOSTICS MISCELLANEOUS SETUP MENU Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 68: Service Mode Key Functions

Scrolling through menu items / Selecting a menu item Conf Changing values and functions in the menus + / – Storing the modified values (Audio paused) Exiting a menu without saving the data Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 69: Setup Menu

SET BPM see Part 22 Conf Conf UF EINSTELLUNGEN see Part 11 STORE DEFAULT VALUES see Part 23 Conf Conf SET STD. PRIME-TIME see Part 12 BACK TO MAIN MENU ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 70: Part 1: Setting Alarm And Warning Times

Set ART-AL DELAYTIME Conf Art Al Delay = 5s Set the desired delay time (0 to 5 seconds) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 seconds Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 71

Part 1.4: Setting the UF warning time Set UF-WARNING-TIME Conf UF-Warn-Time = 10min Set the desired warning time (10, 30 min) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 seconds Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 72: Part 2: Setting The Cleaning Program

3 seconds 5.1.3.3 Part 2: Setting the cleaning program SETUP CLEANING PGM Conf Conf CLEANING Times see Part 2.1 Conf DEFAULT Cleaning Pgm see Part 2.2 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 73

Part 2.1.1: Rinsing time Rinsing TIME Conf Rinsing Time = 15min Set the desired time (5 to 30 min) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 seconds Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 74

Part 2.1.4: Rinsing free time Rinsing Free TIME Conf R.-Free Time = 6min Set the desired time by pressing the +/– keys. Audio paused DATA STORED After approx. 3 seconds Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 75

Part 2.1.7: Citro mandatory rinsing time CITRO-Mandat-Ri-Time Conf CITRO-MRTime = 10min Set the desired time (10 to 25 min) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 seconds Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 76

PGM 2: -F-HDIS-M- DATA STORED 3 seconds +/– Audio After PGM 3: -F-D-M-HR- paused DATA STORED approx. 3 seconds +/– Audio After PGM 4: -F-HDIS-M-HR- paused DATA STORED approx. 3 seconds +/– 5-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 77: Part 3: Mixing Ratio

After paused canister 1+44 C DATA STORED approx. 3 s +/– Audio After canister 1+44 ACF paused DATA STORED approx. 3 s +/– Conf VARIABLE SETTING See Part 3.1 +/– Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-11…

-

Page 78

CDS 1+44 C +/– CDS 1+34 Audio After paused DATA STORED Audio approx. 3 s canister 1+44 ACF paused ACKNOWLEDGED +/– CDS 1+44 C +/– Conf VARIABLE SETTING See Part 3.1 +/– 5-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 79

1+44 ACF paused ACKNOWLEDGED CDS 1+34 paused DATA STORED approx. 3 s +/– Audio Conf After VARIABLE SETTING see Part 3.1 CDS 1+34 paused DATA STORED approx. 3 s +/– Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-13… -

Page 80

+/– keys. Audio paused ACKNOWLEDGED After approx. 3 s Na(B)[mmol]: 25 Set the desired value (25 to 80) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s 5-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 81: Part 4: Setting The Conductivity Limit

AdaptedFlow ON/OFF see Part 6.1 Conf SET Flow Parameter see Part 6.2 Conf SET Temp. Parameter see Part 6.3 Conf SET Na/Bic Parameter see Part 6.4 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-15…

-

Page 82

Conf Optional AdpFlow factor: 1.9 Set the desired value (from 1.0 to 2.0, except 1.2 and 1.5) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s 5-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 83

SET Temp. Parameter Conf Temp.[°C]: 36,5 Set the desired value (35.0 to 39.0) by pressing the +/– keys. Value set in Dial Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-17… -

Page 84

Audio paused ACKNOWLEDGED After approx. 3 s Limit Na/Base 13mmol Set the desired value (0 – 13) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s 5-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 85: Part 7: Cumulated Blood Volume

OCM MEASUREMENT Conf Audio After OCM Measurement: OFF paused DATA STORED approx. 3 s (default +/– value: OFF) Audio After paused OCM Measurement: ON DATA STORED approx. 3 s +/– Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-19…

-

Page 86: Part 9: Automatically Starting Single-Needle Mode

5.1.3.10 Part 9: Automatically starting Single-Needle mode AUTOM. SN-START Conf Audio After paused autom. SN: OFF DATA STORED approx. 3 s +/– Audio After autom. SN: ON paused DATA STORED approx. 3 s +/– 5-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 87: Part 10: Activating Monit_Ntc 109

5.1.3.13 Part 12: Setting the priming time SET STD. PRIME-TIME Conf Prime-Time = 2min Set the desired time (1 to 5 min) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-21…

-

Page 88: Part 13: Sound I/O Switch

In dialysis mode, the BPR/UFR warning must always be enabled, i.e. «ON». BPR/UFR-WARNING Conf Audio After paused BPR/UFR-Warning: ON DATA STORED approx. 3 s +/– Audio After BPR/UFR-Warning: OFF paused DATA STORED approx. 3 s +/– 5-22 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 89: Part 16: Setting The Rinse Volume

+/– 5.1.3.19 Part 18: Setting the venous alarm window VENOUS LIMITS Conf Conf ASYM. LIMITS see Part 18.1 Conf VEN. WINDOW POSITION see Part 18.2 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-23…

-

Page 90: Part 19: Setting Central Delivery

5.1.3.21 Part 20: AutoOFF after AutoON AutoOFF after AutoON Conf Audio After paused Auto OFF: OFF DATA STORED approx. 3 s +/– Audio After Auto OFF: ON paused DATA STORED approx. 3 s +/– 5-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 91: Part 21: Camus Baud Rate

Upper MAP limit see Part 22.6 Conf Lower MAP limit see Part 22.7 Conf Upper Pulse limit see Part 22.8 Conf Lower Pulse limit see Part 22.9 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-25…

-

Page 92

Conf Lower SYS = 90mmHg Set the desired value (30 to 245 mmHg in 5 mmHg increments) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s 5-26 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 93

Conf Upper MAP = 120mmHg Set the desired value (75 to 255 mmHg in 5 mmHg increments) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-27… -

Page 94

Low. Pulse = 60/min Set the desired value (20 to 175 per min in 5 per min increments) by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s 5-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 95: Part 23: Storing Default Values

PGM 1: -R- PGM 1: -R- PGM 2: -R- endless PGM 1: -F-HR-C- PGM 2: -F-HR- PGM 3: -IHR- PGM 1: -F-D-M- PGM 2: -F-HDIS-M- PGM 3: -F-D-M-HR- PGM 4: -F-HDIS-M-HR- Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-29…

-

Page 96

BPR/UFR warning: ON BPR/UFR warning: ON BPR/UFR warning: OFF SET RINSE-VOLUME RINSE-VOL: 1000 ml 1000 ml 0–5000 ml 100 ml T1-TEST AUTOSTART T1-T. Autostart: OFF T1-T. Autostart: OFF T1-T. Autostart: ON 5-30 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 97

70 mmHg 20-230 mmHg 5 mmHg Upper Pulse limit 120 1/min 45–245 1/min 5 1/min Lower Pulse limit 60 1/min 20-175 1/min 5 1/min STORE DEFAULT VALUES Press Audio paused key Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-31… -

Page 98: Diagnostics

The active signal state (may indicate both voltage and no voltage) is indicated by 1111 on the display (fields to ), by the operation status indicators being activated and by an audible signal. 5-32 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 99

The four arrow keys, the On/Off key and the Conf key are not implemented because their function can be checked by selecting the appropriate menu. The fields to in the display are defined as follows: XXXX XXXX XXXX XXXX Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-33… -

Page 100: Diagnostics Menu Structure

Conf back to menu ? Conf Conf Conf Conf CAN-COMPONENTS see Part 10 Conf back to menu ? Conf Conf see Part 11 Conf Conf BACK TO MAIN MENU ? 5-34 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 101: Reading The Analog Inputs Of Cpu 1

0 V, IC 27/27, ADC 0 E: CPU1_P_VEN Venous pressure 0–12 V, IC 27/28, ADC 0–255 E: CPU1_BPR_VEN Venous blood pump rate 0-10 V, IC 27/1, ADC 0-215 (Line diameter: 8 mm) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-35…

-

Page 102

E: CPU1_FREE1 Not used 0 V, IC 29/26, ADC 0 E: CPU1_TEMP_DIAL2 Temperature NTC 109 0–12 V, IC 29/27, ADC 0–255 E: CPU1_COND_SIGNAL2 Not used 0 V, IC 29/28, ADC 0 5-36 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 103: Reading The Analog Inputs Of Cpu 2

E: CPU2_P_DIAL Dialysate pressure 0-10 V, IC 12/9, ADC 0-231 E: CPU2_COND_SIGNAL CD display 0-10.8 V, IC 12/8, ADC 0-251 E: CPU2_TEMP_DIAL1 Temperature display 0-10.8 V, IC 12/7, ADC 0-251 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-37…

-

Page 104: Reading The Digital Inputs Of Cpu 1

Audio paused key. In this case, the Audio paused LED is lit. Part 3 Conf Conf CPU1: RD DIGITAL INP I: CPU1_COND_V84 back to menu ? 5-38 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 105

LD alarm channel 2 IC 13/7 Preparation: LD alarm-free, and set CLAMP_CTRL (CPU 1: WR DIGIT. OUTPUT) to 1. Test: Initiate LD alarm E: CPU1_SUB_W_P Feedback from UF pump 2 IC 13/8 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-39… -

Page 106

Shunt interlock microswitch IC 15/6 Only red tube in shunt interlock and shunt interlock closed: 0 E: CPU1_SHUNT Shunt interlock microswitch IC 15/7 Open/close shunt interlock E: CPU1_SERV_EN Not used IC 15/8 5-40 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 107

External alarm IC 20/2 Initiate an external alarm E: CPU1_SERVICE_MODE Switching Dialysis / Service mode IC 20/3 Toggle the service switch E: CPU1_LEVEL_UP Raise LD level IC 20/4 Actuate Raise level Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-41… -

Page 108

E: CPU1_LATCH7_FREE1 Not used IC 7/2 E: CPU1_LATCH7_FREE2 Not used IC 7/3 E: CPU1_LATCH7_FREE3 Not used IC 7/4 E: CPU1_LATCH7_FREE4 Not used IC 7/5 E: CPU1_LATCH7_FREE5 Not used IC 7/6 5-42 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 109: Reading The Digital Inputs Of Cpu 2

If high level is applied, an audible alarm is active at the same time. This can be suppressed by pressing the Audio paused key. In this case, the Audio paused LED is lit. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-43…

-

Page 110

IC 5/6, LD alarm / alarm-free E: CPU2_LDA2 LD alarm channel 2 IC 5/7 Preparation: LD alarm-free, and set CLAMP_CTRL (CPU1: WR DIGIT. OUTP) to 1 Test: Initiate LD alarm 5-44 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 111

Concentrate reed contact IC 7/2 Actuate rinse chamber / concentrate reed contact E: CPU2_V147 IC 7/3 E: CPU2_REED_BIC Bicarbonate reed contact IC 7/4 Actuate rinse chamber / bicarbonate reed contact Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-45… -

Page 112

(1: DIP switch ON) E: CPU2_DIP2: 11000001 DIP switch CPU 2, array 2 IC 10/2–9 DIP switch position shown on the display (1: DIP switch ON) Back to menu ? 5-46 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 113: Setting The Analog Outputs Of Cpu 1

0–4.4 V (X634L/ between A, B, C 27 and A, B, C 28, 0–21 V) A: CPU1_STEUER_FP Flow pump speed setting IC 18-A_19 0–4.4 V (X634L/ between A, B, C 29 and A, B, C 30, 0–21 V) Back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-47…

-

Page 114: Setting The Analog Outputs Of Cpu 2

Setting the digital outputs of CPU 1 Explanation Display (field ): 0000 = not active 1111 = active (level P.C.B. LP 634) (adjustable by pressing the + / – keys) 5-48 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 115

(Valve automatically closes after a short time to prevent water from overflowing) A: CPU1_V43 Valve 43 IC 7/15 A: CPU1_V84 Valve 84 IC 7/18 Note: Activation of valve V84 must be followed by a rinse program. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-49… -

Page 116

Flow pump stop IC 4/15 A: CPU1_SET_UF1_ON UF pump 1 activation IC 4/14 (0/1 jump = 1 stroke) A: CPU1_SET_UF2_ON UF pump 2 activation IC 4/13 (0/1 jump = 1 stroke) 5-50 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 117

IC 5/16 to 0: intrinsic clock pulse; to 1: current increase switchover A: CPU1_BC_PULSE Balancing chamber switchover IC 5/15 A: CPU1_EN_STEP_PULS Gal switchover IC 5/14 A: CPU1_BC_FUNCTION Balancing chamber Gal switchover IC 5/13 A: CPU1_STEPPER_PULS Intrinsic clock pulse IC 5/12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-51… -

Page 118

A: CPU1_HOT_RINSE Hot rinse switchover IC 11/17 A: CPU1_TEST_BATT Battery test IC 11/16 A: CPU1_CPU_AKKU Battery relay IC 11/15 A: CPU1_HEAT_OFF Heater blockage IC 11/14 A: CPU1_STAFF_CALL Staff call IC 11/13 5-52 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 119

P.C.B. LP 922/X5.5 A: CPU1_OVERLAP_VALUE Loads the dead time counter IC 3/12-19 (DAC 0–255 adjustable) A: CPU1_V_ADS Not used A: CPU1_NC_I Not used A: CPU1_NC_II Not used A: CPU1_NC_III Not used Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-53… -

Page 120: Setting The Digital Outputs Of Cpu 2

Preparation: Activate V 24B (CPU1: WR DIGIT. OUTP) Test: Switch valve on / off with V 24B_EN A: CPU2_UF_P_CTRL UF pump 1 activation IC 24/14, 0/1 jump = 1 stroke Preparation: Set CPU2_UF_P_EN to 1. 5-54 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 121

Optical LD system weakened X632/C15 A: CPU2_CLAMP_CTRL Air detector clamp control X632/C10 Preparation: Air detector alarm-free A: CPU2_NC5 Not used X632/B25 A: CPU2_NC7 Not used X632/B10 A: CPU2_BLL_DET Blood leak detector detuning X632/A25 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-55… -

Page 122

A: CPU2_LED6 P.C.B. LP 632 LED 6 IC 21/14 A: CPU2_LED7 P.C.B. LP 632 LED 7 IC 21/13 A: CPU2_LED8 P.C.B. LP 632 LED 8 IC 21/12 Back to menu ? 5-56 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 123: Setting / Reading The Digital Outputs Of Cpu 1

Feedback P.C.B. LP 633-5/IC 13/6 (If setting from 0 to 1 = 1 stroke; feedback is brief jump to 1) CPU 1_COMBI: AIR_SEP ASP activation / deactivation Back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-57…

-

Page 124: Hpu

A:WTR_AIR_P Compressor Conf back to menu ? A:WTR_V_TEST Test valve V183 A:WTR_V39 Negative pressure valve A:WTR_RETENT_V Retentate valve V189 A:WTR_V_EVAC_INDI implemented A:WTR_V_EVAC_SOD Evacuation valve V188 Conf back to menu ? 5-58 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 125: Bpm (Option)

Field 2, after approx. 3 minutes: Final pressure in mmHg (Tolerance: +/– 3 mmHg) Field 3: Leakage in mmHg (Tolerance: +/– 2 mmHg) Field 4: Leakage rate in mmHg (< 6 mmHg/min) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-59…

-

Page 126: Miscellaneous

SYSTEM CLOCK see Part 1 SW-VERSION-NUMBER see Part 2 Conf Conf BACK TO MAIN MENU ? see Part 3 Conf SYSTEM CLOCK see Part 1 Conf BACK TO MAIN MENU ? 5-60 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 127: System Clock

Conf Press the +/– keys to set the seconds, day, month and year in the same way. Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-61…

-

Page 128: Sw-Version-Number

BPM (option) Part 3 Conf Conf Serial number XXXXXXXX Conf Serial number BPU XXXXXXXXXX Conf Operating hours XXXXXXXXX h Conf No. meas. cycles XXXXXXXXXX Conf back to menu ? 5-62 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 129: Calibration

Chapter 5: Setup / service program 5.1.6 CALIBRATION For a description of the CALIBRATION service menu, please refer to Chapter Calibration / adjustment (see chapter 9.1 page 9-1). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-63…

-

Page 130: Dip Switch Overview

T1 test 500 ml/min / cleaning 600 ml/min T1 test 800 ml/min / cleaning 800 ml/min The basic position on delivery is in italics. «No assignment» requires the OFF position. 5-64 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 131: Lp 1631 (Cpu 1) Dip Switch Array 2

The basic position on delivery is in italics. «No assignment» requires the OFF position. * DIP switch 7 is no longer relevant if DIP switch 8 is set to ON. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-65…

-

Page 132: Lp 1631 (Cpu 1) Dip Switch Array 3

P.C.B. LP 1631 (CPU 1) DIP switch array 3 LP1631 DIP switch / Function Position Language setting English German French Portuguese Spanish Czech Russian Turkish Polish Bulgarian Greek Arabic Slovenian Serbian Romanian Lithuanian Macedonian Croatian Chinese Hebrew Swedish 5-66 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 133

Chapter 5: Setup / service program DIP switch / Function Position Software update with SD-card Active Not active not assigned The basic position on delivery is in italics. «No assignment» requires the OFF position. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-67… -

Page 134: Lp 632 (Cpu 2) Dip Switch Array 1

Every 12.5 minutes, alarm output only with cyclic PHT alarm Cyclic PHT Air Detector Not permitted with P.C.B. LP 450-2 not assigned The basic position on delivery is in italics. «No assignment» requires the OFF position. 5-68 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 135: Lp 632 (Cpu 2) Dip Switch Array 2

With HPU Not permitted V39 Test Fast heater for HDIS Inactive Active not assigned not assigned The basic position on delivery is in italics. «No assignment» requires the OFF position. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-69…

-

Page 136: Lp 634: Dip Switch (Array 1)

If an alarm system is set for which the staff has not been trained yet, instructions must be given prior to the first treatment. In the Treatment types menu, you can select between the Acute alarm system (default setting) or the Standard alarm system. 5-70 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 137: Software Update

D8 serve for evaluating the error (see Error code table page 5-72). 5. Turn the device off 6. Re-set DIP switch 7 to OFF 7. The SD-card may be removed or remain inserted Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-71…

-

Page 138: Error Code Table

Memory location in the update client not written on correctly / Repeat update (change MDC-II board, if necessary) Transfer buffer underrun / Communication error, repeat update (change LP 1631 or MDC-II board, if necessary) 5-72 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 139

Communication error, repeat update (change LP 1631 or MDC-II board, if necessary) Data block acknowledge – error 5 / Communication error, repeat update (change LP 1631 or MDC-II board, if necessary) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-73… -

Page 140: Service Program (Quick Guide)

With the Service Software 4008 application open, use «Help» from the menu bar to access the Quick Guide, as follows: → → «Help“ «Help Topics“ (1) → → „Help“ „Context Help“ (2) (see Fig. below) 5-74 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 141

«Documentation» directly from the folder on the corresponding drive (3). The «Documentation» folder contains the German and the English version of the Quick Guide in PDF format (4) (see following Fig.). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 5-75… -

Page 142

Chapter 5: Setup / service program 5-76 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 143: Tsc / Maintenance

Specifications The technical specifications must be adhered to. Warning When the device is returned to use, check that the pressure of the water supply meets the prescribed minimum pressure. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 144: Accessories And Supplies

TSC / MA test report See the following pages. This report differs from the TSC test report in the first column Type (e.g., TSC, MA) and the maintenance items (see chapter 6.5 page 6-32). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 145

– Array 2, switch 5 is on OFF ® DIASAFE plus ® DIASAFE plus filter life checked. – – Hydrophobic filter (F111) and hydrophobic filter / test valve (F184) – – replaced. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 146

– 100 mmHg / ±3 mmHg – 50 mmHg / ±3 mmHg 11.5 Safety valve: Emptied at 320 mmHg ±10 mmHg DIAGNOSTICS – – 11.6 Blood pressure measurement performed. Preparation – – Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 147

The device has been released for further use Yes (attach inspection label). No Date of next inspection: Remarks: Date: Signature: Stamp: Warning On completion of these procedures it is imperative to run a disinfection. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 148: Explanations On The Test Report — Tsc / Ma Tsc, Explanations On Test Report

The battery fuse accessible (see illustration below) (1) from the outside corresponds to the indicated value. Alternative to checking the fuse: If the seal is undamaged, the battery fuse does not have to be checked. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 149

Re 1.2 Labels and identifications are present and legible (with illustrations below). 2 x label «Type label complete device“ Check device specification: Serial number Equipment code 1 x label «Made in Germany» Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 150

(monitor / chassis unit) 1 x label «Type label monitor unit / chassis unit“ 1 x label «Hot surface“ 1 x label «Power supply unit type label“ 1 x label «Hydraulic unit type label“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 151

Chapter 6: TSC / maintenance 1 x label «Type label EBM“ 1 x label «Insert dialyzer lines here“ 1 x label «Refer to instruction manual/booklet“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 152

Chapter 6: TSC / maintenance ® 1 x label „Hot rinse“ (DIASAFE plus) 1 x label „Hot rinse“ (overflow tube) 1 x label „Hot rinse“ (shunt interlock) 1 x label „Hot rinse“ (disinfection solution) 6-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 153

Chapter 6: TSC / maintenance 1 x label „Potential equalization“ 1 x label «To / from dialyser“ 1 x label «CDS warning label“ (option) 1 x label «Water input / drain, max. 6 bar“ Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-11… -

Page 154

1 x label „max. 5 kg“ (IV pole) ® 1 x label „Hot rinse“ (bibag connector, on the outside) ® ® 1 x label „bibag “ (bibag connector, on the inside) 6-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 155

1 x label „Hot rinse“ (sealing cap, on the outside) 2 x Label «Warning label risk of hand injury» (EBM hinge bracket on the left and on the right) 1 x label „Warning“ (BPM connection) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-13… -

Page 156

Chapter 6: TSC / maintenance 2 x labels «Tipping hazard» (housing left and housing right) Bed-Side-Link (option): 2 x label: „LAN“ and „CardBox“ 6-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 157

Mechanical condition permits further safe use. There are no signs of damage or contamination affecting proper function of the device. To be checked: – Tubings and cuff of BPM (option) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-15… -

Page 158

Replace the filters in the suction tubes: – Filter / concentrate (F71) – Filter / bicarbonate (F72) Re 2.4 Replace the vent valve (V92). With CDS option, replace the concentrate check valve (V117). 6-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 159

Replace filter / degassing orifice (F210) (if present). ® Re 2.13 bibag connector (H136), replace O-rings. Grease the O-rings with Unisilkon grease before installation. Re 2.14 Replace shabby and/or dirty tubes. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-17… -

Page 160

The basic settings of the DIP switches are marked red in the illustrations below. A detailed overview can be found in chapter 5 (see chapter 5.2 page 5-64). Check of the DIP switches P.C.B. LP 1631 (CPU 1): 6-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 161

– Array 2, switch 5 is on OFF LP632 ® Re 4 DIASAFE plus ® Re 4.1 Check of the DIASAFE plus filter life, maximum filter life: 12 weeks. Operating condition: Off Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-19… -

Page 162

(measuring point D in HU). The negative pressure must be between 0.81 bar and 0.85 bar. Re 7.4 Check balancing chamber relief pressure at a flow of 800 ml/min (relief valve A78). 6-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 163

Re 8.2 Measure the volume of the concentrate pump in liters or compare with an appropriate reference device. If necessary, make settings according to calibration instructions. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-21… -

Page 164

Re 9.3 Arterial and Single-Needle blood pump. Operating condition: Service mode / CALIBRATION Check the blood pump rate under CALIB. (B)-PUMP-RATE. Calibrating the blood pump rate (see chapter 9.1.8 page 9-9) 6-22 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 165

– Venous pressure inlet open against atmosphere – Flow off Check zero point. With the dialysate circuit open, the water level must be approx. 10 cm above the shunt interlock. Check slope. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-23… -

Page 166

After the system has recognized that the circuit is open, the flow is switched on automatically. Wait for MUTE-LED The Audio paused LED is flashing. Audio paused DATA STORED After approx. 3 s 6-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 167

The venous occlusion clamp must close in the event of a blood alarm. Operating condition: Preparation Re 10.6 Air detector, check the venous occlusion clamp. Pressure may not drop by more than 0.1 bar within 3 minutes. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-25… -

Page 168

Remove any differences by running a calibration program. Re 10.8 Desired temperature 36.5 °C ±0.2 °C checked with reference device. Operating condition: Dialysis The device must be entirely closed during this check! 6-26 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 169

– 200 mmHg / ±3 mmHg – 150 mmHg / ±3 mmHg – 100 mmHg / ±3 mmHg – 50 mmHg / ±3 mmHg Operating condition: Service mode / DIAGNOSTICS Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-27… -

Page 170

Max. 0.3 (with power cable). Operating condition: Off The protective earth resistance must be checked on the following measurement points. The exact measuring points are indicated in the figures. 6-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 171

– Heater rod — outward measurement point (screw head) (1) on the bottom right on the rear side of the device – Screw head (2) / monitor rear – Screw head (3) / power supply unit Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-29… -

Page 172

Differential current measurement according to figure 5: Direct measurement according to fig. 4: The unit under test must be insulated when installed. All earth connections (e.g. potential equalization, …) have to be removed. 6-30 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 173

470 + (470 – 390) = 470 + 80 = 550 (-> not passed!) Re 13 Functional test Re 13.1 T1 test performed. Operating condition: T1 Test T1 test passed without errors. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-31… -

Page 174: Test Report — Tsc

The explanations on this report can be found on the previous pages (see chapter 6.4 page 6-6). TSC report numbering Numbers, which are not listed here, are not included in the TSC. They are part of the Maintenance procedures. 6-32 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 175

– – 50 mmHg / ±3 mmHg – 11.5 Safety valve: Emptied at 320 mmHg ±10 mmHg DIAGNOSTICS – – 11.6 Blood pressure measurement performed. Preparation – – Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 6-33… -

Page 176

The device has been released for further use Yes (attach inspection label). No Date of next inspection: Remarks: Date: Signature: Stamp: Warning On completion of these procedures it is imperative to run a disinfection. 6-34 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 177: Error Messages

(V24 = off, V26 = on, V24B = off). – Acknowledgement (V24, X637/C1) X632/A4 not 24 V – Acknowledgement (V26, X637/C2) X632/A6 not 0 V – Acknowledgement (V24B, X637/C23) X632/A5 not 24 V Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 178: Opt. Detector Test

CPU2 recognizes that the optical detector senses opaque fluid (required because of the test in the cleaning program). – Acknowledgement X632/A30 not 12 V. – AD28 defective F95 opt. Detector System error Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 179: Blood System Test

– Control line (BPSST_VEN, X634L/B15) X348V/1 not 12 V or (BPST_VEN, X634L/A15) X348V/3 not 12 V – IC16 on P.C.B. LP 633-5 defective. – P.C.B. LP 633-5 recognizes Single-Needle pump although it is not connected. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 180

– Acknowledgement line (BPUS, X348A/8) X632/A13 not 0 V – Acknowledgement line (BPUS, X348A/8) X632/A13 not 12 V – Blood pump speed is set to “0”: preset speed during the T1 test Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 181: Ven. Pressure System Test

– Control (VENT_VALVE, X634R/C18) X351/1 of the vent valve in the LD is defective – Acknowledgement (P_VEN, X351/4) X632L/C17 that the voltage value is outside the zero point tolerance – P-venous has not been calibrated Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 182: Air Detector Test

Closing of the air detector clamp via the CPU1 control line was not possible, or CPU2 acknowledgement is incorrect. – Clamp control (CLP_CTL, X634/C14) X351/8 not 0 V. – Acknowledgement (LDA2, X351/6) X632/C14 not 0 V Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 183

6.5–13.5 V after 3 seconds. – Adapter board AD28 not connected – Acknowledgement (X351/11 X633L/25A jumper to X633L/ B7) not 12 V – Relay on AD28 failed to drop. F95 Air Detector System error Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 184: Display Test

– The test level is incorrect (TESTBATT, X634R/C23) X639/A10, no 12 V pulse (100 ms) – Fuse in the base is defective – R39 on P.C.B. LP 647 defective, possibly caused by flickering power supply unit F95 Battery System error Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 185: Blood Leak Test

The actual temperature is higher than 39.0 °C (test running time 15> 15 minutes). – Calibrate the temperature – The regulating sensor (NTC-2) is defective – Acknowledgement (T_DIAL1, X633L/B16) X632/A24, voltage got stuck. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 186: Negative Pressure Test (Negative Pressure Holding Test)

– The D-A converter (IC11) on P.C.B. LP 632 is defective – The operational amplifier (IC1/IC3) on P.C.B. LP 632 is defective – Acknowledgement (P_DIAL, X633L/B6) X632/A29 is defective – CI signal is missing (P.C.B. LP 632 X632/B22). 7-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 187: Positive Pressure Test (Positive Pressure Holding Test)

– Solenoid valve V26 mechanically not open – Solenoid valve V43 mechanically not closed The balancing chamber is switched to passage during this test sequence. V24, V24B and V43 are closed; V26 is open. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-11…

-

Page 188

The second working point (116 digits) of the differential amplifier cannot be set correctly. – The D-A converter (IC11) on P.C.B. LP 632 is defective – The operational amplifier (IC1/IC3) on P.C.B. LP 632 is defective 7-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 189

– The D-A converter (IC11) on P.C.B. LP 632 is defective – The operational amplifier (IC1/IC3) on P.C.B. LP 632 is defective – Acknowledgement (P_DIAL, X633L/B6) X632/A29 is defective Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-13… -

Page 190: Uf Function Test

No activity of the UF pump 1 during the test (5 seconds). – Acknowledgement (UF_P1, X637/B23) X632/A7, no LOW pulses. – Control line (UF_P1, X634L/ABC23) X637/B23, no LOW pulses. 7-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 191: Conductivity Test

The bibag CD detuning is not more than 1 mS/cm. – Acknowledgement (COND_SIGNAL3, X633R/A12) MP TP3 on P.C.B. LP 633-5, change in voltage insufficient – Detuning (COND_DET, X632/A21) X633L/B31 insufficient Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-15…

-

Page 192: Diasafe Plus Test/ Hpu Test

V183 in the system. – V183 fails to open, mechanically defective – Compressor P185 defective, not running – HPU, V183 and / or compressor P185 output stage etc. defective 7-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 193

F43 DIASAFE plus See error message between F03 and F04 DIASAFE plus F44 DIASAFE plus See error message between F03 and F04 DIASAFE plus F95 DIASAFE plus System error F95 HPU Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-17… -

Page 194: Device Error During Cleaning Programs

Dis I – IV. Another possibility of correcting the problem can be found in the service mode (by a service technician only) in the NOVRAM menu item (clear V84 malfunction). 7-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 195: Psw (Pressure Switch) Monitoring During Free Rinsing (Only With Devices With Cds)

– Check acknowledgement of pressure switch on P.C.B. LP 633-5: Bicarbonate: X633L/A19 – Cartridge filter (F210) upstream of degassing pump clogged or wrong filter (filter for disinfectant container) installed. Filters can be distinguished by different adapters. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-19…

-

Page 196

– Switching point of pressure switch too low: Desired= 700 mbar ±20 mbar – Check acknowledgement of pressure switch on P.C.B. LP 633-5: Bicarbonate: X633L/A19 7-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 197

However, this message is displayed only if a mandatory rinse program is requested, since the concentrate and bicarbonate lines still have to be emptied before the device is switched off. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-21… -

Page 198: Rinse Section Test (Check Of V91, V99, V100) (Only Devices With Cds)

– Pressure switch for PSW_102 (S123) fails to open Rinse Failure F14 Shortly before the end of the mandatory rinse in Dis I – V. Rinse section test not completed correctly. Possibly caused by flow problems. 7-22 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 199: Rinse Section Test (Check Of V91 And V98) (Only Devices Without Cds)

– V100 fails to open mechanically (possibly clogged) – V91 constantly electrically or mechanically open – Concentrate pump fails to pump – Filter (148) clogged – Pressure switch fails to open Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-23…

-

Page 200

– Concentrate line squeezed at strain relief Rinse Failure F14 Shortly before the end of the mandatory rinse in Dis I – V. Rinse section test not completed correctly. Possibly caused by flow problems. 7-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 201: V39 Test

CPU-II failed During a cleaning program in RI I to II, HR I to III, Dis I to V. The watchdog relay has dropped. Communication (RxD or TxD) may be disturbed. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-25…

-

Page 202

During a cleaning program in RI I to II, HR I to III, Dis I to V. V102 electrically opened. 24 V will be turned off. The error cannot be acknowledged. 7-26 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 203

Battery voltage < 17.2 V ±2.5 % Only in the event of a power failure during the cleaning programs. If the voltage drops below 17 V, the device will switch off. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-27… -

Page 204: Error Messages After Turning Power On

No valid value has been filed during start in the NOVRAM. The temperature difference between NTC109 and NTC3 is too high. Switch off NTC 109 in the SETUP MENU, or recalibrate the temperature. 7-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 205: Error Messages During Treatment

Cyclic PHT F03 IC1 or IC3 on P.C.B. LP 632 is defective, or device leakage Cyclic PHT F04 It was not possible to complete the test within a specific time interval Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-29…

-

Page 206

Possible cause: – Controlling monoflop on LP 634 defective F329 UF failure Pulse time of one UF1 pump stroke exceeds 500 ms. Possible cause: – Controlling monoflop on LP 634 defective 7-30 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 207

CPU2 UF deviation compared to the theoretical UF target volume. Possible cause: – System error F354 UF failure UF rate exceeds the maximum rate allowed. Possible cause: – System error Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-31… -

Page 208: Hpu (Hydraulic Processing Unit) Error Messages

HPU Error F08 General valve malfunction: – System error HPU Error F09 Compressor error(185) – MV43 defective or activated – Compressor 185 defective or activated – Error on P.C.B. LP 941 7-32 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 209

– CRC error in the transfer HPU CPU1 – The electrical test (VDE) was performed directly after turning the device on. Turn the device on at least 2 minutes before the test. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-33… -

Page 210: Blood Pump (Arterial) Error Messages

Time basis error gate array <- -> microcontroller Interrupt INT0 constantly triggered by gate array (no main loop runs) Error serial communication between CPU1 and LP 950 Optical sensor (no pulses) 7-34 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 211: Bpm Module Error Messages

(Remove the cuff from the A failure is detected if the CPU-P1 pressure is > ±9 mmHg or the pressure patient!) change is > ±1 mmHg 5 seconds after starting a measurement. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-35…

-

Page 212

Interval pause < 30 seconds (Remove the cuff from the patient!) E90 BPM error CPU-P2 pressure > 330 mmHg for more than 300 ms. (Remove the cuff from the patient!) 7-36 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 213

25 seconds. Monitoring will then be active in order to detect a pressure stage. patient!) E99 BPM error Pressure difference between CPU-P1 and CPU-P2 on 1st stage > 20 mmHg (Remove the cuff from the patient!) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 7-37… -

Page 214

Chapter 7: Error messages 7-38 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 215: Tools (Service Equipment)

35 °C to 39 °C. We recommend using UMED measuring equipment as supplied by the manufacturer. HMED pressure measuring instrument with case (set) Universal measuring device UMED with case (set) (temperature, conductivity, pressure) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 216

Chapter 8: Tools (service equipment) Secutest VDE test device (without printer module) Printer module Carrying case (not illustrated) Service Software Set 4008 Measuring cylinder 100 ml Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 217

Chapter 8: Tools (service equipment) ESD service kit ESD workshop kit Extraction tool for ICs Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 218

Chapter 8: Tools (service equipment) Electronic pocket scales Adjustment set for 22-mm air detector ® Calibration connector for bibag Conductivity / temperature Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 219

Chapter 8: Tools (service equipment) ND grey foil filter 0.4 Deep hexagon socket wrench for Luer-Lock Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 220

Chapter 8: Tools (service equipment) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 221: Calibration / Adjustment

(see chapter 9.1.11 page 9-11) (Single-Needle pressure) (optional) Adjusting the current increasing pulse (see chapter 9.1.15 page 9-14) Setting the Hall sensors in the heparin pump (see chapter 9.1.46 page 9-39) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 222: Calibration Menu Structure

Part 14 Conf CALIBRATE BLD see Part 15 Conf CALIB. BIBAG VALUES see Part 16 Conf RESET FAILURE RECORD see Part 17 Conf NOVRAM see Part 18 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 223

(see chapter 9.1.38 page 9-34) CALIBRATE BLD (see chapter 9.1.42 page 9-37) CALIB. BIBAG VALUES (see chapter 9.1.43 page 9-38) RESET FAILURE RECORD (see chapter 9.1.44 page 9-38) NOVRAM (see chapter 9.1.45 page 9-39) Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 224: Part 1: Calibrating The Arterial Pressure

The accuracy of the pressure gauge used must correspond to that of the UMED or HMED. The accuracy of the pressure gauge used must at least correspond to the following values: –1 to 2 bar: ±5 mbar 2 to 8 bar: ±20 mbar Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 225: Part 2: Calibrating The Pressure In The Arterial Blood Pump

Start/Stop key on the blood pump module The values are stored. Should this message fail to appear, repeat the calibration procdure. Reset the hex switch to position 2 in the final step. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 226: Without Menu Display: Setting The Blood Pump Stop Alarm

Without menu display: Setting the blood pump stop alarm Set the hex switch on P.C.B. LP 624 (pos. 1) to position B. If the error message E02 appears on the blood pump display, reset it with the Start/Stop key. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 227: Part 3: Calibrating The Venous Pressure

The accuracy of the pressure gauge used must correspond to that of the UMED or HMED. The accuracy of the pressure gauge used must at least correspond to the following values: -1 to 2 bar ±5 mbar 2 to 8 bar ±20 mbar Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 228: Part 4: Calibrating The Venous Pressure Measurement In The Air Detector

Check zero point and slope; if necessary, repeat the procedure. Note: When adjusting the air detector, execute the CAL. VENOUS PRESSURE menu item. Fig.: P.C.B. LP 450-2 Potentiometer P3 Potentiometer P4 P.C.B. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 229: Part 5: Calibrating The Blood Pump Rate

Note: Set the line diameter to 8 mm before starting the calibration procedure and press Start/Stop on the blood pump. * The BP rate of 550 ml/min represents a default value. It can be changed using the LM (+/–) keys. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 230: Part 5.2: Calibrating The Sn Blood Pump Rate (Option)

Setting the Single-Needle stroke volume 1. Simultaneously press the and Start/Stop keys. 2. Press the and (+ / –) keys to set the stroke volume and confirm with Start/Stop. 9-10 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 231: Without Menu Display: Calibrating The Single-Needle Blood Pump (Single-Needle Pressure) (Optional)

Single-Needle pump: the lower switching point is fixed (75 mmHg). – the upper switching point depends on the stroke volume, see table below: Stroke volume (ml) Upper switching point (mmHg) ±7 mmHg Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-11…

-

Page 232: Part 6: Measuring The Volume Of The Uf Pump In Liters

Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. 9-12 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 233: Part 7: Calibrating The Degassing Pressure

«Calibrate flow», maybe the setting of the current increasing pulse must be changed. Note The flow selected first is accompanied by the DIASAFE-filling act. message which is displayed for the duration of 17 balancing chamber switchings. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-13…

-

Page 234: Without Menu Display: Adjusting The Current Increasing Pulse

10 seconds after each half revolution!) until the actual flow is again approx. 300. – Turn potentiometer P1 in clockwise direction for another 2 revolutions. Case 2: The device is in intrinsic pulse mode («Eigentakt»). – Display: flow (300) = 147 9-14 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 235: Part 9: Calibrating The 500 Flow Rate

Change the digits in display (field y) by pressing the +/– keys, until the actual value agrees with the specified value (500). Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-15…

-

Page 236: Part 10: Calibrating The 800 Flow Rate

Part 11.1 Conf Check TEMPERATURE see Part 11.2 Conf OCM TEMP.-Check see Part 11.3 Conf back to menu ? Note Accuracy of the measuring instrument to be connected externally: ±0.2 °C. 9-16 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 237: Part 11.1: Setting The Dialysate Temperature

NTC3 temperature NTC4, 12 bit Dynamic measuring range switching Note The hydraulic unit must be installed, the rear wall closed and the ® DIASAFE plus must be covered. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-17…

-

Page 238: Part 11.2: Check The Dialysate Temperature

Repeat the Tolerance: ±0.5 °C procedure with different values (e.g. 35/39 °C) Note The hydraulic unit must be installed, the rear wall closed and the ® DIASAFE plus must be covered. 9-18 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 239: Part 11.3: Checking The Dialysate Temperature For Ocm

Repeat the ±0.2 °C procedure with different values (e.g. 35/39 °C) Note The hydraulic unit must be installed, the rear wall closed and the ® DIASAFE plus must be covered. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-19…

-

Page 240: Part 12: Calibrating The Mixing System

MAND. FILLING active Time left displayed in display field Œ After 9 s Press ALARMTONE MUTE Audio paused act temp = XX.X °C The membrane pumps are running; the display counts down. 9-20 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 241: Part 12.2: Determining The Balancing Chamber Volume

BC-Volume = 30.19 ml Audio paused DATA STORED After approx. 3 s Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-21…

-

Page 242: Part 12.3: Calibrating The Concentrate Pump Stroke

CONP-Vol = 0.828 ml Enter the determined volume of one pump stroke by pressing the +/– keys. Audio paused DATA STORED After approx. 3 s Note Measuring cylinder accuracy: ±0.5 %. 9-22 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 243: Part 12.4: Measuring The Volume Of The Concentrate Pump In Liters

Check the volume and, if necessary, repeat the procedure. Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-23…

-

Page 244: Part 12.5: Calibrating The Bicarbonate Pump Stroke

+/– keys. Audio paused DATA STORED After approx. 3 s Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. 9-24 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 245: Part 12.6: Measuring The Volume Of The Bicarbonate Pump In Liters

Check the volume and, if necessary, repeat the procedure. Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-25…

-

Page 246: Part 12.7: Checking The Concentrate And Bicarbonate Volumes

However, when returning to “CAL. MIXING-SYSTEM”, the display will indicate the factory setting again. Note Measuring cylinder accuracy: ±0.5 %. Note When using scales as a measuring instrument, please ensure that concentrate is not connected. 9-26 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 247

OCM PULSE calibr. see Part 13.3 Conf CONDUCTIVITY Check see Part 13.4 Conf OCM COND.-Check see Part 13.5 Conf TEMP/COND COMP Check see Part 13.6 Conf back to menu ? Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-27… -

Page 248: Part 13.1: Conductivity Setting

CD cell 7; 12 bit / 8 bit switching Steps for concentrate pump Steps for bicarbonate pump CD cell 110; 12 bit / 8 bit switching 9-28 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 249: Part 13.2: Temperature/Conductivity Compensation Setting

Verify that the preset temperature of 39 °C is achieved and that it has stabilized. Check: Display, LED bargraph display Tolerance: ±0.5 °C Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-29…

-

Page 250: Part 13.3: Calibrating The Ocm Pulse

Tolerance per pulse: ±25 Audio paused DATA STORED After approx. 3 s Note If the value is outside ±25, the conductivity measuring system of the hemodialysis device must be checked. 9-30 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 251: Part 13.4: Conductivity Test

3 s CD cell 110; 12 bit / 8 bit switching act.cond: XX.X mS/cm Verify the conductivity. Check: Reference meter, display, LED bargraph display. Repeat the procedure with different values. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-31…

-

Page 252: Part 13.5: Checking The Ocm Conductivity

CD cell 110; 12 bit After approx. 3 s CD cell 110 OCM Cond.-Check Verify the conductivity. Check: Reference meter, display, LED bargraph display. Repeat the procedure with different values. 9-32 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 253: Part 13.6: Temperature / Conductivity Compensation Test

(7, 110) against each other. The tolerance of the two conductivity cells may not exceed 0.05 mS/cm. If this tolerance is exceeded, the OCM pulse must be calibrated. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-33…

-

Page 254: Part 14: Calibrating The Dialysate Pressure

UMED or HMED. The accuracy of the pressure gauge used must at least correspond to the following values: -1 to 2 bar ±5 mbar 2 to 8 bar ±20 mbar 9-34 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 255: Part 14.1: Dialysate Pressure

After the system has recognized that the circuit is open, the flow is switched on automatically. Wait for MUTE-LED The Audio paused LED is flashing. Audio paused DATA STORED After approx. 3 s Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-35…

-

Page 256: Part 14.2: Tmp-Check

Use the following steps to check flow compensation: – Use the Arrow keys to select the Flow setting field. – Set the flow by pressing the + / – keys – Confirm with Audio paused key 9-36 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 257: Part 15: Blood Leak Voltage

Tolerance for dimness voltage: 5 V ±0.3 V. Note: If values deviate check the glass burette for contamination. Close the housing; temperature 37 °C; avoid incident light from an external source. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-37…

-

Page 258: Part 16: Calibrating The Bibag ® Values

With test plug: 45,7 mS/cm or 84,5 mS/cm 9.1.44 Part 17: Reset the failure record RESET FAILURE RECORD Conf Audible alarm Are you sure ? Audio paused ACKNOWLEDGED After approx. 3 s 9-38 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 259: Part 18: Initializing The Novram, Clearing The Mandatory Rinse, Erasing A V84 Malfunction

– Adjust Hall sensor 1, so that the the bottom of the plunger and the end of the syringe’s scale (0 ml) are on the same level. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-39…

-

Page 260

Each time Hall sensor 2 was adjusted, the complete setting for Hall sensor 2 have to be repeated. – Briefly press the key (syringe plunger holder moves to its upper end position). 9-40 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 261

Chapter 9: Calibration / adjustment Hall sensor 1 Hall sensor 2 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-41… -

Page 262: Hydraulics Unit

– Pull back the knurled nut on the pressure reducing valve A61. – Turn the knurled nut to set the water pressure to the desired value (clockwise: «+», counterclockwise: «–»). – Push the knurled nut back in. 9-42 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 263: Degassing Pump Pressure

Adjusting the pressure of the degassing pump: – Enter the CALIBRATION service menu, select and start the option CAL. DEGAS. PRESSURE (see Part 7: Calibrating the degassing pressure page 9-13). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-43…

-

Page 264

The setting for the degassing pump has to be increased in increments from a low speed until no significant increase of the degassing pump pressure can be detected anymore. This setting can also be saved. 9-44 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 265: Balancing Chamber Loading Pressure

Adjusting the loading pressure of the balancing chamber: – Use the loading pressure valve A65 to adjust the loading pressure to the desired value. Turning the adjusting screw clockwise will increase the loading pressure. Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-45…

-

Page 266: Flow Pump Pressure

– If it deviates from the desired value, the pressure of the flow pump must be adjusted. Adjusting the pressure of the flow pump – Use the relief valve A78 to adjust the rated value. 9-46 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 267: Uf Pump Volume

– Change the delivery volume, using the adjusting screw (turning the adjusting screw clockwise reduces, turning it counter-clockwise increases the stroke volume). – Retighten the lock nut – Verify the delivery volume Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-47…

-

Page 268: Cds (Central Delivery System) Pressure Switch

0.7 bar continues to act on the pressure switch. – Check the switching point by means of the audible alarm. Desired value: Pressure switch (Envec): 0.68–0.72 bar. Fig.: CDS pressure switch (PSW 123) 9-48 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 269

Chapter 9: Calibration / adjustment Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-49… -

Page 270

Measured switching pressure: 130 mbar +30 mbar. Note In the menu item E: CPU1_BIBAG_PSW, the active level is identified by 1111. The active level of the circuit output is LOW (< 1 V). 9-50 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 271: Air Detector

UMED «External Sensors 1–5» using the External sensor cable. Only for UMED: not applicable for HMED or pressure gage! Luer-Lock adapter Put the tubing into the venous occlusion clamp Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-51…

-

Page 272

The ambient temperature should be between 15 °C and 35 °C. Warning The calibration using the set for the air detector calibration is only valid for devices running with Fresenius tubing systems. Observe the “use by” date! 9-52 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 273: Adjustment Using The Set For Air Detector Calibration (See Adjustment Instructions)

Remove residual grease using lint-free cloth and a permissible disinfectant. – In addition, the venous occlusion clamp has to be checked and the optical detector has to be calibrated and checked (see chapter 9.3.1.2 page 9-54). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-53…

-

Page 274: Checking The Venous Occlusion Clamp

DIAGNOSTICS service menu: Read digital inputs CPU 1, select the menu item E: CPU1_OD_IN: – Install the grey filter, single-laid; close the flap – The display changes from 1111 to 0000 9-54 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13…

-

Page 275: Alternative: Adjustment Without The Set For Air Detector Calibration

– Remove the venous bubble catcher from the air detector. – In addition, the venous occlusion clamp has to be checked and the optical detector has to be calibrated and checked (see chapter 9.3.1.2 page 9-54). Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13 9-55…

-

Page 276

Chapter 9: Calibration / adjustment 9-56 Fresenius Medical Care 4008 S (Version V10) SM-EN 7/01.13… -

Page 277: Servicing / Repair