SMART Digital DDA представляет собой компактный объемный, дозирующий насос с диафрагмой, двигателем с переменной скоростью вращения (двигатель PMS) и интеллектуальной электронной системой управления. Потребляет минимальное количество электроэнергии. Серия SMART Digital Dosing работает с полной длиной хода, чтобы обеспечить оптимальную точность, дозирования и всасывание даже для жидкостей с высокой вязкостью или дегазацией. Продолжительность каждого такта выпуска зависит от установки мощности, что обеспечивает оптимальный плавный и непрерывный расход. Монтажная панель обеспечивает быструю установку и обслуживание. Блок управления можно легко поворачивать в переднее, левое или правое положение. Колесо управления и разноцветная подсветка графического текстового ЖК-дисплей делают ввод в эксплуатацию интуитивно понятным. Элементы управления защищены прозрачной крышкой.

Система FlowControl (FCM) на основе датчиков обнаруживает неисправности непосредственно в дозирующей головке и отображает их в виде обычного текста в меню сигнализации, например. Воздушные пузыри, разрыв линии, избыточное давление. Интегрированная функция измерения расхода измеряет фактический расход и делает избыточное избыточное контрольное и контрольное оборудование (точность ± 1% от заданного значения в случае безотказной работы). Измеренный поток отображается и может быть интегрирован в управление процессом, например. SCADA. Кроме того, функция AutoFlowAdapt автоматически регулирует скорость работы насоса в соответствии с условиями процесса для поддержания целевого потока, даже напр. Различное противодавление или вспенивание пузырьков воздуха (принцип работы дегазации).

Дозирующая головка состоит из:

- Тефлоновой мембраны, материал которой является универсальным, химически стойким и обеспечивает длительный срок службы.

- Двойных шариковых (всасывающего и нагнетательного) клапанов для устранения перетечек жидкостей и максимальной точности дозирования.

- Клапана деаэрации для удаления воздуха из дозирующей головки в момент пуска, что облегчает запуск насоса.

- Датчика давления

Режимы работы:

- Ручное дозирование в мл / ч, л / ч или гал.

- Импульсное управление в мл / импульс (с функцией памяти).

- Аналоговое управление 0/4-20 мА (масштабируемое).

- Режим работы «Партия» в мл, л или гал.

- Таймер на основе функции «Партия» (дозирование по таймеру, недельным циклом).

- Цифровое управление (GENIbus подготовлены для модулей Grundfos CIU).

Другие особенности:

- Авто-деаэрация во время работы насоса в режиме ожидания, чтобы избежать аварии из-за воздушных пробок.

- SlowMode (анти-кавитация), позволяет уменьшать частоту вращения двигателя на 50% (maximum flow: 100 л/ч) и 25% (maximum flow: 50 л/ч), например, высокой вязкостью или дегазации жидкостей.

- Дисплей “Сервис” показывает, когда необходимо выполнить техобслуживание изнашиваемых деталей.

- Два варианта блокировки клавиш в зависимости от уровня защиты для защиты насоса от несанкционированного доступа.

- Дополнительная функция для отображения дополнительной информации, например, фактический ввод мА.

- Счетчик для общего дозированного объема (сброс), часы работы и т.д.

- Сохранять и загружать пользовательские настройки, а также изменять заводские настройки.

Сигнальные входы / выходы:

- Вход для импульсов, аналоговый 0 / 4-20 мА и внешний останов.

- Вход для сигнала низкого уровня и пустого резервуара.

- Два беспотенциальных выходных реле для максимального 30 В переменного / постоянного тока (настраиваемый, например, сигнал тревоги, сигнал хода, дозировка насоса, таймер и т. Д.).

- Выходной аналоговый 0 / 4-20 мА.

- Интерфейс связи Fieldbus (GENIbus, для подключения преобразователя fieldbus Grundfos CIU).

Предлагаем Вам купить Grundfos DDA 12-10 AR-PVC/E/C-F-31U2U2FG по выгодной цене 221 359 р.

Grundfos DDA 12-10 AR-PVC/E/C-F-31U2U2FG отличается высоким качеством и оптимальной ценой. Производитель известен во всем мире и предоставляет гарантию на свою продукцию.

Чтобы купить Grundfos DDA 12-10 AR-PVC/E/C-F-31U2U2FG в нашем интернет магазине вам достаточно оформить заказ онлайн на сайте

SMART Digital S

DIGITAL DOSING up to 30 l/h

DDA, DDC, DDE

Pumps and accessories

GRUNDFOS

DATA BOOKLET

2

SMART Digital S

1.

General data 3

Performance range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features at a glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.

Identification 6

Type key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.

Functions 7

Overview of functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control cube DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring diagram, DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring diagram, DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring diagram, DDE-PR, -P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.

Construction 22

DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.

Dimensions 24

DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.

Technical data 25

DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.

Pump selection 28

DDA, standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DDC, standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DDE, standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DDA, DDC, DDE, non-standard range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.

Accessories for small dosing pumps up to 60 l/h 33

Accessories overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation kits for dosing pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cables and plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

E-box for SMART digital S DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Foot valves FV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rigid suction lances RSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Injection units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Multi-function valves, pressure relief valves, pressure loading valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pump connection kits and inlay kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dosing tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Water meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.

Pumped liquids

10. Grundfos Product Center

56

57

SMART Digital S

1. General data

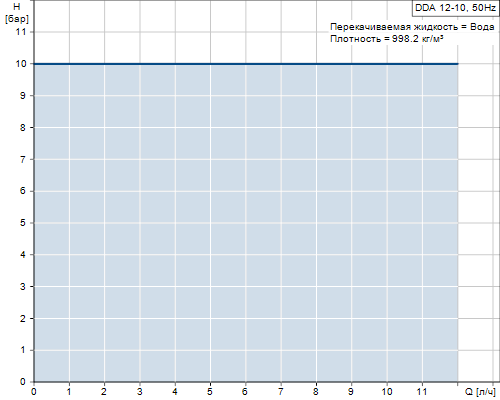

Performance range

p

[bar]

16

DDA 7.5-16

10

7

DDC 6-10

DDE 6-10

DDA 12-10

DDC 9-7 DDA 17-7

4

DDC 15-4

DDE 15-4

0

Fig. 1

Performance range

6 7.5

9 12 15 17

DDA 30-4

30 Q [l/h]

1

3

1

SMART Digital S

Features at a glance

Precise and easy setting / usability and interaction

The operator can easily install the pump and set it to discharge exactly the quantity of dosing liquid required for the application. In the display, the setting of the pump is read out directly, the flow is shown in ml/h, l/h, or gph.

The click wheel (turn-and-push knob) and the graphical LC display with plain-text menu in more than

25 languages make commissioning and operation intuitive. As the LCD is backlit in different colours, the pump status can be seen from a distance (traffic-light concept).

Fig. 2

DDA, DDC, DDE

Digital Dosing

TM

The SMART Digital S generation DDA, DDC and DDE with powerful variable-speed stepper motor brings state-of-the-art technology to perfection.

Combined expert knowledge and the patented solutions set future standards. Traditional technologies such as stroke length or stroke frequency adjustment with synchronous motor or solenoid drive become a thing of the past.

Unique flexibility with only a few variants

The included click-stop mounting plate makes the pump more flexible. Three different positions are possible without using any additional accessories, such as wall brackets. Service and pump exchange can now be done easily and fast just by clicking the pump in and out of the mounting plate.

The control cube on the DDA and DDC pump can be lifted and turned easily into three different positions: front, left or right.

Fig. 3

Modularity of the control cube

A turn-down ratio of up to 1:3000, a wide supply voltage range (100-240 V; 50/60 Hz), combined connection sets and other features reduce the models and variants to a minimum.

Fig. 4

Display DDA, DDC

Thanks to a variety of operation modes, signal inputs and outputs, the pump can easily be integrated into every process.

Advanced process reliability

An intelligent drive and microprocessor control ensures that dosing is performed precisely and with low pulsation, even if the pump is dosing high-viscosity or degassing liquids. Malfunctions, caused e.g. by air bubbles, are detected quickly by the maintenance-free

FlowControl system and then displayed in the alarm menu.

The AutoFlowAdapt function automatically adjusts the pump according to the process conditions, e.g. varying backpressure. The integrated flow measurement makes additional monitoring and control equipment redundant.

Designed to save costs

In general, the investment for a dosing pump installation is low compared to its life cycle costs including the cost of the chemicals. The following features make the SMART Digital S DDA, DDC and

DDE pumps contribute to low life cycle costs:

• No underdosing or overdosing due to high dosing accuracy and FlowControl

• Longer maintenance intervals thanks to the universal chemical resistance of the full-PTFE diaphragm

• Reduced energy consumption thanks to state-of-the-art drive technology.

4

SMART Digital S

Three application-oriented type ranges

DDA: High-end pump range for extended flow and pressure ranges with sensor-based FlowControl and measurement functions for challenging industrial applications, e.g.

• Process water

• Food and beverage

• Ultrafiltration and reverse osmosis

• Pulp and paper

• Boiler feed water

• CIP (Cleaning-In-Place).

DDC: User-friendly pump range with standard inputs and outputs for common applications, e.g.

• Drinking water

• Waste water

• Swimming pool water

• Cooling tower

• Chemical industry.

DDE: Low-budget pump range with basic functions including manual operation or control via PLC for OEM applications, e.g.

• Car wash

• Irrigation.

1

5

2

SMART Digital S

2. Identification

Type key

Example: DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

Type range

DDA

7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

DDA

DDC

DDE

Max. flow [l/h]

DDA

7.5

-16 AR-PP/V/C-F-3 1 U2U2 F G

Maximum pressure [bar]

DDA 7.5-

16

AR-PP/V/C-F-3 1 U2U2 F G

Control variant

DDA 7.5-16

AR

-PP/V/C-F-3 1 U2U2 F G

B Basic (DDE)

P

PR

A

AR

FC

FCM

B with pulse mode (DDE)

P with relay output (DDE)

Standard (DDC)

A with alarm relay and analog input (DDA, DDC)

AR with FlowControl (DDA)

FC with flow measurement (DDA)

Dosing head variant

DDA 7.5-16 AR-

PP

/V/C-F-3 1 U2U2 F G

PP Polypropylene

PVC

PV

SS

Polyvinyl chloride**

PVDF (polyvinylidene fluoride)

Stainless steel 1.4401

Gasket material

DDA 7.5-16 AR-PP/

V

/C-F-3 1 U2U2 F G

E

V

T

EPDM

FKM

PTFE

Valve ball material

DDA 7.5-16 AR-PP/V/

C

-F-3 1 U2U2 F G

C

SS

Ceramic

Stainless steel 1.4401

Control cube position

DDA 7.5-16 AR-PP/V/C-

F

-3 1 U2U2 F G

F Front-mounted (change to left and right possible)

X No control cube (DDE)

Supply voltage

DDA 7.5-16 AR-PP/V/C-F-

3

1 U2U2 F G

3 1 x 100-240 V, 50/60 Hz

Valve type

DDA 7.5-16 AR-PP/V/C-F-3

1

U2U2 F G

1

2

Standard

Spring-loaded

0.1 bar suction opening pressure

0.1 bar discharge opening pressure

Connection, suction/discharge

DDA 7.5-16 AR-PP/V/C-F-3 1

U2U2

F G

U2U2

Union nut G 5/8″ with parts for hose connection

4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

U7U7

AA

VV

XX

Union nut G 5/8″ with parts for hose connection

0.17″ x 1/4″; 1/4″ x 3/8″; 3/8″ x 1/2″

Union nut G 5/8″ with threaded connection Rp 1/4″, internal thread

Union nut G 5/8″ with threaded connection 1/4″ NPT, internal thread

No connections included

I001

*

I002

*

I003

*

I004

*

Hose 4/6 mm (up to 7.5 l/h, 13 bar)

Hose 9/12 mm (up to 60 l/h, 9 bar)

Hose 0.17″ x 1/4″ (up to 7.5 l/h, 13 bar)

Hose 3/8″ x 1/2″ (up to 60 l/h, 10 bar)

Mains plug

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2

F

G

F

B

EU

USA, Canada

E

J

I

G

L

UK

Australia, New Zealand

Switzerland

Japan

Argentina

Design/approval

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F

G

G

A

Grundfos red

Grundfos green

B

X

C

Grundfos black

Neutral/black

China approval

Special variant

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

C3

C3 Inspection Certificate 3.1 (EN 10204)

* Installation set: Including 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose (4/6 mm)

** PVC dosing heads only up to 10 bar

6

SMART Digital S

3. Functions

Overview of functions

Control variant: FCM

General

Digital Dosing: Internal stroke speed and frequency control

Mounting plate (basic/wall mounting)

Control panel, see page

9

Control cube mountable in three positions: front, left, right

Control panel position: front-fitted

Transparent protective cover for control elements

Capacity setting in millilitres, litres or US-gallons

Graphical display with background light in four colours for status indication: white, green, yellow, red

Plain-text menu in different languages

Turn-and-push knob (click wheel) for easy navigation

Capacity adjustment knob (0.1 — 100 %)

Start/Stop key

100 % key (deaearation)

Operation mode switch (manual/pulse)

Operation modes, see page

11

Manual speed control

Pulse control in ml/pulse

Pulse control (1:n)

Analog control 0/4-20 mA

Batch control (pulse-based)

Dosing timer cycle

Dosing timer week

Fieldbus control

Functions, see page

13

Auto deaeration also during pump standby

FlowControl system with selective fault diagnosis

Pressure monitoring (min/max)

Flow measurement

AutoFlowAdapt

SlowMode (anti-cavitation)

Calibration mode

Scaling of analog input

Service information display

Relay setting: alarm, warning, stroke signal, pump dosing, pulse input*

Relay setting (additionally): timer cycle, timer week

Inputs/outputs, see page 14

Input for external stop

Input for pulse control

Input for analog 0/4-20 mA control

Input for low-level signal

Input for empty tank signal

Output relay (2 relays)

Output analog 0/4-20 mA

Input/Output for GENIbus

Input/Output for E-box (e.g. E-box 150 with Profibus DP)

●

●

●

●

●

●

●

●

●

●

* DDE-PR: relay 1: alarm; relay 2: low-level signal, stroke signal, pulse input

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

DDA

FC

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

AR

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

AR

DDC

A

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

PR

DDE

P

●

●

●

●

B

●

●

● ● ●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

3

7

3

Functional description

The electronically controlled variable-speed motor

(stepper motor) of the DDA, DDC and DDE pumps provides optimum control of the stroke speed.

The duration of each discharge stroke varies according to the capacity set, resulting in optimum discharge flow in any operating situation, while the duration of each suction stroke is constant (see figure below).

The advantages are as follows:

• The pump always operates at full stroke length, irrespective of the capacity set; this ensures optimum accuracy, priming and suction.

• A capacity range of up to 1:3000 (turn-down ratio) reduces variants and spare parts.

• Smooth and continuous dosing ensuring an optimum mixing ratio at the injection point without needing static mixers.

• Significant reduction of pressure peaks, preventing mechanical stress on wearing parts such as diaphragm, tubes, connections, resulting in extended maintenance intervals.

• The installation is less affected by long suction and discharge lines.

• Easier dosing of high-viscosity and degassing liquids (SlowMode).

The optimum dosing control shown below takes place in any operation mode.

SlowMode Capacity setting

100 % —

Discharge

Suction

Discharge

50 % —

Suction

Discharge

10 % —

Suction

Discharge

10 % 50 %

Suction

Extended suction stroke (SlowMode)

Fig. 5

Relation between stroke-frequency adjustment and capacity

SMART Digital S

Duration

Duration

Duration

Duration

8

SMART Digital S

Control cube DDA and DDC

DDA and DDC pumps are supplied with front-mounted control cube. The position of the control cube can easily be changed by unfastening 2 screws, lifting the cube, turning it to the left or to the right and fastening both screws again.

Fig. 6

Two of three possible control cube positions

Operating elements DDA and DDC

1

2

Operation

Manual

7.5

l/h

7.49 l/h

3

4

Fig. 7

Operating elements DDA and DDC

Pos.

Description

1

2

3

4

Graphical LC display

[Start/Stop] key

Click wheel

[100%] key

The click wheel guides the user quickly and easily through the plain-text menu.

If the maximum capacity is required over a short period of time, for example during start-up, press the 100 % key. To set the pump to run for a specific number of seconds at maximum capacity, press the 100 % key and turn the click wheel clockwise simultaneously.

Operating elements DDE

0.6

0.5

0.4

1

0.8

0.3

0.2

0.15

1.5 2

0%

3 4 5 6

8

10

15

20

30

80

60

40

50

100

%

100%

Fig. 8

Operating elements DDE

5

6

3

4

7

1

2

Pos.

Description

5

6

7

3

4

1

2

Status LED pulse (DDE-PR and DDE-P)

Operation mode switch (DDE-PR and DDE-P)

Status LED manual

Capacity adjustment knob

Logarithmic scale

100 % key (DDE-PR and DDE-P)

Mechanical lock

With the capacity adjustment knob the capacity of the pump can easily be adjusted in % of the maximum flow.

Applies to DDE-PR, DDE-P

When holding down the operation mode switch, the pump changes from manual operation to pulse mode or vice versa.

If the maximum capacity is required over a short period of time, for example during start-up, press the 100 % key.

Depending on the selected operation mode, the respective status LED (pulse or manual) is activated according to the following table:

LED colour

Green (flashing)

Green

Red-green (flashing)

Yellow

Red

Red (flashing)

Pump status

Stopped

Running

External stop

Low level (warning)

Empty tank (alarm)

Motor blocked (alarm)

3

9

3

SMART Digital S

Menu

The DDA and DDC dosing pumps feature a user-friendly plain-text menu. The menu consists of 4 tabs: Operation;

Info; Alarm; Setup. During initial start-up, all menu text appears in the English language. The menu can be set to display other languages.

This example applies to DDA pumps:

Operation

Manual

7.50

l/h

7.49 l/h

Setup

Language

Operation mode

Analog output

SlowMode

………………………..

English >

Manual >

Input >

Off >

Info

Fr 12.12.2009

Counter

Service

Service kit

………………………..

12:34

>

—

Alarm

1

Low level

12.12.2009

2

Empty

11.12.2009

13:34

14:34

Fig. 9

Menu overview (example of main menus)

The menu text appears in more than 25 languages on a big graphical display, backlit in four different colours according to the traffic light concept.

Display

White

Green

Yellow

Red

Fault

—

—

Warning

Alarm

Pump status

Stop Standby

Running

Stop Standby

10

SMART Digital S

Operation modes

Manual control

The pump ensures constant dosing according to the quantity set in l/h or ml/h or gph by means of the click wheel. The pump automatically changes between the measuring units.

Setting range

Setting range*

Pump type

DDA 7.5-16

DDA 12-10

DDA 17-7

DDA 30-4

DDC 6-10

DDC 9-7

DDC 15-4

DDE 6-10

DDE 15-4

From [l/h]

0.0025

0.0120

0.0170

0.0300

0.0060

0.0090

0.0150

0.0060

0.0150

To [l/h]

7.5

12.0

17.0

30.0

6.0

9.0

15.0

6.0

15.0

* When the SlowMode function is enabled the max. flow is reduced

(see page 13

)

Pulse control

The pump doses in proportion to an external potential-free pulse signal, for example from a water meter. There is no direct relation between pulses and dosing strokes. The pump automatically calculates its optimal speed to ensure that the required quantity is dosed for each incoming pulse.

Applies to DDA and DDC

The quantity to be dosed is set in ml/pulse. The pump adjusts its speed according to two factors:

• the frequency of external pulses

• the set quantity per pulse.

Setting range

Pump type

DDA 7.5-16

DDA 12-10

DDA 17-7

DDA 30-4

DDC 6-10

DDC 9-7

DDC 15-4

Setting range [ml/pulse]

0.0015 — 14.9

0.0029 — 29.0

0.0031 — 31.0

0.0062 — 62.0

0.0016 — 16.2

0.0017 — 16.8

0.0032 — 31.6

The frequency of external pulses is multiplied by the set quantity. If the product exceeds the maximum flow of the pump, a maximum of 65,000 pulses can be stored for later processing with the Memory pulse function, when activated.

Applies to DDE-PR, DDE-P control variant

The dosing quantity per pulse is adjusted with the adjustment knob according to the scale from 0.1 to

100 % of the stroke volume. The pump adjusts its speed according to two factors:

• the frequency of external pulses

• the set percentage of stroke volume.

Setting range, DDE-PR, DDE-P

Pump type

DDE 6-10

DDE 15-4

Setting range [ml/pulse]

0.0008 — 0.81

0.0016 — 1.58

Analog 0/4-20 mA control

Applies to DDA and DDC-AR control variant

The pump ensures dosing according to an external analog signal. The dosed capacity is proportional to the input value in mA.

Operation mode

4-20

0-20

Input signal

≤ 4.1 mA

≥ 19.8 mA

≤ 0.1 mA

≥ 19.8 mA

Dosing capacity

0 %

100 %

0 %

100 %

Dosing capacity

Q [%]

100

80

60

40

20

4 — 20 mA

0

0 4 8

0 — 20 mA

12 16 20

Input signal

[mA]

Fig. 10

0/4-20 mA control

Applies to DDA

With the analog scaling function, the curve can be individually drawn between two arbitrary points: l and l

2

/Q

2

.

1

/Q

1

Dosing capacity

Q [%]

100

80

60

40

20

0

0 4 8 12 16 20

Input signal

[mA]

Fig. 11

Analog scaling

3

11

3

SMART Digital S

Pulse-based batch control

Applies to DDA

The set quantity is dosed in batches within the set dosing time (t

1

). A batch is dosed every time the pump receives an external pulse. If the pump receives new pulses before a batch is completed, these pulses will be ignored. In the event of interrupts such as external stop or alarm, incoming pulses will also be ignored.

After ending of the interrupts, a new batch will be dosed with the next incoming pulse.

Batch volume t

1 t

1

Pulse Pulse

Fig. 12

Pulse-based batch control

Setting range

Setting range

Pump type

DDA 7.5-16

DDA 12-10

DDA 17-7

DDA 30-4

From

[ml/batch]

0.74

1.45

1.55

3.10

To [l/batch]

999

999

999

999

Resolution [ml]*

0.09

0.18

0.19

0.39

* Due to the digital motor control, down to 1/8 of the dosing volume can be dosed.

Dosing timer cycle

Applies to DDA

After a start delay (t

2

) the set batch volume is repeatedly dosed in the set cycle time (t

3 time (t

1

). The dosing

) can be adjusted. Batch dosing is stopped during any interrupt, e.g. power supply failure or external stop while the time continues running in the background (real-time clock). After ending of the interrupt, batch dosing proceeds according to the current status in the timeline.

Batch volume

Dosing timer week

Applies to DDA

The integrated real-time clock features also batch dosing based on a weekly period. There is a maximum of 16 procedures per week. Each dosing procedure consists of:

• Batch volume

• Dosing time

• Start time

• 1 to 7 weekdays (Monday to Sunday).

In case several procedures are overlapping, the procedure with the highest flow rate has the highest priority. Batch dosing is stopped during any interrupt, e.g. power supply failure or external stop, while the time continues running in the background (real-time clock). After ending of the interrupt, batch dosing proceeds according to the current status in the timeline.

0:00

1 1 1

6:00

4 4

12:00

2 2

18:00

0:00

3

Mo Tu

3 3

We

3

Th Fr

3

Sa

3

3

Su

Fig. 14

Dosing timer week (example with 4 procedures)

Setting range

The batch volume setting range corresponds to the pulse-based batch control setting range.

t

1 t

1 t

2 t

3

Fig. 13

Dosing timer cycle

Setting range

The batch volume setting range corresponds to the pulse-based batch control setting range.

12

SMART Digital S

Functions

SlowMode

Applies to DDA, DDC

When the SlowMode function (anti-cavitation) is selected, the pump extends and smooths its suction stroke. This results in a softer suction stroke.

The SlowMode function is used in these situations:

• when pumping high-viscosity liquids

• when pumping degassing liquids

• when the suction line is long

• when the suction lift is high.

Depending on the application, the motor speed during the suction stroke can be reduced individually to approximately 50 % or 25 % of the normal motor speed.

The maximum pump capacity is reduced accordingly.

See pages 25 and

26 for further details.

Auto deaeration

Applies to DDA

The auto deaeration function avoids breakdown of the dosing process due to air-locking, when dosing degassing liquids such as sodium hypochlorite.

During long dosing breaks, e.g. at the weekend or overnight, air-bubbles can form in the suction line and get into the dosing head. If too much air is in the dosing head, and the dosing process is started again, no liquid will be dosed (air-lock). Software-controlled diaphragm movements at regular intervals encourage the air bubbles to rise and finally to be displaced out of the dosing head.

These movements are executed

• when the pump is not stopped and

• during dosing breaks (e.g. external stop or no incoming pulses).

Calibration

Applies to DDA and DDC

The pump is calibrated in the factory at the nominal pressure of the respective pump type (see maximum pressure Technical data page

25 ,

26

). After start-up, the dosing pump can be calibrated for the actual installation to ensure that the displayed value (ml, l or gph) is correct. A calibration program in the setup menu facilitates this process. The AutoFlowAdapt function keeps the dosing precision (DDA-FCM control variant), even if the backpressure changes.

For the description of the AutoFlowAdapt function, see page

18

.

External stop

Applies to DDA, DDC, DDE-PR, DDE-P

With the external stop function, the pump can be stopped from a remote place via an external contact. It is not recommended to switch on and off the power supply as it was usual when working with a conventional dosing pump. When working with microprocessor-controlled digital dosing pumps, the external stop signal has to be used, in order to keep the optimal dosing precision and to prevent damages to the electronics.

When activating the external stop signal, the pump changes from running to standby . The operation display shows an activated external stop .

The signal input can be set to normally open (default) or normally closed contact.

Counters

Applies to DDA and DDC

The pump displays resettable and non-resettable counters in the info menu tab.

Counter

Volume

Operating hours

Motor runtime

Strokes

Power on/off

Description

Accumulated dosed quantity in litres or

US gallons

Accumulated number of operating hours

(power-on)

Accumulated number of motor runtime hours

Accumulated number of dosing strokes

Accumulated number of times the mains supply has been switched on

Resettable

Yes

No

No

No

No

3

13

3

SMART Digital S

Service display

Applies to DDA, DDC

Due to the optimised construction and the smooth digital dosing principle, the service periods are more than twice as long, if compared to conventional pumps.

However, the wear parts have to be exchanged in regular intervals in order to keep the dosing precision and the process reliability at a high level. The service display in the pump shows when service of the wear parts is required. The displayed service kit product number makes service more convenient. The following information is displayed in the Info display:

Display

Service

Service kit

—

Soon

Now

8-digit Grundfos product number

Reset service system

Description

No service required

Order parts for service soon

Service must be performed now

The service kit contains all parts needed for standard maintenance: diaphragm + valves

After performing the service, reset the system

The following service messages appear, depending on what happens first:

Display

Service soon

Service now

* Applies to DDA only

Motor runtime

[h]

7,500

8,000

Regular intervals

[months]*

23

24

In case of difficult liquids the service intervals can be shorter and service has to be performed earlier.

Level control

Applies to DDA, DDC, DDE-PR and DDE-P

The pump can be connected to a dual level control unit for monitoring of the chemical level in the tank. The pump can react to two level signals:

Pump reaction*

Level sensors

Low-level signal

Empty tank signal

DDA, DDC

• Display is yellow

(Warning)

• is flashing

• Pump continues running

• Display is red (Alarm)

• is flashing

• Pump stops

DDE-PR, DDE-P

• LED lights up in yellow

• Pump continues running

• LED lights up in red

• Pump stops

* Depending on the pump model and settings, the relay outputs can be activated (see

Relay output

, page 14

)

Relay output

Applies to DDA, DDC-AR and DDE-PR

The pump can activate 2 external signals by means of built-in relays switched via internal potential-free contacts. Depending on the process control requirements, the following relay output settings can be chosen:

Applies to DDA and DDC-AR

Signal

Description

Relay 1 Relay 2

Alarm*

Warning*

Alarm

Warning

Timer week

Display red, pump stopped

(e.g. empty tank signal, etc.)

Display yellow, pump running

(low level signal, etc.)

Stroke signal Stroke signal Every completed stroke

Pump dosing Pump dosing* Pump is running and dosing

Pulse input Pulse input

Bus control Bus control

Timer cycle

Every pulse coming in from pulse input

Set by a command in the Bus

communication function (page 15 )

(only DDA)

Timer can be set in menu: on-time, cycle-time, start delay (only DDA)

Timer can be set in menu: procedure, on-time, start time and weekdays (only

DDA)

NO*

NC

Contact type

NO*

NC

Normally Open Contact

Normally Closed Contact

* default setting

Applies to DDE-PR control variant

Relay 1

Alarm*

NO*

NC

Signal

Description

Relay 2

Low level*

Empty tank, motor blocked

Low level tank

Stroke signal Every completed stroke

Pulse input Every pulse coming in from pulse input

Contact type

NO*

NC

Normally Open Contact

Normally Closed Contact

* default setting

14

SMART Digital S

Analog output

Applies to DDA

In addition to the analog input (operation mode: analog

0/4-20 mA) the pump is also equipped with an analog

0/4-20 mA output signal. Depending on the process control requirements, the following analog output settings are available:

Setting

Description of analog output signal

Control variant

FCM FC AR

Output = Input

Actual flow

Backpressure

Bus control

Analog feedback signal (not for master-slave application).

The analog input signal is mapped 1:1 to the analog output.

Flow measured in the dosing head

(Flow Measurement page

18

)

Backpressure measured in the dosing head

(Pressure monitoring page

18 )

Set by a command in the bus communication (see below)

X

X

X

X

X

X*

X

X

X

X*

X

* Output signal is calculated based on motor speed and pump status

(target flow rate).

Bus communication

Applies to DDA

The pump is equipped with a built-in module for

GENIbus communication. With the additional E-Box module (please see page

36 ) the pump can be

integrated into a fieldbus network.

The bus communication possibilities enable remote monitoring and setting via the fieldbus system.

Key lock and mechanical lock

Applies to DDA, DDC

To protect the pump from maloperation, a key lock can be set by entering a 4-digit PIN-code. When the pump is locked, it is still possible to navigate through the menus Alarm and Info and to acknowledge alarms. Two levels of protection are available:

• Settings: the keys and 100% are still available.

• Settings + keys: the keys locked.

and

100%

are also

For temporary (2 minutes) or final deactivation the preset 4-digit pin-code has to be entered again.

Applies to DDE

The adjustment knob can be locked with a locking screw to fix the current setting.

Basic settings

Applies to DDA, DDC

With load factory settings, the pump can be reset to the default settings. In addition, with save customer settings, the current configuration of the pump is stored and can be activated later by load customer settings. The latest saved configuration is stored in the memory.

Units

Applies to DDA, DDC

It is possible to select metric units (litre/millilitre/bar) or

US units (US gallons/psi). Depending on the operation mode and menu, the following units are displayed:

Operation mode/Function

Manual control

Pulse control

Analog 0/4-20 mA control

Batch control

(pulse- or timer-based)

Calibration

Volume counter

Pressure monitoring

Metric units

ml/h or l/h ml/ ml/h or l/h ml or l l ml bar gal ml gal psi

US units

gph ml/ gph

Fig. 15

DDA with E-box

3

15

3

SMART Digital S

Additional display

Applies to DDA, DDC

The additional display function provides further useful status information, e.g. the target flow rate as well as the actual flow rate. The value is shown in the operation display together with the corresponding symbol.

Operation

Manual

7.50

l/h

7.49 l/h

Additional display

Fig. 16

Additional display

The following additional information can be selected:

Settings Description

Depending on the operation mode:

Actual flow (manual, pulse)

1)

Default display

Dosed volume

Actual flow

Backpressure

Target flow (pulse)

Input current (analog)

4)

Remaining batch volume (batch, timer)

3)

Time until next batch (timer)

3)

Total dosed volume (Counters see page

13 )

Actually measured flow

1)

Current backpressure in the dosing head

2)

1) Only DDA-FCM control variant

2) Only DDA-FCM/FC control variant

3) Only DDA pumps

4) Only DDA pumps and DDC-AR control variant

FlowControl

Applies to DDA-FC/FCM

Fig. 17

DDA FlowControl

The pump monitors the dosing process of liquids when the FlowControl function is activated. Although the pump is still operating, some influences such as air bubbles may cause reduced flow rates or even stop the dosing process. For optimal process safety and reliability, the activated FlowControl function immediately detects and displays the following malfunctions:

• Overpressure

• Discharge line burst

• Air bubbles in the dosing head

• Cavitation at the suction side

• Suction valve leakage

• Discharge valve leakage.

The unique FlowControl is based on an intelligent and maintenance-free sensor integrated in the dosing head. During the dosing process, the sensor measures the actual pressure and sends the measured value to the microprocessor in the pump. An internal indicator diagram is generated combining the actual pressure value with the diaphragm position (stroke length).

With it, the dosing process is monitored, as the different malfunctions can immediately be detected due to their specific deviations in the curve.

Compressible air bubbles, for instance, will reduce the discharge phase and the stroke volume (see fig.

18

).

The sensitivity and the delay of the FlowControl function can be adjusted individually.

FlowControl requires a minimum backpressure of

2 bar. Grundfos recommend an additional spring-loaded valve (approx. 3 bar) on the discharge side for dosing low capacities (< 1 l/h) (please see page

46

).

16

SMART Digital S

Pressure

Trouble-free dosing stroke

1

2

Air bubbles disturbing the dosing stroke

4

Stroke length

Fig. 18

Indicator diagram

3

4

1

2

Compression phase

Discharge phase

Expansion phase

Suction phase

3

3

17

3

SMART Digital S

Pressure monitoring

Applies to DDA-FC/FCM

The integrated pressure sensor measures the actual pressure of the system, which is shown in the display.

A maximum pressure can be set. If the pressure in the system exceeds the set maximum (e.g. caused by a closed valve), the pressure monitoring function stops the dosing process immediately. As soon as the backpressure falls below the set maximum, the dosing process is continued. In case the pressure drops below the minimum limit (e.g. caused by a burst discharge line) the pump stops and major chemical spills are prevented.

Pressure setting range

Pump type

DDA 7.5-16

DDA 12-10

DDA 17-7

DDA 30-4

Fixed min. pressure

[bar]*

< 2

< 2

< 2

< 2

Adjustable max. pressure

[bar]**

3 … 17 (default)

3 … 11 (default)

3 … 8 (default)

3 … 5 (default)

* Can be either set as a warning (pump keeps running) or as an alarm (pump stops)

** The adjustable max. pressure is equivalent to the max. operating pressure plus 1 bar

Flow measurement

Applies to DDA-FCM

The pump can precisely measure and display the actual dosing flow. Via the analog 0/4-20 mA output, the actual flow signal can easily be integrated in any process control system, without needing any additional measurement equipment.

The Flow measurement function is based on an indicator diagram as described in FlowControl

(page

16 ). Accumulating the length of each discharge

stroke phase and multiplying it with the stroke frequency results in the displayed actual flow.

Any malfunctions, such as air bubbles or lower backpressure, will result in a reduced or increased actual flow rate. When the AutoFlowAdapt function

(page 18 ) is activated, the pump compensates these

influences by correcting the stroke speed.

AutoFlowAdapt

Applies to DDA-FCM

When activating the AutoFlowAdapt function even environmental changes will be compensated, so that the required target flow rate will be achieved.

The integrated AutoFlowAdapt makes additional monitoring and control devices redundant.

The AutoFlowAdapt function is based on:

• FlowControl: malfunctions are detected

• Pressure monitoring: system pressure changes are detected

• Flow measurement: deviations in the target flow are detected.

Examples:

• FlowControl detects air bubbles in the system.

Due to a special motor drive strategy and a certain speed increase, the pump will try to keep the flow rate constant. This is especially important when dosing degassing liquids.

• In general, increasing system pressure reduces the stroke volume whereas falling system pressure increases the stroke volume. The AutoFlowAdapt function compensates this by automatically and continuously adapting the motor speed.

Despite fluctuating system pressure, dosing accuracy is maintained.

18

SMART Digital S

Wiring diagram, DDA

2

3

1

4

4

1

3

2

2

3

1

5

4

2

3

1

4

Sensor

FlowControl input

1

GND

2

3

►

4

1

2

3

GND

Cable 1

Analog/external stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

Cable 2

Level input see page

39

, suction lances

Cable 1: Analog, external stop and pulse input

5

GND

4

3

BUS

2

BUS

1

Cable 3

GENIbus, analog output

Product No.

2 m cable: 96632921

5 m cable: 96632922

3

4

2

1

2

1

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

Function

Analog

External stop

Pulse

Cable 2: Level input

1/brown

GND/ (-) mA

GND

GND

2/white

(+) mA

Pin holes

3/blue

X

4/black

X

Function

Low level

Empty tank

Cable 3: GENIbus, analog output

1

X

2

X

Pin holes

3

GND

GND

4

Function

GENIbus

Analog output

Cable 4: Relay output

1/brown

+30 V

2/white

GENI bus A

Pin holes

3/blue

GENI bus B

4/black

(+) mA

5/yellow-green

GND

GND/ (-) mA

Plug type

mA signal

Contact

Contact

Plug type

Contact

Contact

Plug type

Bus mA signal

Function

Relay 1

Relay 2

1/brown

X

2/white

X

Pin holes

3/blue

X

4/black

X

Plug type

Contact

Contact

3

19

3

Wiring diagram, DDC

2

3

1

4

4

1

3

2

2

3

1

4

SMART Digital S

3

►

4

1

GND

2

Cable 1

Analog/external stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

1

2

3

GND

Cable 2

Level input see page

39 , suction

lances

Cable 1: Analog, external stop and pulse input

Function

Analog*

External stop

Pulse

Cable 2: Level input

1/brown

GND/ (-) mA

GND

GND

2/white

(+) mA

Pin holes

3/blue

X

1

X

2

X

Pin holes

3

GND

GND

Function

Low level

Empty tank

Cable 4: Relay output*

Function

Relay 1

Relay 2

* applies to DDC-AR

1/brown

X

2/white

X

Pin holes

3/blue

X

4

4/black

X

3

4

2

1

2

1

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

4/black

X

Plug type

mA signal

Contact

Contact

Plug type

Contact

Contact

Plug type

Contact

Contact

20

SMART Digital S

Wiring diagram, DDE-PR, -P

4

1

3

2

2

3

1

4

2

3

1

4

1

2

3

GND

Cable 2

Level input see page

39 , suction

lances

Cable 1: External stop and pulse input

Function

External stop

Pulse

Cable 2: Level input

1/brown

GND

GND

Function

Low level

Empty tank

Cable 4: Relay output*

Function

Relay 1 (Alarm)

Relay 2 (see page

14 )

* applies to DDE-PR

1

X

1/brown

X

2/white

Pin holes

3/blue

X

4/black

X

2

X

4

1

GND

3

Ź

Cable 1

External stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

3

4

2

1

2

1

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

Pin holes

3

GND

GND

4

2/white

X

Pin holes

3/blue

X

4/black

X

Plug type

Contact

Contact

Plug type

Contact

Contact

Plug type

Contact

Contact

3

21

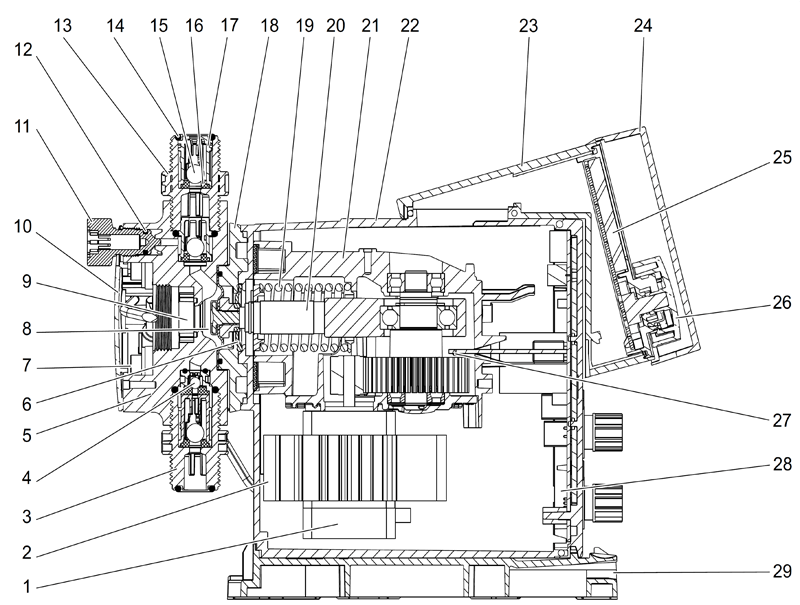

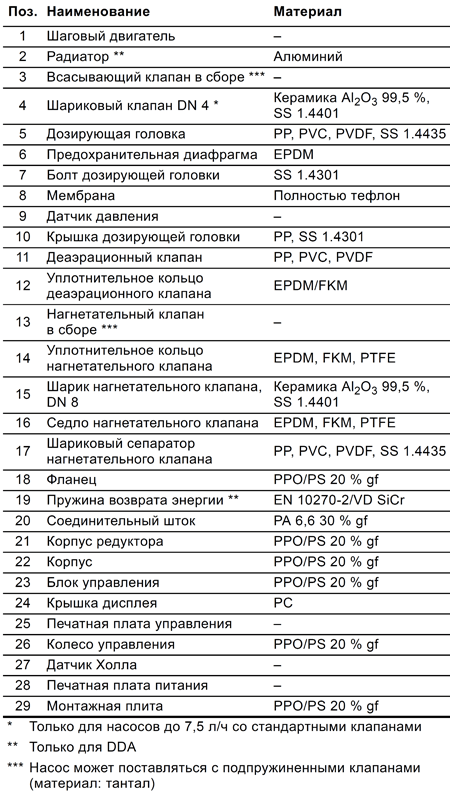

4

SMART Digital S

4. Construction

DDA and DDC

12

13 14 15 16 17 18 19 20 21 22

11

10

9

8

7

6

5

4

3

2

1

Fig. 19

Sectional drawing, DDA

Construction

The DDA and DDC pumps are motor-driven diaphragm dosing pumps consisting of the following main parts:

Dosing head:

Patented design with a minimum of clearance space optimised for degassing liquids.

With integrated deaeration valve for priming and venting complete with connection for a 4/6 mm or 0.17″ x 1/4″ tubing. DDA-FCM/FC pumps have an integrated pressure sensor in the dosing head.

Valves:

Double-ball discharge and suction valve* design for less clearance space — optimised for degassing liquids. Spring-loaded valves for higher viscosities are available as an option.

Connections:

Robust and easy-to-use connection packages for various sizes of tubing or pipes.

Diaphragm:

Full PTFE diaphragm designed for long life and universal chemical resistance.

Flange:

With separation chamber, safety diaphragm and drain hole.

Drive unit:

Positive return crank with patented noiseless spur gear drive, energy recovery spring for high efficiency (only DDA), stepper motor, all mounted in a robust gear housing.

Control cube:

Containing operation electronics with display, keys, click-wheel and protective cover.

Housing:

Containing drive unit and power electronics with robust signal sockets. The housing can be clicked on the mounting plate.

23 24

25

26

27

28

29

Material specification

Pos. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Stepper motor

Cooling element**

Suction valve, complete***

Valve ball, DN 4*

Dosing head

Safety diaphragm

Dosing head screw

Diaphragm

Pressure sensor

Dosing head cover

Deaeration valve

Deaeration valve O-ring

Discharge valve, complete***

Discharge valve O-ring

Discharge valve ball, DN 8

16 Discharge valve seat

17 Discharge valve ball cage

18 Flange

19 Energy recovery spring**

20 Connecting rod

21 Gear box

22 Housing

23 Control cube

24 Display cover

25 Operation PCB

26 Click wheel

27 Hall sensor

28 Power PCB

29 Mounting plate

—

—

—

Material options

—

Aluminium

—

Ceramic Al

2

SS 1.4401

O

3

99.5 %,

PP, PVC, PVDF, SS 1.4435

EPDM

SS 1.4301

full PTFE

—

PP, SS 1.4301

PP, PVC, PVDF

EPDM/FKM

—

EPDM, FKM, PTFE

Ceramic Al

2

SS 1.4401

O

3

99.5 %,

EPDM, FKM, PTFE

PP, PVC, PVDF, SS 1.4435

PPO/PS 20 % gf

EN 10270-2/VD SiCr

PA 6.6 30 % gf

PPO/PS 20 % gf

PPO/PS 20 % gf

PPO/PS 20 % gf

PC

PPO/PS 20 % gf

PPO/PS 20 % gf

* Only for pumps up to 7.5 l/h with standard valves

** Only for DDA

*** Pump can be supplied with spring-loaded valves (Material: Tantal)

22

SMART Digital S

DDE

10

11

9

12 13 14 15 16 17 18 19

20

8

7

3

2

6

5

4

1

Fig. 20

Sectional drawing, DDE

Construction

The DDE pump is a motor-driven diaphragm dosing pump consisting of the following main parts:

Dosing head:

Patented design with a minimum of clearance space optimised for degassing liquids.

With integrated deaeration valve for priming and venting complete with connection for a 4/6 mm or 0.17″ x 1/4″ tubing.

Valves:

Double-ball discharge and suction valve* design for less clearance space — optimised for degassing liquids. Spring-loaded valves for higher viscosities are available as an option.

Connections:

Robust and easy-to-use connection packages for various sizes of tubing or pipes.

Diaphragm:

Full PTFE diaphragm designed for long life and universal chemical resistance.

Flange:

With separation chamber, safety diaphragm and drain hole.

Drive unit:

Positive return crank with patented noiseless spur gear drive, stepper motor, all mounted in a robust gear housing.

Housing:

Containing drive unit, control panel and electronics with robust signal sockets. The housing can be clicked on the mounting plate.

21

22

23

Material specification

Pos. Description Material options

1

2

3

Stepper motor

Suction valve, complete**

Valve ball, DN 4*

4 Dosing head

5 Safety diaphragm

6 Dosing head screw

7 Diaphragm

—

—

Ceramic Al

SS 1.4401

2

O

3

99.5 %,

PP, PVC, PVDF, SS 1.4435

EPDM

SS 1.4301

full PTFE

8 Dosing head cover

9 Deaeration valve

13 Discharge valve ball, DN 8

PP, SS 1.4301

PP, PVC, PVDF

10 Deaeration valve O-ring

11 Discharge valve, complete** —

EPDM/FKM

12 Discharge valve O-ring EPDM, FKM, PTFE

Ceramic Al

SS 1.4401

2

O

3

99.5 %,

14 Discharge valve ball cage

15 Discharge valve seat

16 Flange

17 Connecting rod

18 Gear box

19 Housing

20 Hall sensor

21 Capacity adjustment knob

22 Power PCB

23 Mounting plate

—

—

PP, PVC, PVDF, SS 1.4435

EPDM, FKM, PTFE

PPO/PS 20 % gf

PA 6.6 30 % gf

PPO/PS 20 % gf

PPO/PS 20 % gf

PPO/PS 20 % gf

PPO/PS 20 % gf

* Only for pumps up to 6 l/h with standard valves

** Pump can be supplied with spring-loaded valves (Material: Tantal)

4

23

5

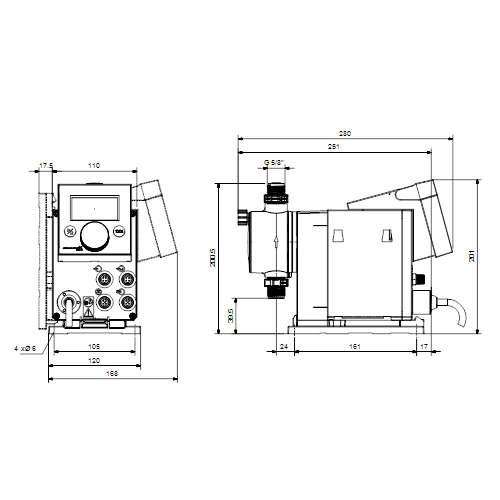

5. Dimensions

DDA and DDC

17.5

110

100%

G 5/8

A1

A

4 x Ø6

105

120

168

Fig. 21

DDA and DDC with front-fitted or side-fitted control cube

D

DDE

17.5

110

G 5/8

A1

161 17

SMART Digital S

24

4 x Ø6

105

120

Fig. 22

DDE-PR with front-fitted control elements

Pump type

DDA 7.5-16

DDC 6-10

DDC 9-7

DDE 6-10

DDA 12-10

DDA 17-7

DDC 15-4

DDE 15-4

DDA 30-4

A [mm]

280

280

295

A1 [mm]

251

251

267

D

B [mm]

196

200.5

204.5

161 17

C [mm]

46.5

39.5

35.5

D [mm]

24

24

38.5

SMART Digital S

6. Technical data

DDA

DDA

Turn-down ratio (setting range)

Max. dosing capacity

Max. dosing capacity with SlowMode 50 %

Max. dosing capacity with SlowMode 25 %

Min. dosing capacity

Max. operating pressure

Mechanical data

Max. stroke frequency

1)

Stroke volume

Accuracy of repeatability

Max. suction lift during operation

2)

Max. suction lift when priming with wet valves

2)

Min. pressure difference between suction and discharge side

Electrical data

Signal input

Signal output

Weight/size

Max. inlet pressure, suction side

Max. viscosity in SlowMode 25 % with spring-loaded valves

3)

Max. viscosity in SlowMode 50 % with spring-loaded valves

3)

Max. viscosity without SlowMode with spring-loaded valves

3)

Max. viscosity without spring-loaded valves

3)

Min. internal hose/pipe diameter suction/discharge side

4), 2)

Min. internal hose/pipe diameter suction/discharge side (high viscosity)

4)

Min./Max. liquid temperature

Min./Max. ambient temperature

Voltage

Length of mains cable

Max. inrush current for 2 ms at 100 V

Max. inrush current for 2 ms at 230 V

Max. power consumption P

1

Enclosure class

Electrical safety class

Max. load low-level / empty tank / pulse / external stop input

Min. pulse length

Max. pulse frequency

Impedance at analog 0/4-20 mA input

Accuracy of analog input (full-scale value)

Min. resolution of analog input

Max. resistance in level/pulse circuit

Max. ohmic load on relay output

Max. voltage on relay/analog output

Impedance at 0/4-20 mA analog output

Accuracy of analog output (full-scale value)

Min. resolution of analog output

Weight (PVC, PP, PVDF)

Weight (stainless steel)

Diaphragm diameter

Sound pressure

Max. sound pressure level

Approvals

1) The maximum stroke frequency varies depending on calibration

2) Data is based on measurements with water

3) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

4) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

5) With E-box

[V]

[

Ω

]

[%]

[mA]

[kg]

[kg]

[mm]

[ms]

[Hz]

[

Ω

]

[%]

[mA]

[

Ω

]

[A]

[dB(A)]

[1:X]

[l/h]

[gph]

[l/h]

[gph]

[l/h]

[gph]

[l/h]

[gph]

[bar]

[psi]

[strokes/min]

[ml]

[%]

[m]

[m]

[bar]

[bar]

[mPas] (= cP) 2500

[mPas] (= cP) 1800

[mPas] (= cP) 600

[mPas] (= cP) 50

4 [mm]

[mm]

[°C]

[°C]

[V]

[m]

[A]

[A]

[W]

7.5-16 12-10 17-7 30-4

3000

7.5

2.0

3.75

1000

12.0

3.1

6.00

1000

17.0

4.5

8.50

1000

30.0

8.0

15.00

1.00

1.88

1.55

3.00

2.25

4.25

4.00

7.50

0.50

0.78

1.13

2.00

0.0025

0.0120

0.0170

0.0300

0.0007

0.0031

0.0045

0.0080

16

★

10 7 4

230 150 100 60

190 155 205 180

0.74

1.45

1.55

3.10

2

± 1

6

3 3

1 (FC and FCM: 2)

2

2

1500

600

200

150

9

2.4

3.2

44

2500

1300

500

300

2000

1300

500

300

6 6

9

-10/45

0/45

100-240 V, 50/60 Hz

1.5

8

25

24

5)

IP65, Nema 4X

II

12 V, 5 mA

5

100

15

± 1.5

0.05

1000

0.5

30 VDC/30 VAC

500

± 1.5

0.02

2.4

3.2

50

60

2.6

4.0

74

CE, CB, CSA-US, NSF61, EAC, ACS, C-Tick

★

Max. pressure for PVC version: 10 bar

6

25

6

SMART Digital S

DDC

DDC

Turn-down ratio (setting range)

Max. dosing capacity

Max. dosing capacity with SlowMode 50 %

Max. dosing capacity with SlowMode 25 %

Min. dosing capacity

Max. operating pressure

Mechanical data

Max. stroke frequency

1)

Stroke volume

Accuracy of repeatability

Max. suction lift during operation

2)

Max. suction lift when priming with wet valves

2)

Min. pressure difference between suction and discharge side

Electrical data

Signal input

Signal output

Weight/size

Max. inlet pressure, suction side

Max. viscosity in SlowMode 25 % with spring-loaded valves

3)

Max. viscosity in SlowMode 50 % with spring-loaded valves

3)

Max. viscosity without SlowMode with spring-loaded valves

3)

Max. viscosity without spring-loaded valves

3)

Min. internal hose/pipe diameter suction/discharge side

4), 2)

Min. internal hose/pipe diameter suction/discharge side (high viscosity)

4)

Min./Max. liquid temperature

Min./Max. ambient temperature

Voltage AC

Length of mains cable

Max. inrush current for 2 ms at 100 V

Max. inrush current for 2 ms at 230 V

Max. power consumption P

1

Enclosure class

Electrical safety class

Max. load low-level / empty tank / pulse / external stop input

Min. pulse length

Max. pulse frequency

Impedance at analog 0/4-20 mA input

Accuracy of analog input (full-scale value)

Min. resolution of analog input

Max. resistance in level/pulse circuit

Max. ohmic load on relay output

Max. voltage on relay output

Weight (PVC, PP, PVDF)

Weight (stainless steel)

Diaphragm diameter

Sound pressure

Max. sound pressure level

Approvals

1) The maximum stroke frequency varies depending on calibration

2) Data is based on measurements with water

3) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

4) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

[ms]

[Hz]

[

Ω

]

[%]

[mA]

[

Ω

]

[A]

[V]

[kg]

[kg]

[mm]

[dB(A)]

[1:X]

[l/h]

[gph]

[l/h]

[gph]

[l/h]

[gph]

[l/h]

[gph]

[bar]

[psi]

[strokes/min]

[ml]

[%]

[m]

[m]

[bar]

[bar]

[mPas] (= cP)

[mPas] (= cP)

[mPas] (= cP)

[mPas] (= cP)

[mm]

[mm]

[°C]

[°C]

[V]

[m]

[A]

[A]

[W]

6-10

1000

6.0

1.5

3.00

0.75

1.50

0.38

0.0060

0.0015

10

150

140

0.81

9-7

1000

9.0

2.4

4.50

1.20

2.25

0.60

0.0090

0.0024

7

100

200

0.84

± 1

6

2 2 3

2500

1800

600

50

4

1

2

2000

1300

500

50

2000

1300

500

300

6 6

9

-10/45

0/45

100-240 V, 50/60 Hz

1.5

8

25

22

IP65, Nema 4X

II

12 V, 5 mA

5

100

15

± 1.5

0.05

1000

0.5

30 VDC/30 VAC

2.4

3.2

44

2.4

3.2

50

60

15-4

1000

15.0

4.0

7.50

2.00

3.75

1.00

0.0150

0.0040

4

60

180

1.58

CE, CB, CSA-US, NSF61, EAC, C-Tick

26

SMART Digital S

DDE

DDE

Turn-down ratio (setting range)

Max. dosing capacity

Min. dosing capacity

Max. pressure

Mechanical data

Max. stroke frequency

Stroke volume

Accuracy of repeatability

Max. suction lift during operation

1)

Max. suction lift when priming with wet valves

1)

Min. pressure difference between suction and discharge side

Electrical data

Signal input

Signal output

Weight/size

Max. inlet pressure, suction side

Max. viscosity with spring-loaded valves

2)

Max. viscosity without spring-loaded valves

2)

Min. internal hose/pipe diameter suction/discharge side

1), 3)

Min. internal hose/pipe diameter suction/discharge side (HV)

3)

Min./Max. liquid temperature

Min./Max. ambient temperature

Voltage

Length of mains cable

Max. inrush current for 2 ms at 100 V

Max. inrush current for 2 ms at 230 V

Max. power consumption P

1

Enclosure class

Electrical safety class

Max. load low-level / empty tank / pulse / external stop input

Min. pulse length

Max. pulse frequency

Max. resistance in level/pulse circuit

Max. ohmic load on relay output

Max. voltage on relay output

Weight (PVC, PP, PVDF)

Weight (stainless steel)

Diaphragm diameter

Sound pressure

Max. sound pressure level

Approvals

1) Data is based on measurements with water

2) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

3) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

[1:X]

[l/h]

[gph]

[l/h]

[gph]

[bar]

[psi]

[strokes/min]

[ml]

[%]

[m]

[m]

[bar]

[bar]

[mPas] (= cP)

[mPas] (= cP)

[mm]

[mm]

[°C]

[°C]

[V]

[m]

[A]

[A]

[W]

[ms]

[Hz]

[

Ω

]

[A]

[V]

[kg]

[kg]

[mm]

[dB(A)]

6-10

1000

6.0

1.5

0.0060

0.0015

10

150

140

0.81

± 5

6

2 3

1

2

600

50

500

50

4 6

9

-10/45

0/45

100-240 V, 50/60 Hz

1.5

8

25

19

IP65, Nema 4X

II

12 V, 5 mA

5

100

1000

0.5

2.4

30 VDC/30 VAC

2.4

3.2

44

3.2

50

60

15-4

1000

15.0

4.0

0.0150

0.0040

4

60

180

1.58

CE, CB, CSA-US, NSF61, EAC, C-Tick

6

27

7

SMART Digital S

7. Pump selection

DDA, standard range

Power supply: 1 x 100-240 V, 50/60 Hz (switch mode)

Mains plug:

Valves:

EU

Standard

Connection set: U2U2 / I001 / AA (see

Type key

on page

6

)

Max. flow

[l/h]

Max. pressure

[bar]

Materials

Dosing head

Gaskets

Valve balls

Installation set*

Type designation**

AR

Product number

FC FCM

7.5

12

17

30

16

10

7

4

PP

PVC***

PVDF

SS

PP

PVC

PVDF

SS

PP

PVC

PVDF

SS

PP

PVC

PVDF

EPDM

FKM

EPDM

FKM

PTFE

PTFE

EPDM

FKM

EPDM

FKM

PTFE

PTFE

EPDM

FKM

EPDM

FKM

PTFE

PTFE

EPDM

FKM

EPDM

FKM

PTFE

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

SS 1.4401

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

SS 1.4401

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

SS 1.4401

Ceramic

Ceramic

Ceramic

Ceramic

Ceramic

No

Yes

No

Yes

No

Yes

No

Yes

Yes

No

Yes

No

Yes

No

No

Yes

No

Yes

No

No

Yes

No

Yes

No

No

Yes

No

Yes

No

Yes

No

Yes

No

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

DDA 7.5-16

AR

-PP/E/C-F-31U2U2FG

DDA 7.5-16

AR

-PP/E/C-F-31I001FG

DDA 7.5-16

AR

-PP/V/C-F-31U2U2FG

DDA 7.5-16

AR

-PP/V/C-F-31I001FG

DDA 7.5-16

AR

-PVC/E/C-F-31U2U2FG

DDA 7.5-16

AR

-PVC/E/C-F-31I001FG

DDA 7.5-16

AR

-PVC/V/C-F-31U2U2FG

DDA 7.5-16

AR

-PVC/V/C-F-31I001FG

DDA 7.5-16

AR

-PV/T/C-F-31U2U2FG

DDA 7.5-16

AR

-PV/T/C-F-31I001FG

DDA 7.5-16

AR

-SS/T/SS-F-31AAFG

DDA 12-10

AR

-PP/E/C-F-31U2U2FG

DDA 12-10

AR

-PP/E/C-F-31I002FG

DDA 12-10

AR

-PP/V/C-F-31U2U2FG

DDA 12-10

AR

-PP/V/C-F-31I002FG

DDA 12-10

AR

-PVC/E/C-F-31U2U2FG

DDA 12-10

AR

-PVC/E/C-F-31I002FG

DDA 12-10

AR

-PVC/V/C-F-31U2U2FG

DDA 12-10

AR

-PVC/V/C-F-31I002FG

DDA 12-10

AR

-PV/T/C-F-31U2U2FG

DDA 12-10

AR

-PV/T/C-F-31I002FG

DDA 12-10

AR

-SS/T/SS-F-31AAFG

DDA 17-7

AR

-PP/E/C-F-31U2U2FG

DDA 17-7

AR

-PP/E/C-F-31I002FG

DDA 17-7

AR

-PP/V/C-F-31U2U2FG

DDA 17-7

AR

-PP/V/C-F-31I002FG

DDA 17-7

AR

-PVC/E/C-F-31U2U2FG

DDA 17-7

AR

-PVC/E/C-F-31I002FG

DDA 17-7

AR

-PVC/V/C-F-31U2U2FG

DDA 17-7

AR

-PVC/V/C-F-31I002FG

DDA 17-7

AR

-PV/T/C-F-31U2U2FG

DDA 17-7

AR

-PV/T/C-F-31I002FG

DDA 17-7

AR

-SS/T/SS-F-31AAFG

DDA 30-4

AR

-PP/E/C-F-31U2U2FG

DDA 30-4

AR

-PP/E/C-F-31I002FG

DDA 30-4

AR

-PP/V/C-F-31U2U2FG

DDA 30-4

AR

-PP/V/C-F-31I002FG

DDA 30-4

AR

-PVC/E/C-F-31U2U2FG

DDA 30-4

AR

-PVC/E/C-F-31I002FG

DDA 30-4

AR

-PVC/V/C-F-31U2U2FG

DDA 30-4

AR

-PVC/V/C-F-31I002FG

DDA 30-4

AR

-PV/T/C-F-31U2U2FG

DDA 30-4

AR

-PV/T/C-F-31I002FG

DDA 30-4

AR

-SS/T/SS-F-31AAFG

97721938 97721972 97722006

97721939 97721973 97722007

97721942 97721976 97722010

97721943 97721977 97722011

97721946 97721980 97722014

97721947 97721981 97722015

97721950 97721984 97722018

97721951 97721985 97722019

97721966 97722000 97722034

97721967 97722001 97722035

97721970 97722004 97722038

97722040 97722074 97722108

97722041 97722075 97722109

97722044 97722078 97722112

97722045 97722079 97722113

97722048 97722082 97722116

97722049 97722083 97722117

97722052 97722086 97722120

97722053 97722087 97722121

97722068 97722102 97722136

97722069 97722103 97722137

97722072 97722106 97722140

97722142 97722176 97722210

97722143 97722177 97722211

97722146 97722180 97722214

97722147 97722181 97722215

97722150 97722184 97722218

97722151 97722185 97722219

97722154 97722188 97722222

97722155 97722189 97722223

97722170 97722204 97722238

97722171 97722205 97722239

97722174 97722208 97722242

97722244 97722278 97722313

97722245 97722279 97722314

97722248 97722282 97722317

97722249 97722283 97722318

97722252 97722286 97722331

97722253 97722288 97722332

97722256 97722291 97722335

97722257 97722292 97722336

97722272 97722307 97722351

97722273 97722308 97722352

97722276 97722311 97722355 SS PTFE SS 1.4401

* Installation set includes: 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose

(4/6 mm)

** Also available in — and

FCM

-control version

*** PVC dosing heads only up to 10 bar

28

SMART Digital S

DDC, standard range

Power supply: 1 x 100-240 V, 50/60 Hz (switch mode)

Mains plug: EU

Valves: Standard

Connection set: U2U2 / I001 / AA (see

Type key

on page