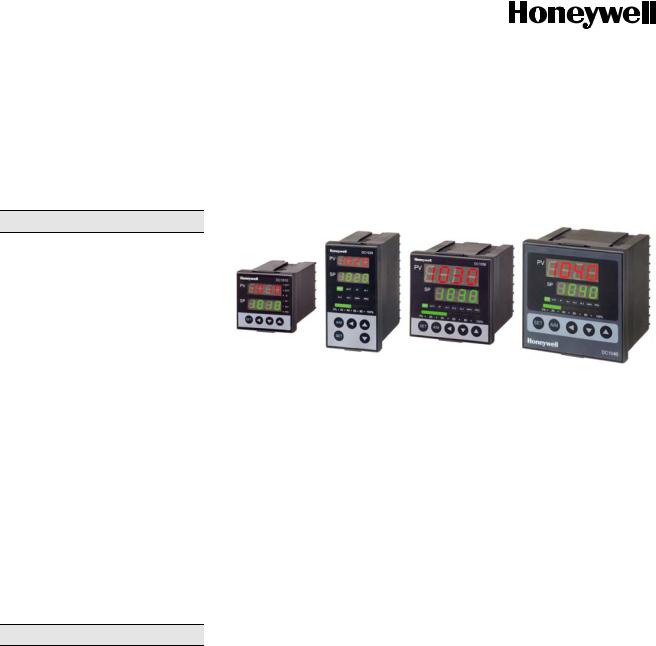

DC1010/DC1020/DC1030/DC1040

DIGITAL CONTROLLERS

Overview

The DC1000 Series are microprocessorbased controllers designed with a high degree of functionality and reliability at a competitive price. The controllers are available in different formats: 48×48 (1/16 DIN), 48×96 (1/8 DIN), 72×72 (3/16 DIN), 96×96 (1/4 DIN). This controller series is ideal for the control of temperature, humidity, pressure, flow etc. in a variety of applications including:

zPlastic Processing

zPackage Machinery

zPainting and coating

zSemiconductor packaging / Testing

zDryers

Features

z Easy to Configure

Different configuration levels provide easy access to parameters.

z Various Control Algorithm

Several different algorithms are available as follows:

—PID or ON/OFF Control

—Heat/Cool Control with 2 PID sets

—Motor Position Control

(without slidewire feedback)

z Auto-Tuning Capability

Advanced auto-tuning function calculates the optimized PID values for your specific control system.

z Dual Display and Bar graph

Two large 4 digits display PV, SP and configuration parameters. One 10 LED bar-graph displays the control output (MV), and up to 8 LEDs display the status of the different outputs (Control, Alarm, …) and also provide indication of the Auto/Manual and programmer states.

z Setpoint Programming

Two programs are available with a maximum of 8 segments. The 2 programs can be linked together and perform as a single 16 segment program.

z Extended Alarm Capability

Up to three different alarm outputs are available per instrument and 17 kinds of event modes can be assigned to each of alarm output.

z Communications

RS232 or RS485 (with ASC II & Modbus RTU Protocol) is optionally available with a maximum communication speed of 38400 bps.

10/06 30-10-10-06-EN Page 1 of 16

Specification

z IP65 Front Face Protection

IP65 rated front face permits use in applications where it may be subjected to moisture, dust conditions.

z Remote Setpoint Capability

The setpoint can be defined from a remote PLC or other controller.

z Manual & Automatic Modes

The control mode can be switched between Automatic and manual by clicking A/M key. (The A/M key is available with DC1020, DC1030 and DC1040)

z Global Approvals – CE & cUL

All models are CE certified as a standard, and UL approved version for all models are available optionally.

z Parameter Lock

A 4-digit security code prevents any unauthorized changes of parameters or configurations. Parameters can be hidden to user to prevent any mis-configuration of the unit.

Specifications General

|

Rated power supply voltage |

100 to 240V AC 50/60Hz, 8VA max. |

|||||||||||||

|

15 to 50V DC, 10VA max. |

||||||||||||||

|

Over 10 under DC500V megger between input terminal and |

||||||||||||||

|

Insulation Resistance |

||||||||||||||

|

case(ground). |

||||||||||||||

|

Over 10 under DC500V megger between output terminal and |

||||||||||||||

|

case(ground). |

||||||||||||||

|

Withstand voltage |

1000V AC 50/60Hz for 1min across input terminal and case(ground) |

|||||||||||||

|

1500V AC 50/60Hz for 1min across output terminal and case(ground) |

||||||||||||||

|

23 ± 2 °C |

||||||||||||||

|

Standard |

Ambient Temp. |

|||||||||||||

|

Conditions |

||||||||||||||

|

Ambient Humi. |

60 ± 5% RH |

|||||||||||||

|

Rated Power Supply |

110V AC |

|||||||||||||

|

Power Frequency |

50 ± 1Hz or 60 ± 1HZ |

|||||||||||||

|

0 to 50°C |

||||||||||||||

|

Operating |

Ambient Temp. |

|||||||||||||

|

Conditions |

||||||||||||||

|

Ambient Humi. |

20 to 90%RH (non-condensing) |

|||||||||||||

|

Rated Power Supply |

100 to 240V AC |

|||||||||||||

|

20 to 50V DC |

||||||||||||||

|

Allowable Power |

85 to 264V AC |

|||||||||||||

|

Supply |

15 to 55VDC |

|||||||||||||

|

Power Frequency |

50 ± 2Hz or 60 ± 2Hz |

|||||||||||||

|

10m/s2 (approx. 1G), 10 to 55Hz for 10min each X, Y, Z directions |

||||||||||||||

|

Vibration Resistance |

||||||||||||||

|

Transportatio |

Ambient Temp. |

-20 to +65 °C |

||||||||||||

|

n and storage |

||||||||||||||

|

Ambient Humi. |

10 to +95% RH (non-condensing) |

|||||||||||||

|

conditions |

||||||||||||||

|

Vibration Resistance |

20m/s2 (Approx. 2G), 10 to 55Hz for 2 hours each in X, Y, Z directions |

|||||||||||||

|

Exterior |

Case and front panel : plastic |

|||||||||||||

|

Mounting |

Panel-mount |

|||||||||||||

|

Model |

DC1010 |

DC1020 |

DC1030 |

DC1040 |

||||||||||

|

Exterior Size (unit: |

mm |

) |

50 X 50 X 97 |

50 X 96 X 97 |

74 X 74 X 97 |

96 X 96 X 97 |

||||||||

|

inch |

||||||||||||||

|

: W X H X D |

(1.97X1.97X 3.82) |

(1.97X3.78X3.82) |

(2.91X2.91X3.82) |

(3.78X3.78X3.82) |

||||||||||

|

Panel Cutout (unit: |

mm |

) |

44.5 X 44.5 |

44.5 X 90.5 |

68.5 X 68.5 |

90.5 X 90.5 |

||||||||

|

inch |

||||||||||||||

|

: W X H |

(1.75 X 1.75) |

(1.75 X 3.56) |

(2.97 X 2.97) |

(3.56 X 3.56) |

||||||||||

|

Global Approvals |

CE, cUL |

|||||||||||||

Interval = 20.5mm (0.807 in)

Specifications

Input/Output

|

Analog |

Number of Point |

1 point (TC, RTD or Linear) |

||

|

Input 1 |

TC: |

K, J, R, S, B, E, T, N, W, U, PLII, L |

||

|

Type |

RTD : |

DPt100, JPt100, JPt50 |

||

|

Linear : 4~20mA / 1~5V / 2~10V * Note 1 |

||||

|

0~20mA / 0~5V / 0~10V * Note 1 |

||||

|

Refer to Table 1-1. |

||||

|

Range |

||||

|

* Temperature unit : ºC, ºF ( switchable) |

||||

|

Sampling cycle |

250 ms |

|||

|

Indication |

± 0.2% FS ± 1digit (for details Table1-1) |

|||

|

Accuracy |

||||

|

Cold |

junction |

±1.0ºC (under standard conditions) |

||

|

accuracy |

||||

|

Input bias (offset) |

LSPL ~ USPL |

|||

|

Digital Filter |

0 — 200 sec (0: filter off) |

|||

|

Decimal Point |

0000, 000.0, 00.00, 0.000 |

|||

|

Analog |

Type |

0~20mA / 0~5V / 0~10V |

||

|

Input 2 |

4~20mA / 1~5V / 2~10V |

|||

|

Sampling Cycle |

250ms |

|||

|

CT Input |

Measure AC current of single phase |

|||

|

Type |

||||

|

SC-80T : 0.0~80.0A |

||||

|

Sampling Cycle |

500msec |

|||

|

Indication |

1% FS |

|||

|

Accuracy |

||||

|

Resolution |

0.1A ac |

|||

|

12g |

||||

|

Weight |

||||

|

Dielectric strength |

2500Vac, for 1 min between terminal and case |

|||

NOTE 1. When OUT1 is ON and CT input value is less than HBA set value for 5 seconds, AL1 is activated. Otherwise, AL1 is not activated.

Specification

|

Model |

DC1010 |

DC1020 |

DC1030 |

DC1040 |

|||||

|

Input/Output |

|||||||||

|

Relay |

SPST |

SPDT |

SPST |

SPDT |

|||||

|

3A, 220Vac, Resistive Load(100,000 time electrical life) |

|||||||||

|

PWM(SSR drive), ON: 20 Vdc, OFF: 0 V (max. load current 20mA) |

|||||||||

|

Analog |

Voltage Pulse |

Open Time Terminal Voltage: 20 Vdc or less |

|||||||

|

Time Proportional Cycle Time: 0-150 sec |

|||||||||

|

Output 1 |

|||||||||

|

DC Current (mA) |

: 0~20mA, 4~20mA (load resistance 500Ω) |

||||||||

|

Linear |

DC Voltage (V) |

: 0~5V, 0~10V, 1~5V, 2~10V (max. load current 20mA) |

|||||||

|

Accuracy |

± 5% of Span |

||||||||

|

Update Cycle |

500m sec |

||||||||

|

Relay |

SPST |

SPST |

SPST |

SPST |

|||||

|

3A, 220Vac, Resistive Load(100,000 time electrical life) |

|||||||||

|

PWM(SSR drive), ON: 20 Vdc, OFF: 0 V (max. load current 20mA) |

|||||||||

|

Analog |

Voltage pulse |

Open Time Terminal Voltage: 20 Vdc or less |

|||||||

|

Output 2 |

Time Proportional Cycle Time: 0-150 sec |

||||||||

|

(* Note 1) |

|||||||||

|

DC Current (mA) |

: 0~20mA, 4~20mA (load resistance 500Ω) |

||||||||

|

Linear |

DC Voltage (V) |

: 0~5V, 0~10V, 1~5V, 2~10V (max. load current 20mA) |

|||||||

|

Accuracy |

± 5% of Span |

||||||||

|

Update Cycle |

500m sec |

||||||||

|

Output Direction (OUD) |

HEAT(Direct)/COOL(Reverse) (Selectable) |

||||||||

|

Auto/Manual operation is switchable. |

|||||||||

|

Control Mode |

*Manual output : Bumpless in normal mode |

||||||||

|

OUTL in abnormal mode |

|||||||||

|

Object |

SP, PV |

||||||||

|

Transmission |

No. of point |

1 point |

|||||||

|

Type |

4-20mA, 0~20mA, 0~5V, 0~10V, 1~5V, |

2~10V |

|||||||

|

Output |

|||||||||

|

Accuracy |

+/- 0.2% of span |

||||||||

|

Update Cycle |

500 ms |

||||||||

|

AL1 |

SPST |

SPDT |

SPST |

SPDT |

|||||

|

Digital Output |

Relay |

AL2 |

SPST |

SPDT |

SPST |

SPDT |

|||

|

AL3 |

— |

SPST |

SPST |

SPST |

|||||

|

3A, 220Vac, Resistive Load(100,000 time electrical life) |

|||||||||

* For Heat/Cool Control Output only.

Specification

PID Control & Auto-Tuning

|

Proportional Band (P1,P2) |

Proportional Band: 0.0 ~ 200.0% |

|||||

|

Integral time (I1, I2) |

Integral time : 0 ~ 3600 sec |

|||||

|

Derivative time (D1, D2) |

0 |

~ 900 sec |

||||

|

Auto-Tuning Value |

0 |

~ USPL |

||||

|

HYS1, HYS2 |

0 |

~ 1000 (for ON/OFF control) |

||||

|

Dead Band (DB1) |

Not defined. |

|||||

|

GAP1, GAP2 |

0 |

~ 1000(for HEAT/COOL control) |

||||

|

Cycle Time |

0 |

~ 150 sec |

||||

|

Communication |

||||||

|

Speed |

1200, 2400, 4800, 9600, 19200, 38400 bps |

|||||

|

Protocol |

ModBus RTU, ModBus ASCII |

|||||

|

Parity check |

Odd / Even |

|||||

|

Bit length |

8 |

|||||

|

Communication |

RS232C, RS485 |

|||||

|

Events(ALARMS) |

||||||

|

01 / 11 |

Deviation-High alarm (inhibit / no-inhibit) |

|||||

|

02 / 12 |

Deviation-Low alarm (inhibit / no-inhibit) |

|||||

|

Code |

03 / 13 |

Deviation High/Low Limit alarm (inhibit / no-inhibit) |

||||

|

04 / 14 |

Deviation High/Low Limit range alarm (inhibit / no-inhibit) |

|||||

|

05 / 15 |

Absolute High alarm by PV (inhibit / no-inhibit) |

|||||

|

PV Event |

||||||

|

06 / 16 |

Absolute Low alarm by PV (inhibit / no-inhibit) |

|||||

|

SET VALUE |

-1999~ USPL (Absolute value, Deviation value) |

|||||

|

Activation Hysterisis |

0 |

~ 1000 |

||||

|

0 |

: Flicker |

|||||

|

On Delay Time |

99M 59S : Continuance |

|||||

|

00M 01S to 99M 58S : Time Delay |

||||||

|

Program |

Code |

07 |

Segment End alarm(in progress of program) |

|||

|

17 |

Program RUN |

|||||

|

System |

Code |

08 |

System Error ON |

|||

|

18 |

System Error OFF |

|||||

|

TIME |

Code |

19 |

Delaying timer (00Hours 00Min ~ 99Hour 59Min) |

|||

|

HBA |

Code |

09 |

Heater Break Alarm |

|||

DC1000 SERIES DIGITAL CONTROLLER PRODUCT MANUAL Industrial Measurement & Control 51-52-25-113 Issue1 March 2004 DC1010/1020/1030/1040 Product Manual Copyright, Notices, and Trademarks Printed in Taiwan - © Copyright 2004 Honeywell International Inc. Issue 1 - March 2004 Warranty / Remedy Honeywell warrants goods of its manufacture as being free to defective materials and faulty workmanship. Contact your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this printing. However, we assume no responsibility for its use. While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the customer to determine the suitability of the product in the application. © Copyright 2004 Honeywell International Inc. Sales and Service Honeywell serves its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing, or name of the nearest Authorized Distributor, contact your local sales office. See back page Industrial Measurement and Control Honeywell Korea 191 HanGangRo 2ga, YongSanGu Seoul, Korea DC1010/1020/1030/1040 Product Manual Contacts World Wide Web The following lists Honeywell’s World Wide Web sites that will be of interest to our customers Corporate http://content.honeywell.com/ Automation & Control Solutions http://www.acs.honeywell.com/ichome/Rooms/DisplayPages/LayoutInitial Industrial Measurement & Control http://content.honeywell.com/imc/ Telephone Contact us by telephone at the numbers listed below United States and Canada 1-800-423-9883 Technical. Support 1-888-423-9883 Q&A Faxback (TACFACS) 1-800-525-7439 Service Asia Pacific + (65) 6355 2828 Asia Pacific Headquarters Europe + (32) 2 728 2111 Honeywell PACE, Brussels, Belgium Latin America + (854) 845 2600 Honeywell, Sunrise, Florida U.S.A DC1010/1020/1030/1040 Product Manual Symbol Definitions The following advisory convention is used in this document to denote certain conditions. Symbol Definition CAUTION This CAUTION symbol on the equipment refers the user to the Product Manual for additional information. In this manual, this symbol appears next to required information. Failure to comply with these instructions may result in product damage. WARNING PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of the potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these instructions could result in death or serious injury. DC1010/1020/1030/1040 Product Manual Contents 1. Overview ............................................................................................................................ 1 1.1 Introduction.............................................................................................................................1 2. Installation ......................................................................................................................... 2 2.1 Model Number Interpretation..................................................................................................2 2.2 Specification ...........................................................................................................................3 2.3 Mounting.................................................................................................................................4 2.4 External Dimension ................................................................................................................4 2.4.1 DC1010...........................................................................................................................4 2.4.2 DC1020...........................................................................................................................5 2.4.3 DC1030...........................................................................................................................5 2.4.4 DC1040...........................................................................................................................5 2.5 Wiring Diagrams.....................................................................................................................6 2.5.1 DC1010...........................................................................................................................7 2.5.2 DC1020...........................................................................................................................8 2.5.3 DC1030...........................................................................................................................9 2.5.4 DC1040.........................................................................................................................10 3. Configuration ................................................................................................................... 11 3.1 Operator Interface ................................................................................................................ 11 3.2 MODE Access ......................................................................................................................12 3.3 MODEs .................................................................................................................................13 3.3.1 Operation ......................................................................................................................13 3.3.2 Configuration 1 .............................................................................................................14 3.3.3 Configuration 2 .............................................................................................................15 3.4 Alarms ..................................................................................................................................17 3.4.1 Deviation Alarm.............................................................................................................17 3.4.2 Absolute Value Alarm....................................................................................................18 3.4.3 Program Alarm..............................................................................................................19 3.4.4 System Alarm................................................................................................................19 3.5 Function Lock .......................................................................................................................20 4. Input Codes ...................................................................................................................... 21 4.1 Thermocouples.....................................................................................................................21 4.2 RTDs ....................................................................................................................................22 4.3 Linear Inputs.........................................................................................................................22 5. Operation.......................................................................................................................... 23 5.1 Type of Control .....................................................................................................................23 5.1.1 Manual Operation .........................................................................................................23 5.1.2 ON/OFF Control............................................................................................................23 5.1.3 PID Control ...................................................................................................................23 5.2 Set Point ...............................................................................................................................23 5.3 Alarm Set Point ....................................................................................................................23 6. Error Message................................................................................................................... 24 DC1010/1020/1030/1040 Product Manual 1. Overview 1.1 Introduction Function The DC1000 family of microprocessor based controllers combine a high degree of functionality and reliability in 4 different formats: 1/16 DIN, 1/8 DIN, 3/16 DIN, and 1/4 DIN. With a typical accuracy of ± 0.5% of span, the DC1000 is an ideal controller for regulating temperature and other process variables in a variety of applications including dryers, semiconductor packaging & testing, plastic processing, packaging machinery, painting & coating, and climatic chambers. Easy to Configure Two different configuration levels provide easy access to parameters. A 4-digit security code prevents unauthorized changes. Parameters can also be hidden to the user to prevent improper configuration of the unit. Various Control Algorithms The DC1000 series of controllers provides several different algorithms: PID or ON/OFF Control Hear/Cool Algorithms with 2 different PID sets Motor Position Control without slidewire feedback Single Phase Control with/without zero crossover control Three Phase Control with/without zero crossover control Mount Anywhere The DC1000 family is industrial control equipments that must be panel mounted. The wiring terminals must be enclosed within the panel. The DC1000 is environmentally hardened and, when suitably enclosed, can be mounted virtually anywhere in plant or factory; on the wall, in a panel, or even on the process machine. It withstands ambient temperature up to 50°C (122°F). CE Conformity (Europe) This product is in conformity with the protection requirements of the following European Council Directive: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC Directive. Conformity of this product with any other “CE Mark” Directive(s) is not guaranteed. Enclosure Rating: Panel-mounted equipment rating IP00. This controller must be panel mounted and all terminals must be enclosed within the panel. Front panel IP65 (IEC 529) option is available. DC1010/1020/1030/1040 Product Manual 1 2. Installation WARNING Local Regulations regarding electrical & safety must be observed. Failure to comply with these instructions could result in death or serious injury. 2.1 Model Number Interpretation DC10 0 - - - Size 1 48*48 2 48*96 3 72*72 4 96*96 Table III Manual E English C Chinese K Korean Program Input C None R RTD P Program T TC L Linear Table I Table II Output 1 Output 2 Alarm Aux. Input 2 0 None 0 None 0 None 0 None 0 None 0 None 1 Relay 1 Relay 1 1 alarm 1 4~20mA 1 4~20mA 1 RS-232 2 Volt Pulse 2 Volt Pulse 2 2 alarms 2 0~20mA 2 0~20mA 2 RS-485 3 4~20mA 3 4~20mA 3 3 alarms A 0~5V A 0~5V 5 1ϕ SSR A 0~5V B 0~10V B 0~10V 6 3ϕ SSR B 0~10V C 1~5V C 1~5V 7 Motor V C 1~5V D 2~10V D 2~10V 8 1ϕ SCR D 2~10V 9 3ϕ SCR A 0~5V B 0~10V C 1~5V D 2~10V DC1010/1020/1030/1040 Product Manual 2 Comm. 2.2 Specification TECHNICAL DATA Type of Input PV Input Indication Control Mode Output Alarm Aux. Output 2nd Input (RSP) Program Communication Input Sampling Time Input Resolution PV/SP Indication Constant Value Storage System Indication Accuracy Proportional Band (P) Integral Time (I) Derivative Time (D) Cycle Time Relay Output Voltage Output Linear Output Motor Control Output Others Channel Mode Timer Output Signal Type of Output Type of Input Sampling Time Pattern/Segment Availability Type of Communication Rated Power Supply Voltage & Frequency Power Consumption Storage Temperature Ambient Temperature Ambient Humidity INPUT ACTUATIONS K J R S B E TC N T W PL II U L Pt100 RTD JPt100 JPt50 AN1 -10~10mV AN2 0~10mV Linear AN3 0~20mV AN4 0~50mV AN5 10~50mV General Specifications TC (K, J, R, S, B, E, N, T, W, PL II, U, L), RTD (Pt100Ω, JPt100Ω, JPt50Ω) Linear (-10~10mV, 0~10mV, 0~20mV, 0~50mV, 10~50mV) 500 ms 14 bit (each) 4-digit, 7 segment display Non-volatile memory (EEPROM) ± 0.5%FS 0~200% (On/Off action at P=0) 0~3600 sec (PD action at I=0) 0~900 sec (PI action at D=0) 0~150 sec (4~20mA 0, SSR 1, relay 10) Contact, SPST(DC1010)/SPDT(1020,1030,1040), 3A/240VAC Voltage Pulse, 20VDC/20mA 4~20mA, 0~5V, 0~10V, 1~5V, 2~10V Three Position Step Control (Time proportional motor control) 1ϕ SSR, 3ϕ SSR, 1ϕ SCR, 3ϕ SCR 3 channels (optional) 17 alarm mode available Flicker alarm, continued alarm, on delay timer alarm SP, PV 4~20mA, 0~20mA, 0~5V, 0~10V, 1~5V, 2~10V 4~20mA, 0~20mA, 0~5V, 0~10V, 1~5V, 2~10V 500 ms 2 pattern/ 8 segment (each) Pattern link & repeat, program/segment end alarm RS-232, RS-485 AC 90-240V, 50/60Hz or DC15-50V, 4VA Max. 8VA -25°C~65°C 0°C~50°C 50~85% RH (no condensation) 0.0~200.0, 400.0, 600.0, 800.0, 1000, 1200 °C 0.0~200.0, 400.0, 600.0, 800.0, 1000, 1200 °C 0.0~1600, 1769 °C 0.0~1600, 1769 °C 0.0~1820 °C 0.0~800, 1000 °C 0.0~1200,1300 °C 0.0~400.0, 200.0 °C, 0.0~350.0 °C 0.0~2000, 2320 °C 0.0~1300, 1390 °C -199.9~600.0, 200.0 °C, 0.0~400.0 °C 0.0~400.0, 800.0 °C -199.9~600.0, 400.0, 200.0 °C, 0.0~200.0, 400.0, 600.0 °C -199.9~600.0, 400.0, 200.0 °C, 0.0~200.0, 400.0, 600.0 °C -199.9~600.0, 400.0, 200.0 °C, 0.0~200.0, 400.0, 600.0 °C 0~20mA, 0~1V, 0~5V, 0~10V 4~20mA, 1~5V, 2~10V DC1010/1020/1030/1040 Product Manual 3 2.3 Mounting CAUTION Installation Precautions The controller can be mounted on either a vertical or tilted panel using the mounting bracket supplied. Adequate access space must be available at the back of the panel for installation and servicing activities. Failure to comply with these instructions may result in product damage. 1 - Put the mounting bracket in the rail on the top & bottom of the case. 2 - Bend the grip of the bracket & slide the bracket along the rail until the case is secured against the panel. 3 - Put the grip of the bracket on the groove to fasten the case to the panel. Side View 2.4 External Dimension 2.4.1 DC1010 DC1010/1020/1030/1040 Product Manual 4 2.4.2 DC1020 2.4.3 DC1030 2.4.4 DC1040 DC1010/1020/1030/1040 Product Manual 5 2.5 Wiring Diagrams WARNING Electrical Consideration / Precautions The controller is considered “rack and panel mounted equipment” per EN61010-1, Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use, Part 1: General Requirements. Conformity with 72/23/EEC Low Voltage Directive, requires the user to provide adequate protection against a shock hazard. The user shall install this controller in an enclosure that prevents OPERATOR access to the rear terminals. Failure to comply with these instructions could result in death or serious injury. CAUTION Applying 85-264Vac to a controller rated for 15-50Vdc will severely damage the controller and is a fire and smoke hazard. Failure to comply with these instructions may result in product damage. CAUTION Wiring Requirements Shielded twisted pair cable is required for all Analog I/O, Process Variable, RTD, Thermocouple, dc millivolt, low level signal, mA, Digital Output, and computer interface circuits. Failure to comply with these instructions may result in product damage. CAUTION Line Voltage Wiring This controller is suitable for connection to 90-240 Vac, 50/60 Hz or 15-50 Vdc, power supply mains. It is the user responsibility to provide the following 90-240 Vac - a switch, fuse (1/2A, 250V) or a circuit breaker. 15-50 Vdc – a switch, fuse (1A, 125A) or a circuit breaker Fuse types – North America non-time delay, Europe – Type F, quick acting fuse(s). The above items should be installed together with DC1000 for the products electrical protection. The switch or circuit-breaker should be located close to the controller, within easy reach of the operator. The switch or circuit-breaker should be marked as the disconnecting device for the controller. When applying power to multiple instruments, make sure that sufficient current is supplied. Otherwise, the instruments may not start up normally due to the voltage drop caused by the inrush current. Failure to comply with these instructions may result in product damage. DC1010/1020/1030/1040 Product Manual 6 2.5.1 DC1010 N Noise Filter POWER 1 L 2 AC 90 ~ 240V (50 / 60Hz) 4 10 PV Relay Volt 2 9 14 OUTPUT 1 8 13 5 OUT2 7 12 3 DC 15 ~ 50V (option) 6 11 2 3 Linear 3 A,B,C,D Linear OUT1=5 7 11 G1 Relay Volt 4 1 2 Linear 3 B 8 12 K1 13 G2 OUT1 RTD 14 K2 TC 7 7 8 8 9 B 9 9 10 A 10 10 ALARM 5 A,B,C,D OUT1=7 AL1 AL1 AL2 2 11 13 3 12 14 2 AUX. OUT TRS 3 CLOSE 11 4 OPEN COMM. COMM RS232 RD 12 5 COM SD SG DC1010/1020/1030/1040 Product Manual 7 11 12 13 COMM RS485 D- 11 D+ 12 13 2.5.2 DC1020 L 1 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 10 20 L inear R TD Noise Filter POW ER N AC 90 ~ 240V (50 / 60Hz) DC 15 ~ 50V (option) PV OUTPUT OUT2 6 Relay 1 Vo lt 2 Lin ear 3 17 TC 17 17 18 18 B 18 7 A, B , C, D OUT1 Relay Vo lt 1 8 NO 2 3 9 NC 10 COM OUT1= 7 19 B 19 19 20 A 20 20 Lin ear ALARM AUX. OUT AL1 A, B , C, D AL2 3 NC AL3 NC 11 4 NO NO 11 6 TRS 12 7 12 6 5 7 COM COM 13 13 CLOSE 8 OPEN 9 10 COM INPUT2 COMM. COMM RS232 RD 14 14 15 SD 16 SG 16 15 COMM RS485 D- D+ 14 15 16 DC1010/1020/1030/1040 Product Manual 8 2.5.3 DC1030 L Noise Filter POW ER N AC 90 ~ 240V (50 / 60Hz) DC 15 ~ 50V (option) 1 15 8 2 16 9 3 17 10 4 18 11 5 19 12 6 20 13 7 21 14 PV OUTPUT OUT2 3 Relay 1 Vo lt 2 Lin ear 3 4 A, B , C , D OUT1 Relay Vo lt Linear 1 5 NO 2 3 L inear OUT1= 5 15 G1 11 17 G2 12 COM OUT1= 7 19 CLOSE PROT 20 12 12 13 13 14 A 14 14 ALARM AL1 OUT1= 8 AUX. OUT AL2 COM 3 A, B , C , D NO 4 TRS 8 18 9 19 10 16 K1 INPUT2 5 OPEN 17 G2 6 18 K2 7 COM 11 B NC 4 11 13 15 G1 3 TC B 6 NC 7 R TD Rem o te SP 9 20 10 COM M . COMM RS232 RD 15 SD 16 PROT 21 SG 17 DC1010/1020/1030/1040 Product Manual 9 COMM RS485 D- D+ 15 16 17 2.5.4 DC1040 L Noise Filter POWER N AC 90 ~ 240V (50 / 60Hz) DC 15 ~ 50V (option) 1 31 11 2 32 12 3 33 13 4 34 14 5 35 15 6 36 16 7 37 17 8 38 18 9 39 19 10 40 20 Relay Vo lt Linear 1 2 3 6 7 Relay Vo lt Linear 1 8 NO 2 3 9 NC COM OUT1=7 31 D- D+ SG 33 31 32 33 AUX. OUT TRS 39 40 L inear 31 RG 31 G1 17 33 RG 33 G2 18 35 TG1 39 37 TG2 40 TC 17 17 18 18 B 19 B 19 19 20 A 20 20 ALARM OUT1=9 39 A, B, C, D RTD PROT AL1 AL2 3 NC 31 G1 AL3 NC 11 6 40 OUT1=8 31 G1 33 G2 7 CLOSE 32 K1 34 K2 8 OPEN 33 G2 35 G3 9 34 K2 36 K3 5 NO COM COM INPUT2 Rem o te SP 14 PROT PROT 40 13 COMM. COMM RS232 RD 14 SD 15 16 SG 16 COMM RS485 D- D+ 14 15 16 * Once INPUT2 and COMM. options are selected together, the wiring terminal for COMM will be changed as above. DC1010/1020/1030/1040 Product Manual 10 7 12 15 39 35 36 4 NO 32 K1 6 10 COM COMM RS485 SD 32 OUT1=5 PROT 10 RD OUT1=6 A, B, C, D OUT1 COMM RS232 PV OUTPUT OUT2 COMM. 3. Configuration 3.1 Operator Interface Upper Display Lower Display Bar Graph LEDs OUT1 OUT2 AT AL1 AL2 AL3 MAN PRO 4 digits dedicated to display the PV. In configuration mode, this display indicates the name of parameter. 4 digits dedicated to display the SP. In configuration mode, this display indicates the value of parameter or the status of parameter selected. A bargraph of 10 green LEDs’ indicates the value of the output in percentage. Status of ‘Output 1’. Status of ‘Output 2’. When the LED is ON, it indicates the controller is in automatic tuning process . Status of ‘Alarm 1’. Status of ‘Alarm 2’. Status of ‘Alarm 3’. When the LED is ON, it indicates the controller is in manual mode. When a program is running, the LED flickers. When a program is suspended, the LED is ON. When no program is running, the LED is OFF. Keys SET A/M SHIFT UP DOWN SET key allows moving from one parameter to another or saving a new value of parameter or a status of parameter changed. A/M key allows switching from automatic mode to manual mode or from manual mode to automatic mode. SHIFT key allows shifting the digits to modify parameters. UP key allows increasing the value of a digit selected or changing the status of parameter. DOWN key allows decreasing the value of a digit selected or changing the status of parameter. Upper Display Lower Display LEDs Bar Graph SHIFT key 0% 20 40 60 80 100% SET key Up key A/M key Down key DC1010/1020/1030/1040 Product Manual 11 3.2 MODE Access Operation (1) Configuration 1 (2) (3) Program (2) Configuration 2 (3) Set Up How to move from one MODE to another (1) Press ‘SET’ key for 5 seconds; it grants access to ‘Configuration 1’ mode or return to ‘Operation’ mode from ‘Configuration 1’ mode. (2) Press ‘SHIFT’ key for 5 seconds while pressing ‘SET’ key first; it grants access to ‘Configuration 2’ mode or return to ‘Operation’ mode. (3) All parameters related to program configuration will be displayed next to parameters in ‘Operation’ mode. (* These parameters will be shown in program model only) NOTICE DO NOT access ‘Set Up’ mode without instruction from technical assistant. DC1010/1020/1030/1040 Product Manual 12 3.3 MODEs 3.3.1 Operation Parameter Description PV Display SP Display SET Output Limit To limit the Maximum of Control Ouput Percentage (%) SET Auto Tuning Status * Default ‘No’ Alarm 1 Enter deviation value or absolute value Value of alarm setpoint Depending on alarm mode selected SET SET Alarm 2 The same with Alarm1 SET Alarm 3 The same with Alarm 1 * The ‘OUTL’ is not shown in default mode. * ‘AL2’ & ‘AL3’ are shown only in the model the relevant options are taken. DC1010/1020/1030/1040 Product Manual 13 3.3.2 Configuration 1 ‘Configuration 1’ will be shown by pressing ‘SET’ key for 5 seconds in ‘Operation’ mode. Parameter SET SET Description Main Control (OUT1) Range: 0~200% P value (Proportional Band) P1=0, ON/OFF Control Main Control (OUT1) Range: 0~3600 seconds I value (Integral Time) I=0, Integral off Main Control (OUT1) Range: 0~900 seconds D value (Derivative Time) D=0, Derivative off Main Control * DO NOT CHANGE THE VALUE SET Dead-Band Time SET Main Control (OUT1) Range: 0~ Upper limit value (USPL) ‘Auto tuning’ offset Prevent from ‘Overshoot’ during auto tuning SET Main Control (OUT1) Output type (SSR Cycle of Control Output Range: 0~150 seconds Main Control (OUT1) Actuation of Hystersis Just in case of ON/OFF control (P1=0) (Range: 0~1000) ON : PV<=(SP-HYS1) OFF : PV > (SP+HYS1) Sub Control (OUT2) The same with the method of P1 configuration 1, 4~20mA 0, relay 10) SET SET P value (Proportional band) SET The same with the method of I1 configuration Sub Control (OUT2) I value (Integral Time) SET The same with the method of D1 configuration Sub Control (OUT2) D value (Derivative Time) SET The same with the method of CYT1 configuration Sub Control (OUT2) Cycle of Control Output SET The same with the method of HYS1 configuration Sub Control (OUT2) Hysteresis SET Main Control (OUT 1) Control ouput is turned off before getting to SP Gap Turning Point = SP-GAP1; OFF (OUT1=Heat) Sub Control (OUT2) Control Output to be turned on before getting to SP SET Gap Turning Point = SP+GAP2; ON (OUT2=Cool) Function Lock * Refer to ‘2.3 Function Lock’ in P.10 SET SET * The parameters are only for ‘Output’ 2 function, so it will appear only in the model which has the “OUT2” option. DC1010/1020/1030/1040 Product Manual 14 3.3.3 Configuration 2 ‘Configuration 2’ mode will be shown by pressing ‘SHIFT’ key for 5 seconds WHILE pressing ‘SET’ key FIRST in ‘Operation’ or ‘Configuration 2’ mode. Parameter Description To define input type & input range Input 1 (INP1) * Refer to SET SET Input 1 (INP1) To be used during the calibration for linear input Lower limit of linear Input * DO NOT change this value without technical support Input 1 (INP1) To be used during the calibration for linear input Upper limit of linear Input * DO NOT change this value without technical support Decimal Point Available in linear input only Lower limit of Input range i.e) Linear input = 4~20mA, SET SET when 4mA (0%), set the indication value for lower limit SET when 20mA (100%), set the indication value for upper limit Upper limit of Input range SET Input 2 (INP2) To be used during the calibration for linear input Lower limit of linear input * DO NOT change this value without technical support Input 2 (INP2) To be used during the calibration for linear input Upper limit of linear input * DO NOT change this value without technical support Alarm Code of ‘Alarm 1’ * Refer to SET SET SET Time Set for ‘Alarm 1’ * Range: 0 - 99 min 59 sec 0= flickering alarm, 99.59= continuant alarm SET Others = Time delay of alarm Alarm Code of ‘Alarm2’ SET The same configuration method with ALT1 Time Set for ‘Alarm 2’ SET Alarm Code of ‘Alarm 3’ SET Time Set for ‘Alarm 3’ The same configuration method with ALT1 Hysteresis of alarms To set the hysteresis of alarm actuation (Range: 0 – 1000) ON : PV<=(SP-HYS1) OFF : PV > (SP+HYS1) SET SET DC1010/1020/1030/1040 Product Manual 15 Parameter Description Main Control (OUT1) To adjust the linear control output during the calibration Lower limit of linear output * DO NOT change the value without technical support Main Control (OUT1) To adjust the linear control output during calibration Upper limit of linear output * DO NOT change the value without technical support Sub Control (OUT2) The same configuration method with ‘CL01’ SET SET Lower limit of linear output SET Sub Control (OUT2) The same configuration method with ‘CH01’ Upper limit of linear output SET Aux. Output Lower limit of linear output The same configuration method with ‘CL01’ Aux. Output The same configuration method with ‘CH01’ SET Upper limit of linear output SET Full actuation time of Time proportional motor control Timer for Motor Control Range: 5 – 200 sec SET To set ‘wait’ for program operation WAIT function 0= No wait, others = Wait volume SET Extra SET DO NOT change the value of this parameter ID Number Communication ID number Baud Rate DO NOT change the value of this parameter SP compensation Range: -1000~1000 PV compensation Range: LSPL~USPL Unit of PV & SP Selection: C, F, and A (linear) Soft Filter To adjust PV response time (Range: 0.05 – 1.00) SET SET SET SET SET SET * The bigger value gives the faster response. SET * Those 2 parameters are only for adjusting the linear signal of control output, not for the limitation of the control output or any other purpose. Please, DO NOT change the values without Technical Support, see Contacts page. DC1010/1020/1030/1040 Product Manual 16 Parameter Description * DO NOT change the value SET Operation Mode Heating (direct) or Cooling (reverse) Control Process PID or Fuzzy Frequency 50 or 60Hz SET SET * Please, check whether the proper frequency is selected SET 3.4 Alarms 3.4.1 Deviation Alarm The Alarm SP (Set Point) is to be changed as the SP moves. In this case, the Alarm SP preserves a certain deviation value with the SP. When an alarm is set, a certain deviation value with the preset SP should be defined. Alarm SP moves along SP change Deviation (Lower limit) SP1 SP1 SP2 SP Change Alarm SP Alarm SP moves along SP change Deviation (Upper Limit) SP1 SP1 Alarm SP SP2 SP Change 3.4.1.1 Upper Limit Deviation Alarm (Alarm Code 01, Alarm release in the first alarming situation) : Set Point : Alarm Set Point 3.4.1.2 Upper Limit Deviation Alarm (Alarm Code 11, No alarm release in the first alarming situation) DC1010/1020/1030/1040 Product Manual 17 3.4.1.3 Lower Limit Deviation Alarm (Alarm Code 02, Alarm release in the first alarming situation) 3.4.1.4 Lower Limit Deviation Alarm (Alarm Code 12, No alarm release in the first alarming situation) 3.4.1.5 Dev. Band Breakaway Alarm(Alarm Code 03, Alarm release in the first alarming situation) 3.4.1.6 Dev. Band Breakaway Alarm(Alarm Code 13, No alarm release in the first alarming situation) 3.4.1.7 Deviation Band Alarm (Alarm Code 04, Alarm release in the first alarming situation) 3.4.1.8 Deviation Band Alarm (Alarm Code 14, No alarm release in the first alarming situation) 3.4.2 Absolute Value Alarm The Alarm SP (Set Point) is to be fixed even though the SP moves. When an alarm is set, the absolute value of the Alarm SP should be defined. Alarm Set Point (Fixed) SP1 SP2 SP3 3.4.2.1 Absolute Upper Limit Alarm (Alarm Code 05, Alarm release in the first alarming situation) 3.4.2.2 Absolute Upper Limit Alarm (Alarm Code 15, No alarm release in the first alarming situation) DC1010/1020/1030/1040 Product Manual 18 3.4.2.3 Absolute Lower Limit Alarm (Alarm Code 06, Alarm release in the first alarming situation) 3.4.2.4 Absolute Lower Limit Alarm (Alarm Code 16, No alarm release in the first alarming situation) 3.4.3 Program Alarm 3.4.3.1 Segment End Alarm (Alarm Code 07) Once the selected segment is completed, the alarm becomes actuated - ALD1 – ALD3 Set the Alarm Code 07 - AL1 – AL3 Enter Segment No. for alarms - ALT1 – ALT3 Define the alarm timing (0 Flickering, 99.59 Continuant, Others Time Delay) 3.4.3.2 Program RUN Alarm (Alarm Code 17) While a program runs, the alarm becomes actuated 3.4.4 System Alarm 3.4.4.1 System Error Alarm (Alarm Code 08) 3.4.4.2 System Error Alarm (Alarm Code 18) 3.4.4.3 Timer Alarm (Alarm Code 19) Once the PV reaches to the SP, the alarm becomes actuated after a certain time delay. (Range: 00 hour 00 min – 99 hour 59 min) DC1010/1020/1030/1040 Product Manual 19 3.5 Function Lock According to the status of the parameter “LCK” in ‘Configuration 1’ mode, ‘access to modes’ and ‘change of values’ can be prohibited. LCK=0000 MODE ACCESS Access to ‘Operation’, ‘Configuration1 & 2’ modes allowe (* Default) LCK=0100 MODE ACCESS Access to ‘Operation’ & ‘Configuration 1’ mode allowed VALUE CHANGE Every value change in each mode allowed MODE ACCESS Access to ‘Operation’ & ‘Configuration 1’ mode allowed VALUE CHANGE Value changes only in ‘Operation’ mode allowed MODE ACCESS Access to ‘Operation’ mode allowed VALUE CHANGE Value change of SP (Set Point) allowed only LCK=1111 MODE ACCESS Access to “Set Up” mode allowed LCK=0101 All access & value changes prohibited except the change of “LCK” status LCK=0110 LCK=0001 WARNING PERSONAL INJURY: Configuration should be performed only by personnel who are technically competent to do so. Local Regulations regarding electrical & safety must be observed. Failure to comply with these instructions could result in death or serious injury. DC1010/1020/1030/1040 Product Manual 20 4. Input Codes The input code in ‘Configuration 2’ mode must be selected properly before the operation starts. 4.1 Thermocouples TYPE K J R S B E N T W PLII U L CODE RANGE 0.0~200.0°C 0.0~392.0°F 0.0~400.0°C 0.0~752.0°F 0~600°C 0~1112°F 0~800°C 0~1472°F 0~1000°C 0~1832°F 0~1200°C 0~2192°F 0.0~200.0°C 0.0~392.0°F 0.0~400.0°C 0.0~752.0°F 0~600°C 0~1112°F 0~800°C 0~1472°F 0~1000°C 0~1832°F 0~1200°C 0~2192°F 0~1600°C 0~2912°F 0~1796°C 0~3216°F 0~1600°C 0~2912°F 0~1796°C 0~3216°F 0~1820°C 0~3308°F 0~800°C 0~1472°F 0~1000°C 0~1832°F 0~1200°C 0~2192°F 0~1300°C 0~2372°F 0.0~400.0°C 0.0~752.0°F 0.0~200.0°C 0.0~392.0°F 0.0~350.0°C 0.0~662.0°F 0~2000°C 0~3632°F 0~2320°C 0~2372°F 0~1300°C 0~2372°F 0~1390°C 0~2534°F -199.9~600.0°C -199.9~999.9°F -199.9~200.0°C -199.9~392.0°F 0.0~400.0°C 0.0~752.0°F 0~400°C 0~752°F 0~800°C 0~1472°F * The default of Input Code is ‘K2’ for the model of thermocouple input type. (DC10X0XT-XXX-XXX-X) DC1010/1020/1030/1040 Product Manual 21 4.2 RTDs TYPE CODE JIS Pt100 DIN Pt100 JIS Pt50 RANGE -199.9~600.0°C -199.9~999.9°F -199.9~400.0°C -199.9~752.0°F -199.9~200.0°C -199.9~392.0°F 0~200°C 0~392°F 0~400°C 0~752°F 0~600°C 0~1112°F -199.9~600.0°C -199.9~999.9°F -199.9~400.0°C -199.9~752.0°F -199.9~200.0°C -199.9~392.0°F 0~200°C 0~392°F 0~400°C 0~752°F 0~600°C 0~1112°F -199.9~600.0°C -199.9~999.9°F -199.9~400.0°C -199.9~752.0°F -199.9~200.0°C -199.9~392.0°F 0~200°C 0~392°F 0~400°C 0~752°F 0~600°C 0~1112°F * The default of Input Code is ‘DP3’ for the model of RTD input type. (DC10X0XR-XXX-XXX-X) 4.3 Linear Inputs CODE SIGNAL INPUT TYPE RANGE -10 - 10mV -1999~9999 0 - 10mV -1999~9999 0 - 20mV -1999~9999 0 - 50mV 0-20mA, 0-1V, 0-5V, 0-10V -1999~9999 10 - 50mV 4-20mA, 1-5V, 2-10V -1999~9999 * The default of Input Code is ‘AN5’ (4-20mA) for the model of linear input type. (DC10X0XL-XXX-XXX-X) NOTICE * DO NOT change the input type without Technical Support because some hardware changes are required on the input board in order to select a certain linear input type. DC1010/1020/1030/1040 Product Manual 22 5. Operation 5.1 Type of Control 5.1.1 Manual Operation The control output can be managed manually. When the ‘A/M’ key is pressed, the parameter of ‘OUTL’ will appear in the upper display, and a fixed control output is shown in lower display (% value). Once the value is changed, the control output is changed and fixed again. 5.1.2 ON/OFF Control The output type must be Relay Output (DC10X0XX-1XX-XXX-X). The ‘P’ value can be changed to 0 in ‘Configuration 1’ mode to produce an ON/OFF control output. When the PV (process variable) reaches the SP (set point), the control output is ON (100%), when it reaches the SP the control output becomes OFF (0%). * To prevent the control output from flickering too frequently the hysteresis (‘HYS1’ in ‘Operation’ mode) is to be set. 5.1.3 PID Control PID control is the default control type of this controller. If ‘AT’ in ‘Operation’ mode becomes ‘YES’, the auto tuning process will start. After the auto tuning is completed, the controller gets optimum PID values for the control system and starts the operation automatically. (PID values can be set manually in ‘Configuration 1’ mode without auto tuning procedure.) 5.2 Set Point After all the wiring connection is completed and power is applied, the targeted SP (Set Point) is to be entered. When power is applied, the default display is the PV & SP display. The SP may now be entered. (Change the value targeted, and press ‘SET’ key for saving) 5.3 Alarm Set Point If necessary, each alarm should be set properly. - Set the Alarm Code required in ‘ALd1’ (ALd2 / ALd3) in ‘Configuration 2’ mode (Alarm Code: 00 to 19) - Define the alarm timing required for ‘ALt1’ (ALt2 / ALt3) in ‘Configuration 2’ mode ‘0000’ ‘XXXX’ flickering alarm, ‘9959’ continuant alarm XX min XX sec (Time Delay) - Enter the deviation value or absolute value in ‘AL1’ (AL2 / AL3) in ‘Operation’ mode depending on the Alarm Code selected above. - Set the hysteresis of alarms in ‘HYSA’ in ‘Configuration 2’ mode. (If necessary) DC1010/1020/1030/1040 Product Manual 23 6. Error Message In case the following error messages appear in the upper display of controller, please refer to the Error message table below, or call technical support. See Contacts page for details. Sign Description Solution Open the circuit of ‘INPUT 1’ (sensor) Check the wiring * A/D Convert Failure Service Call required * Cold junction compensation failure Service Call required Open the circuit of ‘INPUT 2’ (sensor) Check the wiring Excess of PV over upper limit (INPUT 1) - Check sensor wiring & input code Shortage of PV under lower limit (INPUT1) Excess of PV over upper limit (INPUT2) * Shortage of PV under lower limit (INPUT2) - Adjust the range of indication Memory (RAM) failure Service call required Interface failure Check wiring of input Auto tuning failure Check wiring of output WARNING PERSONAL INJURY: Controller checks should be performed only by personnel who are technically competent to do so. Local Regulations regarding electrical & safety must be observed. Failure to comply with these instructions could result in death or serious injury. DC1010/1020/1030/1040 Product Manual 24 DC1010/1020/1030/1040 Product Manual 25 Sales and Service For application assistance, current specifications, pricing, or name of the nearest Authorized Distributor, contact one of the offices below. Warranty/Remedy Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. Specifications may change without notice. The information we supply is believed to be accurate and reliable as of printing. However, we assume no responsibility for its use. While we provide application assistance personally, through our literature and the Honeywell website, it is up to the customer to determine the suitability of the product in the application. © Copyright 2004. Honeywell International Inc. All rights reserved. ASIA PACIFIC Australia Honeywell Limited Phone: +(61) 2-9370-4500 FAX: +(61) 2-9370-4525 Beijing Honeywell (Tianjin) Ltd Phone: +(86-10) 8458-3280 Fax: +(86-10) 8458-3103 Shanghai Honeywell (Tianjin) Ltd Phone: (86-21) 6237-0237 Fax: (86-21) 6237-0775 Hong Kong S.A.R. Honeywell Ltd. Phone: +(852) 2953-6412 Fax: +(852) 2953-6767 Chengdu Honeywell China Inc. Phone: +(86-28) 8678-6348 Fax: +(86-28) 8678-7061 Guangzhou Honeywell China Inc. Phone: +(86-20) 3879-1169 Fax: +(86-20) 3879-1269 Shenzhen Honeywell China Inc. Phone: +(86) 755-25181226 Fax: +(86) 755-2518-1221 Indonesia PT Honeywell Indonesia Phone: +(62) 21-535-8833 FAX: +(62) 21-536-71008 India TATA Honeywell Ltd. Phone: +(91) 20 687 0445/0446 Fax: +(91) 20 681 2243/ 687 5992 Japan Honeywell Inc Phone: +(81) 3 5440 1425 Fax: +(81) 3 5440 1368 South Korea Honeywell Co., Ltd Phone: +(82) 2 799-6146 Fax: +(82) 2 792-9013 Malaysia Honeywell Engineering Sdn Bhd Phone: +(60-3) 7958-4988 Fax: +(60-3) 7958-8922 New Zealand Honeywell Limited Phone: +(64-9) 623-5050 Fax: +(64-9) 623-5060 Philippines Honeywell Systems (Philippines) Inc. Phone: +(63-2) 633-2830 Fax: +(63-2) 638-4013 Singapore Honeywell Pte Ltd Phone: +(65) 6355-2828 Fax: +(65) 6445-3033 Thailand Honeywell Systems (Thailand) Ltd. Phone: +(662) 693-3099 FAX: +(662) 693-3085 Taiwan R.O.C. Honeywell Taiwan Ltd. Phone: +(886-2) 2245-1000 FAX: +(886-2) 2245-3242 LATIN AMERICA Argentina Honeywell S.A.I.C. Phone: +(54-11) 4383-3637 FAX: +(54-11) 4325-6470 Brazil Honeywell do Brasil & Cia Phone: +(55-11) 7266-1900 FAX: +(55-11) 7266-1905 Chile Honeywell Chile, S.A. Phone: +(56-2) 233-0688 FAX: +(56-2) 231-6679 Mexico Honeywell S.A. de C.V. Phone: +(52) 55 5259-1966 FAX: +(52) 55 5570-2985 Puerto Rico Honeywell Inc. Phone: +(809) 792-7075 FAX: +(809) 792-0053 Trinidad Honeywell Inc Phone: +(868) 624-3964 FAX: +(868) 624-3969 Venezuela Honeywell CA Phone: +(58-2) 238-0211 FAX: +(58-2) 238-3391 Industrial Measurement & Controls Honeywell Korea 191 HanGangRo 2ga YongSanGu Seoul, Korea 51-52-25-113 Issue 1 March 2004 NORTH AMERICA Canada Honeywell LTD Phone: 1-800-737-3360 FAX: 1-800-565-4130 USA Honeywell Control Products, International Headquarters Phone: 1-800-537-6945 1-815-235-6847 FAX: 1-815-235-6545 E-mail: [email protected] EUROPE Austria Honeywell Austria Ges.m.b.H. Phone: +43 (1) 727 80 – 0 Fax: +43 (1) 727 80 – 8 Balkan Countries Please contact the Honeywell Italian office Belgium Honeywell SA/NV Phone: +32(0)27282776 FAX: +32(0)27282329 Bulgaria Honeywell EOOD Phone: +359 29790017 & ext /18 /23 /26 FAX: +35-929 790024 & +359 29713213 Czech Republic Honeywell spol. s.r.o. Phone: +420 242442205 FAX: +420 242442131 Denmark Honeywell A/S Phone: +(45) 39 55 55 55 FAX: +(45) 39 55 55 58 Finland Honeywell OY Phone: +358 (3) 2727625 FAX: +358 (3) 2728600 France Honeywell SA Phone: +33 (0)1 60198075 FAX: +33 (0)1 60198201 Germany Honeywell GmbH Phone: +49 (69)8064299 FAX: +49 (69)8064931 Hungary Honeywell Kft. Phone: +36-1-451 4335 FAX: +36-1-451 4343 Italy Honeywell S.p.A. Phone: +39 02 9214 6347 FAX: +39 0292146377 The Netherlands Honeywell B.V. Phone: +31(0)205656200 FAX: +31(0)205656210 Norway Honeywell A/S Phone: +47 66762000 FAX: +47 66762090 Poland Honeywell Sp. zo.o Phone: +48-22-6060900 FAX: +48-22-6060901 Portugal Honeywell Portugal S.A. Phone: +351 21 424 5000 FAX: +351 21 424 50 99 Romania Honeywell Bucharest Phone: 0040212316437 & 0040212316438 FAX: 0040212316439 Russia and (CIS) Z.A.O. Honeywell, Moscow Phone: +(7 095) 796 98 00/81 FAX: +(7 095) 796 98 93/94 Slovak Republic Honeywell s.r.o. Phone: +421-2-58247 400 FAX: +421-2-58247 415 Spain Honeywell S.A. Phone: +34 (0)91313 61 00 FAX: +34 (0)91313 62 78 Sweden Honeywell AB Phone: +(46) 8 775 55 00 FAX: +(46) 8 775 56 00 Switzerland Honeywell AG Phone: +41 (1) 855 24 24 FAX: +41 (1) 855 24 25 Turkey Honeywell Turkey A.S. Phone: +90 216 575 6600 FAX: +90 216 575 6637 United Kingdom Honeywell Control Systems Ltd Phone: +(44) 1344 655251 FAX: +(44) 1344 655554 Ukraine Honeywell Phone: 38-044 201 4474 Fax: 38-044 201 4475 AFRICA South Africa (Republic of) Honeywell Southern Africa Honeywell S.A. Pty. Ltd Phone: +27 11 6958000 FAX +27 118051504 English Speaking Africa Please contact the Honeywell South African office. French Speaking Africa Please contact the Honeywell French office in EUROPE MIDDLE EAST Abu Dhabi U A E Middle East Headquarters Honeywell Middle East Ltd Phone: +971 24432119 FAX: +971 24432536 Sultanate of Oman Honeywell & Co Oman LLC Phone: +968 701397 FAX +968 787351 Egypt Honeywell Egypt Ltd Phone: +202 6905516 & ext. /17 /18 /19 FAX : +202 6905523 Saudia Arabia Honeywell Turki Arabia Limited Phone: +966-3-341-0140 Fax: +966-3-341-0216 Kuwait Honeywell Kuwait KSC Phone: +965 2421327 Fax: +965 2428315 Qatar Honeywell Middle East Phone: 974-4837768/9 Fax: 974-4837765

-

Contents

-

Table of Contents

-

Bookmarks

L

POW ER

N

AC 90 ~ 240V

(50 / 60Hz)

DC 15 ~ 50V

(option)

OUTPUT

O UT2

Relay

Vo lt

1

2

6

7

O UT1

Relay Vo lt

1

2

NO

8

NC

9

10

COM

OUT1= 7

6

CLOSE

7

OPEN

8

9

COM

10

Noise

Filter

PV

L

inear

Lin ear

3

A, B , C, D

Lin ear

3

ALARM

AL1

NC

3

A, B , C, D

NO

4

5

COM

INPUT2

DC1010/1020/1030/1040 Product Manual

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

9

19

10

20

R

TD

17

17

B

18

18

19

B

19

A

20

20

AL2

AL3

NC

11

6

NO

12

7

13

CO M

COMM.

COMM

COMM

RS232

RS485

RD

14

14

D-

SD

15

15

D+

SG

16

16

8

T

C

17

18

19

20

AUX. OUT

TRS

14

15

16

11

12

13