1

СОДЕРЖАНИЕ

ОСНОВНЫЕ ЧАСТИ

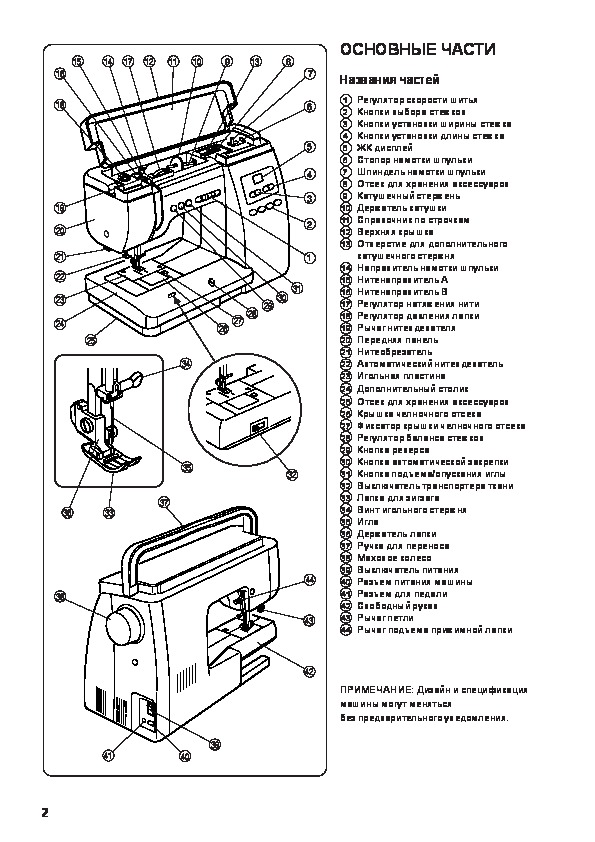

Названия частей ………………………………………..2

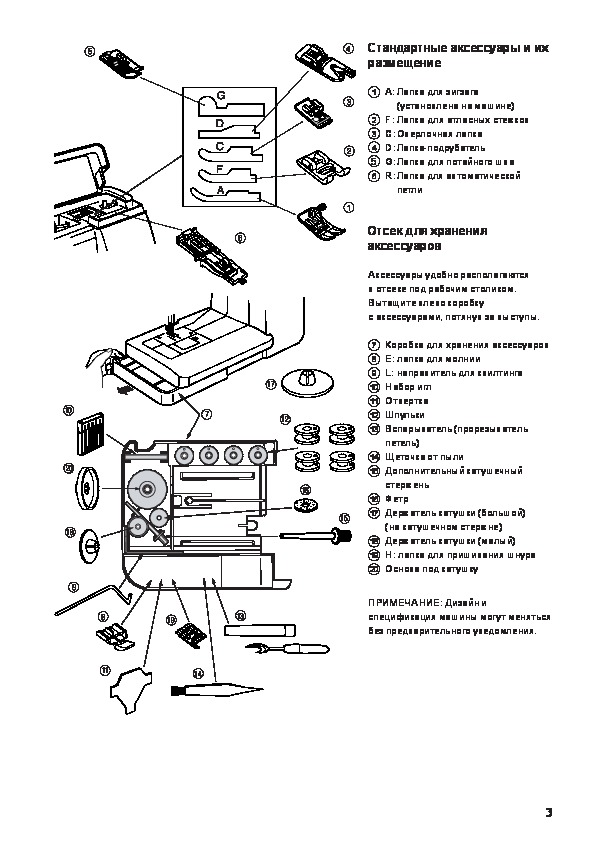

Стандартные аксессуары и их размещение .. 3

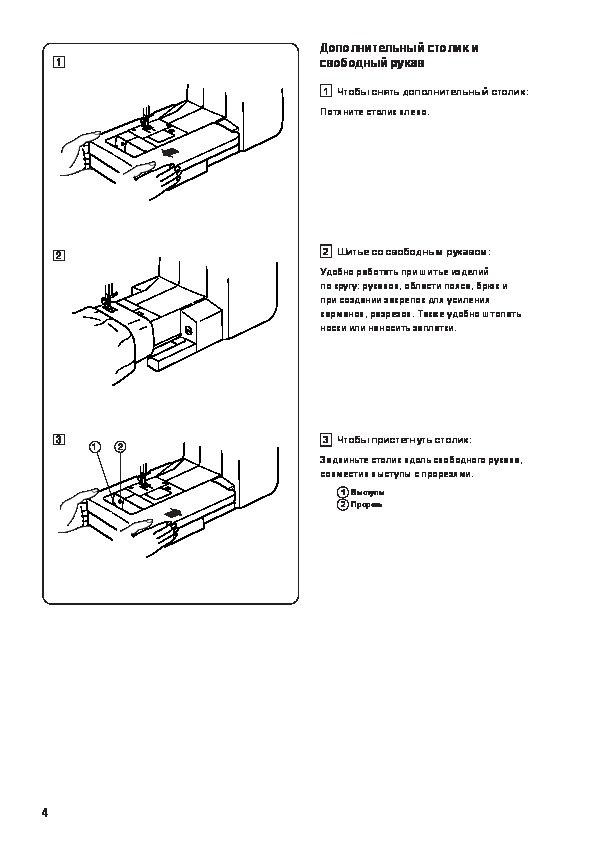

Дополнительный столик и свободный рукав ..4

ПОДГОТОВКА К ШИТЬЮ

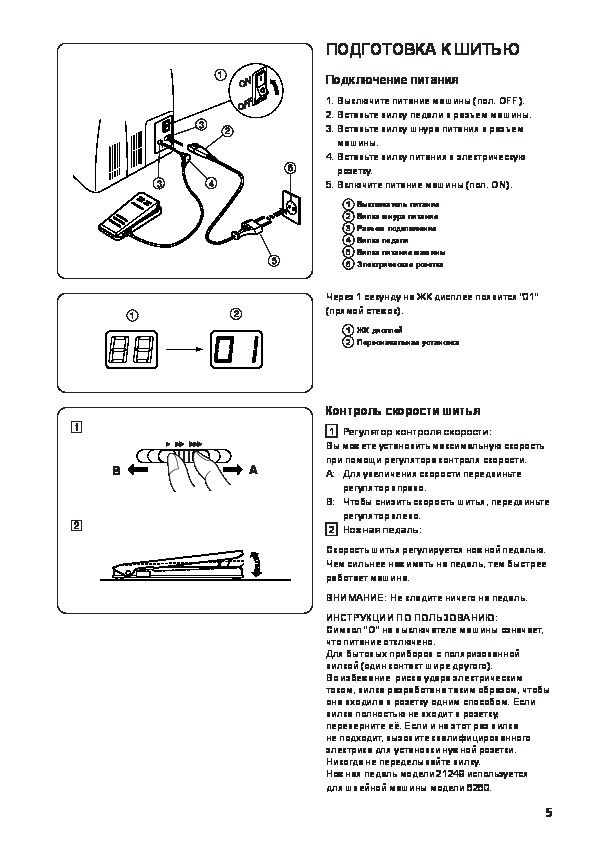

Подключение питания ………………………………..5

Контроль скорости шитья …………………………..5

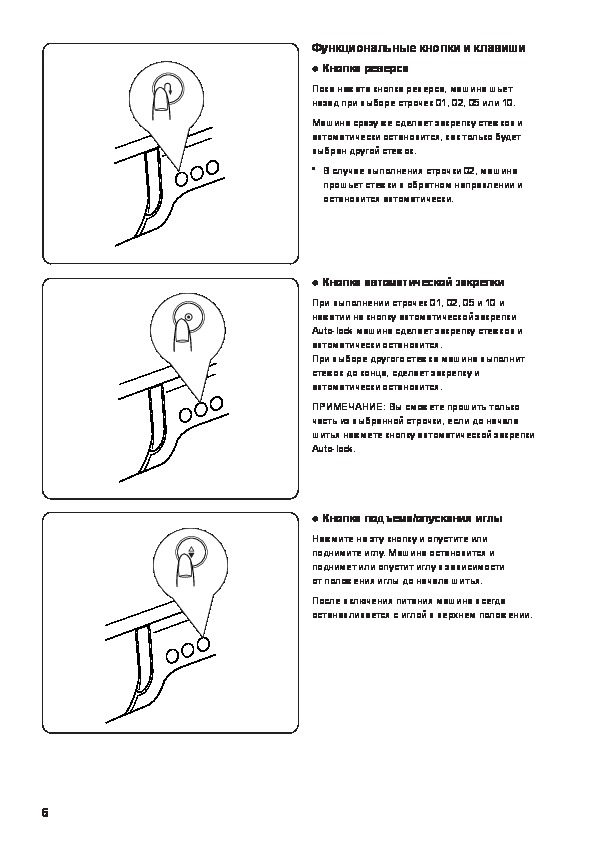

Функциональные кнопки и клавиши …………….6

z

Кнопка реверса …………………………………… 6

z

Кнопка автоматической закрепки …………..6

z

Кнопка подъема/опускания иглы ………….. 6

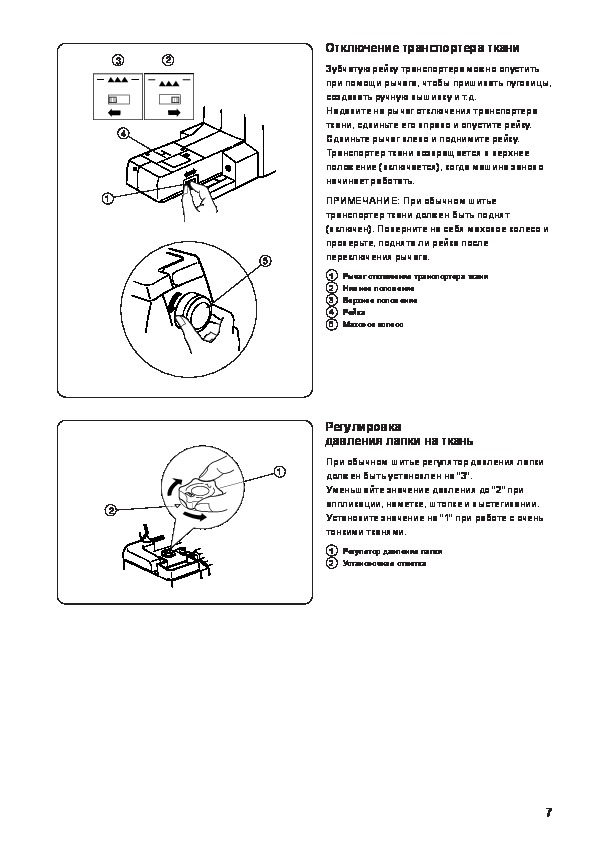

Отключение транспортера ткани ………………..7

Регулировка давления лапки на ткань ……….. 7

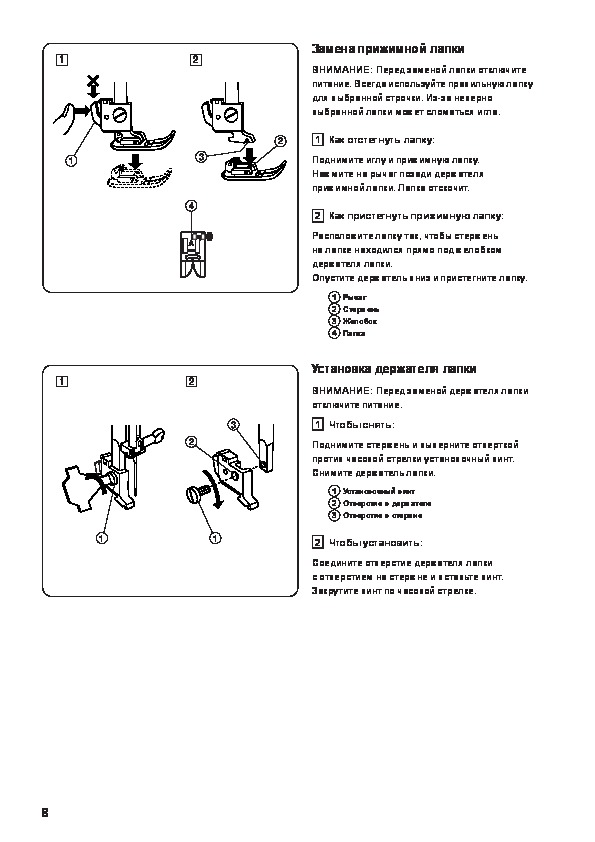

Замена прижимной лапки …………………………..8

Установка держателя лапки ………………………. 8

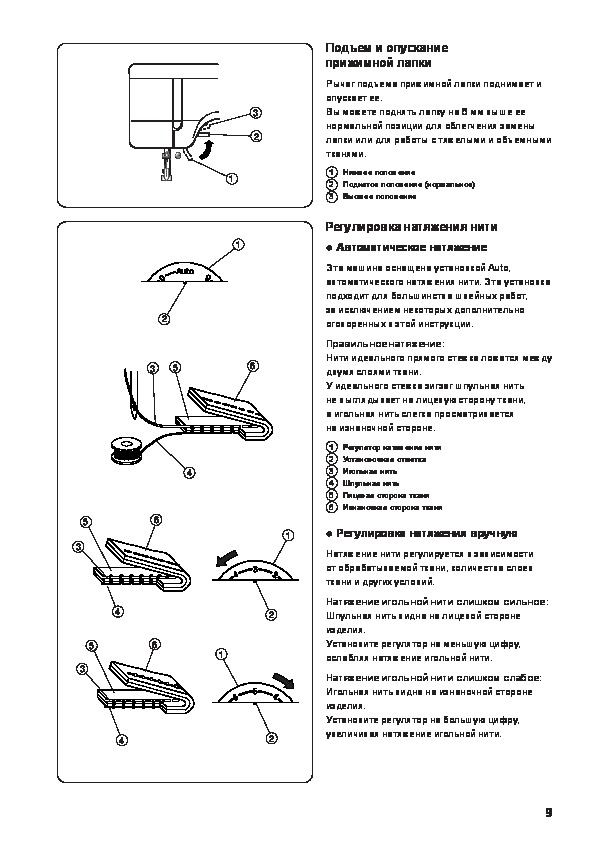

Подъем и опускание прижимной лапки ……….9

Регулировка натяжения нити ………………………9

z

Автоматическое натяжение …………………..9

z

Регулировка натяжения вручную ………….. 9

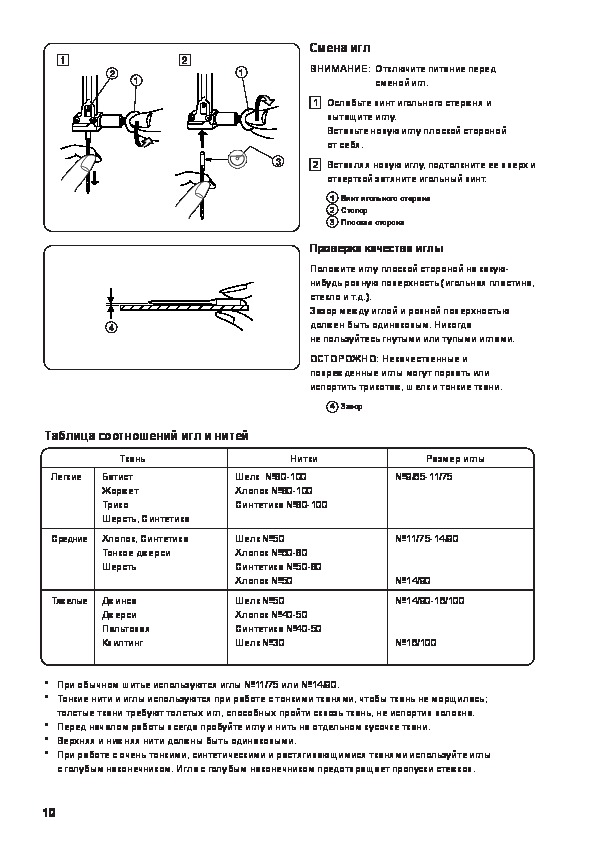

Смена игл ………………………………………………. 10

Таблица соотношений игл и нитей …………… 10

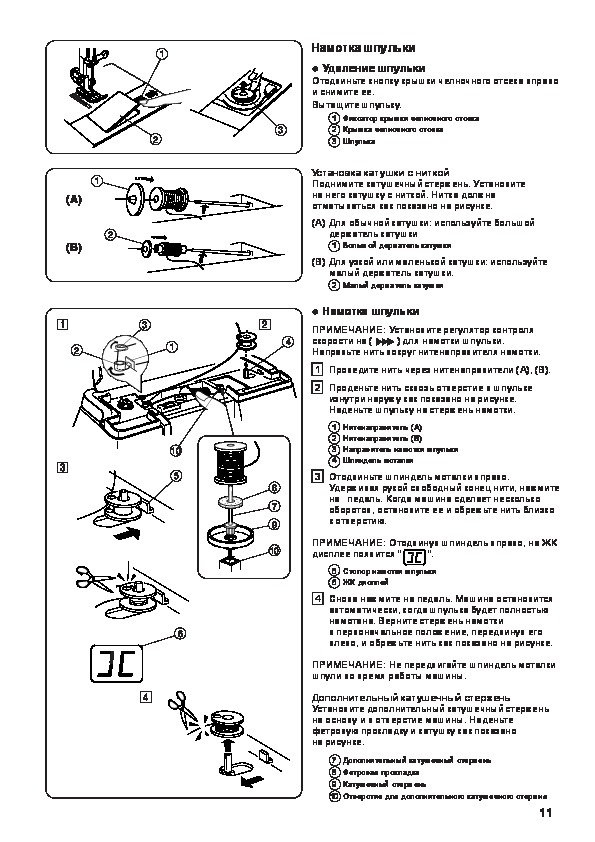

Намотка шпульки ……………………………………..11

z

Удаление шпульки ………………………………11

z

Намотка шпульки ………………………………..11

z

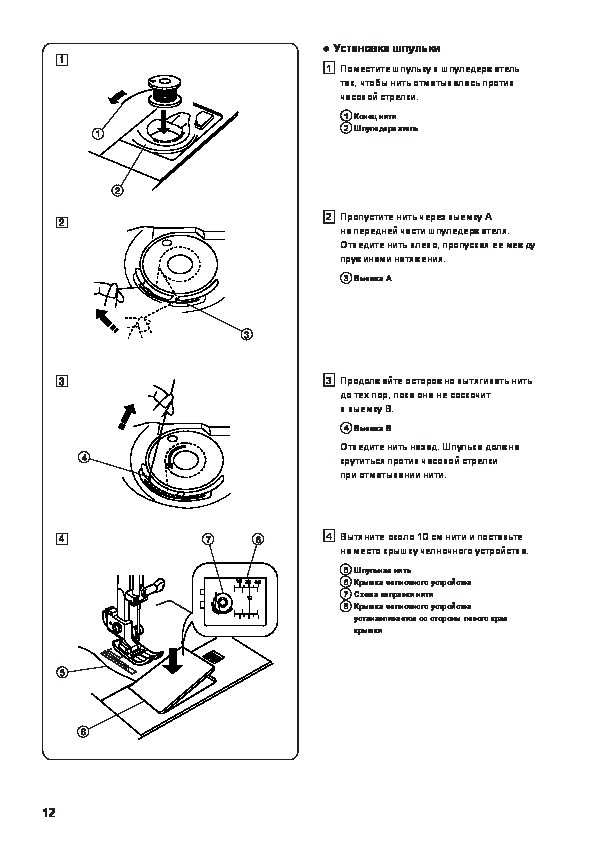

Установка шпульки ……………………………..12

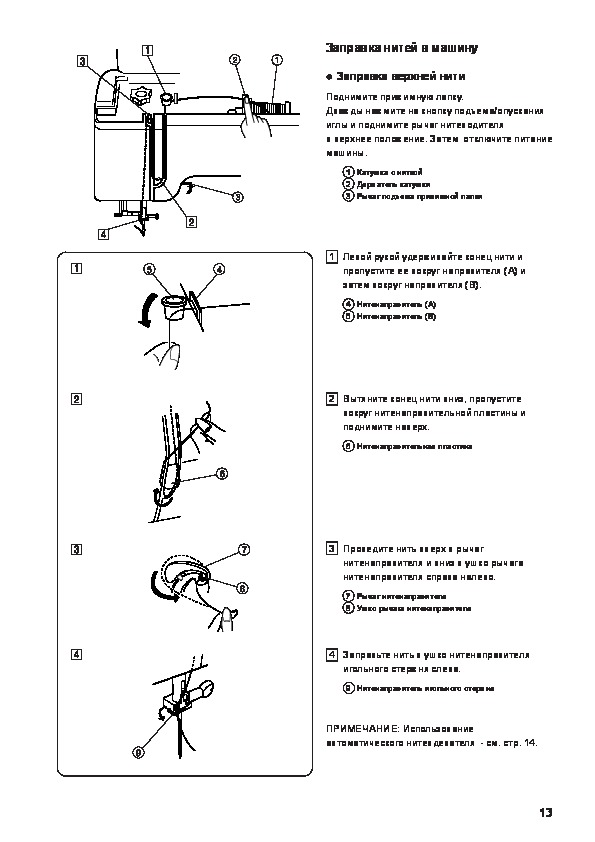

Заправка нитей в машину ……………………….. 13

z

Заправка верхней нити ……………………….13

Автоматический нитевдеватель ………………..14

Вытягивание нижней нити ……………………….. 15

Ручка выбора стежков …………………………….. 16

Регулятор ширины стежка ……………………….. 16

Регулятор длины стежка …………………………..16

ОСНОВНЫЕ ШВЕЙНЫЕ ТЕХНИКИ

Прямой стежок ……………………………………….. 17

z

Начало шитья …………………………………….17

z

Смена направления шитья ………………… 17

z

Закрепление шва/обрезка нити ………….. 17

z

Подбор длины стежка …………………………18

z

Смена положения иглы ……………………… 18

z

Направительные линии ……………………… 19

z

Шитье от края толстой ткани ……………… 19

Разнообразие прямых стежков ………………… 20

Основной стежок зигзаг …………………………… 21

z

Изменение ширины стежка …………………21

z

Изменение длины стежка ……………………21

Оверлочивание ………………………………………. 22

z

Стежок зигзаг ……………………………………. 22

z

Мультизигзаг (Стежок трико) ……………….22

z

Трикотажный стежок ………………………….. 22

z

Обработка края ………………………………….23

z

Оверлочный стежок …………………………… 23

Пришивание пуговиц ………………………………..24

Автоматическая петля …………………………25-31

Зажгутованная петля ………………………………. 32

Пришивание молнии ……………………………33-35

Роликовый шов ………………………………………..36

Глазок ……………………………………………………..36

Потайная строчка …………………………………….37

Штопка …………………………………………………… 38

АППЛИКАЦИИ

И ДЕКОРАТИВНЫЕ СТЕЖКИ

Аппликация ……………………………………………..39

Квилтинг ………………………………………………….39

Узкие складки …………………………………………. 40

Пэчворк ………………………………………………….. 40

Мережка ………………………………………………….41

Шов-ракушка ……………………………………………41

Сборки …………………………………………………….42

Декоративные атласные стежки ………………. 42

Комбинации стежков ………………………………. 43

Шитье крестом …………………………………………43

Пришивание шнура ………………………………….44

Эластичный стежок стреч …………………………44

Декоративные стежки стреч …………………….. 45

Регулировка баланса стежков стреч ………….45

УХОД ЗА МАШИНОЙ

Замена лампочки ……………………………………. 46

Чистка челночного

отсека и тканенаправителей ……………………. 47

ПРОБЛЕМЫ И

ПРЕДУПРЕЖДАЮЩИЕ СИГНАЛЫ ………….48

УСТРАНЕНИЕ НЕИСПРАВНОСТЕЙ ………… 49

- Manuals

- Brands

- Janome Manuals

- Sewing Machine

- OC 6260

- Instruction book

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Janome OC 6260

Summary of Contents for Janome OC 6260

-

Page 1

INSTRUCTION BOOK… -

Page 2: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic safety precautions should always be followed, including the followings: Read all instructions before using this appliance. DANGER— To reduce the risk of electric shock: 1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the electric outlet immediately after using and before cleaning.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Name of Parts …………2 Overcasting ………….. 22 • Zigzag stitch ………… 22 Standard Accessories and Storage ……3 • Extension Table and Free Arm Sewing ….. 4 Multiple zigzag stitch (Tricot stitch) ….22 • Knit stitch …………22 GETTING READY TO SEW •…

-

Page 4: Product View And Parts

Name of Parts Speed control lever Direct pattern selection keys Stitch width control keys Stitch length control keys LED display Bobbin winder stopper Bobbin winder spindle Accessory storage compartment Spool pin Spool holder Stitch reference chart Top cover Hole for additional spool pin Bobbin winder thread guide Thread guide A Thread guide B…

-

Page 5: Standard Accessories And Storage

Standard Accessories and Storage A: Zigzag foot (set in the machine) F: Satin stitch foot C: Overedge foot D: Rolled hem foot G: Blind hem foot R: Automatic buttonhole foot Accessory storage box Accessories are conveniently stored in the storage box. Draw out the storage box by pulling the dent on the box to the left.

-

Page 6: Extension Table And Free Arm Sewing

Extension Table and Free Arm Sewing To detach: Pull the extension table to the left. Free arm sewing: The free arm is useful for stitching sleeves, waistbands, pant legs or any tubular garment, also for darning socks or mending knees, elbows and children’s wear. To attach: Slide the extension table along the free arm, inserting the pin into the hole to attach.

-

Page 7: Getting Ready To Sew Connecting To The Power Supply

GETTING READY TO SEW Connecting to the Power Supply 1. Turn the power switch OFF. 2. Insert the foot control jack into the machine socket. 3. Insert the machine plug into the machine socket. 4. Insert the power supply plug into the outlet. 5.

-

Page 8: Function Keys And Buttons

Function Keys and Buttons • Reverse stitch button While the reverse stitch button is pressed, the machine sews backwards when the pattern 01, 02, 05 or 10 has been selected. The machine will immediately lock the stitches and stop automatically when other stitch has been selected. * In case of 02, the machine will sew in reverse and stop automatically.

-

Page 9: Dropping The Feed Dog

Dropping the Feed Dog The feed dog can be lowered by the drop feed lever for sewing on buttons, manual embroidery etc. Push the drop feed lever to the right to lower the feed dog. Push the lever to the left to raise the feed dog, it will return to the up position when starting the machine.

-

Page 10: Changing The Presser Foot

Changing the Presser Foot WARNING: Turn OFF the power switch before changing the foot. Always use the proper foot for the selected pattern. Wrong foot can cause needle to break. To snap off: Raise the needle and presser foot. Press the black lever on the back of the foot holder and the foot will drop off.

-

Page 11: Raising And Lowering The Presser Foot

Raising and Lowering the Presser Foot The presser foot lifter raises and lowers the presser foot. You can raise it about 0.6 cm (1/4˝) higher than the normal up position for easy removal of the presser foot, or to help you to place thick fabric under the foot. Lowered position Normal up position Highest position…

-

Page 12: Changing The Needle

Changing the Needles WARNING: Turn OFF the power switch before changing the needle. Loosen the needle cramp screw and pull out the needle. Insert a new needle into the needle cramp with the flat side facing back. Push the needle up against the stopper pin and tighten the needle cramp screw firmly.

-

Page 13: Winding The Bobbin

Winding the Bobbin • Removing the bobbin Slide the hook cover release button to the right, and remove the hook cover. Take the bobbin out. Hook cover release button Hook cover Bobbin Setting the spool of thread Place the spool of thread on the spool pin with the thread coming off the spool as shown.

-

Page 14: Inserting The Bobbin

• Inserting the bobbin Place the bobbin in the bobbin holder with the thread running counter-clockwise. End of the thread Bobbin holder Guide the thread into the notch A on the front side of the bobbin holder. Draw the thread to the left sliding it between the tension spring blades.

-

Page 15: Threading The Machine

Threading the Machine • Threading the needle thread Raise the presser foot. Press the needle Up/Down button twice to bring the take- up lever to its highest position then turn off the power switch. Spool of thread Spool holder Presser foot lifter Draw the end of the thread with your left hand and pass it under the thread guide (A) then hook around the thread guide (B) while holding the spool with your…

-

Page 16: Automatic Needle Threader

Automatic Needle Threader Raise the needle to its highest position by pressing the needle Up/Down button twice. Raise the presser foot. Depress the needle threader knob as far as it will go. The hook comes out through the needle eye from behind.

-

Page 17: Drawing Up Bobbin Thread

Drawing Up Bobbin Thread Raise the presser foot and hold the needle thread with your fingers. Needle thread Press the needle Up/Down button twice to raise the needle to its highest position. Pull the needle thread to pick up a loop of the bobbin thread. Needle thread Bobbin thread Needle Up/Down button…

-

Page 18: Selecting The Stitch Pattern

Selecting the Stitch Pattern Press the pattern selection key until pattern number of the desired stitch is shown in the LED display. The key (1) on the left selects patterns #01 to #15. The key (2) second from the left selects patterns #16 to #30.

-

Page 19: Utility Stitches Straight Stitch

UTILITY STITCHES Straight Stitch Machine setting Pattern Foot A: Zigzag foot Thread tension Auto • Starting to sew Raise the presser foot and place the fabric on the machine. Lower the needle into the fabric where you want to start. Lower the presser foot and start sewing.

-

Page 20: Adjusting The Stitch Length

• Adjusting the Stitch Length The LED display shows “ 2.2 ” (default setting) when the plus or minus key is pressed once. Press the plus (+) key to increase stitch length. Press the minus (–) key to decrease stitch length. The stitch length can be varied from 0.0 to 5.0.

-

Page 21: Using The Seam Guide Lines

• Using the seam guide lines The seam guides on the needle plate and hook cover help you to measure seam allowance. NOTE: The number indicates the distance from the center needle position. Number 1 1/2 Distance (cm) 4.0 1.3 Center needle position Edge of the fabric Guide lines…

-

Page 22: Variety Of Straight Stitches

Variety of Straight Stitching Pattern #01 Straight stitch Foot A: Zigzag foot For seaming garments, zipper application and more. Pattern #02 Lock-a-Matic stitch Foot A: Zigzag foot Seaming with auto reverse stitches at the beginning and end Press the reverse stitch button once, the machine will sew the reverse stitches and stop automatically.

-

Page 23: Basic Zigzag Stitch

Basic Zigzag Stitch Machine setting Pattern Foot A: Zigzag foot Thread tension Auto Zigzag stitch is one of the most useful and versatile stitches. It is used for overcasting, mending, appliqué also used as a decorative stitch. NOTE: Use an interface when sewing on the stretch fabric such as knit, jersey or tricot.

-

Page 24: Overcasting

Overcasting • Zigzag stitch Machine setting Pattern Foot C: Overcasting foot Thread tension Auto CAUTION: Do not set the stitch width less than 5 when using the overcasting foot to prevent the needle from hitting the wires on the foot. Place the raw edge of the fabric next to the guide of the foot and start sewing.

-

Page 25: Overedge Stitch

• Overedge stitch Machine setting Pattern Foot C: Overcasting foot Thread tension Auto CAUTION: Do not set the stitch width less than 5 when using the overedge foot to prevent the needle from hitting the wires on the foot. This stitch overcasts and seams the raw edge at the same time, it prevents fraying.

-

Page 26: Sewing On Buttons

Sewing on Buttons Machine setting Pattern Foot F: Satin stitch foot Thread tension Auto Feed dog Dropped Unthread the needle. Adjust the stitch width to match the needle swing with the span of the holes on the button, by pressing the plus (+) or minus (–) key. Rethread the needle and lower the presser foot to hold the button in place.

-

Page 27: Automatic Buttonhole

Automatic Buttonhole Variety of buttonholes #16 Square buttonhole (Sensor buttonhole): Sensor Widely used for medium to heavy weight fabrics. The buttonhole size is automatically determined by placing a button on the back of the automatic buttonhole foot. #17 Square buttonhole (Auto buttonhole): Similar to the sensor buttonhole, but you can set the buttonhole length as desired and memorize it to repeat the same size buttonholes.

-

Page 28: Square Buttonhole

Square buttonhole Machine setting Pattern Foot R: Automatic buttonhole foot Sensor Thread tension Auto NOTES: The size of buttonhole is automatically set by placing the button in the rear of the automatic buttonhole foot R. The button holder of the foot takes a button size up to 2.5 cm (1˝) in diameter.

-

Page 29

Raise the buttonhole foot and draw the needle thread to the left through the hole on the foot. Place the fabric under the foot and lower the needle at the starting point by turning the handwheel. Then lower the foot. Needle thread Bobbin thread Buttonhole mark… -

Page 30

Remove the fabric and place a pin just before the bartack at each end to prevent cutting bartacks. Cut the opening with the seam ripper. Use an awl to open the keyhole buttonhole. Seam ripper After the buttonhole sewing is finished, push the buttonhole lever upward as far as it will go. -

Page 31

Adjusting the buttonhole width and density Adjusting the buttonhole width. Press the plus (+) key to increase buttonhole width. Press the minus (–) key to decrease buttonhole width. The LED display shows “ 5.0 ” (default setting) when the plus or minus key is pressed. The buttonhole width can be varied from 2.5 to 7.0. -

Page 32

Round end/Keyhole buttonhole Machine setting Pattern #18, #19 or #21 LED display Foot R: Automatic buttonhole foot The sewing sequence is the same as sensor buttonhole. Refer to pages 26, 27, 28 for sewing instruction. Starting point End point Adjusting the buttonhole width Press the plus (+) key to increase buttonhole width. -

Page 33

#17 Square buttonhole (Auto buttonhole) Machine setting Pattern Foot R: Automatic buttonhole foot Auto Thread tension Auto Mark the buttonhole position on the fabric. Pull the 1 2 3 button holder all the way out. Draw the needle thread to the left through the hole on the foot. -

Page 34: Corded Buttonhole

Corded Buttonholes Machine setting Pattern Foot R: Automatic buttonhole foot Sensor Thread tension Auto With the buttonhole foot raised, hook the filler cord on the cord spur on the back of the buttonhole foot. Bring the ends toward you under the foot, and hook the filler cord into the forks on the front of the foot to hold them tight.

-

Page 35: Zipper Application

Zipper Application Machine setting Pattern Foot E: Zipper foot Thread tension Auto To attach the zipper foot: (1) Attach the zipper foot with the pin on the right, when sewing on the left side of the zipper. (2) Attach the zipper foot with the pin on the left, when sewing on the right side of the zipper.

-

Page 36

To sew: Fold up the upper seam allowance. Fold back the bottom seam allowance to form a 0.3 cm (1/8˝) fold. Place the zipper teeth next to the fold and pin it in place. Bottom fabric End of the zipper opening Zipper teeth 0.3 cm (1/8˝) Wrong side of the upper fabric… -

Page 37

Detach the foot and attach it with the pin on the left. Backstitch across the end of opening to 1 cm (3/8˝). Turn the fabric 90 degrees and stitch through the garment and zipper tape. Stop the machine 5 cm (2˝) before the foot reaches the slider on the zipper tape. -

Page 38: Rolled Hem

Rolled Hem Machine setting Pattern Foot D: Rolled hem foot Thread tension Auto Trim off the corner of the fabric 0.5 cm (3/16˝) by 0.8 cm (5/16˝) to avoid a bulkiness of the hem at the corner. Fold the fabric edge twice 0.3 cm (1/8˝) wide and 6 cm (2 3/8˝) long.

-

Page 39: Blind Hem Stitch

Blind Hem Stitch Machine setting Pattern #14, #15 Foot G: Blind hem foot Thread tension Auto Fold a hem with the wrong side up forming a 0.4-0.7 cm (3/16-5/16˝) allowance. Wrong side of the fabric 0.4-0.7 cm (3/16-5/16˝) Overcasting (1) On heavy weight fabrics that ravel, the raw edge should be overcast first.

-

Page 40: Darning

Darning Machine setting Pattern Foot R: Automatic buttonhole foot Thread tension Auto 1. Pull the button holder all the way out. 2. Draw the needle thread to the left through the hole on the foot. 3. Lower the needle into the fabric where start to sew. Lower the foot and depress the foot control.

-

Page 41: Sewing Application And Decorative Stitches

SEWING APPLICATION AND DECORATIVE STITCHES Appliqué Machine setting Pattern Foot F: Satin stitch foot Thread tension Auto Foot pressure The patterns #05 and #26 can also be used. Baste or glue appliqué pieces on the fabric. Stitch around the appliqué making sure the needle falls along the outer edge of the appliqué.

-

Page 42: Pin Tucking

Pin Tucking Machine setting Pattern Foot G: Blind hem foot Thread tension Auto Needle drop position Left (0.0) Fold the fabric with wrong side together. Position the fabric so that the folded edge is next to the guide on the presser foot. Lower the foot and Sew guiding the folded edge along the guide.

-

Page 43: Fagoting

Fagoting Machine setting Pattern Foot F: Satin stitch foot Thread tension Auto Fold under 1.5 cm (1/2˝) on each fabric edge and press. Pin the two edges to a piece of paper 0.3 cm (1/8˝) apart. Sew guiding the fabric so the needle catches the folded edge on each side.

-

Page 44: Smocking

Smocking Machine setting Pattern Foot F: Satin stitch foot Thread tension Auto The patterns #51 to #55 can also be used. 1. Set the thread tension dial at 1-3, and stitch length at 3-4, sew straight lines 1 cm (3/8˝) apart across the area to be smocked.

-

Page 45: Pattern Combination

Pattern Combination Machine setting Pattern #42 and #54 Foot F: Satin stitch foot Thread tension Auto You can sew a combination of decorative pattern with the aid of the auto lock button. Auto lock button Example: To sew a combination of two units of the pattern #42 and one unit of #54.

-

Page 46: Cording

Cording 3-strand cording Machine setting Pattern Foot H: Cording foot Thread tension Auto Insert 3 strands of cord under the spring blade on the foot and draw them under the foot to the back. Hold the 3 strands parallel and stitch over the cords evenly.

-

Page 47: Decorative Stretch Stitch

Decorative Stretch Stitches Machine setting Pattern #06-09, #11-13, #24-30 and #43-60 Foot A: Zigzag foot Thread tension Auto As the fabric moves back and forth in the stretch stitch sewing, guide the fabric carefully to keep the seams straight, NOTE: If the patterns are uneven when sewing with a particular fabric, adjust them with the stretch stitch balancing dial.

-

Page 48: Care Of Your Machine

CARE OF YOUR MACHINE Replacing the Light Bulb WARNINGS: Turn OFF the power before replacing the light bulb. The bulb could be HOT, wait until it has cooled down before touching it. To remove: Remove the cap and setscrew on the faceplate. Remove the faceplate.

-

Page 49: Cleaning Hook Race And Feed Dog

Cleaning Hook Race and Feed Dog WARNING: Raise the presser foot and needle, and then unplug the machine. DO NOT dismantle the machine other than as explained in this section. Remove the needle and presser foot. Remove the two setscrews and unhook the hook to remove the needle plate.

-

Page 50: Problems And Warning Signals

PROBLEMS AND WARNING SIGNALS When beep sounds and the LED display shows warning signal, follow the guidance below to deal with. Visual signal Cause and Action The foot control has been disconnected while sewing. Turn OFF the power and connect the foot control. A button is pressed when the machine halts due to the overload.

-

Page 51: Troubleshooting

TROUBLESHOOTING Cause Reference Condition The needle thread The needle thread is not threaded properly. Page 13 breaks. The needle thread tension is too tight. Page 9 The needle is bent or blunt. Page 10 The needle is incorrectly inserted. Page 10 The needle thread and the bobbin thread are not set under the presser foot when start sewing.

-

Page 52

Printed in Taiwan 845-800-001(E)

-

Инструкции по эксплуатации

1

Janome QC 2325 (6260QC) инструкция по эксплуатации

(52 страницы)

- Языки:Русский

-

Тип:

PDF -

Размер:

4.72 MB -

Описание:

Швейная машина

Просмотр

На NoDevice можно скачать инструкцию по эксплуатации для Janome QC 2325 (6260QC). Руководство пользователя необходимо для ознакомления с правилами установки и эксплуатации Janome QC 2325 (6260QC). Инструкции по использованию помогут правильно настроить Janome QC 2325 (6260QC), исправить ошибки и выявить неполадки.

Перед Вами Инструкция — 6260 QC. Вы можете ознакомиться и скачать данное руководство по эксплуатации бесплатно.

Инструкция по применению на русском языке, предложенная производителем, позволяет

правильно использовать Вашу бытовую технику и электронику.

-

1

-

2

-

3

-

4

-

5

-

6

-

7

-

8

-

9

-

10

-

11

-

12

-

13

- Manuals

- Brands

- Janome Manuals

- Sewing Machine

- 6260QC —

- Service manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

SERVICE MANUAL

MODEL 6260QC

Related Manuals for Janome 6260QC

Summary of Contents for Janome 6260QC

-

Page 1

SERVICE MANUAL MODEL 6260QC… -

Page 2: Table Of Contents

Table Of Contents What To Do When …………………… 1-3 Service Access Face Cover ……………………..4 Top Cover ……………………..5 Belt Cover ……………………..6 Base ……………………….7 Front Cover ……………………..8 Rear Cover ……………………..9 Mechanical Adjustment Needle Thread Tension ………………….10 Presser Bar Height And Alignment ………………

-

Page 3: What To Do When

What to Do When Condition Cause How to fix Reference 1. Skipped 1. Needle is not inserted Insert the needle properly. stitches properly. 2. Needle is bent or worn. Change the needle. 3. Incorrectly threaded. Rethread. 4. Needle or thread is Use the recommended inappropriate for fabric sewing needle and thread.

-

Page 4

Condition Cause How to fix Reference 3. Breaking 1. Initial sewing speed is too Start with medium speed. upper fast. thread 2. Thread path is incorrect. Use the proper thread path. 3. Needle is bent or dull. Replace with a new needle. 4. -

Page 5

Condition Cause How to fix Reference 6. Noisy 1. Backlash between shuttle See mechanical adjustment p.18 operation hook gear and lower shaft “backlash (lower shaft gear)”. gear is too great. 2. Lower shaft gear is loose. Eliminate the looseness. 3. Inappropriate belt tension. See mechanical adjustment p.28 “motor belt tension”. -

Page 6: Service Access

Service access (1) Face cover Face cover Setscrew (A) Setscrew (B) Setscrew (C) To remove: 1. Remove the cap (A). 2. Remove the setscrews (B) and (C). 3. Lift up the top cover and unfasten the tab of the top cover from the face cover. Remove the face cover To attach: 4.

-

Page 7: Top Cover

Service Access (2) Top cover Top cover Handle Setscrew (A) (2 pcs) To remove: 1. Remove the face cover (see page 4). 2. Remove the 2 setscrews (A) and remove the handle and top cover. To attach: 3. Follow the above procedure in reverse.

-

Page 8: Belt Cover

Service Access (3) Belt cover Setscrew (A) Setscrew (B) Belt cover To remove: 1. Remove the face cover and top cover (see pages 4 and 5). 2. Remove the cap. 3. Remove the setscrews (A), (B) and remove the belt cover. To attach: 4.

-

Page 9: Base

Service Access (4) Base Setscrew (B) Setscrew (C) Setscrew (A) Setscrew (D) Setscrew (E) Setscrew (F) Base To remove: 1. Remove the setscrews (A) to (F). Remove the base. To attach: 2. Follow the above procedure in reverse.

-

Page 10: Front Cover

Service Access (5) Front cover Setscrew (B) Setscrew (A) Front cover Setscrew (E) Setscrew (D) Setscrew (F) To remove: 1. Remove the face cover, top cover and belt cover. (See pages 4-6.) 2. Remove the setscrews (A) to (E) and loosen the setscrew (F). To attach: 3.

-

Page 11: Rear Cover

Service Access (6) Rear cover Rear cover Setscrew (D) Setscrew (A) Setscrew (B) Setscrew (C) To remove: 1. Remove the face cover, top cover and belt cover. (See pages 4-6.) 2. Remove the setscrews (A), (B), (C), (D) and remove the rear cover. To attach: 3.

-

Page 12: Mechanical Adjustment

Mechanical Adjustment Needle Thread Tension The standard tension should be 75 to 90 grams when the tension dial is set at “A” (Auto), measured with a #50 white polyester thread being pulled at approximately 50 mm/sec. If the tension is outside the standard range, adjust it as follows. Adjustment procedure: 1.

-

Page 13: Presser Bar Height And Alignment

Mechanical Adjustment Presser Bar Height and Alignment When the presser foot is raised, the clearance between the presser foot and the needle plate should be 6.0 mm. When the presser foot is lowered, the edge of the foot and the feed dog window on the needle plate should be parallel.

-

Page 14: Needle Drop Position

Mechanical adjustment Needle Drop Position Set the stitch pattern to “ “. The standard needle drop position should be at the center of the needle plate hole. Select zigzag stitch “ “ and set the stitch width at “7.0”. The clearance between the needle and the edge of the needle hole on the needle plate should be at least 0.2 mm on either side.

-

Page 15: Stretch Stitch Feed Balance

Mechanical adjustment Stretch Stitch Feed Balance If the stretch stitch patterns are deformed when sewing the patterns with the feed balancing dial is set at the standard position “ “, correct it as follows: Adjustment procedure: 1. Select the straight stretch stitch “ “.

-

Page 16: Feed Dog Height

Mechanical adjustment Feed Dog Height The height of the deed dog should be 0.8-0.9 mm above the needle plate. Adjustment procedure: 1. Select the straight stitch “ “. 2. Set the foot pressure dial at “3” and lower the foot. 3.

-

Page 17: Needle Bar Height

Mechanical adjustment Needle Bar Height When the tip of the hook meets the left side of the needle in ascending travel of the needle from its left and lowest position, the distance between the top of the needle eye and the tip of the hook should be in the range of 1.6 to 2.0 mm.

-

Page 18: Needle Timing To Hook

Mechanical adjustment Needle Timing to Hook When the hook point meets with the right side of the needle, the height of needle point from its lowest and left most position should be 3.25-3.55 mm. Adjustment procedure: 1. Select the straight stitch “ “…

-

Page 19: Clearance Between Needle And Hook

Mechanical adjustment Clearance between Needle and Hook The clearance between the needle and hook should be -0.10 to +0.05 mm. Adjustment procedure: 1. Select the zigzag stitch “ “ and set the stitch width at “7.0”. 2. Remove the needle plate (A) and bobbin holder (B). 3.

-

Page 20: Backlash Between Hook Gear And Lower Shaft Gear

Mechanical adjustment Backlash between Hook Gear and Lower Shaft Gear The rotary play of the hook point should be 0.8 mm or less when it is in between the span of the feed dog teeth. And, the gears should turn smoothly. Adjustment procedure: 1.

-

Page 21: Replacement And Adjustment Of Needle Threader Plate

Mechanical adjustment Replacement and Adjustment of Needle Threader Plate To replace: 1. Pry out the threader plate holder with a screwdriver while pushing up and holding the threader knob (See fig. 1.). 2. Align the groove on the new threader plate holder with the pin (B) on the threader shaft. Push the threader plate holder (C) up until it snaps in place.

-

Page 22: Self-Diagnostic Test

Self-diagnostic Test Preparation: 1. Turn off the power switch. 2. Move the bobbin winder spindle to the left. 3. Raise the feed dog. 4. Set the speed control lever to the left. 5. Remove the presser foot and raise the presser foot lifter. 6.

-

Page 23

Step and items Procedure Correct Condition Defective Condition to check Turn on the power switch while Beep sounds when the Does not enter self-diagnostic simultaneously pressing the button is pressed. mode. 7-segment LED needle up/down button and the LED displays “8.8.” And it LED does not blink on or off. -

Page 24

Step and items Procedure Correct Condition Defective Condition to check Press the needle up/down button, When the needle is at the LED display is different from that highest position, LED displays shown to the left. LED displays “07” for one second. Upper shaft “H.L”. -

Page 25: Replacing A-Board And Fuse

Replacing A-Board and Fuse To Replace the A-board: 1. Remove the rear cover (see page 9). 2. Remove the 3 setscrews (A) and unplug the connectors from the A-board. 3. Remove the 6 setscrews (B) and 2 setscrews (C) then remove the board supporter and function button frame.

-

Page 26: Connector Diagram

Connector Diagram Machine socket connector (primary) Transformer connector (primary) DC motor connector Transformer connector (secondary) BH sensor connector Lamp connector F-board connector Slide volume Bobbin winder switch connector Upper shaft sensor connector Machine socket connector (secondary) Zigzag motor connector Feed motor connector Slide volume F-board connector Bobbin winder switch connector…

-

Page 27: Replacing Machine Socket

Replacing Machine Socket To remove: 1. Remove the front cover (see page 8). 2. Remove the board supporter (see page 23) and unplug the machine socket connectors (both primary and secondary). 3. Remove the 2 setscrews (A) and remove the machine socket. To attach: 4.

-

Page 28: Replacing Transformer

Replacing Transformer o remove: 1. Remove the front cover (see page 8). 2. Remove the board suppoerter (see page 23) and unplug the transformer connectors (both primary and secondary). 3. Remove the 2 setscrews (A) and remove the transformer. To attach: 4.

-

Page 29: Replacement And Adjustment Of Upper Shaft Sensor

Replacement and Adjustment of Upper Shaft Sensor During zigzag sewing, lateral movement of the needle should take place 7.4 to 9.8 mm above the needle plate. Adjustment procedure: 1. Remove the top cover (see page 15). 2. Select the zigzag stitch “ “…

-

Page 30: Replacing Dc Motor

Replacing DC Motor To remove: 1. Remove the front cover (See page 8.). 2. Remove the board supporter (see page 23) and unplug the DC motor connector. 3. Remove the 2 setscrews (A) and replace the DC motor. To attach: 4.

-

Page 31: Replacing Slide Volume And F-Board

Replacing Slide Volume and F-Board Replacing the slide volume control To remove: 1. Remove the front cover (see page 8). Unplug the slide volume connector. 2. Remove the 6 CS rings and replace the slide volume. Replacing the F-board To remove: 1.

-

Page 32: Replacing Zigzag Motor

Replacing Zigzag Motor To remove: 1. Remove the front cover (see page 8). 2. Unplug the zigzag motor connector. 3. Remove the 2 setscrews (A) and replace zigzag motor. To attach: 4. Follow the above procedure in reverse. Note: After replacement, check the needle drop position and adjust it if necessary (see page 13). Setscrew (A) Zigzag motor Setscrew (A)

-

Page 33: Replacing Feed Motor

Replacing Feed Motor To remove: 1. Remove the front cover (see page 8). 2. Unplug the feed motor connector. 3. Remove the 2 setscrews (A) and replace feed motor. To attach: 4. Follow the above procedure in reverse. Setscrew (A) Feed motor Setscrew (A)

-

Page 34: Adjusting Bobbin Winder Switch

Adjusting Bobbin Winder Switch The LED display shows “ ” when the bobbin winder spindle is set to the left and “ “ when the bobbin winder spindle is set to the right. Adjustment procedure: 1. Remove the top cover (see page 8). 2.

-

Page 35: Adjusting Buttonhole Lever Position

Adjusting Buttonhole Lever Position To adjust the buttonhole lever guide: 1. Enter the buttonhole sensor adjusting mode. (See below. The LED should display “H” or “L”.) 2. Remove the face cover (see page 4) and loosen setscrew (A). 3. Move the buttonhole lever guide so the LED displays “L” when the buttonhole lever is lowered. Tighten setscrew (A).