1

103

36

8_

EN

G.xm

l

2

003

-06-

0

3

Subject to reasonable modifications due to technical advances.

Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

KFD2-SR2-Ex2.W

Isolated switch amplifiers

Input I EEx ia IIC

Input II EEx ia IIC

green

red

red

Output

I

Output

II

Power

Rail

LB/SC

collective

error message

Switch S3 in position I

Switch S3 in position I

Switch S3 in position I

Switch S3 in position II

Power

supply

only

KFD2-SR2-Ex2.W

LB

SC

LB

SC

Saf

e area

Hazar

dous area,

zone 0,

zone 1

yellow

yellow

without

LB, SC

without SC

1+

3-

1+

3-

1+

3-

2+

3-

2+

3-

1+

S1

S2

S3

S3

II

I

II

I

1

10 k

Ω

10 k

Ω

14 15

400

Ω ≤ R ≤ 2 kΩ

4+

6-

4+

6-

4+

6-

5+

6-

5+

6-

4+

10 k

Ω

10 k

Ω

400

Ω ≤ R ≤ 2 kΩ

7

8

9

10 11 12

+

—

+

—

&

&

Composition

24 V DC

• 2-channel

• Control circuit EEx ia IIC

• Reversible mode of operation

• 1 signal output with 1 changeover

contact per channel

• EMC acc. to NAMUR NE 21

• LB/SC monitoring

• LB/SC collective error message via

Power Rail

• Usable up to SIL 2 acc. to IEC 61508

The transformer isolated barrier

transfers digital signals from the

hazardous area. Sensors per

DIN EN 60947-5-6 (NAMUR) and

mechanical contacts may be used as

alarms. Control circuits are monitored

for lead breakage (LB) and short circuit

(SC). The external faults are indicated

according to NAMUR NE44 by a red

flashing LED. For type KFD2-SR2-

Ex2.W, an LB/SC collective error

message is in addition transferred

through the Power Rail to the power

feed module. The intrinsically safe

inputs per DIN EN 50020 are safely

isolated from the output and the power

supply. Relay outputs are galvanically

separated from the mains power in

accordance with IEC 61140. Relay

outputs are galvanically separated from

each other in accordance with

IEC 61140.

Function

Output: relay

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Functional Safety

Switch Amplifier

KFD2-SR2-Ex*.W(.LB)

Manual

2

ISO9001

Related Manuals for Pepperl+Fuchs KFD2-SR2-Ex Series

Summary of Contents for Pepperl+Fuchs KFD2-SR2-Ex Series

-

Page 1

Functional Safety Switch Amplifier KFD2-SR2-Ex*.W(.LB) Manual ISO9001… -

Page 2

Phone: +49 621 776 — 0 E-mail: info@de.pepperl-fuchs.com North American Headquarters Pepperl+Fuchs Inc. 1600 Enterprise Parkway Twinsburg, Ohio 44087 Phone: +1 330 425-3555 E-mail: sales@us.pepperl-fuchs.com Asia Headquarters Pepperl+Fuchs Pte. Ltd. P+F Building 18 Ayer Rajah Crescent Singapore 139942 Phone: +65 6779-9091 E-mail: sales@sg.pepperl-fuchs.com https://www.pepperl-fuchs.com… -

Page 3: Table Of Contents

Functional Safety KFD2-SR2-Ex*.W(.LB) Contents Introduction …………5 Content of this Document .

-

Page 4

Functional Safety KFD2-SR2-Ex*.W(.LB) Contents… -

Page 5: Introduction

Additionally, the following parts may belong to the documentation, if applicable: • EU-type examination certificate • EU declaration of conformity • Attestation of conformity • Certificates • Control drawings • FMEDA report • Assessment report • Additional documents For more information about Pepperl+Fuchs products with functional safety, see www.pepperl-fuchs.com/sil.

-

Page 6: Safety Information

Functional Safety KFD2-SR2-Ex*.W(.LB) Introduction Safety Information Target Group, Personnel Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator. Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have read and understood the instruction manual and the further documentation.

-

Page 7: Symbols Used

Functional Safety KFD2-SR2-Ex*.W(.LB) Introduction Symbols Used This document contains symbols for the identification of warning messages and of informative messages. Warning Messages You will find warning messages, whenever dangers may arise from your actions. It is mandatory that you observe these warning messages for your personal safety and in order to avoid property damage.

-

Page 8: Product Description

Product Description Product Description Validity This manual is only valid for devices with a part number greater than #203350. Contact your Pepperl+Fuchs representative for information about older devices. Function KFD2-SR2-Ex1.W This isolated barrier is used for intrinsic safety applications. The device transfers digital signals from NAMUR sensors or dry contacts from the hazardous area to the non-hazardous area.

-

Page 9: Interfaces

• Non-safety relevant interfaces: fault indication output Note For corresponding connections see datasheet. Marking Pepperl+Fuchs Group Lilienthalstraße 200, 68307 Mannheim, Germany Internet: www.pepperl-fuchs.com KFD2-SR2-Ex1.W, KFD2-SR2-Ex2.W, KFD2-SR2-Ex1.W.LB Up to SIL 2 The *-marked letters of the type code are placeholders for versions of the device.

-

Page 10: Planning

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning Planning System Structure 3.1.1 Low Demand Mode of Operation If there are two control loops, one for the standard operation and another one for the functional safety, then usually the demand rate for the safety loop is assumed to be less than once per year.

-

Page 11: Assumptions

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning Assumptions The following assumptions have been made during the FMEDA: • Failure rates are constant, wear is not considered. • Failure rate based on the Siemens standard SN 29500. • The safety-related device is considered to be of type A device with a hardware fault tolerance of 0.

-

Page 12: Safety Function And Safe State

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning Safety Function and Safe State Safe State In the safe state of the safety function the output is de-energized. Safety Function for 1-channel Devices KFD2-SR2-Ex1.W S1 position I (normal The safe state is reached if the NAMUR sensor input operation) is in the off state.

-

Page 13

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning LB/SC Diagnosis If the line fault detection is active (mandatory, see datasheet), the input loops of all device versions are supervised. The line fault detection is activated if switch S3 is in position I. The related safety function is defined as the outputs are de-energized (safe state), if there is a line fault detected. -

Page 14: Characteristic Safety Values

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning Characteristic Safety Values Parameters Characteristic values Assessment type and Full assessment documentation Device type Mode of operation Low demand mode or high demand mode Safety function Output is de-energized 113 FIT 0 FIT 37.8 FIT …

-

Page 15: Useful Lifetime

Functional Safety KFD2-SR2-Ex*.W(.LB) Planning Useful Lifetime Although a constant failure rate is assumed by the probabilistic estimation this only applies provided that the useful lifetime of components is not exceeded. Beyond this useful lifetime, the result of the probabilistic estimation is meaningless as the probability of failure significantly increases with time.

-

Page 16: Mounting And Installation

Functional Safety KFD2-SR2-Ex*.W(.LB) Mounting and Installation Mounting and Installation Mounting and Installing the Device Observe the safety instructions in the instruction manual. Observe the information in the manual. Observe the requirements for the safety loop. Connect the device only to devices that are suitable for this safety application. Check the safety function to ensure the expected output behavior.

-

Page 17: Operation

Functional Safety KFD2-SR2-Ex*.W(.LB) Operation Operation Danger! Danger to life from missing safety function If the safety loop is put out of service, the safety function is no longer guaranteed. • Do not deactivate the device. • Do not bypass the safety function. •…

-

Page 18

Functional Safety KFD2-SR2-Ex*.W(.LB) Operation 5.1.1 Procedure for Manual Proof Test Equipment required: • Digital multimeter with an accuracy of 0.1 % Use for the proof test of the intrinsic safety side of the device a special digital multimeter for intrinsically safe circuits. If intrinsically safe circuits are operated with non-intrinsically safe circuits, they must no longer be used as intrinsically safe circuits. -

Page 19

Functional Safety KFD2-SR2-Ex*.W(.LB) Operation Multimeter KFD2-SR2-Ex1.W (mA) 240 :/2.5 W 24 V DC Multimeter (mA) Multimeter (mA) 24 V DC Zone 0, 1, 2 Zone 2 Power I supply Supply Div. 2 Div. 1, 2 supply Figure 5.1 Proof test set-up for KFD2-SR2-Ex1.W Multimeter KFD2-SR2-Ex1.W.LB (mA) -

Page 20

Functional Safety KFD2-SR2-Ex*.W(.LB) Operation Multimeter KFD2-SR2-Ex2.W (mA) 240 :/2.5 W 24 V DC Multimeter (mA) Multimeter (mA) 240 :/2.5 W 24 V DC Multimeter (mA) Multimeter (mA) 24 V DC Zone 0, 1, 2 Zone 2 Power I supply Supply Div. -

Page 21: Maintenance And Repair

Functional Safety KFD2-SR2-Ex*.W(.LB) Maintenance and Repair Maintenance and Repair Danger! Danger to life from missing safety function Changes to the device or a defect of the device can lead to device malfunction. The function of the device and the safety function is no longer guaranteed. Do not repair, modify, or manipulate the device.

-

Page 22: List Of Abbreviations

Functional Safety KFD2-SR2-Ex*.W(.LB) List of Abbreviations List of Abbreviations Diagnostic Coverage of dangerous faults Failure In Time in 10 Failure Mode, Effects, and Diagnostics Analysis FMEDA Probability of safe failure Probability of dangerous detected failure Probability of dangerous undetected failure …

-

Page 23

Functional Safety KFD2-SR2-Ex*.W(.LB) Notes… -

Page 24

Pepperl+Fuchs Quality Download our latest policy here: www.pepperl-fuchs.com/quality www.pepperl-fuchs.com © Pepperl+Fuchs · Subject to modifications Printed in Germany / DOCT-6656A…

|

Isolated switch amplifiers |

KFD2-SR2-Ex2.W |

|

Output: relay |

|

24 V DC

•2-channel

•Control circuit EEx ia IIC

•Reversible mode of operation

•1 signal output with 1 changeover contact per channel

•EMC acc. to NAMUR NE 21

•LB/SC monitoring

•LB/SC collective error message via Power Rail

•Usable up to SIL 2 acc. to IEC 61508

Function

The transformer isolated barrier transfers digital signals from the hazardous area. Sensors per DIN EN 60947-5-6 (NAMUR) and

mechanical contacts may be used as alarms. Control circuits are monitored for lead breakage (LB) and short circuit (SC). The external faults are indicated according to NAMUR NE44 by a red flashing LED. For type KFD2-SR2- Ex2.W, an LB/SC collective error message is in addition transferred through the Power Rail to the power feed module. The intrinsically safe inputs per DIN EN 50020 are safely isolated from the output and the power supply. Relay outputs are galvanically separated from the mains power in accordance with IEC 61140. Relay outputs are galvanically separated from each other in accordance with

IEC 61140.

|

Input I EEx ia IIC |

Input II EEx ia IIC |

||||||

|

1+ |

3- |

4+ |

6- |

||||

|

400 Ω ≤ R ≤ 2 kΩ |

400 Ω ≤ R ≤ 2 kΩ |

||||||

|

10 kΩ |

3- |

4+ |

10 kΩ |

6- |

|||

|

1+ |

|||||||

|

without SC |

10 kΩ |

5+ |

10 kΩ |

||||

|

2+ |

3- |

6- |

|||||

|

without |

|||||||

|

LB, SC 1+ |

3- |

4+ |

6- |

||||

|

1+ 2+ |

3- |

4+ 5+ |

6- |

||||

|

LB |

LB |

||||||

|

SC |

SC |

||||||

|

I |

II |

S3 |

I |

II |

S3 |

||

|

red |

|||||||

|

S1 |

S2 |

red |

|||||

|

& |

& |

||||||

|

green |

|||||||

|

yellow |

yellow |

||||||

|

7 |

8 |

9 |

10 11 12 |

||||

|

Output I |

Output II |

Composition

Subject to reasonable modifications due to technical advances.

Switch S3 in position I

Switch S3 in position I

Switch S3 in position I

zone Hazardouszone0, area,1

Switch S3 in position II

|

area |

||

|

+ — |

1 |

Safe |

+—

14 15

Power Power LB/SC supply Rail collective

error message

only KFD2-SR2-Ex2.W

103368_ENG.xml 2003-06-03

Copyright Pepperl+Fuchs, Printed in Germany

|

1 |

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com |

You can only view or download manuals with

Sign Up and get 5 for free

Upload your files to the site. You get 1 for each file you add

Get 1 for every time someone downloads your manual

Buy as many as you need

1

103368_GER.xml 2003-06-03

umutbare Änderungen aufgrund technischer Verbesserungen vorbehalten. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs GmbH • 68301 Mannheim • Telefon +49 621 776-2222 • Telefax +49 621 776 272222 • Internet http://www.pepperl-fuchs.com

KFD2-SR2-Ex2.W

Trennschaltverstärker

Eingang I EEx ia IIC Eingang II EEx ia IIC

grün

rot rot

Ausgang I

Ausgang II

Power

Rail

LB-/LK-

Sammel-

meldung

Schalter S3 in Pos. I

Schalter S3 in Pos. I

Schalter S3 in Pos. I

Schalter S3 in Pos. II

Netz

nur bei

KFD2-SR2-Ex2.W

LB

LK

LB

LK

Nicht-Ex-Bereich

Ex-Bereich, Zone 0, Zone 1

gelb gelb

ohne

LB, LK

ohne LK

1+ 3-

1+ 3-

1+ 3-

2+

3-2+

3-1+

S1 S2

S3 S3

II

I

II

I

1

10 kΩ

10 kΩ

14 15

400 Ω ≤ R ≤ 2 kΩ

4+ 6-

4+ 6-

4+ 6-

5+

6-5+

6-4+

10 kΩ

10 kΩ

400 Ω ≤ R ≤ 2 kΩ

789 101112

+-

+-

&&

Aufbau

24 V DC

• 2-kanalig

• Steuerstromkreis EEx ia IIC

• Umkehrbare Wirkungsrichtung

• 1 Signalausgang mit 1 Wechsler je

Kanal

• EMV gemäß NAMUR NE 21

• LB-/LK-Überwachung

• LB-/LK-Sammelmeldung über Power

Rail

• Bis SIL 2 gemäß IEC 61508

einsetzbar

Der Trennschaltverstärker überträgt di-

gitale Signale aus dem explosionsge-

fährdeten Bereich. Signalgeber können

Sensoren nach DIN EN 60947-5-6

(NAMUR) oder mechanische Kontakte

sein. Die Steuerstromkreise werden auf

Leitungsunterbrechung (LB) und Lei-

tungskurzschluss (LK) überwacht. Die

Anzeige externer Störungen erfolgt ge-

mäß NAMUR NE44 durch eine rot blin-

kende LED. Beim Typ KFD2-SR2-

Ex2.W wird zusätzlich eine LB-/LK-

Sammelmeldung über das Power Rail

auf den Einspeisebaustein übertra-

gen. Die eigensicheren Eingänge sind

gemäß DIN EN 50020 sicher von Aus-

gang und Netz getrennt. Die Relaisaus-

gänge sind gemäß IEC 61140 sicher

vom Netz getrennt. Die Relaisausgän-

ge sind untereinander gemäß

IEC 61140 galvanisch getrennt.

Funktion

Ausgang: Relais

Instruction Manual

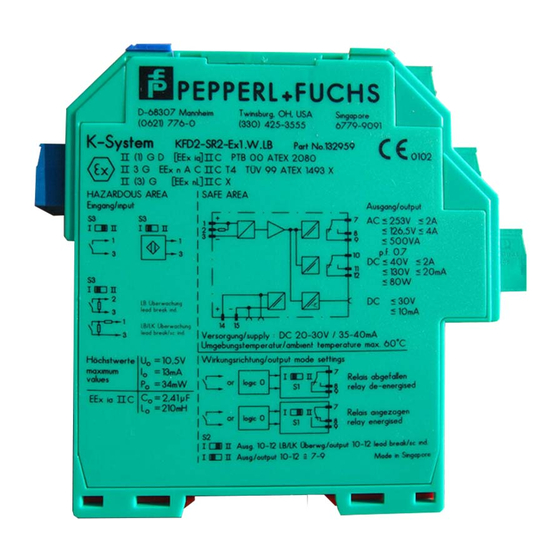

1. Marking

Switch amplifier

KFD2-SR2-Ex1.W, KFD2-SR2-Ex1.W.LB, KFD2-SR2-Ex2.W

ATEX certificate: PTB 00 ATEX 2080

ATEX marking:

1 II (1)G [Ex ia Ga] IIC

1 II (1)D [Ex ia Da] IIIC

1 I (M1) [Ex ia Ma] I

ATEX certificate: TÜV 99 ATEX 1493 X

ATEX marking: : 1 II 3G Ex ec nC IIC T4 Gc

IECEx certificate: IECEx PTB 11.0034 , IECEx TUN 19.0013X

IECEx marking:

[Ex ia Ga] IIC

[Ex ia Da] IIIC

[Ex ia Ma] I

Ex ec nC IIC T4 Gc

North America Certifcates: E106378 (UL)

Class I, Division 2, Groups A-D, T4

Class I, Zone 2, Group IIC T4

Associated apparatus with intrinsically safe circuits for:

Class I, Division 1, Groups A-D; Class II, Division 1, Groups E-G;

Class III

[AEx ia Ga] IIC, [AEx ia Da] IIIC, [Ex ia Ga] IIC, [Ex ia Da] IIIC

USA certificates: FM19US0207X

Class I, Division 2, Groups A-D, T4

Associated apparatus with intrinsically safe circuits for:

Class I, Division 1, Groups A-D; Class II, Division 1, Groups E-G;

Class III

Pepperl+Fuchs Group

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

2. Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

Prior to using the product make yourself familiar with it. Read the

instruction manual carefully.

3. Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location.

For mining applications, observe laws, standards, and directives

applicable to the operating location.

The corresponding datasheets, manuals, declarations of conformity, EU-

type examination certificates, certificates, and control drawings if

applicable supplement this document. You can find this information under

www.pepperl-fuchs.com.

If you use the device in safety-related applications, observe the

requirements for functional safety. You can find these requirements in the

functional safety documentation under www.pepperl-fuchs.com.

4. Intended Use

The device is only approved for appropriate and intended use. Ignoring

these instructions will void any warranty and absolve the manufacturer

from any liability.

The device is used in control and instrumentation technology

(C&I technology) for the galvanic isolation of signals such as 20 mA and

10 V standard signals or alternatively for adapting or standardizing signals.

The device has intrinsically safe circuits that are used for operating

intrinsically safe field devices in hazardous areas.

The device transfers digital signals from NAMUR sensors or dry contacts

from the hazardous area to the non-hazardous area.

Use the device only within the specified ambient and operating conditions.

Only use the device stationary.

The device is an associated apparatus according to IEC/EN 60079-11.

The device may be installed in the non-hazardous area.

The device is an electrical apparatus for hazardous areas of Zone 2.

If you use the device in safety-related applications, observe the

information for safety function and safe state.

5. Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

6. Mounting and Installation

Do not mount a damaged or polluted device.

The device is designed for mounting on a 35 mm DIN mounting rail

according to EN 60715.

Mount the device in a way that the device is protected against mechanical

hazard. Mount the device in a surrounding enclosure for example.

The device fulfills a degree of protection IP20 according to IEC/EN 60529.

The device must be installed and operated only in a controlled

environment that ensures a pollution degree 2 (or better) according to

IEC/EN 60664-1.

If used in areas with higher pollution degree, the device needs to be

protected accordingly.

Do not mount the device in the dust hazardous area.

The device must be installed and operated only in an environment of

overvoltage category II (or better) according to IEC/EN 60664-1.

Supply the device with a power supply that meets the requirements for

safety extra-low voltage (SELV) or protective extra-low voltage (PELV).

If you are using the Power Rail, supply the Power Rail only via the

corresponding power feed modules or power supplies. Do not supply the

Power Rail via isolators.

Observe the installation instructions according to IEC/EN 60079-14.

If you install the device in safety-related applications, observe the

requirements for functional safety.

Requirements for Cables and Connection Lines

Observe the permissible core cross section of the conductor.

When using stranded conductors, crimp wire end ferrules on the

conductor ends.

Use only one conductor per terminal.

When installing the conductors the insulation must reach up to the

terminal.

Use conductors with a rated temperature suitable for the application.

If you use the device in an ambient temperature above 60 °C, use

conductors rated for a temperature of at least 80 °C.

Observe the tightening torque of the terminal screws.

Requirements for Usage as Associated Apparatus

If circuits with type of protection Ex i are operated with non-intrinsically

safe circuits, they must no longer be used as circuits with type of

protection Ex i.

Keep the separation distances between all non-intrinsically safe circuits

and intrinsically safe circuits according to IEC/EN 60079-14.

Observe the compliance of the separation distances between two

adjacent intrinsically safe circuits according to IEC/EN 60079-14.

Observe the respective peak values of the field device and the associated

apparatus with regard to explosion protection when connecting intrinsically

safe field devices with intrinsically safe circuits of associated apparatus

(verification of intrinsic safety). Also observe IEC/EN 60079-14 and

IEC/EN 60079-25.

Requirements for Equipment Protection Level Gc

The device must be installed and operated only in surrounding enclosures

that

l

comply with the requirements for surrounding enclosures according to

IEC/EN 60079-0,

l

are rated with the degree of protection IP54 according to

IEC/EN 60529.

Ensure that the surrounding enclosure can only be opened with a tool.

Connection or disconnection of energized non-intrinsically safe circuits is

only permitted in the absence of a potentially explosive atmosphere.

7. Operation, Maintenance, Repair

If you operate the device in safety-related applications, observe the

requirements for functional safety. For the proof test, plan appropriate

intervals for the operation in low demand mode.

Do not use a damaged or polluted device.

Do not repair, modify, or manipulate the device.

If there is a defect, always replace the device with an original device.

Requirements for Equipment Protection Level Gc

Connection or disconnection of energized non-intrinsically safe circuits is

only permitted in the absence of a potentially explosive atmosphere.

Only use operating elements in the absence of a potentially explosive

atmosphere.

8. Delivery, Transport, Disposal

Check the packaging and contents for damage.

Check if you have received every item and if the items received are the

ones you ordered.

DOCT-6724 / 2020-03 1 / 2