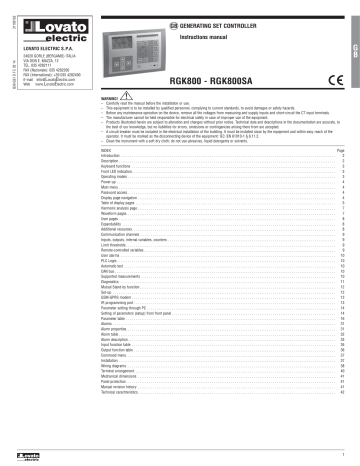

Контроллер RGK800 разработан на основе самых современных технологий, необходимых для управления генераторными установками как с автоматическим контролем отказа сети, так и без него. RGK800 выполнен в чрезвычайно компактном корпусе, в котором современный дизайн передней панели совмещается с практичностью установки, а ЖК-дисплей делает интерфейс пользователя ясным и интуитивно понятным.

Основные характеристики:

RGK 800 автоматически управляет электроагрегатом для переключения Сеть/Генератор (RGK 800) или для дистанционного включения RGK 800 SA.

— Графический дисплей LCD 128×80 пикс., с подсветкой, 4 уровня серого цвета.

— 13 кнопок для функций и настроек

— Встроенный зуммер(отключаемый)

— 10 светодиодов для отражения режима работы и состояний

— Текст показаний, установок и сообщений на 5 языках

— Шина расширения с 3 гнездами для модулей расширения серии EXP:

• интерфейс связи RS232, RS485, USB,Ethernet,Profibus, GSM/GPRS

• дополнительные цифровые I/O,статические или релейные выходы

• аналоговые I/O, mA, mV, температура PT100

— Расширенные программируемые функции I/O

— Управление 4 альтернативными функциями, выбор которых производится с помощью переключателя

— PLC (Программируемый Логический Контролер) с пороговыми величинами, счетчиками, аварийными сигнализациями и состояниями

— Аварийная сигнализация полностью программируемая пользователем

— Высокая точность измерений TRMS

— Вход измерения напряжений сети трехфазное + нейтраль

— Вход измерения напряжений генератора трехфазное + нейтраль

— Вход измерения напряжений токов нагрузки трехфазное + нейтраль или земля

— Питание от универсальной батареи 12-24 VDC

— Внешний оптический вход на лицевой панели для программирования: гальванически изолирован, высокоскоростной, водонепроницаемый, совместимый с USB и WiFi

— 4 аналоговых входа для резистивных датчиков:

• давление масла

• температура охлаждающей жидкости

• уровень топлива

• программируемый

— 9 цифровых входов:

• 8 программируемых, отрицательных

• 1 для кнопки аварийной сигнализации, положительный

— 10 цифровых выходов:

• 6 защищенных позитивных статических выходов

• 3 реле

• 1 статический импульсивный выход

— Вход pick-up и W для считывания скорости двигателя

— Интерфейс коммуникаций CAN bus-J1939 для контроля ECU двигателя

— Указатель даты с энергосберегающим режимом

— Запоминание последних 250 событий

— Поддержка внешних аварийных сигналов и внешних устройств

— Внешние габариты (ШхВхГ), мм: 240х180х44

— Габариты монтажного проема (ШхВ), мм: 220х160

— Вес, кг: 0,96

Модули расширения для RGK800 (максимально 3 модуля)

Цифровые входы и выходы:

EXP10 00 — 4 цифровых изолированных входа

EXP10 01 — 4 статических изолированных входа

EXP10 02 — 2 цифровых изолированных входа и 2 статических изолированных релейных выхода

EXP10 03 — 2 релейных выхода 5А 250В переменного тока

EXP10 06 — 2 релейных выхода, нормально открытый (НО) контакт 5А 250В переменного тока

EXP10 07 — 3 релейных выхода, нормально открытый (НО) контакт 5А 250В переменного тока

EXP10 08 — 2 цифровых изолированных входа и 2 релейных выхода 5А 250В переменного тока

RGK RR — Релейный модуль для индикации аварийных сигналов и сигналов состояния

Аналоговые входы и выходы:

EXP10 04 — 2 изолированных аналоговых входа 0/4…20мА или РТ100 или 0…+-5В

EXP10 05 — 2 изолированных аналоговых выхода 0/4…20мА или 0…10В или 0…+-5В

Порты связи:

EXP10 10 — Изолированный интерфейс USB

EXP10 11 — Изолированный интерфейс RS232

EXP10 13 — Изолированный интерфейс Ethernet

EXP10 15 — Изолированный интерфейс GSM-GPRS

Сертификация и соответствие

Полученные сертификаты: внесены в список UL для США и Канады (cULus-File E93601) в качестве контроллеров генераторных установок-вспомогательных устройств; EAC.

Соответствие стандартам: IEC/EN 61010-1, IEC/EN 61000-6-2, IEC/EN 61000-6-3, UL 508, CSA C22.2 n° 14.

Видео презентация контроллеров LOVATO Electric

Программное обеспечение для конфигурирования RGK800 и удаленного мониторинга оборудования

ПО для конфигурирования параметров и дистанционного мониторинга всех устройств LOVATO Electric последнего поколения, снабженных портом связи.

Данное ПО устанавливается в среде ОС Windows и предусматривает соединение в однопользовательском режиме (по одному узлу одновременно) с устройствами LOVATO Electric, подсоединенными к сети

Утилиты и драйверы

RGK Customization Manager Rev.7.8.2 14.02.2017

Мобильные приложения

Sam1

Конфигурирование и работы по техобслуживанию часто осуществляются в малодоступных и/или неудобных местах. Теперь выполнение таких операций стало проще в случае всех изделий LOVATO Electric, имеющих фронтальный порт связи, совместимый с устройством CX02. Фактически к ним можно подключиться через новое приложение Sam1 для планшетов и смартфонов, работающих на базе операционных систем Android или iOS. Теперь больше нет необходимости иметь доступ к компьютеру, подключать его и различные кабели для проведения операций смены конфигурации, конфигурирования параметров и т. д. Через это приложение можно загружать файл со всеми результатами программирования, сохраненными ранее, отправлять команды и

проверять значения характеристик, считанные устройствами LOVATO Electric. Данные о событиях, сохраненных в памяти устройств, можно выводить на экран, а также сохранять в виде текстового файла для отправки по электронной почте.

Приложение Sam1 можно скачать бесплатно в Google Play Store или Apple iTunes.

NFC

Операции с параметрами для отдельных устройств LOVATO Electric, выполняемые через смартфоны и планшеты, теперь могут проводиться с применением технологии NFC. При приближении смартфона или планшета (с активированной функцией соединения NFC) к устройству LOVATO Electric происходит запуск приложения NFC и автоматическое распознавание подключенного устройства. Конфигурирование параметров может выполняться без подачи питания на устройство LOVATO Electric.

Данное приложение позволяет выполнять следующие действия:

– Конфигурировать параметры подключенного устройства

– Сохранять параметры в файл и отправлять его по электронной почте

– Загружать файл с параметрами, сохраненный ранее.

Приложение можно скачать бесплатно в Google Play Store.

- Home

- Brands

- LOVATO ELECTRIC Manuals

- Controller

- RGK800

|

|

Related Devices:

|

Types of Manuals:

The main types of LOVATO ELECTRIC RGK800 instructions:

- User guide — rules of useing and characteristics

- Service manual — repair, diagnostics, maintenance

- Operation manual — description of the main functions of equipment

Controller, Control Unit User Guides by LOVATO ELECTRIC:

Similar to LOVATO ELECTRIC RGK800 Manuals, User Guides and Instructions:

-

Federal Signal Corporation SmartSystem SS2000-LMS

Price $4.00HARDWARE INSTALLATION AND MAINTENANCE INSTRUCTIONSModel SS2000-LMSSmartSystem™ Load Management SystemLOAD MANAGER WITH ELECTRONIC SIREN/LIGHTCONTROL SYSTEM ANDSignalMaster™ DIRECTIONAL LIGHT(with Slide Switch Control Head) …

SmartSystem SS2000-LMS Server, 20

-

Johnson Controls FAC3613

FAC3613 Advanced Application Field EquipmentController Installation GuideApplicationThe FAC3613 Advanced Application Field EquipmentController (FAC) is part of the Metasys® systemField Equipment Controller family. The FAC36Series controllers run pre-engineered and user-programmed applications and provides the inputsa …

FAC3613 Controller, 24

-

Vimar SW230.T

SW230.T / SW230.T.120Scheda con trimmer 230/120 Vac per cancelli battentiBoard with 230/120 VAC trimmer for swing gatesCarte avec trimmer 230/120 Vca pour portails à battantsLeiterplatte 230/120 Vac mit Trimmer für FlügeltorantriebTarjeta con trimmer 230/120 V para cancelas batientesΠλακέτα με trimmer 230/1 …

SW230.T Controller, 110

-

SOMFY animeo

animeo ConnectConnect Main Controller Ref. 1860304Návod k instalaciInstallationsvejledningGebrauchsanweisungInstallation guideMontagehandleidingInstallasjonsanvisningerInstrukcja instalacjiInstallationsanvisningarGuía de instalaciónNotice d’installationGuida all‘installazione시공 가이드Montaj kılavuzu SOLU …

animeo Controller, 19

-

Meridian 861

Meridian Audio Limited, Stonehill, Stukeley Meadows, Huntingdon, Cambs PE29 6EXTel +44 1480 52144 Fax +44 1480 459934http://www.meridian-audio.com/RS 232 InformationJMB v 1.0 – 18-07-2000Text entry for Meridian decodersIntroduction.A feature has been added to Meridian 561,568 and 861 which allows users to input text …

861 Stereo System, 1

-

Compaq

221050-001 — ProLiant — 5000R

COMPAQ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ …

221050-001 — ProLiant — 5000R Desktop, 19

-

EntraPass

KT-400

27KT-400 Ethernet Four-Door Controller Installation ManualTroubleshooting Table 3: Reset Types and DescriptionsJumpers Heartbeats Patterns ResetsContinuous quick flashingSoft Reset: When JP2 and JP3 are ON, the controller will reset on a) power up, b) pushbutton, or c) EntraPass software ‘Manual operator soft rese …

KT-400 Controller, 2

-

ProMinent

DCM 5 Series

Visit our XTRANET <www.prominentxtranet.com> to:• sign up for our electronic newsletter • download literature and manuals • validate your product warrantyBACK ENTERProMinent®OKALARMPool 750.0mV 7.40pH 85.0FBACK ENTERProMinent®OKALARMPool 750.0mV 7.40pH 85.0FBACK ENTERProMinent®OKALARMENTENTENTENT …

DCM 5 Series Controller, 2

-

Verasys

ZEC410

ZEC410 VAV Controllers Installation Instructions Refer to the QuickLIT website for the most up-to-date version of this document.Contents subject to change.1ZEC410 VAV ControllersInstallation InstructionsLC-ZEC410-xxPart No. 24-10143-1264, Rev. –Issued January 2017ApplicationsThe ZEC410 VAV Controllers are components …

ZEC410 Controller, 19

Recommended Documentation: