Описание

Характеристики

Заявки просим присылать на адрес sales@texenergo.com

По всем другим вопрос ЦПК support@texenergo.com

ООО «Тэксэнерго Электрик» находится по адресу 141580, Московская обл, Солнечногорский р-н, дер. Черная Грязь, дом 65

Одним из эффективных методов повышения энергоэффективности системы освещения и снижения затрат на её эксплуатацию является использование систем управления освещением. Основываясь на многолетнем опыте эксплуатации различных объектов, холдинг БЛ ГРУПП разработал собственную систему управления АСУНО «БРИЗ».

АСУНО «БРИЗ» включает в себя линейку различного оборудования и ПО, предназначенного для автоматизации систем уличного, архитектурного и промышленного освещения.

— Шкафы управления освещением (ШУНО);

— Регуляторы напряжения;

— Автоматизированные пункты питания наружного освещения (АППНО);

— Контроллеры;

— Программное обеспечение.

Дополнительно НПО GALAD предоставляет услуги по проектированию объектов, шеф-монтажу и обучению персонала клиента. Ниже представлен перечень стандартного оборудования. При этом наша компания предлагает возможность разработки и изготовления оборудования по требованию клиента.

Шкафы управления освещением (ШУНО)

Предназначены для автономного и/или удаленного включения освещения, сбора и обработки диагностической и контрольной информации, коммерческого учета электроэнергии.

Шкаф управления освещением на базе контроллеров БРИЗ-РВ предназначен для автономного включения и отключения наружного освещения по астрономическому расписанию с возможностью синхронизации по системам ГЛОНАСС/GPS. Встроенное программное обеспечение позволяет определять время включения и отключения по координатам установки оборудования (широте и долготе).

Шкаф управления освещением на базе контроллера БРИЗ-ТМ (до 6 отходящих трехфазных линий, связь по GSM/GPRS или Ethernet) предназначен для дистанционного включения и отключения наружного освещения по командам диспетчера, сбора и передачи диагностической информации.

Шкаф управления освещением на базе контроллера БРИЗ DMX. Предназначен для управления архитектурным RGBW освещением по протоколу DMX 512.

Преимущества использования ШУНО:

— Снижение затрат на обслуживание системы освещения за счет удаленного контроля её параметров;

— Точный учет и анализ потребляемой электроэнергии;

— Быстрое выявление и, как следствие, быстрое устранение аварийных ситуаций.

Регуляторы напряжения

Предназначены для группового управления световым потоком в линии методом снижения напряжения в сети. Являются энергосберегающим оборудованием и предназначены для управления процессом пуска, стабилизации и понижения энергопотребления светильников наружного освещения с лампами высокого давления (натриевыми или ртутными), использующих электромагнитные ПРА, и специальными LED светильниками GALAD (LED, Стандарт LED, Волна LED[e6] )

Регулятор напряжения БРИЗ.GALAD

Регулятор напряжения с ручным управлением предназначен для оптимизации расхода электрической энергии, питающей осветительные системы, путем снижения напряжения питания.

Регулятор напряжения БРИЗ.GALAD.РВ

Регулятор напряжения с автоматическим управлением по годовому расписанию предназначен для оптимизации расхода электрической энергии, питающей осветительные системы, путем снижения напряжения питания.

Преимущества использования Регулятора напряжения:

— Экономия потребляемой электроэнергии до 35%;

— Выравнивание фазного напряжения – увеличение срока службы светотехнического оборудования.

Автоматизированные пункты питания наружного освещения (АППНО)

Предназначены для питания и управления установками наружного освещения по отходящим трехфазным линиям. АППНО выполняет функции вводно-распределительного устройства и имеет возможность подключения регулятора напряжения, а также подсоединение шкафов управления типа ШУНО-СС.GALAD.хх и автоматизированной информационно-измерительной системы учета электроэнергии (АИИСКУЭ).

Автоматизированный пункт питания наружного освещения (6 отходящих трехфазных линий по 100А), обеспечивающий автономное управление наружным освещением с помощью контроллера «БРИЗ-РВ» (автономное включение и отключение наружного освещения по годовому расписанию).

Автоматизированный пункт питания наружного освещения (6 отходящих трехфазных линий по 100А), обеспечивающий дистанционное управление наружным освещением с помощью контроллера «БРИЗ-ТМ» (включение и отключение наружного освещения по командам диспетчера, сбор и передача диагностической информации).

Преимущества использования АППНО:

— Одновременное выполнение функций вводно-распределительного устройства и шкафа управления;

— Полный удаленный контроль системы.

Контроллеры

НПО GALAD предлагает различные контроллеры для автоматизации инфраструктурных сетей и процессов (освещение, водоснабжение, отопление и др.). Все контроллеры являются собственной разработкой компании. Данные контроллеры являются основным компонентом ШУНО, АППНО и регуляторов напряжения.

Контроллер управления Бриз РВ

Предназначен для автономного управления наружным освещением по хранящемуся в нем астрономическому расписанию включений и выключений. Имеет в своем составе модуль Глонасс/GPS.

Контроллер управления «БРИЗ-ТМ»

Предназначен для дистанционного включения и отключения наружного освещения по командам диспетчера, сбора и передачи диагностической информации (до 6 отходящих трехфазных линий, связь по GSM/GPRS или Ethernet).

Контроллер управления Бриз-DMX

Предназначен для воспроизведения загруженных цветодинамических сценариев (потоков DMX-512).

Контроллер предназначен для управления уличным освещением по данным календаря, хранящегося в энергонезависимой памяти и показаний часов реального времени. Контроллер имеет два канала управления. Первый канал работает по программе управления (календарю), где указывается время включения и отключения на каждый день года. Второй канал может работать как по календарю, так и в режиме «ночного сокращения освещения».

Общие технические характеристики

Рабочие условия применения:

Относительная влажность от 5 до 95% при 35 °C

Атмосферное давление от 66,0 до 106,7 кПа

Синусоидальные вибрации частотой 10-55 Гц, с амплитудой смещения не более 0,15 мм

Температура транспортирования от минус 40 до плюс 55 °C

Средний срок службы 40 лет

Средняя наработка на отказ 140 000 часов

Основные технические и метрологические характеристики:

Номинальное напряжение питания 220 (+10/-15) В

Потребляемая мощность 6 Вт

Количество каналов управления 2

Коммутируемое напряжение не более 250 В

Коммутируемый ток на канал не более 0,3 А

Количество срабатываний 1 000 000

Тип батареи CR 2032

Ведение времени при отсутствии питания 1 год

Срок хранения батареи 10 лет

Погрешность хода часов 1 сек/сутки

Сеть SyBus

Физический интерфейс сети RS-485

Скорость обмена 9600, 38400, 153600, 307200 бод

Степень защиты IP20

Диапазон рабочих температур окружающего воздуха от -40 до +70 °C

Масса 0,6 кг

На чтение 20 мин Просмотров 6 Опубликовано 11 апреля 2023 Обновлено 11 апреля 2023

Содержание

- Основные виды схем управления освещением

- Управление освещением при помощи автоматических выключателей в щите

- Управление освещением местными выключателями с одного, двух, трех и более мест

- Управление выключателями с одного места

- Управление выключателями двух мест

- Управление выключателями трех и более мест

- Управление освещением с использованием импульсного реле

- Управление освещением с использованием контакторов (магнитных пускателей)

- Конструкция контактора и принцип работы

- Базовая схема управления освещением при помощи контактора

- Схемы управления освещением при помощи контактора и кнопок — схема «самоподхвата»

- Базовая схема и принцип работы

- Схема «самоподхвата» для управления освещением с нескольких мест

- Схемы управления освещением при помощи контактора и импульсного реле

- Управление освещением с использованием реле времени

- Базовая схема и принцип работы

- Схемы управления освещением нескольких линий при помощи реле времени

- Управление освещением с использованием реле времени для лестничных клеток

- Управление освещением с использованием фотореле

- Управление освещением с использованием реле напряжения

- Управление освещением с использованием датчиков движения

- Управление освещением с использованием контроллеров

- Скачать примеры схем управления освещением

Основные виды схем управления освещением

В статье рассмотрим основные виды схем управления освещением, которые применяются в щитах освещения и шкафах управления освещением как для автоматического, так и для ручного управления наружным (уличным, декоративным) и внутренним освещением.

Управление освещением при помощи автоматических выключателей в щите

Простейшим способом управления освещением является включение и отключение автоматического выключателя в щите освещения. Это решение применяется в щитах аварийного освещения с постоянно горящими светильниками, которые не требуют частого включения и отключения, а доступ к управлению освещением должен иметь только квалифицированный персонал.

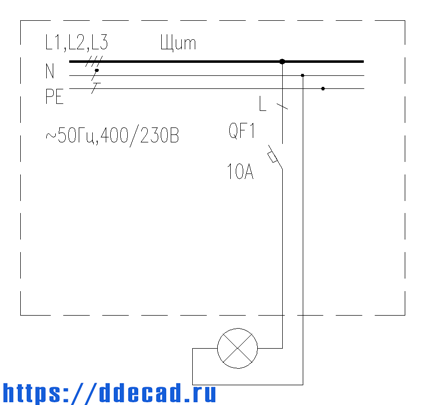

Схема управления освещением при помощи автомата в щите

Но вообще, автоматические выключатели не предназначены для частого включения и отключения, поэтому для управления освещением дополнительно внутрь щита устанавливают выключатель.

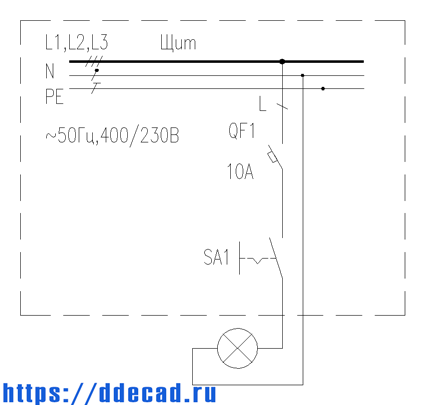

Схема управления освещением при помощи переключателя внутри щита

У ведущих производителей подобные выключатели есть в модульном исполнении (например, переключатели E211 у ABB или iSSW у Schneider Electric).

Номинальный ток переключателя ограничен, поэтому для управления мощными нагрузками его может быть недостаточно. В таком случае следует использовать схемы управления освещением при помощи контакторов.

Управление освещением местными выключателями с одного, двух, трех и более мест

Самый распространённый способ управления освещением — выключателями освещения. Данный способ знаком каждому, т.к. управление освещением в квартирах реализовано именно так. Этот способ применяется также в общественных (офисные, торговые, административные) и промышленных зданиях для местного управления освещением.

Управление выключателями с одного места

Простейший и наиболее распространённый — управлением одно- , двух- и трехклавишными выключателями с одного места.

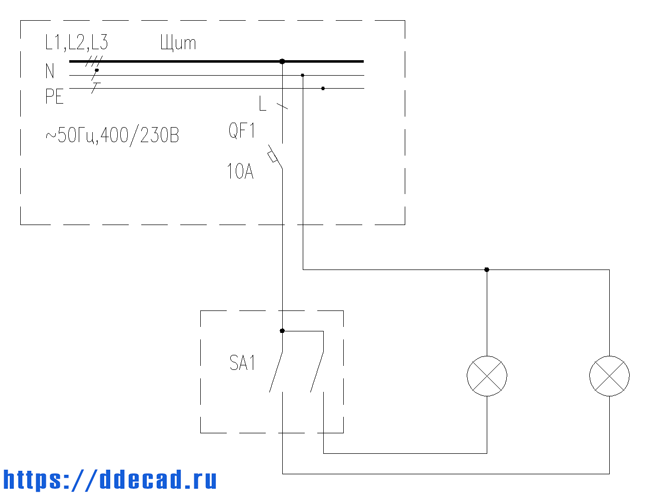

Схема управления освещением одноклавишным выключателем

Двухклавишные и трехклавишные выключатели позволяют управлять несколькими светильниками или разными группами включения в многоламповом светильнике.

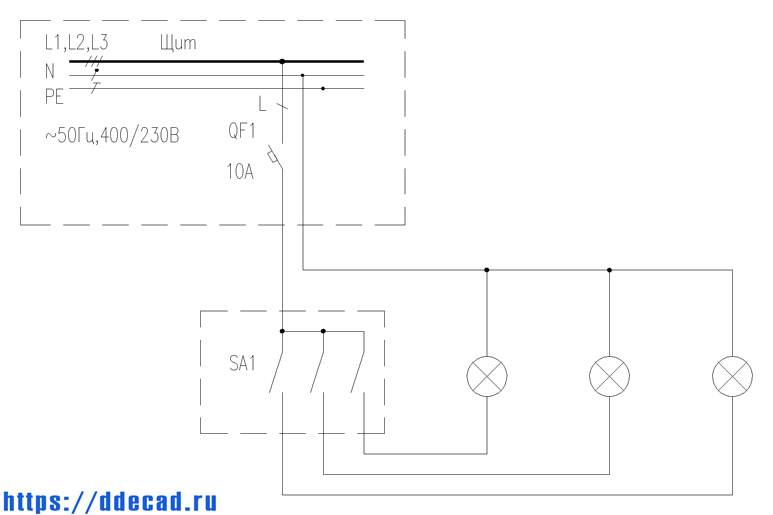

Схема управления освещением двухклавишным выключателем

Схема управления освещением трехклавишным выключателем

Управление выключателями двух мест

Для управления освещением в двух мест используют переключатели. Внешне они выглядят как обычные выключатели, но конструктивно отличаются. Такой переключатель содержит перекидной контакт. Соответственно, включение и отключение светильника зависит от положения клавиш на обоих переключателях.

Схема управления освещением переключателями с двух мест

Данная схема управления чаще всего используется в коридорах, т.к. позволяет включить освещение при входе в коридор и отключить при выходе из него. Также переключатели используют для управления освещением в гостиничных номерах и квартирах. Удобно включить общее освещение при входе в спальню, а отключить не вставая с кровати.

Управление выключателями трех и более мест

Для управления освещением с трех мест потребуется ещё один вид выключателя — перекрестный переключатель. Он устанавливается в схеме между переключателями (на схеме обозначен SA2).

Схема управления освещением переключателями с трех мест

Для управления освещением с четырёх мест потребуется установка ещё одного перекрестного переключателя.

Схема управления освещением переключателями с четырех мест

Теоретически, таким образом можно организовать управлением освещением с большого числа мест, добавляя в схему перекрестные переключатели, но так не делают. С точки зрения простоты схемы, удобства и по экономическим соображениям, управление с трех и более мест целесообразнее делать с использованием импульсных реле и кнопочных выключателей.

Управление освещением с использованием импульсного реле

Импульсное реле позволяет организовать управление освещением одного, двух, трех, четырех и практически неограниченного числа мест. Для реализации схемы потребуется импульсное (бистабильное) реле и кнопочные (нажимные) выключатели.

Для понимания логики работы схемы следует разобраться с особенностями работы импульсного реле. Это реле каждый раз переключает свои контакты при подачи импульса на катушку управления.

В зависимости от производителя, подача импульса может быть как на основной питающий вход реле, так и на отдельный вход управления.

Существуют различные версии импульсного реле с разным набором пар контактов NO (нормально открытыми), NC (нормально закрытыми), перекидными контактами и их различной комбинацией.

Рассмотрим работу схемы управления освещением с самой простой версией импульсного реле с одной NO парой контактов.

Схема управления освещением при помощи импульсного реле

Силовая цепь питания светильников состоит из автоматического выключателя QF1 и контактов импульсного реле KI1. Управление импульсным реле осуществляется кнопочными (нажимными) выключателями SB1, SB2. подключенными параллельно на клеммы X1:1 и X1:2.

В начальном положении контакты реле KI1 разомкнуты (NO). При нажатии на кнопку SB её контакты 1 и 2 замыкаются и на катушку реле поступает управляющий импульс. Реле меняет положение контактов — силовая цепь замыкается, освещение включается.

Повторное нажатии на кнопку SB подаст на катушку реле ещё один импульс и реле опять сменит состояние контактов — силовая цепь разомкнётся, освещение отключится.

Как видим, применяя данную схему можно существенно сэкономить на кабеле и монтажных работах.

Схемы с использованием импульсного реле для управления освещением применяют в жилых, общественных и промышленных зданиях.

Управление освещением с использованием контакторов (магнитных пускателей)

Контакторы (магнитные) пускатели широко используются в схемах управления освещением и инженерным оборудованием.

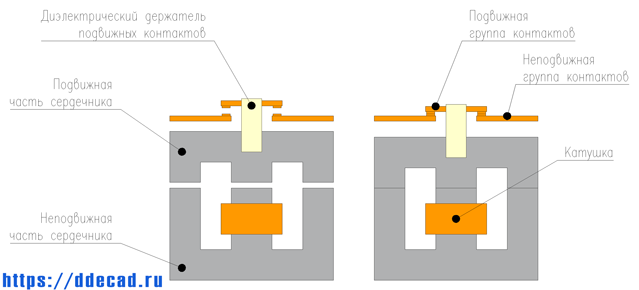

Конструкция контактора и принцип работы

Конструктивно контактор состоит из неподвижной части сердечника, катушки, неподвижной группы контактов, подвижного сердечника с подвижной парой контактов.

При подачи напряжения на катушку, подвижная часть сердечника под воздействием электромагнитного поля вместе с закреплённой на ней подвижной группой контактов притягивается к неподвижной части сердечника. При этом подвижная и неподвижная группа контактов замыкается.

При снятии напряжения с катушки, подвижная часть сердечника под воздействием пружины возвращается в исходное положение и группы контактов размыкаются.

Мы рассмотрели принцип работы контактора с NO (нормально разомкнутыми) контактами. Аналогичным образом работают контакторы с NC (нормально закрытыми) контактами и перекидными контактами.

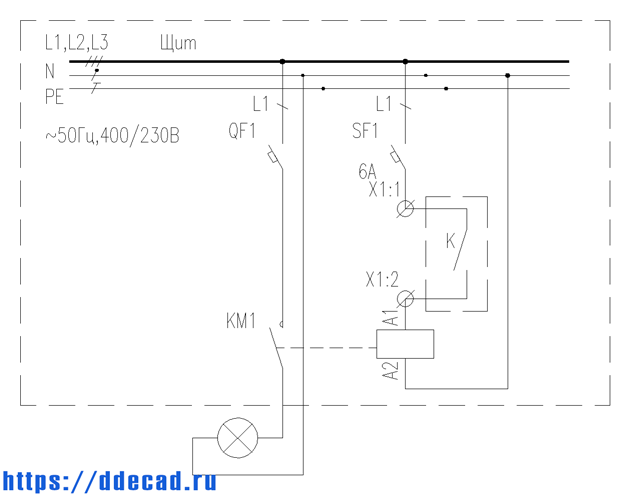

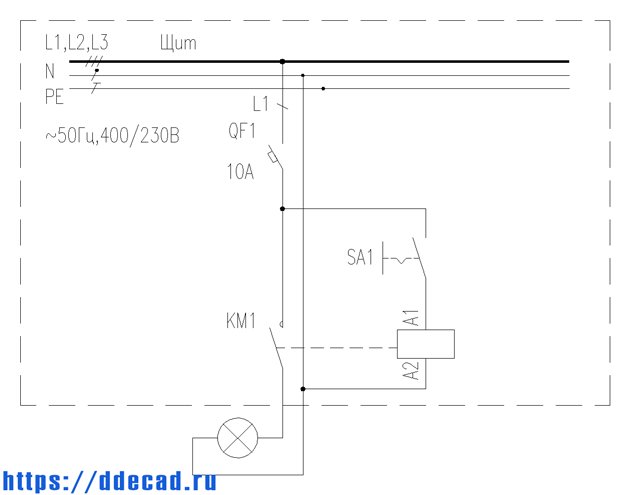

Базовая схема управления освещением при помощи контактора

Рассмотрим работу базовой схемы управления освещением при помощи контактора. Силовая цепь питания светильников состоит из автоматического выключателя QF1 и NO (нормально открытых) контактов контактора KM1. Цепь управления состоит из автоматического выключателя SF1 и катушки контактора KM1, между которыми включается контакт управляющего элемента (подключается между клеммами X1:1 и X1:2).

Управление освещением при помощи контактора. Базовая схема

Управляющий контакт K разомкнут, катушка контактора KM1 без напряжения, контакты контактора разомкнуты.

При замыкании управляющего контакта K на катушку контактора KM1 подаётся питание и контактор замыкает свои контакты. Силовая цепь замкнута — освещение включается.

При размыкании управляющего контакта цепь управления размыкается. С катушки контактора снимается напряжение и его контакты возвращаются в исходное положение (разомкнуты). Силовая цепь размыкается — освещение отключается.

В качестве управляющего контакта может выступать обычный одноклавишный выключатель освещения, устанавливаемый в нужном месте на стене помещения. Такая схема применяется в квартирах, когда устанавливают при входе в квартиру мастер-выключатель, отключающий все нагрузки кроме тех, которые нельзя отключать (холодильник, например).

Такая же схема с мастер-выключателем применяется в гостиницах, когда в щите номера устанавливают контактор, управляемый карточным выключателем.

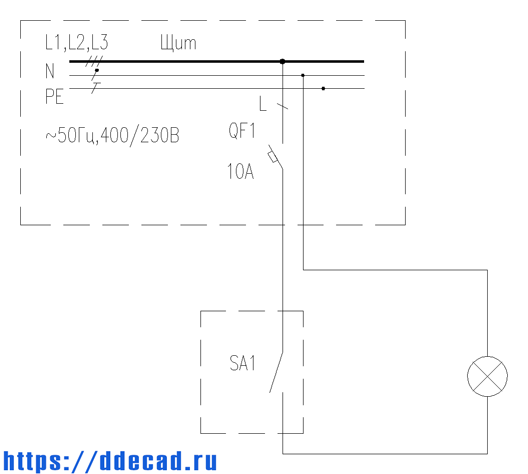

Также в качестве управляющего выключателя может выступать выключатель или переключатель SA1, устанавливаемый в щите (например, модульный переключатель E211 у ABB, iSSW у Schneider Electric или подобный).

Управление освещением при помощи контактора и выключателя в щите

Схемы управления освещением при помощи контактора и кнопок — схема «самоподхвата»

Часто при управлении освещением производственных зданий, а также наружного освещения применяется схема «самоподхвата».

Базовая схема и принцип работы

Рассмотрим работу схемы для питания однофазной цепи освещения. Для реализации данной схемы нам понадобятся:

- автоматических выключателя QF1 для защиты силовой цепи

- автоматический выключатель SF1 для защиты цепи управления

- контактор KM1 c двумя парами нормально разомкнутых контактов 2NO

- кнопка SB1 «ПУСК» с нормально разомкнутыми контактами NO

- кнопка SB2 «СТОП» с нормально замкнутыми контактами NC

- сигнальная лампа HL1 для индикации включения освещения

Управление освещением при помощи контактора и кнопок — схема самоподхвата

Кнопки SB2, SB1 и катушку контактора KM1 подключаем последовательно друг за другом. Параллельно с катушкой подключаем сигнальную лампу. Первую пару NO контактов контактора KM1.1 подключаем в силовую цепь, а вторую пару NO контактов контактора KM1.2 подкючаем параллельно NO контактам кнопки SB1.

- В начальном положении цепь управления разомкнута: контакты кнопки SB1 разомкнуты, катушка контактора KM1 без напряжения, пары контактов KM1.1 и KM1.2 разомкнуты, лампа HL1 не горит.

- Нажимаем кнопку SB1. Контакты SB1 замыкаются, контакты SB2 замкнуты, на катушку контактора KM1 подаётся напряжение и загорается сигнальная лампа HL1. Контактор KM1 замыкает свои пары контактов KM1.1 и KM1.2. Силовая цепь замыкается и включается освещение.

- Отпускаем кнопку SB1. Контакты SB1 размыкаются, но подключенная параллельно пара контактов KM1.2 замкнута, поэтому катушка контактора KM1 остаётся под напряжением и не размыкает свои пары контактов.

- Нажимаем кнопку SB2. Контакты SB2 размыкаются, с катушки контактора KM1 снимается напряжение, пары контактов KM1.1 и KM1.2 размыкаются, сигнальная лампа гаснет, освещение отключается.

Как видим, при замыкании кнопки SB1 контактор сам «подхватывает» своё питание за счёт второй пары контактов. Из-за этого данную схему назвали схемой «самоподхвата».

Пожалуй, это одна из основных схем для шкафов и пультов управления освещением. Корпус шкафа делают металлическим, а на переднюю дверцу выводят кнопки и сигнальные лампы. Эту же схему применяют для управления двигателями.

Схема «самоподхвата» для управления освещением с нескольких мест

Также схему «самоподхвата» можно применить для управления освещением с нескольких мест. В этом случае в качестве пар кнопок использую кнопочные посты, устанавливаемые в нужных местах.

Нормально открытые NO контакты кнопочных постов соединяем параллельно, нормально закрытые NC контакты — последовательно. Таким образом, замыкание любого NO-контакта замкнёт цепь питания катушки контактора, а размыкание любого NC-контакта разомкнёт.

Управление освещением с нескольких мест при помощи контактора и кнопок — схема самоподхвата

Подобным образом можно управлять сразу несколькими группами освещения одновременно. Для этого нужно немного видоизменить схему. Контактор 4KM1, установленный в цепи управления, одной парой контактов 4KM1.2 будет «подхватывать» своё питание, а второй парой контактов 4KM1.1 управлять питанием катушек контакторов, включающих освещение.

Управление освещением нескольких групп с нескольких мест при помощи контактора и кнопок — схема самоподхвата

Схемы управления освещением при помощи контактора и импульсного реле

Ещё одним вариантом схемы управления с нескольких мест является комбинированная схема с использованием контакторов и импульсного реле. Данную схему применяют в случае, когда одной кнопкой нужно включить сразу несколько групп освещения.

Рассмотрим данный тип схемы для управления тремя группами освещения с трех мест.

- В начальном состоянии контакты импульсного реле KI1 разомкнуты. Катушки контакторов 1KM1, 2KM1, 3KM1 находятся без напряжения, их пары контактов разомкнуты. Силовые цепи разомкнуты и освещение отключено.

- Нажимаем кнопку, например, SB1и, тем самым, подаем управляющий импульс на катушку импульсного реле KI1. Импульсное реле меняет состояние контактов и замыкает свою пару контактов. На катушки контакторов 1KM1, 2KM1, 3KM1 подаётся напряжение и они замыкают свои пары контактов. Силовые цепи замыкаются и включается освещение.

- Повторно нажимаем кнопку SB1 (либо любую другую — SB2, SB3) и подаем управляющий импульс на катушку импульсного реле KI1. Импульсное реле меняет состояние контактов и размыкает свою пару контактов. Напряжение с катушек контакторов 1KM1, 2KM1, 3KM1 снимается и они размыкают свои пары контактов. Силовые цепи размыкаются и освещение отключается.

Управление освещением нескольких групп с нескольких мест при помощи контактора и импульсного реле

При необходимости, данную схему можно доработать, включив параллельно катушкам контакторов сигнальную лампу, а также установить в щите кнопку для включения освещения с дверцы щита.

Управление освещением с использованием реле времени

Реле времени широко используются в схемах автоматики, в том числе для управления освещением.

Реле времени можно разделить на две большие группы:

- Программируемые реле времени — реле замыкает и размыкает свои контакты в соответствии с заданной программой;

- Таймеры — реле времени замыкает размыкает свои контакты на заданное время после приложения управляющего сигнала.

Программируемые реле времени и таймеры могут быть электронными и электромеханическими.

Программируемые реле времени могут быть с суточным (одна и та же программа повторяется каждые сутки), недельным (одна и та же программа повторяется каждую неделю) и годовым циклом (программа задаётся на год).

Базовая схема и принцип работы

Рассмотрим работу схемы управления освещением на базе программируемого реле времени, работающего по одной суточной программе.

Управление освещением при помощи реле времени. Базовая схема

Допустим, освещение должно быть включено ежедневно с 9:00 до 18:00. В реле времени устанавливаем текущее время и задаем программу, в соответствии с которой в 9:00 реле должно замкнуть свои контакты сроком на 9 часов. Ежедневно, при наступлении 9:00 реле времени KT1 замыкает свои контакты, силовая цепь оказывается замкнутой и освещение включено. Через 9 часов работа программы заканчивается и реле размыкает свои контакты — освещение отключается.

Схемы управления освещением нескольких линий при помощи реле времени

Для управления несколькими линиями по одной программе применяют реле времени в комбинации с контакторами. Контакторы включают и отключают питание, а реле времени управляет их работой.

Управление освещением при помощи реле времени и контакторов

Питание на катушки контакторов 1KM1, 2KM1, 3KM1 подаётся через трехпозиционный переключатель SA1 с нейтральным положением:

- В положении «Ручное» питание напрямую подаётся на катушки контакторов KM и они замыкают свои пары контактов, освещение включается в соответствии с заданной программой;

- В положении «0» цепь питания катушек контакторов разорвана и освещение отключено;

- В положении «Автомат» питание на катушки контакторов подаётся через контакты реле времени KT1. Включением и отключением освещения управляет реле времени, замыкая и размыкая свои контакты в соответствии с заданной программой.

При необходимости, можно дополнить схему сигнальной лампой HL, включенной параллельно катушкам контакторов, которая будет информировать о включении освещения.

Управление освещением с использованием реле времени для лестничных клеток

Для экономии электроэнергии и управления освещением с нескольких мест используют реле времени из группы таймеров. Данный тип реле замыкают или размыкают свои контакты после подачи на их катушку управляющего сигнала, замыкание или размыкание контактов происходит с заданной временной задержкой.

Основное применение данный тип реле времени нашёл в схемах управления двигателями и схемах АВР (автоматического ввода резерва), но для управления освещением также используется. Например, для управления освещением лестничных клеток.

Рассмотрим применение и работу реле времени для решения данной задачи:

- В начальный момент времени контакты реле KT1 разомкнуты, освещение отключено. Кнопки SB1, SB2. установлены на каждом этаже лестничной клетки и подключены параллельно к управляющим контактам реле времени KT1.

- При нажатии любую из кнопок SB, на катушку реле времени KT1 поступает управляющий сигнал, оно замыкает свои контакты, освещение включается, а реле времени начинает отсчет.

- По прошествии заданного времени реле KT1 размыкает свои контакты и освещение отключается.

- Если при замкнутых контактах реле (т.е. до истечения заданного времени) поступает новый управляющий сигнал, то отсчет времени начинается заново.

Управление освещением лестничных клеток с использованием реле времени

Таким образом, человек, заходя на лестничную клетку, нажимает кнопочный выключатель SB и включает освещение. На следующем этаже опять нажимает кнопку и т.д. Через заданное время освещение на лестничной клетке отключается. Настройка задержки отключения выбирается таким образом, чтобы человек достаточно времени, чтобы дойти от одного кнопочного выключателя до другого.

Данную схему можно также использовать для управления освещением в коридорах. Она позволяет организовать включение освещения с нескольких мест (как при использовании импульсного реле) и при этом ещё сэкономить электроэнергию.

Управление освещением с использованием фотореле

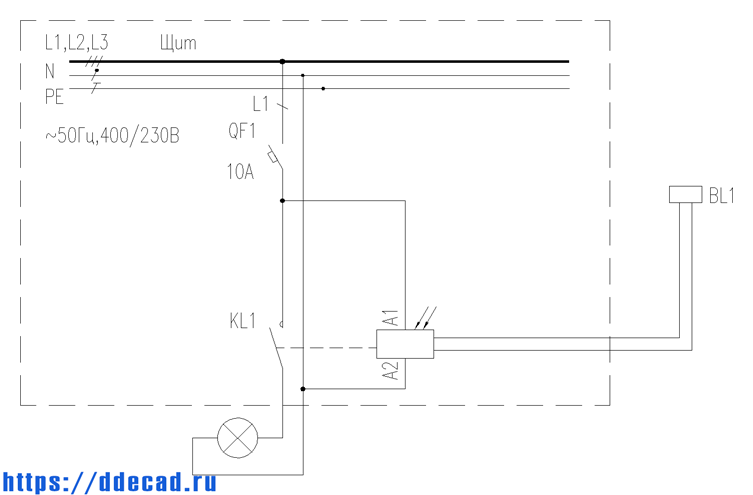

Фотореле (сумеречное реле, сумеречный выключатель) используют для управления наружным (уличным, декоративным) освещением. Фотореле состоит из двух частей: самого реле, устанавливаемого в щит, и выносного датчика освещенности.

Рассмотрим работу схемы управления наружным освещением на базе самой простой версии фотореле, реагирующей только на уровень освещенности.

Датчик освещенности (фотодатчик) BL1 подаёт сигнал на фотореле KL1 пропорционально уровню освещённости. При снижении уровня освещённости ниже заданного, фотореле KL1 замыкает свою пару контактов. Силовая цепь замыкается, включается наружное освещение. При повышении уровня освещенности выше заданного, фотореле KL1 размыкает свою пару контактов и наружное освещение отключается.

Управление наружным освещением при помощи фотореле. Базовая схема

В линейках ведущих производителей представлено несколько вариаций фотореле:

- Самая простая версия — фотореле реагирует только на уровень освещенности. Реле комплектуется фотодатчиком;

- Версия с возможностью задать программу включения (одну или несколько). Фотореле замыкает и размыкает свои контакты в зависимости от уровня освещенности и в соответствии с заданной программой. Реле комплектуется фотодатчиком;

- Астрореле. Реле фотодатчиком не комплектуется. Управление включение осуществляется по заданным программам. Время восхода и заката реле определяет автоматически в зависимости от заданных географических высоты, долготы и астрономического времени.

Как видим, по своему функционалу программируемые фотореле являются своего рода реле времени с дополнительными функциями.

На практике базовая схема управления наружным освещением обычное не применяется, т.к. необходимо одновременно включать сразу несколько групповых линий. Установка на каждую групповую линию фотореле нецелесообразно как с экономической точки зрения, так и с точки зрения здравого смысла. Поэтому в щитах наружного освещения и шкафах управления наружным освещением устанавливают одно фотореле, которое управляет питанием катушек контакторов, замыкающих силовые цепи.

Рассмотрим работу доработанной версии схемы управления наружным освещением.

Управление наружным освещением при помощи фотореле и контакторов

Питание на катушки контакторов 1KM1, 2KM1, 3KM1 подаётся через трехпозиционный переключатель SA1 с нейтральным положением:

- В положении «Ручное» питание напрямую подаётся на катушки контакторов KM и они замыкают свои пары контактов, наружное освещение включается вне зависимости от уровня освещённости

- В положении «0» цепь питания катушек контакторов разорвана и наружное освещение отключено вне зависимости от уровня освещённости

- В положении «Автомат» питание на катушки контакторов подаётся через контакты фотореле KL1. Включением и отключением наружного освещения управляет фотореле, замыкая и размыкая свои контакты в зависимости от уровня освещённости.

При необходимости, можно дополнить схему сигнальной лампой HL, включенной параллельно катушкам контакторов, которая будет информировать о включении наружного освещения.

Фотореле с несколькими программами имеет количество пар контактов в соответствии с количеством предусмотренных программ. Таким образом, можно запрограммировать несколько групп включения наружного освещения.

Управление освещением с использованием реле напряжения

Реле напряжения предназначено для других целей, но мы его будем использовать для управление освещением.

Допустим, при пропадании напряжения (снижении ниже допустимого значения и/или повышении выше допустимого значения) в щите рабочего освещения необходимо включить аварийное освещение в щите аварийного освещения.

Для этого на вводе в щит Щит1 устанавливаем реле напряжения SQZ3 производства ABB (KV1). Данное реле имеет перекидной контакт. При выходе напряжения в сети за допустимые пределы, а также при обрыве любой из фаз, реле меняет положение контактов. Выводим контакты 3 и 5 на клеммы X1:1 и X1:2 для удобства подключения сигнального кабеля.

В щите Щит2 реализована стандартная схема управления освещением при помощи контактора. Сигнальный кабель от щита Щит1 подключаем на клеммы в щит Щит2 в цепь управления питанием катушки контактора KM1.

Управление освещением при помощи реле напряжения с NO контактами

При срабатывании реле KV1 в щите Щит1 реле меняет положение контактов и пара контактов 3 и 5 становится замкнутой. Таким образом, цепь питания катушки контактора KM1 в щите Щит2 замыкается, на катушку подаётся напряжение и контактор KM1 замыкает свою пару контактов. Силовая цепь замыкается, включается освещение, подключенное к щиту Щит2.

При возвращении напряжения на вводе в щит Щит1 в допустимые пределы, реле KV1 возвращает свои контакты в исходное положение, размыкая пару контактов 3 и 5. Цепь питания катушки контактора KM1 размыкается, напряжение с катушки контактора снимается и он размыкает свои контакты. Силовая цепь размыкается, освещение, подключенное к щиту Щит2, отключается.

Вместо реле напряжения SQZ3 можно взять аналог у другого производителя, либо установить несколько реле (реле минимального напряжения, реле максимального напряжения, реле контроля фаз), а их управляющие NO-контакты соединить параллельно. Таким образом, при срабатывании любого реле будет генерироваться управляющий сигнал на включение освещения в щите Щит2.

Для большей надежности и страховки от обрыва сигнального кабеля используют схему с нормально закрытыми NC контактами.

Управление освещением при помощи реле напряжения с NC контактами

Принцип работы данной схемы аналогичен предыдущей с единственным отличием, что мы используем нормально закрытые NC контакты в цепи управления. В нормальном режиме (без напряжения на катушке) контакты контактора KM1 замкнуты. Но, т.к., мы используем NC контакт реле напряжения KV1, то в нормальном режиме катушка контактора KM1 в щите Щит2 оказывается под напряжением и размыкает свои контакты. Соответственно, цепь питания контакторов 1KM1, 2KM1 в щите Щит2 разомкнута, питание с их катушек снято и их контакты разомкнуты. Силовая цепь питания освещения, подключенного к щиту Щит2 разомкнута и освещение отключено.

При срабатывании реле напряжения KV1 в щите Щит1 пара контактов 4 и 5 размыкается и, тем самым, разрывается цепь питания катушки KM1 в щите Щит2. Без напряжения NC контакты контактора KM1 возвращаются в исходное положение — замыкаются, тем самым на катушки контакторов 1KM1, 2KM1 подается напряжение и они замыкают свои контакты. Силовая цепь питания освещения замыкается и освещение включается.

Вместо реле напряжения SQZ3 можно взять аналог у другого производителя, либо установить несколько реле (реле минимального напряжения, реле максимального напряжения, реле контроля фаз), а их управляющие NC-контакты соединить последовательно. Таким образом, при срабатывании любого реле либо обрыве сигнального кабеля будет генерироваться управляющий сигнал на включение освещения в щите Щит2, т.к. будет разрываться сеть питания катушки управляющего контактора KM1 с NC-контактами.

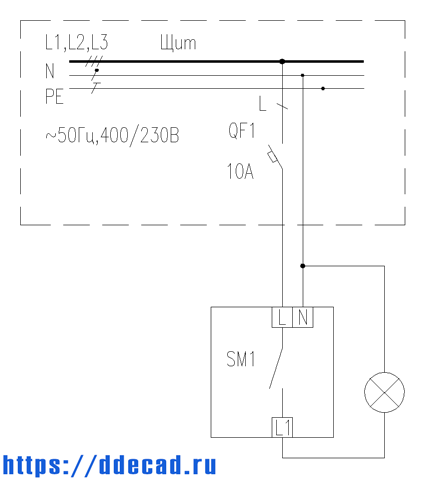

Управление освещением с использованием датчиков движения

Датчики движения давно перестали быть чем-то дорогим и экзотическим. Их давно уже применяют для управления освещением и экономии электроэнергии в общественных зданиях (например, в санузлах) и в загородных домах (в основном для управления наружным освещением).

Датчик представляет собой миниконтактор, который замыкает свои контакты при обнаружении движения в контролируемой зоне.

Как и с обычным выключателем, датчик следует подключать до светильника так, чтобы при его разомкнутых контактах, светильник оказывался без напряжения.

Управление освещением датчиком движения. Базовая схема

Для одновременного управления несколькими группами или для управления трехфазным группами датчики движения используют совместно с контакторами. Контакт датчик SM1 подключают в цепь питания катушки контактора KM1. При срабатывании датчика (обнаружено движение в контролируемой зоне) датчик замыкает свои контакты. Цепь питания катушки контактора KM1, на катушку подается напряжение. Контактор KM1 замыкает свои контакты, силовая цепь замыкается и включается освещение.

При размыкании контактов датчика движения SM1, цепь питания катушки контактора KM1 размыкаетя, с неё снимается напряжение. Контактор размыкает свою пару контактов и разрывает силовую цепь питания освещения. Освещение отключается.

Управление освещением датчиком движения и контактором

При управлении несколькими группами, катушки их контакторов подключаются в схему параллельно.

Также можно реализовать управление освещением по сигналу от нескольких датчиков движения. Контакты датчиков подключаются параллельно на клеммы X1:1, X1:2. При срабатывании любого из датчиков будет замкнута управляющая цепь, подано питание на катушки контакторов и, как следствие, включено освещение.

Управление освещением с использованием контроллеров

На больших объектах управление освещением осуществляют по командам из BMS — Building Management System — Системы управления зданием. Программы управления освещением записаны в контроллерах, контроллеры выдают управляющие сигналы в щиты освещения. В щитах освещения для включения и отключения освещения применены схемы с контакторами.

Скачать примеры схем управления освещением

Для получения чертежа dwg с примерами схем управления освещением из этой статьи заполните контактные данные в форме и на указанный email придёт письмо со ссылкой на скачивание файла.

Источник