Настройка контроллера Johnson Controls серии DX-9100 с помощью инженерного ключа. Часть 3

Опубликовано: 01.02.2021

Видео обзор контроллера Johnson Controls серии DX-9100 — настройка с помощью инженерного ключа.

Видео обзор контроллера Johnson Controls серии DX — DX9100. Часть 1

Видео обзор панели управления контроллера DX9100 от Johnson Controls. Часть 2

Диагностика исправности контроллера Johnson Controls серии DX-9100. Часть 4

Настройка контроллера DX-9100-8454 с панели управления осуществляется только при наличии инженерного ключа AS-LCPKEY-0. Аналогичная настройка для контроллеров Version 1 (DX-9100-8154), Version 2 (DX-9100-8454 or FA-DX9100-8454) и Version 3 (DX-912x-8454).

Можно выполнять — настройку даты и времени, изменение аналоговых и дискретных уставок, перевод контроллера в ручное управление аналоговыми и дискретными выходами. К аналоговым уставкам относятся задание температуры поддержания требуемой температуры подающего воздуха, горячего водоснабжения, обратной воды калорифера. К дискретным уставкам относится задействование того или иного функционала –включение или отключение определенных режимов работы.

Назначение уставок необходимо смотреть в прошивке контроллера, если нет описания. Среда разработки GX-9100 Graphic Configuration Software Tool (GX Tool) позволяет получить прошивку из контроллера и представить её в понятном для человека виде.

Язык программирования FBD (Function Block Diagram) — графический язык программирования покажет связи аналоговых и дискретных уставок с аналоговыми и дискретными выходами контроллера.

Контроллеры сняты с производства и заменены на новую линейку контроллеров FEC/FAC с модулями расширения IOM. В каждом конкретном случае необходимо выполнить свой подбор сочетания контроллера и модулей расширения. Чаще всего используется сочетание MS-FAC2612-1 + MS-IOM4711-0, т.к. часть входов/выходов не задействована. Полным аналогом будет сочетание MS-FAC3613-0 + MS-IOM2711-2. Дополнительно необходимо приобрести дисплей для управления системой MS-DIS1710-0.

Есть вопросы – задавайте! Всегда рады помочь! Пишите комментарии, подписывайтесь на канал, чтобы не пропустить новые видео. Ваше мнение очень важно для нас.

ООО «Центр управления»

Тел. +7 495 255 54 71

European Electronic Controls Catalogue

Catalogue Section

Product Bulletin

Issue

B

SC-9100

0999

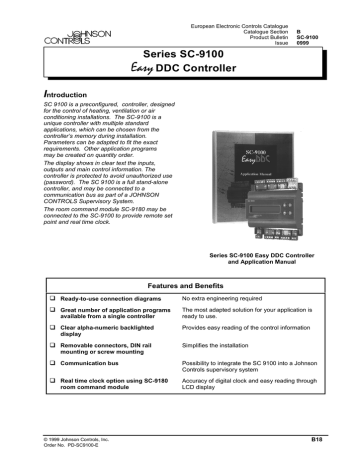

Series SC-9100

Easy DDC Controller

Introduction

SC 9100 is a preconfigured, controller, designed

for the control of heating, ventilation or air

conditioning installations. The SC-9100 is a

unique controller with multiple standard

applications, which can be chosen from the

controller’s memory during installation.

Parameters can be adapted to fit the exact

requirements. Other application programs

may be created on quantity order.

The display shows in clear text the inputs,

outputs and main control information. The

controller is protected to avoid unauthorized use

(password). The SC 9100 is a full stand-alone

controller, and may be connected to a

communication bus as part of a JOHNSON

CONTROLS Supervisory System.

The room command module SC-9180 may be

connected to the SC-9100 to provide remote set

point and real time clock.

Series SC-9100 Easy DDC Controller

and Application Manual

Features and Benefits

! Ready-to-use connection diagrams

No extra engineering required

! Great number of application programs

The most adapted solution for your application is

ready to use.

available from a single controller

! Clear alpha-numeric backlighted

Provides easy reading of the control information

display

! Removable connectors, DIN rail

Simplifies the installation

mounting or screw mounting

! Communication bus

Possibility to integrate the SC 9100 into a Johnson

Controls supervisory system

! Real time clock option using SC-9180

Accuracy of digital clock and easy reading through

LCD display

room command module

© 1999 Johnson Controls, Inc.

Order No. PD-SC9100-E

B18

2

SC-9100

Sensors and Actuators

O rdering data

SC-9100- 8

Version number

Country Code

e.g.

001 For USA

033 For France

852 For Hong Kong

The sensors and actuators, which are to be used in

connection with the SC-9100, are defined in the

“Application Note” bulletins.

Sensor Series:

•

•

TS-91

RS-91

Valves and Actuators:

Accessories:

SC-9100-MK: Panel mount kit

Application Overview

Hardware: 4 analog inputs

(2 x 0/10 V or

NTC, 2 x NTC)

2 digital inputs (potential free

contacts)

3 analog outputs (0/10 V)

2 triacs outputs (24 VAC, 0,5 A)

1 relay output

(24 VAC, 2 A)

Software:

SC-9100 contains PI modules, ON/OFF,

calculations (e.g. set point reset by outside

tempera-ture), logic controls (e.g. frost

protection, clock)

Applications:

The SC-9100 applications are divided into

categories and are stored in memory, available

when it is first installed.

Application Notes

You will find all the available applications fully

described in the “Application Note” bulletins.

Which can be found in the “Application Manual”.

B18

•

•

•

•

•

VB

VG

VA

RA

M-91 and M-92

Auxiliary devices:

•

•

Frost protection 270XT

Room command module SC-9180

Installation

Tools required:

screwdriver, insulation stripping tool.

Wiring:

Before connecting or disconnecting any wires,

ensure that all power supplies have been switched

off to prevent equipment damage and avoid

electrical shock. Separate extra low voltage (safe)

wiring from power line voltage wiring.

The 24 V supply must be stable and not shared

with other switched inductive loads.

Note

These controllers are designed for use as an

operating control. When an operating control failure

would result in personal injury and/or loss of

property, it is the responsibility of the installer to

wire a separate back-up control (a freeze

protection thermostat for instance) in order not to

use the SC-9100 both as an operating and a safety

device.

SC-9100

3

Connection Diagram

AI 1

AI 2

0 /10 V

0 /10 V

+15Vdc

+ - + 11 12 13 14 15

NTC

NTC

11 12 13 14 15

AI 3

AI 4

NTC

NTC

DI 1

21 22 23 24

DI 2

31 32 33 34

N2 Bus

sh co m R T+ R TR S -4 8 5

+15Vdc

COM

AI CO M

3 0 m m a x.

JP 4

AO CO M

82 81

REL

74 73 72 71

TR 1

TR 2

62 61

- +

54 53 52 51

- + - +

AO 2

AO 1.2 AO 1.1

42

41

COM

L

24 Vac

S C -91 80

Note:

AI =

DI =

REL =

TR =

AO =

Analog Input

Digital Input

Relay Output

Triac Output

Analog Output

(0 to 10 V or NTC)

(Potential free contact)

(24 Vac, 2A max.)

(24 Vac, 0.5A max.)

(0 to 10 V)

B18

4

SC-9100

Dimensions:

DIN-rail type 35 mm/13/8 DIN/EN50022

6

4 .6

45

13 8

1 01.6

C

11 8

SC - 91 00

E

Triacs 1 and

2 separation

jumper JP4

JP 4

107

Mounting Bracket

28

Separable Connectors

56

Operation

Front panel:

= “Up” key, used to increase a value, to

scroll among a set of possible values or to

change to next page.

= “Down” key, used to decrease a value, to

scroll among a set of possible values or to

change to previous page.

C

= Used to decrease the access level or to

abandon a modification operation without

confirming modifications.

E

= Used to start a modification operation or

to finish it by confirming modification. Used

also to verify the status of alarms.

B18

When the SC-9100 is switched ON for the first time,

it asks the user to choose one application. After the

application is loaded from the internal library, the SC

9100 will display as a first or default

window the status of the main controlled parameters.

Integration:

SC-9100 belongs to the Johnson Controls

System 91 and is fully compatible with

JC Supervisory Systems.

SC-9100

5

Example

DAT

SP

OAT

19

20

5

Default First Window

DAT

SP

OAT

=

=

=

Discharge Air Temperature

Set Point

Outdoor Air Temperature

C

E

If one of the outputs is in manual mode, the First

Window will display a blinking “m” on the second

line.

Example of one SC 9100 window

(heating valve output in manual mode)

HEATING

VALVE

“m“

100%

C

E

B18

6

SC-9100

Specifications

Supply Voltage:

Power Consumption:

Ambient Operating

Conditions:

Storage Environment:

Terminations:

Serial Interface:

Controller Addressing:

Inputs:

Outputs:

24 VAC, + 15 % - 10 %, 50 - 60 Hz

4 VA

0 - 50 °C, 10 - 90 %, RH non condensing

- 20 °C to + 70 °C, no condensation

Separable terminal blocks for 1 x 1,5 mm²/14AWG

Optically isolated RS-485 interface for N2 bus - 9600 baud rate

0 - 255 selectable on DIP switches (6) and jumpers (2)

(Only required if connected to a communication bus)

Analog (4)

AI 1 / AI 2:

AI 3 / AI 4:

Digital (2)

Analog (3)

AO1.1 / AO1.2 0 - 10 VDC, max. 10 mA. Only one output is active at

one time

AO 2:

0 - 10 VDC, max. 10 mA.

Triacs (2)

TR 1 / TR 2:

Isolated triacs rated at 24 V AC, max. 0.5 A*

(1) PAT or (2) DAT, or (2) ON/OFF outputs

*) Leakage current 1 mA max.

Relays (1)

REL SPST

Isolated contact for 24 V AC, max. 2 A

Voltage (1)

15 V out:

Mounting:

Housing:

Dimensions:

Weight:

Protection class:

Compliance:

0 - 10 VDC or passive NTC for 0 - 40 °C or 20 - 120 °C

Passive NTC for 0 - 40 °C or 20 - 120 °C

Freely configurable, for potential free contracts.

Constant voltage 15 VDC, max. 15 mA, to supply

external transducers

Wall-mount or DIN-rail mount

Material: ABS Polycarbonate (self extinguishing)

108 x 118 x 56 mm (B x H x D)

0.35 kg

IP30 (EN 60529)

EMC (89/336 EEC) according to the standard EN 50081-1 and EN 50082-1

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond

these specifications, consult the local Johnson Controls office or representative. Johnson Controls shall not be liable for damages

resulting from misapplication or misuse of its products.

Johnson Controls International, Inc.

Headquarters: Milwaukee, WI, USA

European Headquarters: Westendhof 8, 45143 Essen, Germany

European Factories: Lomagna (Italy), Leeuwarden (The Netherlands), Essen (Germany)

Branch Offices: principal European Cities

This document is subject to change without notice

B18

Printed in Europe

P/N 24-85638-1036

ENGLISH

SeriesSC-9100

RC31

Series

Electronic

Thermostat

Installation

Sheet

FRANÇAIS

Series SC-9100

READ THIS INSTRUCTION SHEET CAREFULLY BEFORE

INSTALLING

Before installing the device. First select the application needed from the “Application Manual” and refer to the connection

diagram in the “Application Note” related to the application.

For further information, read the “Product Data Sheet”.

Fig. 1

SC-9100 Dimensions and Mounting

A. Mounting Brackets

B. Release Clip

C. To separate Triac 1 and Triac 2 commons, remove jumper JP4.

D. Removable connectors

Fig. 2

Fig. 2 Connection Diagram

Series SC-9100

B

6

4.6

45

118

C

13 8

SC-9100

E

Mounting and Installation (see Fig. 1)

For surface mounting:

•

Slide 2 mounting brackets (A) into the slots. Fix to the surface using using the 4 mm Ø self-tapping screws.

For DIN-rail mounting:

•

Place the controller on the upper edge of the rail and snap

the controller onto the 35 mm Omega rail. To release,

insert a screwdriver into the clip (B) at the base and pull.

Wiring (See Fig. 2)

(see “Application Note”, related to the actual application for

the correct wiring diagram)

•

Switch off power supply when installing or servicing to

prevent damage or electrical; shock.

•

The CMOS circuits in the controller are sensitive to static.

Do not touch components without taking suitable precautions.

•

Terminals are made via the terminal blocks, at the top and

bottom of the controller, which accept up to 1.5 mm2 wires.

•

Low voltage wiring must be physically separated from line

voltage and power wiring, and a distinctive colour (white

or pink) is recommended.

•

Keep all cables as short as possible and tie in position.

•

Do not run cables close to transformers or high frequency

generating equipment.

•

The 24V supply must be stable and not shared with other

switched inductive loads.

•

Complete wiring and check the connections before applying power. Incorrect wiring may cause permanent damage.

Ratings:

JP4

C

Supply Voltage

Power Consumption

CE conformity

107

28

A

56

D

Fig. 1 Dimensions

#5; Régulateur Numérique

LIRE SOIGNEUSEMENT CES INSTRUCTIONS AVANT

DE COMMENCER L’INSTALLATION

Avant de commencer l’installationsélectionner votre application à partir de la notice technique et du manuel d’application où vous trouverez le schéma détaillé de raccordement.

Des informations détaillées se trouvent dans la notice.

Fig. 1

SC-9100 Dimensions et Montage

A. Pattes de montage

B. Clip de verrouillage

C. Pour isoler les communs des Triac1 et

retirer le cavalier JP4.

D. Connecteurs débrochables

General Connection Diagram

Note

Installation, electric wiring and adjustments should conform to

local codes and must be carried out by authorized personnel

only. Users are reminded of their responsibility to ensure that

all Johnson Controls’ products are used safely, and without

risk to health and property.

101.6

Série SC-9100

#5; DDC Controller

with “Off Cycle” Defrost

Amb. Operating

Conditions

Input/Output

Fig. 2

2,

Schéma général de raccordement

Note

L’installation et le raccordement des produits doivent être

réalisés selon les normes en vigueur et les règles de l’art.

Il est rappelé qu’il est de la responsabilité de l’utilisateur

de s’assurer que les produits sont installés sans risque

pour les personnes et les biens.

Montage et Installation ( Fig. 1)

Montage sur panneau :

•

Glisser les pattes de montage (A) dans les logements.

Fixer à l’aide de vis Ø 4 mm.

Montage sur rail DIN :

•

Placer le régulateur sur la partie supérieure du rail et

appuyez pour l’encliqueter sur le rail Omega 35 mm.

Insérez un tournevis en (B) et tirez pour liberer.

Raccordements ( Fig. 2)

(voir “Note d’application”,pour obtenir le schéma correct

de raccordements)

•

Couper l’alimentation avant toute intervention afin d’éviter tout risque de déterioration ou électrocution.

•

Le circuit CMOS du régulateur est sensible à l’électricité statique. Prendre les précautions d’usage avant

toute intervention

•

Les raccordements s’effectuent par des bornes en

parties haute et basse de l’appareil. section 1.5 mm2

•

Dans les armoires il est nécessaire de séparer la basse tension du courant fort. Utilisez du fil blanc ou rose

pour faciliter le repérage.

•

Les liaisons doivent être aussi courtes que possible.

•

Eviter le cheminement des câbles près de sources de

rayonnement électromagnétique.

•

Le 24Vca doit être stable et indépendant de l’alimentation de charges inductives.

•

Tester soigneusement le câblage avantlamise sous

tension. Une erreur de câblage peut déteriorer l’appareil.

Calibres:

24 Vac ± 15%, 50/60 Hz

4 VA

EMC Directive 89/336/EEC

EN-50082-1

EN-50081-1 when mounted in

metal grounded cabinet

0 - 50° C, 10 - 90 R.H.

non-condensing

See “Product Data Sheet”

Repair and Replacement

Field repair is not recommended. If the control is not working

properly and all wiring is correct the control should be replaced. Please check with your nearest supplier.

Alimentation

Consommation

CE conformité

Conditions de

fonctionnement

Entrées/Sorties

24 Vca ± 15%, 50/60 Hz

4 VA

EMC Directive 89/336/EEC

EN-50082-1

EN-50081-1 lorsque monté

dans une armoire métallique

reliée à la terre

0 - 50° C, 10 - 90 H.R.

sans condensation

Voir notice technique

Reparations et remplacement

Il est déconseillé de réparer l’appareil sur site. En cas de

mauvais fonctionnement, après avoir vérifié le câblage,

remplacez l’appareil. Contactez Johnson Controls.

DEUTSCH

NEDERLANDS

ITALIANO

PORTUGUÊS

Kompakter Digitalregler

SC-9100

#5; DDC Regelaar

Serie SC-9100

SC-9100

Regolatore #5; DDC

Série SC-9100

Controlador DDC Simples

BITTE LESEN SIE DIESE ANWEISUNGEN VOR DER

INSTALLATION SORGFÄLTIG DURCH.

Wählen Sie vor der Installation des Geräts zunächst die

gewünschte Anwendung aus dem Anwendungshandbuch

aus. Beachten Sie den Verdrahtungsplan für die entsprechende Anwendung. Näheres hierzu finden Sie im Produktdatenblatt.

Abb. 1 SC-9100 Abmessungen und Montage

A. Halterungen

B. Kalteklammer

C. Zum Trennen der Bezugsspannungen von

Triac 1 und 2 Steckbrücke JP4 entfernen.

D. Lösbare Steckverbinder

Abb. 2 Allgemeiner Verdrahtungsplan

Hinweis

Installations-, Verdrahtungs- und Einstellarbeiten müssen

ent-sprechend den am Einsatzort geltenden Vorschriften

durch befugtes Personal vorgenommen werden. Es wird

darauf hin-gewiesen, daß der Anwender für den sicheren

Betrieb aller Produkte von Johnson Controls verantwortlich

ist, um Gesundheits-risiken oder Sachschäden zu vermeiden.

Montage und Installation (s. Abb. 1)

Oberflächenmontage:

•

Schieb die Halterungen (A) in die Führungen und befestig diese auf der Oberfläche mit selbstschneidenden

Schrauben mit 4mm Ø .

Montage auf DIN-schiene 35 mm.

•

Setz den Regler auf obere Ende der Schiene und

schnapp den Regler auf die schiene auf. Zum Lösen

führ einen Schrauben-dreher in die Halteklammer (B)

ein und drück nach oben.

Verdrahtung (s. Abb. 2)

(Den Verdrahtungsplan für die gewählte Anwendung finden

Sie unter dem entsprechenden Anwendungshinweis.)

•

Schalt vor Wartung oder Installationsarbeiten die Stromversorgung ab, um Schäden oder elektrische Schläge

zu vermeiden.

•

CMOS-Schaltungen können durch statische Entladungen beschädigt werden. Fass keine Bauteile an, ohne

entsprechende Vorkehrungen zu treffen.

•

Anschlüsse erfolgen über Klemmenleisten. Die Klemmen sind für Leiter bis zu 1,5 mm Ø geeignet.

•

Kleinspannungsleitungen und Netz- bzw. Stromversorgungsleitungen müssen räumlich voneinander getrennt

verlegt werden. Es wird empfohlen, für die Kleinspannungsleitungen eine unterschiedliche Kennfarbe (weiß

oder pink) zu verwenden.

•

Halt alle Leitungen so kurz wie möglich und befestig die

Kabelbäume.

•

Verleg keine Leitungen in unmittelbarer Nähe von

Transformatoren oder Hochfrequenzgeräten.

•

Stromversorgung mit 24 V muß stabil sein. Am Netzteil

dürfen keine anderen geschalteten induktiven Lasten

angeschlossen werden.

•

Überprüf vor Einschalten die Verdrahtung und die Anschlüsse. Durch Fehler bei der Verdrahtung können

NEEM DEZE INSTRUCTIES GRONDIG DOOR ALVORENS

TE BEGINNEN MET HET INSTALLEREN

Kies vóór het installeren van het regelaar de gewenste toepassing uit het "Application Manual" en raadpleeg het aansluitschema in de bijhorende "Application Note" Neem voor

meer informatie het "Product Data Sheet" door.

LEGGERE ATTENTAMENTE QUESTO FOGLIO PRIMA

DELL’INSTALLAZIONE

Prima di procedere all’installazione del dispositivo, selezionare

l’applicazione richiesta consultando il foglio “Nota Applicativa” che

contiene inoltre gli schemi elettrici di riferimento. Per ulteriori informazioni leggere il Bollettino Tecnico SC-9100.

Afb. 1

Afmetingen en montage van de SC-9100

A. Montagesteunen

B. Ontgrendelclip

C. Verwijder jumper JP4 om de gemeenschappelijke polen van de Triac 1 en Triac 2 te scheiden

D. Verwijderbare connectoren

Fig. 1

SC-9100 dimensioni e montaggio

A. Staffe per il montaggio a parete

B. Molla per il montaggio a Guida DIN

C. Per separare le uscite Triac 1 e 2 rimuovere

ponticello JP4

D. Morsetti removibili

Afb. 2

Algemeen aansluitschema

Fig. 2

Schema di collegamento generale

Opmerkingen:

De installatie, de elektrische aansluiting en de instellingen

dienen overeen te stemmen met de plaatselijke voorschriften

en mogen enkel worden uitgevoerd door bevoegd personeel.

De gebruiker moeten erop toezien dat de produkten van

Johnson Controls op een veilige manier en zonder gevaar

voor de gezondheid en persoonlijke eigendommen worden

gebruikt.

Montage en installatie (zie Afb. 1)

Voor oppervlaktemontage:

•

Schuif de 2 montagesteunen (A) in de overeenkomstige

sleuven van het regelaar. Zet het regelaar vast met de

zelftappende schroeven (Æ 4 mm).

Voor montage op DIN-rail:

•

Plaats de regelaar op de bovenste rand van de 35 mm

brede Omega-rail en klik hem vast. Om de regelaar te

verwijderen steekt u een schroevedraaier onderaan in de

clip (B) en tilt u hem uit de rail.

Aansluiting (zie Afb. 2)

(raadpleeg in de "Application Note" de toepassing in kwestie

voor het juiste aansluitschema)

•

Schakel bij het installeren of tijdens onderhoud de stroom

uit om beschadiging en/of elektrische schokken te voorkomen.

•

De CMOS-circuits van de regelaar zijn gevoelig voor statische elektriciteit. Neem daarom de nodige voorzorgs

maatregelen.

•

De draden worden aangesloten via de klemmenblokken

(geschikt voor draden tot 1,5 mm) boven- en onderaan de

regelaar.

•

De laagspanningsbedrading moet fysiek gescheiden zijn

van de netspannings- en stroombedrading; deze wordt het

beste in een afwijkende kleur (wit of roze) uitgevoerd.

•

Houd de kabels zo kort mogelijk en maak ze vast.

•

Houd de draden uit de buurt van transformatoren of van

apparatuur die hoge frequenties produceren.

•

De 24 V-voeding moet stabiel zijn en mag niet worden

gedeeld met andere geschakelde inductieve belastingen.

•

Werk de bedrading volledig af en controleer de aansluitpunten

alvorens u de stroom inschakelt. Een foutieve aansluiting kan

onherstelbare schade veroorzaken.

Nenndaten:

Versorgungsspannung 24 V ± 15%, 50/60 Hz

Leistungsaufnahme 4 W

CE Konformität EMK-Richtlinie 89/336/EEC

EN-50082-1

EN-50081-1 bei Montage im

einem geerdeten

Metallgehäuse

Betriebsumgebungs- 0 - 50 °C , rel. Luftfeuchtigkeit

bedingungen 10 - 90% nicht kondensierend

Eingang/Ausgang s. Produktdatenblatt

Kenmerken:

Voedingsspanning

Stroomverbruik

CE gelukvormigheid

Reparatur und Austausch

EineReparatur vor Ort wird nicht empfohlen. Wenn der Regler nicht einwandfrei funktioniert und die Verdrahtung keine

Fehler aufweist, muß der Regler ausgetauscht werden.

Wenden Sie sich hierzu an Ihren Lieferanten.

Reparatie en vervanging

Reparatie ter plaatse wordt niet aangeraden. Als het apparaat

niet naar behoren funktioneert dient het apparaat te worden

vervangen. Neem hiervoor contact op met uw dichtstbijzijnde

leverancier.

Bedrijfsomstandigheden

Input/Output

24 V ac ± 15%, 50/60 Hz

4VA

Directive EMC 89/336/EEC

EN-50082-1

EN-50081-1 wanner gemonteerd

in een geaarde metalen kast

0 - 50°C, 10 - 90% R.V.

niet condenserend

Zie "Product Data Sheet"

Nota:

L’installazione, il cablaggio elettrico e le regolazioni devono

essere conformi alle normative locali e devono essere eseguite esclusivamente da personale autorizzato. Si ricorda agli

utenti la loro responsabilità nel garantire che tutti i prodotti

Johnson Controls vengano usati in condizioni di sicurezza e

senza rischio per la salute e la proprietà

Montaggio e installazione (vedi Fig: 1)

Per il montaggio a parete:

•

Posizionare le 2 staffe di montaggio (A) sopra i relativi fori di

fissaggio. Fissare alla superficie usando viti autofilettanti

(diametro 4 mm).

Per il montaggio su Guida DIN:

•

Inserire il regolatore sul bordo superiore della Guida DIN ad

Omega da 35 mm e agganciare l’apposita molla (B). Per lo

smontaggio, inserire un cacciavite nella scanalatura della molla (B) e tirare verso il basso prima di sollevare il regolatore.

Cablaggio (Vedi fig.2)

Per il corretto schema elettrico fare riferimento alla nota applicativa relativa alla applicazione scelta.

•

Durante l’installazione o la manutenzione disattivare sempre l’alimentazione per prevenire danni o scosse elettriche.

•

I circuiti CMOS nel regolatore sono sensibili alle cariche

elettrostatiche. Non toccare i componenti prima di aver

preso le necessarie precauzioni.

•

Le morsettiere ai lati del regolatore sono adatte per collegare cavi fino a 1,5 mm².

•

I cavi a bassa tensione devono essere separati fisicamente dalla tensione di linea e dalla linea di potenza. Si

consiglia di usare un colore distintivo (bianco o rosa),

•

Tenere tutti i cavi più corti possibile e fissarli in posizione.

•

Non fare passare i cavi vicino ai trasformatori o a sorgenti

di alta frequenza.

•

L’alimentazione 24Vca deve essere stabile e non condivisa con altri carichi induttivi commutati.

•

Completare il cablaggio e controllare i collegamenti prima

di dare tensione. Un cablaggio errato potrebbe causare

danni permanenti.

Valori:

Tensione di alimentazione 24 Vca ± 15%, 50/60 Hz

Potenza assorbita 4VA

Conformità CE Direttiva EMC EEC/89/336

EN-50082-1

EN-50081-1 quando montato in un

contenitore metallico messo a terra

Condizioni ambientali

Ingressi/uscite

0 - 50°C, 10 - 90 R.H. senza operative

condensa

vedi “Bollettino Tecnico”

Riparazione e sostituzione

Si sconsiglia la riparazione in loco. Se il regolatore non funziona in modo adeguato e tutti i cavi sono collegati correttamente è consigliabile sostituirlo. Vi preghiamo di consultare il

rivenditore a voi più vicino.

LEIA ATENTAMENTE ESTA FOLHA DE INSTRUÇÕES ANTES DE PROCEDER À INSTALAÇÃO

Antes de instalar o aparelho. Primeiro, escolha a aplicação

necessária na "Folha de Dados do Produto" e consulte o

diagrama das ligações na "Nota sobre a Aplicação" relativa

à aplicação. Para mais informações, leia a "Folha de Dados

do Produto".

Fig.1

Dimensões e Montagem do SC-9100

A. Suportes de Montagem

B. Grampo de Libertação

C. Para separar Triac 1 de Triac 2, retire a ficha

JP4.

D. Placas de ligação amovíveis.

Fig.2

Diagrama Geral de Ligações

Nota

A instalação, a ligação eléctrica e os ajustes devem fazerse de acordo com os códigos locais e devem ser realizados apenas por pessoal autorizado. Lembramos os utilizadores da sua responsabilidade em assegurarem que todos

os produtos de Controlo Johnson sejam usados com segurança e sem riscos pessoais e materiais.

Montagem e Instalação (ver Fig.1)

Para montagem sobre uma superfície:

•

Encaixe 2 suportes de montagem (A) nas ranhuras.

Fixe à superfície com os parafusos auto-roscantes de

4 mm. de diâmetro.

Para montagem em calha DIN:

•

Coloque o controlador na aba superior da calha e encaixe o controlador na calha Omega de 35 mm. Para

soltar, introduza uma chave de fendas no grampo (B)

da base e puxe.

Ligação eléctrica (Ver Fig.2)

(veja "Nota sobre a Aplicação", relacionada com esta aplicação para obter o diagrama de instalação eléctrica correcta)

•

Desligue o fornecimento de energia eléctrica quando

estiver a instalar ou a reparar para evitar danos ou choques eléctricos.

•

Os circuitos CMOS do controlador são sensíveis à

electricidade estática. Não toque nos componentes

sem tomar precauções adequadas.

•

As ligações são feitas através dos blocos terminais, na

parte de cima e de baixo do controlador, que aceitam

fios até 1,5 mm2.

•

A instalação eléctrica de baixa tensão tem que estar

fisicamente separada das linhas de tensão de alimentação e de potência, e é recomendável uma côr distinta

(branco ou rosa).

•

Assegure-se de que todos os cabos têm o menor comprimento possível e mantenha-os bem fixos.

•

Não coloque cabos perto de transformadores ou de

equipamento gerador de alta frequência.

•

O fornecimento de 24 V tem que ser estável e não pode ser partilhado com outras cargas indutivas.

•

Complete a instalação eléctrica e verifique as ligações

antes de ligar a corrente. Uma instalação eléctrica incorrecta pode causar danos irrecuperáveis.

Capacidades:

Voltagem fornecida

Consumo de energia

CE conformidade

24 Vac + 15%, 50/60 Hz

4 VA

Directiva EMC 89/336/EEC

EN-50082-1

EN-50081-1quando

montados num quadro

ligado à terra

Condições Amb. de 0 - 50°C, 10 - 90 Taxa de

Funcionamento Humidade não condensada

Entrada/Saída Ver "Folha de Dados do

Produto"

Reparação e Substituição

Não é recomendável a reparação no local. Se o controlo não está a funcionar correctamente e toda a instalação eléctrica estiver correcta, o controlo deve ser

substituído. É favor consultar o seu fornecedor.

POLSKO

CĚSKO

£©©¥«§¨

Sterownik

Automatický regulátor s přímým číslicovým řízením #5; Řady SC-9100

±ÃÇϺ 7'

£ÛÕÏÅÑÒÍÐ £ÉÃÁÈҼР(('

#5; DDC serii SC-9100

PRZED INSTALACJ¥ URZ¥DZENIA NALEŻY

UWAŻNIE PRZECZYTAĆ TÊ INSTRUKCJÊ.

Przed instalacj¹ urz¹dzenia należy z "Karty katalogowej

urz¹dzenia" wybrać potrzebne zastosowanie i zapoznać

siê ze schematem poł¹czeń w "Biuletynie aplikacyjnym" dotycz¹cym danego zastosowania. Dodatkowe

informacje można znaleźć w "Karcie katalogowej urz¹dzenia".

Rys.1 Wymiary i montaż sterownika SC-9100

A. Uchwyty montażowe.

B. Ruchomy zatrzask.

C. Aby oddzielić przewody masy wyjść Triaka

1 i Triaka 2, należy usun¹ć zworê JP4.

D. Ruchome zł¹cza.

Rys.2 Ogólny schemat poł¹czeń.

Uwaga

Instalacja, okablowanie i kalibracja powinny być przeprowadzone zgodnie z PN i mog¹ być wykonywane tylko przez upoważniony personel. Użytkownikom przypomina siê, że s¹ odpowiedzialni za zapewnienie bezpiecznej eksploatacji sterowników firmy Johnson Controls, nie zagrażaj¹cej zdrowiu ani mieniu.

Montaż i instalacja (patrz rys. 1)

Montaż naścienny:

•

Wsuń dwa uchwyty montażowe (A) w szczeliny.

Umocuj urz¹dzenie do powierzchni montażowej za

pomoc¹ wkrêtów o średnicy 4 mm.

Montaż na szynie DIN:

•

Umieść sterownik na górnej krawêdzi 35 mm szyny

Omega i dociśnij do zatrzaśniêcia. W celu demontażu wsuń śrubokrêt w otwór zatrzasku (B) u podstawy i przesuń zatrzask do dołu do wypiêcia z szyny.

Okablowanie (patrz rys. 2)

(Aby znaleźć poprawny schemat poł¹czeń zapoznaj siê

z "Biuletynem aplikacyjnym" zwi¹zanym z danym zastosowaniem)

•

•

•

•

•

•

•

•

•

Aby podczas instalacji lub obsługi urz¹dzenia unikn¹ć

porażenia elektrycznego, wył¹cz zasilacz.

Układy scalone CMOS znajduj¹ce siê w urz¹dzeniu s¹

wrażliwe na wyładowania elektrostatyczne.

Nie należy dotykać elementów urz¹dzenia bez podjêcia

odpowiednich środków ostrożności.

Wyprowadzenia s¹ wykonane w postaci kostek

zł¹czowych umieszczonych na górze i na dole urz¹dzenia, do których można podł¹czać przewody o

przekroju do 2,5 mm2.

Okablowanie niskiego napiêcia wewn¹trz szafki automatyki musi być fizycznie odseparowane od przewodów

sieciowych i zasilaj¹cych. Zaleca siê stosowanie różnych

kolorów przewodów.

Należy stosować możliwie najkrótsze przewody i mocować je w wi¹zkach do elementów konstrukcyjnych.

Nie wolno układać przewodów w pobliżu transformatorów ani urz¹dzeń generuj¹cych wysokie czêstotliwości.

Zasilacz 24 V nie powinien zasilać innych przeł¹czanych

obci¹żeń o charakterze indukcyjnym i zapewnić stabilność zasilania w granicach +15% -10%.

Przed wł¹czeniem zasilania należy zakończyć okablowanie i sprawdzić poł¹czenia. Błêdne poł¹czenie może

Dane znamionowe:

PŘED ZAHÁJENÍM INSTALACE SI PEČLIVĚ PŘEČTĚTE

TENTO SEZNAM POKYNŮ

Před zahájením instalace zařízení si nejprve vyberte potřebnou aplikaci ze "Seznamu údajů o produktu" a prostudujte si schéma zapojení v "Poznámce o aplikaci",

která se na danou aplikaci vztahuje.

Další informace naleznete v "Seznamu údajů o produktu".

Obr. 1 Rozměry a připevnění SC-9100

A. Montážní závěsy

B. Uvolňovací svorka

C. Při oddělování společných spojů triaku 1 a

triaku 2 odstraňte můstek JP4.

D. Odstranitelné konektory

Obr. 2 Všeobecné schéma zapojení

Poznámka

Instalace, elektrické zapojení a úpravy by měly být v

souladu s místními předpisy a musí být prováděny pouze

schváleným personálem. Uživatelům připomínáme jejich

odpovědnost při zajištění toho, že všechny produkty společnosti Johnson Controls' se používají bezpečně a bez

ohrožení zdraví a majetku.

Montáž a instalace (viz Obr. 1)

Pro montáž na povrchu:

•

Zasuňte 2 montážní závěsy (A) do drážek. Připevněte

k povrchu pomocí závitořezných šroubů o průměru 4

mm.

Pro montáž na kolejnici DIN:

•

Umístěte regulátor na horní okraj kolejnice a zaklapnutím zajistěte regulátor na 35 mm kolejnici Omega. Při

uvolňování zasuňte šroubovák do svorky (B) na úrovni

základny a zmáčkněte.

Zapojení (viz Obr. 2)

(viz "Poznámka o aplikaci", která se vztahuje ke skutečné

aplikaci kvůli schématu správného zapojení)

•

Vypněte zdroj proudu při instalaci nebo opravách, aby

se zabránilo poškození nebo úrazu elektrickým proudem.

•

Obvody CMOS v regulátoru jsou citlivé na statickou

elektřinu. Nedotýkejte se součástek, aniž byste podnikli vhodná bezpečnostní opatření.

•

Vývody jsou vyvedeny přes svorkovnice na horní a

spodní straně regulátoru, které pojmou dráty až do

průřezu 1,5 mm2.

Zapojení nízkého napÀtí musí být fyzicky oddÀleno od

•

napÀtí linky i rozvodu napájení a doporu³uje se pou©it

odlišnou barvu (bílá nebo rÖ©ová).

•

Všechny kabely udržujte co nejkratší a svažte je v příslušné poloze.

•

Neveïte kabely poblíž transformátorů nebo zařízení,

která produkují vysoké kmitočty.

•

Zdroj 24 V musí být stabilní a nesmí být sdílen s jinými

spínanými indukčními zatíženími.

•

Dokončete zapojení a zkontrolujte spoje před zapnutím

proudu. Nesprávné zapojení může způsobit neopravitelnou škodu.

Jmenovité výkony:

¢§ ±²£ ³² ² ´³©©¢§ ¢¥¡§·« ®¯±£¨

²§¨ ®¯§« ® ²¥« £¡¨²±²±¥

ÎÆÊ ¾ÍÙ ÑÄÊ ÂÀǾѹÐѾÐÄ ÑÄÏ ÁƹѾËÄÏ ÎÛѾ ÂÍÆȺËÑ ÑÄÊ

ÂÓ¾ÎÉÌÀ» ÍÌÒ ÔÎÂƹÃÂÐÑ ¾ÍÙ ÑÌ ³ÒÈȹÁÆÌ ¡ÂÁÌɺÊÖÊ ÎÌ×

XÊÑÌÏ Ç¾Æ ÐÒÉ¿ÌÒÈÂÒѼѠÑÌ ÁƹÀξÉɾ ÐÒÊÁÂÐÉÌÈÌÀ¼¾Ï ÐÑÄÊ

°ÄɼÖÐÄ ¢Ó¾ÎÉÌÀ»Ï ÍÌÒ ¾Ê¾ÓºÎÂÑ¾Æ ÐÑÄÊ ÂÓ¾ÎÉÌÀ» ƾ

ÍÂÎÆÐÐÙÑÂÎÂÏ ÍÈÄÎÌÓÌμÂÏ Áƾ¿¹ÐÑ ÑÌ ³ÒÈȹÁÆÌ ¡ÂÁÌɺÊ

ÖÊ ÎÌ×ÙÊÑÌÏ

±Õ 7' ¢Ç¿ÑÒºÑÃÇÐ È¿Ç ²ÍÎÍÆ»ÒÅÑÅ

²ÍÌÁÌÔºÏ ÍÎÌоÎÉÌÀ»Ï

ÐÓ¹ÈÂƾ ¾ÍÂÈÂÒźÎÖÐÄÏ

' ƾ ÑÌÊ ÁƾÔÖÎÆÐÉÙ ÑÖÊ ÇÌÆÊÛÊ ÑÖÊ 7ULDF ǾÆ

Směrnice EMC 89/336/EEC

EN-50082-1

EN-50081-1 když je namontován

v kovové uzemněné skříni

0 - 50 °C, relativní vlhkost

10 - 90 %, nekondenzující

°ÒÉÉÙÎÓÖÐÄ ((

Patrz "Karta katalogowa

urz¹dzenia".

Naprawa i wymiana.

Nie zaleca siê napraw podł¹czonego sterownika.

Jeśli sterownik nie działa poprawnie, a całe okablowanie jest prawidłowe, należy go wymienić. W

tym celu należy siê skontaktować z dostawc¹.

Vstup/výstup

Wejścia / Wyjścia

Viz "Seznam údajů o produktu"

Opravy a výměny

Opravy na místě provozu se nedoporučují. Jestliže regulace řádně nefunguje a veškeré zapojení je v pořádku, je

třeba regulátor vyměnit. Spojte se, prosím, s Vaším

nejbližším dodavatelem.

Allmänt kopplingsschema

Tekniska data:

v souladu s podpisy CE

Provozní parametry

prostředí

Fig. 2

ËÍÊ¿ÑÒÇȻРÒÇÊ»Ð

Zalecenic EMC 89/336/EEC

EN-50082-1

EN-50081-1 gdy zamonotowany w

uziemionej szafce

0-50 °C, 10 - 90 % wilgotnośc

wzglêdnej, bez kondensacji

Warunki pracy

SC-9100 Dimensioner och montering

A. Monteringskonsoler

B. Snäpplås

C. För att skilja triac 1 och triac 2 gemensamma anslutning, lossas bygling JP4

D. Demonterbara anslutningar

Anm.:

Installation, elektrisk kabeldragning och justeringar skall

utföras enligt lokala bestämmelser och måste göras av

behörig personal. Användaren erinras om sin skyldighet

att tillse att alla Johnson Controls produkter används på

ett säkert sätt och utan risk för hälsa eller egendom.

±¹ÐÄ ¾ÎÌÔ»Ï

Zgodnośc z

normami WF

Fig. 1

¤ ÂÀǾѹÐѾÐÄ ÌÆ ÄÈÂÇÑÎÆÇºÏ Ç¾ÈÖÁÆÛÐÂÆÏ Ç¾Æ ÎÒÅɼÐÂÆÏ Å¾

ÍκÍÂÆ Ê¾ ÐÒÉÉÌÎÓÛÊÌÊÑ¾Æ É ÑÌÒÏ ÑÌÍÆÇÌÚÏ Ç¾ÊÌÊÆÐÉÌÚÏ Ç¾Æ

ž ÍκÍÂÆ Ê¾ ÍξÀɾÑÌÍÌÆÌÚÊÑ¾Æ ÉÙÊÌ ¾ÍÙ ¾ÎÉÙÁÆÌ

ÍÎÌÐÖÍÆÇÙ ²ÍÂÊÅÒɼÃÌÒÉ ÐÑÌÒÏ ÔλÐÑÂÏ Àƾ ÑÄÊ ÂÒÅÚÊÄ ÑÌÒÏ

ʾ ¿Â¿¾ÆÖÅÌÚÊ ÙÑÆ ÙȾ Ѿ ÍÎÌ×ÙÊѾ ¢ÈºÀÔÌÒ -RKQVRQ ÍκÍÂÆ

ʾ ÔÎÄÐÆÉÌÍÌÆÌÚÊÑ¾Æ É ¾ÐÓ¹ÈÂƾ Ç¾Æ ÔÖÎ¼Ï ÑÌÊ Ç¼ÊÁÒÊÌ Ñξ

ÒɾÑÆÐÉÌÚ Ç¾Æ ÒÈÆÇÛÊ ÃÄÉÆÛÊ

®ÏÍÑ¿ÏÊÍÁ¼ È¿Ç ÃÁÈ¿ÒºÑÒ¿ÑÅ ¿ÈºÍ °Ô ƾ ÍÎÌоÎÉÌÀ» РÂÍÆÓ¹ÊÂƾ

±ÌÍÌÅÂÑ»ÐÑ ÑÆÏ ÁÒÌ ÒÍÌÁÌÔºÏ ÍÎÌоÎÉÌÀ»Ï ɺо

•

ÐÑÆÏ

ÂÀÇÌͺÏ

°ÑÂÎÂÛÐÑÂ

ÑÌ

ÐÑÄÊ

ÂÍÆÓ¹ÊÂƾ

ÔÎÄÐÆÉÌÍÌÆÛÊÑ¾Ï ÑÆÏ ¿¼ÁÂÏ ÂÚÇÌÈÄÏ ÑÌÍÌźÑÄÐÄÏ ³ PP

ƾ ÍÎÌоÎÉÌÀ» РιÀƾ ',1

±ÌÍÌÅÂÑ»ÐÑ ÑÌÊ ÂÈÂÀÇÑ» ÐÑÌ ¹ÊÖ ¹ÇÎÌ ÑÄÏ Î¹ÀÆ¾Ï Ç¾Æ

•

¾ÐӾȼÐÑ ÑÌÊ ÂÈÂÀÇÑ» ͹ÊÖ ÐÑÄ Î¹Àƾ PP ÑÚÍÌÒ 2PH

JD ƾ ʾ ÑÌÊ ¾ÍÂÈÂÒÅÂÎÛÐÂÑ ÑÌÍÌÅÂÑ»ÐÑ ºÊ¾

ǾÑо¿¼ÁÆ ÉºÐ¾ ÐÑÄÊ ¾ÐÓ¹ÈÂƾ ÑÄÏ ¿¹ÐÄÏ Ç¾Æ Ñξ¿»ËÑÂ

ÍÎÌÏ Ñ¾ ºËÖ

¨¿É×ÂÇÜÑÃÇРȺÍ °Ô ¿ÈºÍ °ÄɼÖÐÄ ¢Ó¾ÎÉÌÀ»Ï ÍÌÒ ¾Ê¾ÓºÎÂÑ¾Æ ÐÑÄ ÐÔÂÑÆÇ»

ÂÓ¾ÎÉÌÀ» Àƾ ÑÌ Ç¾Ñ¹ÈÈÄÈÌ ÁƹÀξÉɾ ǾÈÖÁÆÛÐÂÖÊ

§È¼ÐÑ ÑÄÊ ÄÈÂÇÑÎÆÇ» ;ÎÌÔ» Ǿѹ ÑÄÊ ÂÀǾѹÐѾÐÄ » ÑÄÊ

•

ÐÒÊÑ»ÎÄÐÄ Àƾ ʾ ¾ÍÌÓÚÀÂÑ ¿È¹¿Ä » ÄÈÂÇÑÎÌÍÈÄ˼¾

±¾ ÇÒÇÈÛɾѾ &026 ÑÌÒ ÂÈÂÀÇÑ» Â¼Ê¾Æ ÂÒ¾¼ÐÅÄѾ ÐÑÌ

•

ÐѾÑÆÇÙ ÄÈÂÇÑÎÆÐÉÙ ©ÄÊ ¾ÇÌÒÉ͹Ñ Ѿ Â˾ÎѻɾѾ ÔÖμÏ

ʾ ͹ÎÂÑ ǾѹÈÈÄÈÂÏ ÍÎÌÓÒȹËÂÆÏ

¬Æ ÐÒÊÁºÐÂÆÏ ÑÖÊ ¾ÇÎÌÁÂÇÑÛÊ ÍξÀɾÑÌÍÌÆÌÚÊÑ¾Æ ÉºÐÖ

•

ÑÖÊ ÑÂÎɾÑÆÇÛÊ ÐÒÀÇÎÌÑÄɹÑÖÊ ÐÑÌ Í¹ÊÖ Ç¾Æ Ç¹ÑÖ ÉºÎÌÏ

ÑÌÒ ÂÈÂÀÇÑ» Ç¾Æ ÁºÔÌÊÑ¾Æ Ç¾ÈÛÁƾ ɺÔÎÆ PP

¬Æ ǾÈÖÁÆÛÐÂÆÏ Ô¾ÉÄÈ»Ï Ñ¹ÐÄÏ ÐÑÌÒÏ ÄÈÂÇÑÎÆÇÌÚÏ Í¼Ê¾ÇÂÏ

•

ÍκÍÂÆ Ê¾ ÔÖμÃÌÊÑ¾Æ ÉÄÔ¾ÊÆǹ ¾ÍÙ ÑÄ ÀξÉÉ» ѹÐÄÏ Ç¾Æ

ÑÆÏ Ç¾ÈÖÁÆÛÐÂÆÏ ÑÎÌÓÌÁÌм¾Ï Ç¾Æ ÐÒÊÆÐÑÌÚÉ ºÊ¾

ËÂÔÖÎÆÐÑÙ ÔÎÛɾ ÈÂÒÇÙ » ÎÌÃ

¡Æ¾ÑÄμѠÙȾ Ѿ ǾÈÛÁƾ É ÙÐÌ ÑÌ ÁÒʾÑÙ ÍÆÌ ÉÆÇÎÙ

•

É»ÇÌÏ Ç¾Æ ÐÑÂÎÂÛÐÑ Ѿ ÐÑÄ ÅºÐÄ ÑÌÒÏ ©ÄÊ ÍÂÎʹÑ Ǿ

HÛÁƾ ÇÌÊѹ ¾ÍÙ ÑÌÒÏ ÉÂѾÐÔÄɾÑÆÐÑºÏ » ¾ÍÙ ÂËÌÍÈÆÐÉÙ

;ξÀÖÀ»Ï ÒÕÄÈÛÊ ÐÒÔÊÌÑ»ÑÖÊ

¤ ;ÎÌÔ» ÑÖÊ 9 ÍκÍÂÆ Ê¾ Â¼Ê¾Æ ÐѾÅÂλ Ç¾Æ ÁÂÊ ÍκÍÂÆ

•

ʾ ÑÎÌÓÌÁÌѼ ¹ÈȾ ÉÂѾÀÙÉÂʾ Â;ÀÖÀÆǹ ÓÌÎѼ¾

¬ÈÌÇÈÄÎÛÐÑ ÑÆÏ Ç¾ÈÖÁÆÛÐÂÆÏ Ç¾Æ ÂȺÀËÑ ÑÆÏ ÐÒÊÁºÐÂÆÏ

•

ÍÎÌÑÌÚ ÐÒÊÁºÐÂÑ ÑÌ ÄÈÂÇÑÎÆÇÙ ÎÂÚɾ ¨¾ÊžÐɺÊÄ ÐÒÊ

ÁÂÐÉÌÈÌÀ¼¾ ÉÍÌμ ʾ ÍÎÌǾȺÐÂÆ ÉÙÊÆÉÄ ¿È¹¿Ä

24 V střídavých ±15 %, 50/60 Hz

4 VA

24 V ±15% -10%, 50 / 60 Hz

4 VA

Serie SC-9100

Easy DDC Styrenhet

Läs noga dessa installationsanvisningar innan installationen utförs.

Den erforderliga applikationen väljs innan utrustningen

installeras med hjälp av ”Produktdatablad” och kopplingsschemat återfinns i den ”Injusteringsmanual” som hänför

sig till applikationen. För ytterligare information, se

”Produktdatabladet”.

7ULDF ¾Ó¾ÆκÐÑ ÑÄ ÀºÓÒξ -3

( Ó¾ÆÎÌÚÉÂÊÂÏ ÐÒÊÁºÐÂÆÏ

±Õ ¡ÃËÇÈÚ ¢ÇºÁÏ¿ÊÊ¿ ±ÓËÂÃÑÊÍÉÍÁ½¿Ð

±ÅÊý×ÑÅ

Napájecí napětí

Spotřeba elektrické

energie

Napiêcie zasilania

Pobór mocy

pobieran¹ przez

SVENSKA

¤ÈÂÇÑÎÆÇ»

§¾Ñ¾Ê¹ÈÖÐÄ

°ÒÊÅ»ÇÂÏ ÂÎÆ¿¹È

¨ÂÆÑÌÒÎÀ¼¾Ï

¢¼ÐÌÁÌÏ¢ËÌÁÌÏ

9$& +]

9$

¬ÁÄÀ¼¾ (0& ((&

(1

(1 ÙÑ¾Ê ÑÌÍÌÅÂÑÄż ÐÂ

ÉÂѾÈÈÆÇÙ ÀÂÆÖɺÊÌ ÂÎɹÎÆÌ

& ÐÔÂÑ ÒÀξм¾ ÔÖÎ¼Ï ÒÀÎÌÍ̼ÄÐÄ ÒÁξÑÉÛÊ

ȺÍ ³ÒÈȹÁÆÌ ¡ÂÁÌɺÊÖÊ

ÎÌ×ÙÊÑÌÏ

£ÎÇÑÈÃÓ¼ È¿Ç ËÒÇÈ¿ÒºÑÒ¿ÑÅ

¤ ÂÍÆÐÇÂÒ» ÐÑÌÊ ÔÛÎÌ ÂÀǾѹÐѾÐÄÏ ÁÂÊ ÐÒÊÆÐÑ¹Ñ¾Æ Ê Ì

ÂÈÂÀÇÑ»Ï Á ÈÂÆÑÌÒÎÀ¼ ÐÖÐѹ Ç¾Æ ÙÈÂÏ ÌÆ ÐÒÊÁºÐÂÆÏ Â¼Ê¾Æ

ÐÖÐÑºÏ Ì ÂÈÂÀÇÑ»Ï Å¾ ÍκÍÂÆ Ê¾ ¾ÊÑÆǾѾÐѾż °ÒÉ¿ÌÒ

HÂÒѼѠÑÌÊ ÍÎÌÉÄÅÂÒÑ» оÏ

Montering och installation (se fig. 2)

För väggmontering:

Skjut på 2 monteringskonsoler (A) i slitsarna. Fäst vid

•

ytan med hjälp av 4 mm självgängande skruvar.

För montering på DIN-skena:

Placera styrenheten på skenans överkant och snäpp

•

fast styrenheten på 35 mm Omega-skenan. Lossa

styrenheten genom att sticka in en skruvmejsel i

snäpplås (B) vid underkanten och dra.

Kabeldragning (se fig. 2)

(Se den ”injusteringsmanual” som hänför sig till den aktuella applikationen för att få korrekt kopplingsschema)

Koppla bort strömförsörjningen före installation eller

•

service för att förhindra skador eller elektrisk stöt.

CMOS-kretsarna i styrenheten är känsliga för statisk

•

elektricitet. Vidrör inte komponenterna utan att vidta

lämpliga säkerhetsåtgärder.

Anslutningar görs via kopplingsplintarna längst upp

•

och längst ner på styrenheten, som är anpassad för

upp till 1,5 mm2 kabel.

Kabeldragning för lågspänning måste vara fysiskt se•

parerad från nätspänning och kraftförsörjning och det

rekommenderas att sådana kablar tilldelas en distinkt

färg (vit eller rosa).

Se till att alla kablar görs så korta som möjligt och fäst

•

dem väl.

Låt inte kablar löpa nära transformatorer eller högfrek•

vensgenererande utrustning.

24 V matning måste vara stabil och får ej delas med

•

andra omkopplade induktiva laster.

Slutför kabeldragningen och kontrollera anslutningar•

na innan strömmen slås på. Felaktig kabeldragning

kan orsaka bestående skada.

Matningsspänning

Strömförbrukning

CE-överensstämmelse

Miljövillkor

Ingång/utgång

24 VAC ±15%, 50-60 Hz

4 VA

EU direktiv 89/336/EEC

EN-50082-1

EN-50081-1 vid montering i

ett jordat metallskåp

0-50°C, 10-90 rel.

icke kondenserande

fuktighet

Se ”Produktdatablad”

Reparation och byte

Reparation på fältet rekommenderas ej. Om styrningen

inte fungerar tillfredsställande och all kabeldragning är

korrekt utförd, skall styrningen bytas. Var vänlig rådgör

med närmaste leverantör.

DANSK

NORSK

Serie SC-9100

#5; DDC-regulator

Serie SC-9100

#5; DDC-regulator

LÆS DENNE VEJLEDNING GRUNDIGT FØR INSTALLATION.

Før regulatoren installeres, vælges den aktuelle applikation fra produktdatablad. Se koblingsskemaet som

vedrører den valgte applikation. For yderligere oplysninger henvises til produktdatablad.

LES DENNE VEILEDNINGEN GRUNDIG FØR INSTALLERING.

Før enheten installeres, velges først den aktuelle applikasjonen fra produktdatabladet. Se koplingsskjemaet som tilhører

den valgte applikasjonen. Ytterligere opplysninger finnes i

produktdatabladet.

Fig. 1

SC-9100 Mål og montering

A. Montageklemmer

B. Udløseklemme

C. For at koble fra Triac 1 og Triac 2, fjernes

bøjle JP4.

D. Aftagelige kontakter

Fig 1

SC-9100 Mål og montering

A. Festebraketter

B. Utløserklemme

C. For å kople fra Triac 1 og Triac 2, fjern bøyle

JP4.

D. Avtakbare kontakter

Fig 2

Generelt koblingsskema

Fig 2

Generelt koblingsskjema

Bemærk.

Installation, kabling og justeringer skal udføres i henhold til lokale foreskrifter og må kun udføres af autoriseret personale. Vi gør opmærksom på brugerens ansvar for at sikre at alle produkter fra Johnson Controls

anvendes på en sikker måde og uden fare for personer

eller ejendom.

Montage og installation (se Fig. 1)

Montage på væg:

•

Før to montageklemmer (A) ind i sporene. Fastgør

på væggen med selvskærende Ø 4 mm skruer.

Montage på DIN-skinne:

•

Placer regulatoren på skinnens øverste kant og

tryk regulatoren fast i Omega-skinnen på 35 mm.

Den løsnes ved at stikke en skruetrækker ind i klipsen (B) i bundpladen og kan derefter trækkes ud.

Eldiagram (se Fig. 2)

(se vejledning i forbindelse med den aktuelle anvendelse og find det riktig koblingsskema)

•

Afbryd forsyningsspændingen ved installation eller

service for at undgå skader eller elektrisk stød.

•

CMOS-kredsene i regulatoren er følsomme for statisk elektricitet. Berør ikke komponenterne uden

forholdsregler.

•

Kobling udføres på klemmene i regulatorens top og

bund. Hver klemme er beregnet for maks. 1,5 mm²

ledning.

•

Ledningsføring for lavspænding skal være fysisk

separeret fra forsyningspænding og hovedstrøskredse. Det anbefales at sådanne ledere tildeles

entydig farvemærkning.

•

Hold alle kabler så korte som muligt og fastgør

dem.

•

Kablene må ikke fremføres i nærheden af transformatorer eller højfrekvent udstyr.

•

Spændingsforsyningen på 24 V skal være stabil og

ikke deles med andre induktive belastninger.

•

Færdiggør kablingen til regulatoren før forsyningsspændingen tilsluttes. Fejlforbindelser kan

forårsage varig skade.

Elektriske data:

Forsyningsspænding

Strømforbrug

I overensstemmelse

med CE

24 VAC + 15 %, 50/60 Hz

4 VA

EMC direktiv 89/336/EEC

EN-50082-1

EN-50081-1 monteret i et

metalbaseret kabinet

Driftsmiljø 0-50 °C, 10-90 % RF (ikkekondenserende)

Indgange/udgange Se Produktdatablad

Reparationer og udskifting

Reparation på anlægget anbefales ikke. Hvis regulatoren ikke fungerer som den skal og alle koblinger er korrekte, bør regulatoren skiftes. Kontakt nærmeste leverandør.

Merk

Installering, kabling og justeringer skal utføres i samsvar med

lokale forskrifter og må bare utføres av autorisert personell.

Vi minner om brukerens ansvar for å sikre at alle produkter

fra Johnson Controls brukes på en sikker måte og uten fare

for personer eller eiendom.

Montering og installering (se Fig 1)

Montering på flate:

•

Før to festebraketter (A) inn i sporene. Festes til flaten

med selvgjengende Ø 4 mm skruer.

Montering i DIN-skinne:

•

Plasser regulatoren på skinnens øvre kant og smekk regulatoren fast i Omega-skinnen på 35 mm. For å løsne

den stikkes en skrutrekker inn i klipset (B) i bunnplaten og

den trekkes ut.

Kabling (se Fig 2)

(se Brukertips i forbindelse med den aktuelle bruken for å

finne riktig koplingsskjema)

•

Bryt strømtilførselen ved installering eller service for å

unngå skader eller elektrisk støt.

•

CMOS-kretsene i regulatoren er følsomme for statisk

elektrisitet. Berør ikke komponentene uten forholdsregler.

•

Kopling utføres i klemmene i regulatorens topp og bunn.

Hver klemme er beregnet for maks. 1,5 mm² ledning.

•

Kabelføring for svakstrøm må være fysisk separert fra

nettspenning, samt kraftforsyning. Det anbefales at slike

kabler får entydig fargekode (eks. hvit eller rosa).

•

Hold alle kabler så korte som mulig og fest dem på plass.

•

Kablene må ikke trekkes i nærheten av transformatorer

eller høyfrekvent utstyr.

•

Spenningsforsyningen på 24 V må være stabil og ikke

deles med andre induktive belastninger.

•

Fullfør kablingen og regulator forbindelsene før strømmen

slås på. Feil kabling kan forårsake varig skade.

Elektriske data:

Tilførselsspenning

Strømforbruk:

CE-overensstemmelse

Driftsmiljø

24 VAC + 15 %, 50/60 Hz

4 VA

EU-direktiver 89/336/EEC

EN-50082-1

EN-50081-1 ved montering i et

jordet metallskåp

0-50 °C, 10-90 % RF (ikkekondenserende)

Innganger/utganger Se Produktdatablad

Reparasjoner og utskifting

Feltreparasjon anbefales ikke. Hvis regulatoren ikke fungerer

som den skal og alle koplinger er korrekte, bør regulatoren

skiftes. Kontakt nærmeste leverandør.

Schaltbefehle und Stellungen manuell vorgeben

24-85638-1109

Der Benutzer kann verschiedene Schaltbefehle und Stellungen vorgeben.

Die Bedienung erfolgt wie unter Bedienung 1. Stufe beschrieben.

Auf der letzten Seite erscheint der Text Zugriff Taste Eingeben Stufe 2. Die y Taste ca. 10 Sek. gedrückt halten bis

der Text Zugriff Taste Eingeben Stufe 2 blinkt und dann die y Taste loslassen. Es erscheint z.B. der Text

Anwendung 06

SC1243

SC--9100

Installationsanweisung

Mit den y oder b Tasten den gewünschten Schalt-- oder Stellbefehl in dieser Anwendung anwählen. Die E Taste

betätigen und mit den y oder b Tasten (z.B. die Ventilstellung auf 100 % stellen oder die VE--Pumpe AUS schalten)

die Änderung vornehmen und mit der E Taste bestätigen. Wenn sich einer der Ausgänge im Hold--Modus (manuell)

befindet, wird im Eingangsfenster ein blinkendes ”m” angezeigt

AI 1

AI 2

0/10V

0/10V

+

--

+

+15Vdc

--

11 12 13 14 15

HEIZUNG VENTIL

”m”

100%

NTC

Bedienung 3. Stufe

N TC

11 12 13 14 15

AI 3

AI 4

NTC

NTC

DI 1

21 22 23 24

DI 2

31 32 33 34

N2 Bus

sh comRT+ RT-RS--485

Auf der 3. Bedienstufe können Klar-- und Zustandstexte neu zugewiesen und Berechtigungen zum Verändern von

Parametern vergeben werden. Diese Änderungen sollten nur von qualifizierten und eingewiesenen Personal

vorgenommen werden. Die 3. Bedienstufe ist paßwortgeschützt. Fragen Sie ggf. hierzu Ihren Ansprechpartner.

+15Vdc

COM

AI C OM

Die 3. Bedienstufe kann jederzeit durch betätigen der C Taste wieder verlassen werden.

JP 4

AO COM

Klar-- oder Zustandstexte neu zuweisen

Der Benutzer kann die Klar-- und Zustandstexte (z.B. Frostschutz = NORMAL oder AUS) sowie die Berechtigung zum

Verändern von Parametern, die vom gewählten Anwendungsprogramm vorgegeben werden, neu zuweisen.

82 81

74 73 72 71

62 61

-- +

Die Bedienung erfolgt wie unter Bedienung 1. Stufe beschrieben.

REL

TR 1

TR 2

AO 2

54 53 52 51

-- +

42 41

-- +

COM

AO 1.2 AO 1.1

Die y Taste ca. 10 Sek. gedrückt halten bis der Text Zugriff Taste Eingeben Stufe 2 blinkt und dann die b Taste

loslassen. Es erscheint z.B. der Text

Abbildung 2:Anschlussklemmen am SC-- 9100

Kompakter DDC – Regler SC-- 9100

Anwendung 06

SC1243

B

Mit der y Taste die letzte Seite suchen. Es erscheint der Text

Taste St. 3 Eing.

5555

6

(Standard-- Paßwort)

4.6

Die E Taste betätigen und der Text Taste St. 3 Eing. und die erste Ziffer 5 blinkt. Mit den y oder b Tasten die erste

Ziffer verändern und mit der E Taste bestätigen -- die zweite Ziffer blinkt usw. Nach bestätigen der letzten Ziffer

erscheint z.B. der Text

Zuluftsollwert

15H

°C

SC--9100

C

Die E Taste 1x betätigen und es erscheint der Text

138

101.6

Punktname

Zuluftsollwert

Mit der y Taste durch die Seiten, die dem Zuluftsollwert zugeordnet sind (siehe Handbuch) blättern, die E Taste

betätigen und mit den y oder b Tasten die Änderung vornehmen und mit der E Taste bestätigen.Wird die E Taste 2x

betätigt blinkt der Text Punktname und mit den y oder b Tasten kann der Klartext neu zugewiesen und mit der E

Taste bestätigt werden.

E

45

118

JP4

C

Weitere bestellbare Dokumentation

Technisches Handbuch SC--9100:

Handbuch Anwendungen für SC--9100--8049:

Handbuch Anwendungen für SC--9100--8149:

Handbuch Anwendungen für SC--9100--8249:

JOHNSON CONTROLS

JCI Regelungstechnik GmbH

Westendhof 8 D 45143 Essen

Tel. (0201) 2400 0 D Fax (0201) 2400 351

L

24 Vac

Auf der letzten Seite erscheint der Text Zugriff Taste Eingeben Stufe 2.

107

MN--9100--2216

GXX--SCy

LFG--XXX

HZG--XXX

A

28

D

Technische Ä nderungen vorbehalten

Printed in Europe

Abbildung 1:Abmessungen in mm

E 09.2000 JOHNSON CONTROLS JCI Regelungstechnik GmbH

Bestellzeichen SCINST_D

56

SC-- 9100 Abmessungen und Montage

A Halterungen

B Halteklammern

C Zum Trennen der Bezugsspannungen von

Triac 1 und 2 bitte Steckbrücke JP4 entfernen.

D Lösbare Steckverbinder

Allgemeiner Verdrahtungsplan

s. Dokumentation

Reparatur und Austausch

Eine Reparatur vor Ort wird nicht empfohlen. Wenn der Regler nicht

einwandfrei funktioniert und die Verdrahtung keine Fehler aufweist,

muss der Regler ausgetauscht werden. Wenden Sie sich hierzu an Ihren Lieferanten.

Eingang/Ausgang

Betriebsumgebungs- 0...50 °C , rel. Luftfeuchtigkeit

bedingungen 10...90% Nicht kondensierend

CE Konformität EMK-Richtlinie 89/336/EEC

EN-50082-1

EN-50081-1 bei Montage im

einem geerdeten Metallgehäuse

Leistungsaufnahme 4 VA

Versorgungsspannung 24 V +/-15 %, 50/60 Hz

Nenndaten

Verdrahtung (s. Abb. 2)

(Den Verdrahtungsplan für die gewählte Anwendung finden Sie im

Handbuch der Anwendung.)

· Schalten Sie vor Wartungs-- oder Installationsarbeiten die

Stromversorgung ab, um Schäden oder elektrische Schläge zu

vermeiden.

· CMOS--Schaltungen

können

durch

statische

Elektrizität

beschädigt werden. Berühren Sie keine Bauteile, ohne

entsprechende Vorsichtsmaßnahmen zu treffen.

· Anschlüsse erfolgen über Klemmenleisten. Die Klemmen sind für

Kabel bis zu max. 2,5 mm diam. geeignet.

· Kleinspannungsleitungen und Netz-- bzw. Stromversorgungsleitungen müssen in den Schaltschränken räumlich voneinander

getrennt verlegt werden. Es wird empfohlen, für die Kleinspannungsleitungen eine unterschiedliche Kennfarbe (weiß oder

pink) zu verwenden.

· Halten Sie Leitungen so kurz wie möglich und befestigen Sie die

Kabelbäume.

· Verlegen Sie keine Leitungen in unmittelbarer Nähe von

Transformatoren oder Hochfrequenzgeräten.

· Die Stromversorgung mit 24 V muß stabil sein. Am Netzteil dürfen

keine anderen geschalteten induktiven oder kapazitiven Lasten

angeschlossen werden.

· Überprüfen Sie vor Einschalten die Verdrahtung und die

Anschlüsse. Durch Fehler bei der Verdrahtung können nicht

behebbare Schäden verursacht werden.

Hinweis

Installations--,

Verdrahtungs-und

Einstellarbeiten

müssen

entsprechend den am Einsatzort geltenden Vorschriften durch

befugtes Personal vorgenommen werden. Es wird darauf

hingewiesen, daß der Anwender für den sicheren Betrieb aller

Produkte

von

Johnson

Controls

verantwortlich

ist,

um

Gesundheitsrisiken oder Sachschäden zu vermeiden.

Montage und Installation (s. Abb. 1)

Oberflächenmontage:

· Schieben Sie die Halterungen (A) in die Führungen und

befestigen diese auf der Oberfläche mit selbstschneidenden

Schrauben 4 mm diam..

Montage auf DIN--Schiene 35 mm

· Setzen Sie den Regler auf das obere Ende der Schiene und

rasten Sie ihn auf die Schiene auf. Zum Lösen des Reglers

drücken Sie ihn vorsichtig gegen die Halteklammer (B) und heben

ihn nach unten ab.

Abb. 2

Abb. 1

Wählen Sie vor der Installation des Geräts zunächst die gewünschte

Anwendung aus. Beachten Sie den Verdrahtungsplan für die

entsprechende Anwendung.

General Connection Diagram

Fig. 2

Supply Voltage

See "product Data Sheet"

0...50°C, 10...90% R.H.

non-condensing

EMC Directive 89/336/EEC

EN-50082--1

EN-50081--1 when mounted

in metal grounded cabinet

4 VA

24 Vac +/-15%, 50/60 Hz

Repair and Replacement

Field repair is not recommended. If the control is not working properly

and all wiring is correct the control should be replaced. Please check

with your nearest supplier.

Input/Output

Amb. Operating

Conditions

CE conformity

Power Consumption

Ratings

Wiring (See Fig. 2)

(see ”Application Note”, related to the actual application for the correct

wiring diagram)

· Switch off power supply when installing or servicing to prevent

damage or electrical; shock.

· The CMOS circuits in the controller are sensitive to static. Do not

touch components without taking suitable precautions.

· Terminals are made via the terminal blocks, at the top and bottom

of the controller, which accept up to 1.5 mm2 wires. Low voltage

wiring in electrical cabinets must be physically separated from

line voltage and power wiring, and a distinctive colour (white or

pink) is recommended.Keep all cables as short as possible and

tie in position.Do not run cables close to transformers or high

frequency generating equipment.The 24V supply must be stable

and not shared with other switched inductive loads. Complete

wiring and check the connections before applying power.

Incorrect wiring may cause permanent damage.

Mounting and Installation (see Fig. 1)

For surface mounting:

· Slide 2 mounting brackets (A) into the slots. Fix to the surface

using using the 4 mm diam. self--tapping screws.

For DIN--rail mounting:

· Place the controller on the upper edge of the rail and snap the

controller onto the 35 mm Omega rail. To release, insert a

screwdriver into the clip (B) at the base and pull.

Note

Installation, electric wiring and adjustments should conform to local

codes and must be carried out by authorized personnel only. Users

are reminded of their responsibility to ensure that all Johnson

Controls’products are used safely, and without risk to health and

property.

SC-- 9100 Dimensions and Mounting

A. Mounting Brackets

B. Release Clip

C. To separate Triac 1 and Triac 2 commons, remove

jumper JP4.

D. Removable connectors

Fig. 1

Before installing the device. First select the application needed from

the ”Application Manual”and refer to the connection diagram in the

”Application Note”related to the application.

For further information, read the ”Product Data Sheet”.

READ THIS INSTRUCTION SHEET CAREFULLy BEFORE

INSTALLING

Series SC--9100

Easy DDC Controller

Kompakter Digitalregler

SC--9100

BITTE LESEN SIE DIESE ANWEISUNGEN VOR DER

INSTALLATION SORGFÄLTIG DURCH

ENGLISH

DEUTSCH

Edit-- (Bearbeiten) Taste um Daten zu ändern und zu bestätigen. Mit dieser Taste wird außerdem der

Alarmstatus abgerufen.

E =

ABT

19°C

SW

20°C

AUT

5°C

Mit den y oder b Tasten den gewünschten Parameter in dieser Anwendung anwählen, die E Taste betätigen und

mit den y oder b Tasten die Änderung vornehmen und mit der E Taste bestätigen.

Anwendung 06

SC1243

Auf der letzten Seite erscheint der Text Zugriff Taste Eingeben Stufe 2. Die Taste y ca. 10 Sek. gedrückt halten bis

der Text Zugriff Taste Eingeben Stufe 2 blinkt und dann die Taste y loslassen. Es erscheint z.B. der Text

Die Bedienung erfolgt wie unter Bedienung 1. Stufe beschrieben.

Der Benutzer kann verschiedene Parameter verändern.

Parameter verändern

Die gewählte Anwendung wird jetzt geladen.

Die E Taste betätigen und Anwendung 06 blinkt. Mit den y oder y Tasten bis zur gewünschten Anwendung blättern

und mit der E Taste bestätigen.

Anwendung 06

SC1243

Die Taste y ca. 10 Sek. gedrückt halten bis der Text Zugriff Taste Eingeben Stufe 2 blinkt und dann die Taste y

loslassen. Es erscheint z.B. der Text

Die Bedienung erfolgt wie unter Bedienung 1. Stufe beschrieben. Auf der letzten Seite erscheint der Text Zugriff

Taste Eingeben Stufe 2.

Der Benutzer kann verschiedene Anwendungsprogramme laden.

Anwendungsprogramme laden

Die 2. Bedienstufe kann jederzeit durch betätigen der C Taste wieder verlassen werden.

Zusätzlich können auf der 2. Bedienstufe andere Anwendungsprogramme geladen, Parameter verändert und

Schaltbefehle sowie Stellungen manuell vorgeben werden.

Bedienung 2. Stufe

Mit den y oder b Tasten durch die Seiten auf-- und abblättern. Es werden die verschiedenen Parameter oder

Zustände angezeigt.

z.B

Auf der 1. Bedienstufe können Klartexte mit Parametern oder Zuständen abgefragt werden. Nach dem Einschalten

erscheint das Eingangsfenster bzw. ein Standardfenster mit den wichtigsten Regelkreisgrößen einer Anwendung.

Bedienung 1. Stufe

Cancel-- (Abbrechen) Taste zum Beenden ohne Speichern und zum Aufrufen der übergeordneten Anzeige.

AB--Taste, um zur vorherigen Seite zu blättern oder um einen Wert zu verringern.

y =

C =

AUF--Taste, um zur nächsten Seite zu blättern oder um Werte zu erhöhen.

y =

Tasten

Bedienungsanleitung für den SC--9100

SC-9100

!

GB

The SC-9100 controller comes from the factory with jumpers installed on all analogue inputs connectors

(11-12; 13-14; 21-22; 23-24) as shown in the diagram. When installing an analogue input device, please

remove the corresponding jumper. For any unused analogue inputs, the jumpers MUST remain installed

for

proper operation.

D

F

!

Bei Werkauslieferung des SC-9100 Reglers sind die Klemmen für die Analogeingänge gebrückt (Siehe

Anschluß-Diagramm). Beim Benutzen der Eingänge sind die Brücken zu entfernen. Nichtbenutze

Eingänge

müssen gebrückt bleiben.

!

!

I

!

Le régulater SC-9100 est livré d’origine avec des jumpers installés sur les entrées analogiques suivant le

shéma joint. Avant d’ installer une sonde sur une entrée analogique, enlever le jumper correspondant.

Pour les entrées analogiques qui ne sont pas utilisées, il FAUT laisser le (s) jumper (s) en place pour un

fonctionnement correct de l’ appareil.

Il regolatore SC-9100 viene spedito con jumpers inseriti in tutti i morsetti degli ingressi analogici come

mostrato nella figura. Quando si collegano sonde / dispositivi sugli ingressi analogici bisogna rimuovere i

jumper corrispondenti. Per gli ingressi analogici che non sono utilizzati i jumpers DEVONO rimanere

installati nei morsetti per consentire il correto funzionamento del regolatore.

CZ

Regulátor SC-9100 je dodáván z továrny s instalovanými propojkami na všechny analogové vstupy,tak jak

je znázorneno ve schematu. Pri pripojení cidla do analogových vstupu,odstrante odpovídající propojku. Pro

jakýkoliv další analogový vstup,který není použit, propojka MUSÍ zustat nainstalována pro zajištení

bezproblémové funkce regulátoru.

PL

P/N 24-85706-46

!

Sterownik SC-9100 jest fabrycznie wyposazony w zworki umieszczone na wszystkich wejsciach

analogowych, jak na schemacie. Aby wykorzystac dane wejscie analogowe nalezy przy podlaczeniu do

niego urzadzenia usunac odpowiednia zworke. Dla poprawnego dzialania sterownika zworki na

pozostalych

nieuzywanych wejsciach analogowych NALEZY pozostawic w pozycji fabrycznej.

P/N 24-85706-46

Wiring connection for: SC-9100

SIMPLE CONTROLLER

SC-9100

Mounting dimension of enclosure

DIN Rail Type 35mm/1 3/8″ DIN/ EN 50022

SC-9100

C

E

107

28

Separable

Connectors

56

P/N 24-85638-110

SC-9180 ROOM COMMAND MODULE

INSTALLATION INSTRUCTIONS

O rdering data

SC-9180

SC- 9100

C

E

SC-9180-

000-W

T

Displays

0 Room Temperature (sensor

included)

1 SC-9100 AI3 temperature

SC-9180-0000-W

TS-9100

SC-9180

SC- 9100

C

E

T

SC-9180-1000-W

Mounting

1. Remove the base of the module from the cover by

inserting a pointed tool (a special tool, Ordering

Code TM-9100-8900, is available from Johnson

Controls) into the small hole at the center top of the

cover (See Figure 1).

2. While pressing down gently, prise the base away

from the cover.

3. As the two parts separate, remove the tool and

continue to pull the cover away from the base until

the cover is in free.

4. Mount the base on the wall to cover the electrical

output and secure with at least two screws (See

Figure 2).

Figure 1: Room Command Module

(dimensions in mm)

33

80

LCD

Display

80

set

esc

Mode

LED

Occupancy

Button

Keypad Butt ons

Figure 2: Room Command Module

(dimensions in mm)

P/N 24-85638-1044 Rev. B

Figure 3: Room Command Module

front panel

(dimensions in mm)

1

Adjustment & Wiring

Enable

Jp1

1/3 2/3 3/3

Disable

To service module socket

on SC-9100 controller

Figure 4: Jumper positions

White

Red

Blue

Jumper 1Position

Jumper

1/3

Function

Real time clock

set enable

Extension cable

14

R/T

15

Clock

21 24 Common

Brown

22

8 VDC

23

Real time clock

set disable

Jumper

2/3

Remote set point

Reset –5…+5k

Figure 6: Wiring connections

Remote set point

12…28°C

Jumper

3/3

Weekly schedule

set enable

Weekly schedule

set disable

Figure 5: Jumper settings and Functions

2

P/N 24-85638-1044 Rev. B

Viewing & setting mode parameters

Time

∆/∇

Room Temperature/

SC-9100 input Ai3

Adjust Temperature

Set Point

set

set/

esc

Use ∆ and ∇ to change

set point.

esc+ ∆

esc+ ∇

Note:

Mode Override

When the

display is

steady, it is

indicated by:

Set Operating Mode

set

∆

∇

set/

esc

esc+ ∆

esc+ ∇

esc+ ∆

esc+ ∇

∆

When the

display

flashes (blinks)

the data can

be modified.

It is indicated by:

Use ∆ and ∇ to select

new operating mode.

Time Schedule

See separate diagram.

set

∇

esc+ ∆

esc+ ∇

∆

∇

Set Minutes

Set Clock

Programming

Mode

set

Use ∆ and ∇ to change

minutes.

esc

set

Set hour

Use ∆ and ∇ to change

hour.

esc

set

Set Weekday

set/esc

P/N 24-85638-1044 Rev. B

Use ∆ and ∇ to change

weekday (1=monday, etc.)

3

Viewing & setting time schedule

4

P/N 24-85638-1044 Rev. B

Устройство:

Johnson Controls XT-9100

Размер: 0,12 MB

Добавлено: 2014-02-18 19:06:02

Количество страниц: 40

Печатать инструкцию

Скачать

Как пользоваться?

Наша цель — обеспечить Вам самый быстрый доступ к руководству по эксплуатации устройства Johnson Controls XT-9100. Пользуясь просмотром онлайн Вы можете быстро просмотреть содержание и перейти на страницу, на которой найдете решение своей проблемы с Johnson Controls XT-9100.

Для Вашего удобства

Если просмотр руководства Johnson Controls XT-9100 непосредственно на этой странице для Вас неудобен, Вы можете воспользоваться двумя возможными решениями:

- Полноэкранный просмотр -, Чтобы удобно просматривать инструкцию (без скачивания на компьютер) Вы можете использовать режим полноэкранного просмотра. Чтобы запустить просмотр инструкции Johnson Controls XT-9100 на полном экране, используйте кнопку Полный экран.

- Скачивание на компьютер — Вы можете также скачать инструкцию Johnson Controls XT-9100 на свой компьютер и сохранить ее в своем архиве. Если ты все же не хотите занимать место на своем устройстве, Вы всегда можете скачать ее из ManualsBase.

Johnson Controls XT-9100 Руководство по эксплуатации

Печатная версия

Многие предпочитают читать документы не на экране, а в печатной версии. Опция распечатки инструкции также предусмотрена и Вы можете воспользоваться ею нажав на ссылку, находящуюся выше — Печатать инструкцию. Вам не обязательно печатать всю инструкцию Johnson Controls XT-9100 а только некоторые страницы. Берегите бумагу.

Резюме

Ниже Вы найдете заявки которые находятся на очередных страницах инструкции для Johnson Controls XT-9100. Если Вы хотите быстро просмотреть содержимое страниц, которые находятся на очередных страницах инструкции, Вы воспользоваться ими.

- Manuals

- Brands

- Johnson Controls Manuals

- Thermostat

- T9100

- Owner’s manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

High Resolution

Touch Screen

Code No. LIT-12012271

Issued September 27, 2017

Owner

Owner

and Installation

Instructions

Digital Thermostat

with Humidity Control

,

,

s Manual

s Manual

model T9100

Commercial

Related Manuals for Johnson Controls T9100

Summary of Contents for Johnson Controls T9100

-

Page 1

T9100 Commercial Digital Thermostat with Humidity Control High Resolution Touch Screen Owner Owner s Manual s Manual and Installation Instructions Code No. LIT-12012271 Issued September 27, 2017… -

Page 2

5.10. Firmware releases after rev. 5.10 may not be adequately depicted in this manual. Please refer to the appropriate website or contact your place of purchase to learn about changes to the thermostat after firmware release 5.10. T9100… -

Page 3

Glossary of Terms Auto-Changeover: A mode in which the thermostat will turn on the heating or cooling based on room temperature demand. Cool Setpoint: The warmest temperature that the space should rise to before cooling is turned on (without regard to deadband). Deadband: The number of degrees the thermostat will wait, once a setpoint has been reached, before energizing heating or cooling. -

Page 4: Table Of Contents

Table of Contents GET TO KNOW YOUR THERMOSTAT Home Screen ………………..1 Menu Screens …………………1 Dropdown Dashboard …………….2 Care and use of your thermostat ………….5 QUICK START Selecting your desired temperature and mode ……..6 Using the Fan button …………….6 Using the Override button …………….7 Setting the time ………………9 Setting the date………………

-

Page 5

Table of Contents DISPLAY ………………..23 Active Brightness ………………24 Idle Brightness ………………24 Night Dimmer ………………24 Maintenance ……………….. 25 PREFERENCES ………………26 User Interface Themes …………….27 Custom Wallpaper ………………. 27 Heat/Cool Indicator …………….. 27 Sound Options ………………27 HUMIDITY ……………….. -

Page 6

Table of Contents General Setup ………………42 Units (F or C) ………………42 Language ………………..43 Smart Recovery On/Off …………..43 Installation Settings …………….43 Heat & Cool Stages …………….43 Heat & Cool Stages ……………. 43 Compressor Stages …………….. 43 Aux Heat Stages ……………. -

Page 7

Making 4 Wires Work When 5 Wires Are Required ……77 Making 5 Wires Work When 6 Wires Are Required ……78 The T9100 Thermostat Backplate …………79 Explanation Of the Thermostat Dip Switches ……..80 Sample Wiring Diagrams ……………. 81 TROUBLESHOOTING ……………. -

Page 8: Get To Know Your Thermostat

Get To Know Your Thermostat Home Screen Indoor Humidity Reading Backlit Color Touch Screen Display Outdoor Temperature (If optional accessory is used Dropdown or connected to Skyport) Sensor Button Connectivity Symbol Table Connectivity Symbol Warmer Not connected Button to Wi-Fi SD Card Connected to local Slot…

-

Page 9: Dropdown Dashboard

Get To Know Your Thermostat Dropdown Dashboard The Dropdown Dashboard displays temperature, humidity, and other readings. It will also show the high and low readings of the day. Dropdown Wi-Fi Dashboard Connection Button Connectivity Symbol Table Icon Not connected to Wi-Fi Connected to local access point w/IP address without…

-

Page 10

Get To Know Your Thermostat Dropdown Dashboard (The contents of your Dashboard may vary) Weather Display with forecast for the following 3 days (Skyport connection required for weather) Weather Display This page displays sensor information. Select ‘Onboard’ to view room temperature, and if equipped, humidity sensors that are… -

Page 11

Get To Know Your Thermostat These 3 screens are for informational purposes only. Settings may not be changed from these screens. Thermostat Info Equipment Configuration Thermostat Outputs… -

Page 12: Care And Use Of Your Thermostat

Get To Know Your Thermostat Care and Use of Your Thermostat Pencils, pens and other sharp objects should never be used on your thermostat; these may damage your touch screen. Only use your finger tip to press the screen buttons. Use a soft, damp cloth to clean the screen.

-

Page 13: Quick Start

Quick Start — Temperature, Modes and Fan Selecting Your Desired Temperature and Mode Press to adjust temperature Cool Setpoint The Heat or Cool Setpoint is Warmer Button the temperature the room has to reach before heating or cooling will turn off. Cooler Button Override…

-

Page 14: Using The Override Button

Quick Start — Override Using the Override Button OVERRIDE NOTE: Override may only be used when the thermostat is set to Program RUN or Holiday ON modes. Override Unoccupied Operation — During programmed, unoccupied periods, pressing the OVERRIDE button will force the thermostat into Occupied 1 settings. When the OVERRIDE button is pressed, a timer screen will appear and allow the user to choose from 30 minutes to up to 4 hours of override time.

-

Page 15

Quick Start — Set Time & Date NOTE: When the thermostat is connected to the Skyport; the Time & Date are automatically synchronized to the Skyport Cloud, including automatic Daylight Savings adjustments. Set Time & Date Your time zone is selected in the Skyport web application. Set Current Time Use AM/PM — ON Set Current Date… -

Page 16: Setting The Time

Quick Start — Set Time & Date Setting the Time Press then MENU Press Set Time & Date Press Set Current Time (12:00 AM) hr + min + Press to set the current time. hr — min — Press when finished. BACK Choose Use AM/PM — ON…

-

Page 17: Setting The Date

Quick Start — Set Time & Date Setting the Date Press Set Current Date 6/1/2013 Press to set the current month and year. Press the day on the calendar Press BACK when finished. Daylight Savings Setup Turn Daylight Savings Daylight Savings Time — OFF Time on or off.

-

Page 18: Connect To Wi-Fi