-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Edition

®

MOVITRAC

07

02/2003

Operating Instructions

1056 411x / EN

Related Manuals for SEW-Eurodrive MOVITRAC 07

Summary of Contents for SEW-Eurodrive MOVITRAC 07

-

Page 1

Edition ® MOVITRAC 02/2003 Operating Instructions 1056 411x / EN… -

Page 2

SEW-EURODRIVE… -

Page 3: Table Of Contents

Contents 1 Important Notes………………..4 2 Safety Notes …………………. 6 3 Unit Structure ………………..7 Unit design ………………..7 Unit designation and scope of delivery ……….. 11 4 Installation ………………….. 13 Installation instructions…………….13 UL compliant installation …………….. 17 Power shield clamp …………….. 18 Touch guard ………………..

-

Page 4: Important Notes

Important Notes Important Notes Safety and warn- Always follow the safety and warning instructions contained in this publication! ing instructions Electrical hazard Possible consequences: Severe or fatal injuries. Hazard Possible consequences: Severe or fatal injuries. Hazardous situation Possible consequences: Slight or minor injuries. Harmful situation Possible consequences: Damage to the unit and the environment.

-

Page 5

Important Notes ® MOVITRAC 07 frequency inverters are units intended for stationary installation in switch cabinets. All instructions referring to the technical data and the permissible con- ditions where the unit is operated must be followed. Do not start up the unit (take it into operation in the designated fashion) until: •… -

Page 6: Safety Notes

Safety Notes Safety Notes Installation and • Never install damaged products or take them into operation. Please submit a startup complaint to the transport company immediately in the event of damage. • Installation, startup and service work on the unit only by trained personnel. The personnel must be trained in the relevant aspects of accident prevention and must comply with the regulations in force (e.g.

-

Page 7: Unit Structure

Unit Structure Unit design Unit Structure Unit design Size 0S, 0M, 0L 02978BXX ® Figure 1: MOVITRAC 07 unit structure, sizes 0S, 0M, 0L 1. X1: Mains connection 3-phase: L1 / L2 / L3 / PE or 1-phase: L/N/PE 2. Operating panel 3.

-

Page 8

Unit Structure Unit design Size 1, 2S, 2 05132AXX ® Figure 2: MOVITRAC 07 unit structure, sizes 1, 2S, 2 1. X1: Mains connection 3-phase: L1 / L2 / L3 / PE screw 2. Operating panel 3. DIP switch S11 changeover U-signal / I-signal 4. -

Page 9

Unit Structure Unit design Size 3 05295AXX ® Figure 3: MOVITRAC 07 unit structure, size 3 1. PE connections 2. X1: Mains connection 3-phase: L1 (1) / L2 (2) / L3 (3) 3. X4: DC link circuit connection (not used) 4. -

Page 10

Unit Structure Unit design Size 4 05296AXX ® Figure 4: MOVITRAC 07 unit structure, size 4 1. X2: PE connection 2. X1: Mains connection 3-phase: L1 (1) / L2 (2) / L3 (3) 3. X4: DC link circuit connection (not used) 4. -

Page 11: Unit Designation And Scope Of Delivery

Unit Structure Unit designation and scope of delivery Unit designation and scope of delivery Sample unit designation Type MC Series and generation Version A Recommended motor 022 = 2.2 kW power 2 = 200 … 240 V Connection voltage 5 = 380 … 500 V B = Radio interference suppres- sion B Radio interference sup-…

-

Page 12

Unit Structure Unit designation and scope of delivery Scope of delivery loose items 03000AXX Figure 6: Scope of delivery, included loose size 0 Scope of delivery, included loose for size • Shield clamps for electronics cables (2 clamps with one screw each) [1] •… -

Page 13: Installation

Installation Installation instructions Installation Installation instructions It is essential to comply with the safety notes during installation! Tightening • Only use genuine connection elements. Note the permitted tightening torques ® torques of MOVITRAC 07 power terminals. → – Size 0S/M/L 0.5 Nm (4.4 lb.in) →…

-

Page 14

Installation Installation instructions Line choke • When more than four 3-phase units or more than one 1-phase unit are connect- ed to a supply system contactor designed for the total current: Insert a line choke in the circuit to limit the inrush current. Separate cable •… -

Page 15

Installation Installation instructions ® Line filter MOVITRAC 07 frequency inverters are equipped with an line filter as standard. They comply with the following limit value class to EN 55011 on the line side without further measures: • B: 1-phase connection •… -

Page 16

Installation Installation instructions ® HD output choke • Install the output choke close to MOVITRAC 07 beyond the minimum clearance. • Always route all three phases (not the PE!) together through the output choke. • If the cable is shielded, the shield is not allowed to be routed through the output choke. -

Page 17: Ul Compliant Installation

Installation UL compliant installation UL compliant installation Please note the following points for UL compliant installation: • Only use copper cables with the following temperature ranges as connection leads: ® – For MOVITRAC 07 … Temperature range 60/75 °C. ® •…

-

Page 18: Power Shield Clamp

Installation Power shield clamp Power shield clamp ® For sizes 1 / 2S SEW-EURODRIVE supplies a power shield clamp as standard with MOVITRAC size 1 / 2S. Install this power shield clamp together with the retaining screws of the unit. 02012BXX ®…

-

Page 19: Touch Guard

Installation Touch guard For size 2 SEW-EURODRIVE supplies a power shield clamp with two retaining screws as stan- ® dard with MOVITRAC 07 size 2. Install this power shield clamp together with the two retaining screws on X6. 01469BXX ® Figure 11: Power shield clamp for MOVITRAC 07 size 2 1.

-

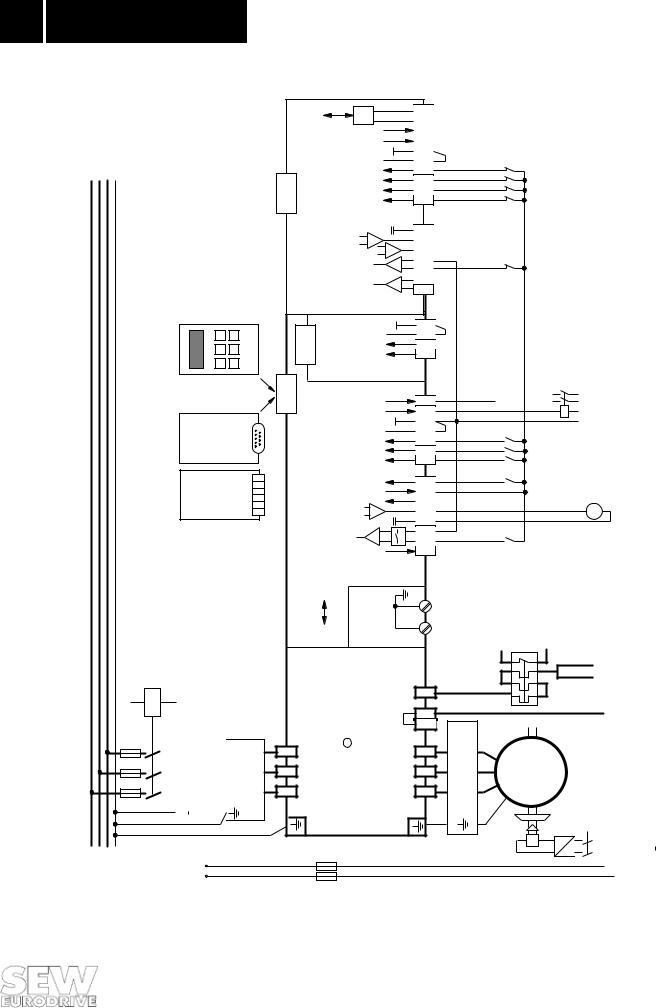

Page 20: Wiring Diagram 230 V 0.37 … 2.2 Kw / 400 V 0.55 … 4.0 Kw

Installation Wiring diagram 230 V 0.37 … 2.2 kW / 400 V 0.55 … 4.0 kW Wiring diagram 230 V 0.37 … 2.2 kW / 400 V 0.55 … 4.0 kW 3 x 230 V / PE 1 x 230 V / N / PE 3 x 400/500 V / PE…

-

Page 21

Installation Wiring diagram 230 V 3.7 … 30 kW / 400 V 5.5 … 30 kW Wiring diagram 230 V 3.7 … 30 kW / 400 V 5.5 … 30 kW 3 x 230 V / PE 3 x 400/500 V / PE F11/F12/F13 (AC-3) -

Page 22

Installation Wiring diagram 230 V 3.7 … 30 kW / 400 V 5.5 … 30 kW Connection of the brake rectifier A separate supply system lead is required for connecting the brake rectifier; sup- ply from the motor voltage is not permitted! Only use contactors in utilization category AC-3 (IEC 158-1) for K11 and K12. -

Page 23: System Bus (Sbus) Installation

SC21 = System bus high SC12 = System bus low SC11 = System bus high = System bus terminating resistor SBus MOVITRAC 07: Connect the terminating equipment to SC11/SC12. SC21/SC22 are only active when S12 = OFF. Operating Instructions – MOVITRAC® 07…

-

Page 24: Startup

Startup General startup instructions Startup Using the IN/OUT key : Press the key once to go further down into the menu struc- ture (selecting functions). Press twice or use one long key press to change to higher lev- els in the menu structure. General startup instructions It is essential to adhere to the safety notes during startup! Prerequisite…

-

Page 25: Integrated Operating Panel

Startup Integrated operating panel Integrated operating panel Operation The following basic principle applies: Press the key once to start editing. Double- click the key to exit edit mode. Functions of the The UP, DOWN and IN/OUT buttons are used for navigating through the menus. The operating panel RUN and STOP/RESET buttons are used for controlling the drive.

-

Page 26: Principles Of Operation With The Integrated Operating Panel

Startup Principles of operation with the integrated operating panel Principles of operation with the integrated operating panel n11 n12 n [rpm] [rpm] [s/rpm] P081 [F-00 … F-99] <-2x 1x-> <-2x 1x-> P100 … P861 [ms/%/…] <-2x 1x-> P-01 … P-05 [kW/Hz/…] <-2x 1x->…

-

Page 27

Startup Principles of operation with the integrated operating panel Available sym- You can select the following symbols using keys bols Symbol Function Displays the inverter status or (in «drive enabled» status) the calculated actual speed in [rpm] Displays the apparent output current in [A] Sets the accelerating ramp in [s] Sets the deceleration ramp in [s] Sets the maximum speed in [rpm]… -

Page 28: Manual Speed Control Module And External Setpoint Selection

Startup Manual speed control module and external setpoint selection Fault indication If a fault occurs, the display changes to the symbol and it shows the flashing fault code, e.g. F-11 (fault list in Sec. Operation and servicing). Warnings Some parameters are not allowed to be altered in all operating states. If you try to do so, the following display appears: r-19 …

-

Page 29

Startup Manual speed control module and external setpoint selection You can limit the speed by P301 Minimum speed and P302 Maximum speed . After a fault, a reset can be performed using the «STOP/RESET» button, the terminal or the interface. «Manual speed control module» operating mode is once again active after the reset. -

Page 30

Startup Manual speed control module and external setpoint selection Enable direction of The direction of rotation is determined by the setpoint if you set P101 Control signal rotation with RS- source and P100 Setpoint source to RS485 or SBus (RS485 only for service purposes). 485 or SBus You must enable the setpoint via SBus or RS-485 using the «CW/STOP»… -

Page 31: Startup With The Integrated Operating Panel

Startup Startup with the integrated operating panel Startup with the integrated operating panel 02975GXX Figure 18: Startup with the integrated operating panel (2x = double-click / * = factory setting) P-01 = Operating mode P-03 = Rated motor speed P-05 = Rated motor voltage P-02 = Rated motor power P-04 = Rated motor frequency Operating Instructions –…

-

Page 32

Startup Startup with the integrated operating panel General informa- If you are not connecting the motor indicated in the motor selection table: Enter param- tion eters P-01 to P-05 correctly according to the nameplate (access via Name Range / factory setting P-01 Operating mode VFC or VFC &… -

Page 33: Starting The Motor

Startup Starting the motor Starting the motor Analog setpoints The following table shows which signals must be present on terminals X10:2 … X10:4 (DIØ1 … DIØ5) when the «UNIPOL/FIX.SETPT» setpoint is selected (P100), in order to operate the drive with analog setpoints. Terminal X10:13/14 X10:2…

-

Page 34: Loading A Logodrive Program

Startup Loading a LOGODrive program Loading a LOGODrive program • Start MOVITOOLS Manager. ® • Connect the MOVITRAC 07 to a vacant serial port on your PC using the UWS21A interface converter. Select this interface in the PC Interface group. ®…

-

Page 35: Parameter List

Startup Parameter list Parameter list All parameters which can also be displayed and edited using the symbol on the op- erating panel have a • in the «OP» (operating panel) column. If more than one value can be selected, the factory setting is highlighted in bold. OP Index Name Range / factory setting…

-

Page 36

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Binary outputs Binary output /FAULT (factory setting) DO01 Binary output BRAKE RELEASED (factory setting) DO02 Binary outputs Binary display DO01, DO02 Unit data Unit type [Text] Output rated cur- rent… -

Page 37

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Analog input 1 (+10 V) • 8463 AI1 scaling 0.1 … 1 … 10 • 8465 AI1 operation 3000 rpm (0 – 10 V) mode N-MAX (0 –… -

Page 38

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Fixed setpoints (set 2) • 8492 Internal setpoint 0 … 150 … 5000 [rpm] • 8493 Internal setpoint 0 … 750 … 5000 [rpm] •… -

Page 39

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Reference signals Speed reference signal • 8539 Speed reference 0 … 750 … 5000 [rpm] value • 8540 Hysteresis 0 … 100 … +500 [rpm] •… -

Page 40

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Binary outputs • 8804 Binary outputs DO01 DO02 /FAULT BRAKE RELEASED READY BRAKE RELEASED SPEED REFERENCE BRAKE RELEASED SP/ACT.VAL.COMP. BRAKE RELEASED /FAULT SPEED REFERENCE /FAULT SP/ACT.VAL.COMP. -

Page 41

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Unit functions Setup • 8594 Factory setting FACTORY SETTING DELIVERY CONDITION • 8595 Parameter lock 8596 Reset statistic data FAULT MEMORY Serial communication • 8597 RS485 address 0 … -

Page 42

Startup Parameter list OP Index Name Range / factory setting Value after startup dec. Display MOVITOOLS Fieldbus parameterization 8304 Setpoint descrip- NO FUNCTION (factory setting P872) tion PO1 SPEED (factory setting P871) MAX. SPEED 8305 Setpoint descrip- RAMP tion PO CTRL. -

Page 43: Fault Information

Operation and Service Fault information Operation and Service Fault information Fault memory The inverter stores the fault message in fault memory P080. The inverter does not save a new fault until the fault message has been acknowledged. The local operating panel shows the fault which occurred most recently.

-

Page 44

Operation and Service Fault information Reset A fault message can be acknowledged by: • Switching the supply system off and on again. Recommendation: Observe a mini- mum switch-off time of 10 s for the supply system contactor. • Reset via input terminals, i.e. via an appropriately assigned binary input (DIØ2…DIØ5). -

Page 45

Operation and Service List of errors (F-00 … F-97) List of errors (F-00 … F-97) Name Response Possible cause Action No error Over-current Immediate • Short circuit on output • Rectify the short circuit switch-off • Output switching • Only switch when output stage inhibited •… -

Page 46

Operation and Service List of errors (F-00 … F-97) Name Response Possible cause Action Overtempera- Rapid stop Thermal overload of inverter • Reduce load and/or ensure ade- ture with inhibit quate cooling • If the braking resistor is integrated in the heat sink: Mount the braking resistor externally System fault Immediate… -

Page 47: List Of Warnings (R-17 … R-32)

Operation and Service List of warnings (r-17 … r-32) Name Response Possible cause Action Initialization Immediate Error during initialization Contact SEW Service for advice. switch-off with inhibit System bus Rapid stop Fault during communication via system Check system bus connection. timeout without inhibit…

-

Page 48: Sew Electronics Service

Operation and Service SEW electronics service SEW electronics service Send in for repair Please contact the SEW electronics service if a fault cannot be rectified (→ «Cus- tomer and spare parts service»). Please always specify the service code number when you contact the SEW electronics service.

-

Page 49: Ce-Marking, Ul Approval And C-Tick

Technical Data CE-marking, UL approval and C-Tick Technical Data CE-marking, UL approval and C-Tick CE-marking ® Low Voltage Direc- MOVITRAC 07 frequency inverters comply with the regulations of the Low Voltage Di- tive rective 73/23/EEC. ® Electromagnetic MOVITRAC 07 frequency inverters are components of machines and systems. They compatibility EMC comply with the EMC product standard EN 61800-3 Variable-speed electrical drives .

-

Page 50: General Technical Data

Technical Data General technical data General technical data ® The following technical data applies to all MOVITRAC 07 frequency inverters, regard- less of size. ® MOVITRAC All sizes Interference immunity To EN 61800-3 Interference emission with To limit value class EMC-compliant installation •…

-

Page 51: Technical Data Of Movitrac® 07

Technical Data Technical data of MOVITRAC® 07 ® Technical data of MOVITRAC 230 V 51115AXX ® Figure 20: MOVITRAC 07 230 V units Size Power [kW / HP] 0.37 / 0.5 1.1 / 1.5 5.5 / 7.5 11 / 15 22 / 30 0.55 / 0.75 1.5 / 2.0…

-

Page 52

Technical Data Technical data of MOVITRAC® 07 230 V / 1-phase / size 0S / 0.37 … 0.75 kW / 0.5 … 1.0 HP 51105AXX ® Figure 22: MOVITRAC 07 / size 0S / 1-phase 230 V ® MOVITRAC MC07A (1-phase supply system) 004-2B1-4-.. -

Page 53

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC MC07A (1-phase supply system) 004-2B1-4-.. 005-2B1-4-.. 008-2B1-4-.. GENERAL Power loss at I 45 W 55 W 65 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 54

Technical Data Technical data of MOVITRAC® 07 230 V / 1-phase / size 0L / 1.1 … 2.2 kW / 1.5 … 3.0 HP ® Figure 24: MOVITRAC 07 / size 0L / 1-phase 230 V ® MOVITRAC MC07A (1-phase supply system) 011-2B1-4-.. -

Page 55

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC MC07A (1-phase supply system) 011-2B1-4-.. 015-2B1-4-.. 022-2B1-4-.. GENERAL Power loss at I 75 W 100 W 125 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 56

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 0S / 0.37 … 0.75 kW / 0.5 … 1.0 HP 51105AXX ® Figure 26: MOVITRAC 07 / size 0S / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 004-2A3-4-.. -

Page 57

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 004-2A3-4-.. 005-2A3-4-.. 008-2A3-4-.. GENERAL Power loss at I 45 W 55 W 65 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 58

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 0L / 1.1 … 2.2 kW / 1.5 … 3.0 HP ® Figure 28: MOVITRAC 07 / size 0L / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 011-2A3-4-.. -

Page 59

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 011-2A3-4-.. 015-2A3-4-.. 022-2A3-4-.. GENERAL Power loss at I 75 W 100 W 125 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 60

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 1 / 3.7 kW / 5.0 HP ® Figure 30: MOVITRAC 07 / size 1 / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 037-2A3-4-.. Part number 827 278 6 Part number with LOGODrive 827 285 9… -

Page 61

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 037-2A3-4-.. GENERAL Power loss at I 210 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range 0 … -

Page 62

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 2 / 5.5 … 7.5 kW / 7.5 … 10 HP ® Figure 32: MOVITRAC 07 / size 2 / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 055-2A3-4-.. -

Page 63

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 055-2A3-4-.. 075-2A3-4-.. GENERAL Power loss at I 300 W 380 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 64

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 3 / 11 … 15 kW / 15 … 20 HP ® Figure 34: MOVITRAC 07 / size 3 / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 110-203-4-.. -

Page 65

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 110-203-4-.. 150-203-4-.. GENERAL Power loss at I 580 W 720 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 66

Technical Data Technical data of MOVITRAC® 07 230 V / 3-phase / size 4 / 22 … 30 kW / 30 … 40 HP ® Figure 36: MOVITRAC 07 / size 4 / 3-phase 230 V ® MOVITRAC 07A (3-phase supply system) 220-203-4-.. -

Page 67

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 220-203-4-.. 300-203-4-.. GENERAL Power loss at I 1100 W 1300 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 68

Technical Data Technical data of MOVITRAC® 07 400/500 V / 3-phase / size 0M / 0.55 … 1.1 kW / 0.75 … 1.5 HP ® Figure 38: MOVITRAC 07 / size 0M / 3-phase 400/500 V ® MOVITRAC 07A (3-phase supply system) 005-5A3-4-.. -

Page 69

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 005-5A3-4-.. 008-5A3-4-.. 011-5A3-4-.. GENERAL Power loss at I 42 W 48 W 58 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 70

Technical Data Technical data of MOVITRAC® 07 400/500 V / 3-phase / size 0L / 1.5 … 4.0 kW / 2.0 … 5.0 HP ® Figure 40: MOVITRAC 07 / size 0L / 3-phase 400/500 V ® MOVITRAC 07A (3-phase supply system) 015-5A3-4- 022-5A3-4- 030-5A3-4-… -

Page 71

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 015-5A3-4- 022-5A3-4- 030-5A3-4- 040-5A3-4- GENERAL Power loss at I 74 W 97 W 123 W 155 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz… -

Page 72

Technical Data Technical data of MOVITRAC® 07 400/500 V / 3-phase / size 2S / 5.5 … 7.5 kW / 7.5 … 10 HP ® Figure 42: MOVITRAC 07 / size 2S / 3-phase 400/500 V ® MOVITRAC 07A (3-phase supply system) 055-5A3-4-.. -

Page 73

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 055-5A3-4-.. 075-5A3-4-.. GENERAL Power loss at I 220 W 290 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 74

Technical Data Technical data of MOVITRAC® 07 400/500 V / 3-phase / size 2 / 11 kW / 15 HP ® Figure 44: MOVITRAC 07 / size 2 / 3-phase 400/500 V ® MOVITRAC 07A (3-phase supply system) 110-5A3-4-.. Part number 827 256 5 Part number with LOGODrive 827 301 4… -

Page 75

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07A (3-phase supply system) 110-5A3-4-.. GENERAL Power loss at I 400 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range 0 … -

Page 76

Technical Data Technical data of MOVITRAC® 07 400/500 V / 3-phase / size 3 / 15 … 30 kW / 20 … 40 HP ® Figure 46: MOVITRAC 07 / size 3 / 3-phase 400/500 V ® MOVITRAC 07 (3-phase supply system) 150-503-4-.. -

Page 77

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07 (3-phase supply system) 150-503-4-.. 220-503-4-.. 300-503-4-.. GENERAL Power loss at I 550 W 750 W 950 W Current limitation 125 % I continuous duty (fan/pump operation) 150 % I for maximum 60 seconds PWM frequency 4 / 8 / 12 / 16 kHz Speed range… -

Page 78

Technical Data Technical data of MOVITRAC® 07 ® MOVITRAC 07 sizes 0S, 0M, 0L for DIN rail mounting (optional accessory) 04329AXX ® Figure 48: MOVITRAC 07 dimensions for DIN rail mounting (optional accessory) ® MOVITRAC 230 V Dimensions A x B x C 90 x 185 x 150 mm 90 x 295 x 150 mm 3.5 x 7.2 x 5.9 in… -

Page 79: Change Index

Change Index Change Index The text has been completely revised and the layout adapted. The following changes were implemented in the respective sections. Technical Data • Information on long-term storage. • Overview of the different series. • Assignment of dimension sheetes to data tables. •…

-

Page 80: Index

Index Index Immediate switch-off 43 Input filter 15 Accelerating ramp 27 Input fuses 14 Actual speed 27 Installation 13 Ambient temperature 50 Installation instructions 13 Analog setpoints 33 Integrated operating panel 25 Apparent output current 27 Operation 26 Application environment 5 Startup 31 Available symbols 27 Interference emission 50…

-

Page 81

Index S11 7, 8, 9, 10 S12 7, 8, 9, 10 Safety Notes 6 Safety notes 4 SBus 30 Scope of delivery 12 Setpoint direction of rotation 29 Setpoint selection, external 28, 29 Setpoint speed 29 Shielding 14 Speed 29 Speed control module, manual 28 Starting the motor 33 Startup 24, 27, 31… -

Page 82

16, rue des Frères Zaghnoun Fax +213 21 8222-84 Bellevue El-Harrach 16200 Alger Argentina Assembly Buenos Aires SEW EURODRIVE ARGENTINA S.A. Tel. +54 3327 4572-84 Sales Centro Industrial Garin, Lote 35 Fax +54 3327 4572-21 Service Ruta Panamericana Km 37,5 sewar@sew-eurodrive.com.ar… -

Page 83

Address List Austria Assembly Wien SEW-EURODRIVE Ges.m.b.H. Tel. +43 1 617 55 00-0 Sales Richard-Strauss-Strasse 24 Fax +43 1 617 55 00-30 Service A-1230 Wien http://sew-eurodrive.at sew@sew-eurodrive.at Belgium Assembly Brüssel CARON-VECTOR S.A. Tel. +32 10 231-311 Sales Avenue Eiffel 5 Fax +32 10 231-336 Service B-1300 Wavre… -

Page 84

Address List Colombia Assembly Bogotá SEW-EURODRIVE COLOMBIA LTDA. Tel. +57 1 54750-50 Sales Calle 22 No. 132-60 Fax +57 1 54750-44 Service Bodega 6, Manzana B sewcol@andinet.com Santafé de Bogotá Croatia Sales Zagreb KOMPEKS d. o. o. Tel. +385 1 4613-158 Service PIT Erdödy 4 II Fax +385 1 4613-158… -

Page 85

Address List India Assembly Baroda SEW-EURODRIVE India Pvt. Ltd. Tel. +91 265 2831021 Sales Plot No. 4, Gidc Fax +91 265 2831087 Service Por Ramangamdi · Baroda — 391 243 sew.baroda@gecsl.com Gujarat Technical Offices Bangalore SEW-EURODRIVE India Private Limited Tel. +91 80 22266565 308, Prestige Centre Point Fax +91 80 22266569 7, Edward Road… -

Page 86

Address List Morocco Sales Casablanca S. R. M. Tel. +212 2 6186-69 + 6186-70 + 6186- Société de Réalisations Mécaniques 5, rue Emir Abdelkader Fax +212 2 6215-88 05 Casablanca srm@marocnet.net.ma Netherlands Assembly Rotterdam VECTOR Aandrijftechniek B.V. Tel. +31 10 4463-700 Sales Industrieweg 175 Fax +31 10 4155-552… -

Page 87

Address List Slovenia Sales Celje Pakman — Pogonska Tehnika d.o.o. Tel. +386 3 490 83-20 Service UI. XIV. divizije 14 Fax +386 3 490 83-21 SLO – 3000 Celje pakman@siol.net South Africa Assembly Johannesburg SEW-EURODRIVE (PROPRIETARY) LIMITED Tel. +27 11 248-7000 Sales Eurodrive House Fax +27 11 494-2311… -

Page 88

Address List Production Greenville SEW-EURODRIVE INC. Tel. +1 864 439-7537 Assembly 1295 Old Spartanburg Highway Fax Sales +1 864 439-7830 Sales P.O. Box 518 Fax Manuf. +1 864 439-9948 Service Lyman, S.C. 29365 Fax Ass. +1 864 439-0566 Telex 805 550 http://www.seweurodrive.com cslyman@seweurodrive.com Assembly… -

Page 92

SEW-EURODRIVE GmbH & Co KG · P.O. Box 3023 · D-76642 Bruchsal/Germany Phone +49 7251 75-0 · Fax +49 7251 75-1970 http://www.sew-eurodrive.com · sew@sew-eurodrive.com…

T

MOVITRAC® 31C…-503-4-01

Frequency Inverters

Manual

Special Version for Crane Control

Edition 11/96

0922 9868 / 1196

|

2 |

MOVITRAC ® 31C Crane Control |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

Table of Contents

|

Page |

|||||||

|

1 |

Inverter data and installation . . . . . |

. . . . |

. . . . . . |

. . . . . . . . . . . . . . |

. |

. |

4 |

|

1.1 |

General information and part numbers |

. . . . |

. . . . . . |

. . . . . . . . . . . . . . |

. |

. |

4 |

1.2Differences to the MOVITRAC® 31C basic version . . . . . . . . . . . . . . . . . . . . . 5

1.3Wiring of crane control pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

|

1.5 |

Control inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

1.6 |

Limit switch connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

2 |

Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

2.1General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

|

2.2 |

Motorized potentiometer mode |

. . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. . |

. |

. 10 |

|

2.3 |

Fixed setpoint mode . . . . . . |

. . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. . |

. |

. 12 |

2.4Approach to limit switches (in “motorized potentiometer” mode) . . . . . . . . . . . . . 14

2.5Mode selection while the inverter is running . . . . . . . . . . . . . . . . . . . . . . . . 16

|

2.6 |

Fault signals . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . 17 |

|

|

3 |

Additional information (state graphs) . . . . . . |

. . . . . . . . . . . . . . . . . . . . 18 |

|

|

3.1 |

State graph for the motorized potentiometer mode |

. . . . . . . . . . . . . . . . . . . . 18 |

|

|

3.2 |

State graph for the fixed setpoint mode . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

|

3.3 |

State graph for the preliminary and ultimate limit switches . . . . . . . . . . . . . . . . |

24 |

|

MOVITRAC ® 31C Crane Control |

3 |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

1

Inverter data and installation

1 Inverter data and installation

1.1General information and part numbers

●This supplementary information does not replace the comprehensive Operating Instructions!

●Equipment may only be installed by qualified electrical personnel in compliance with the applicable accident prevention regulations and the MOVITRAC® Operating Instructions.

The power ratings of the MOVITRAC®31C…-503-4-01 special version for crane control are the same as those of the standard version and can be taken from the MOVITRAC® 31C Operating Instructions.

Part numbers of the special version for crane control:

|

MOVITRAC® type |

Part number |

|

31C008-503-4-01 |

826 339 6 |

|

31C015-503-4-01 |

826 340 X |

|

31C022-503-4-01 |

826 341 8 |

|

31C030-503-4-01 |

826 342 6 |

|

31C040-503-4-01 |

826 343 4 |

|

31C055-503-4-01 |

826 344 2 |

|

31C075-503-4-01 |

826 345 0 |

|

MOVITRAC® type |

Part number |

|

|

31C110-503-4-01 |

826 399 |

X |

|

31C150-503-4-01 |

826 400 |

7 |

|

31C220-503-4-01 |

826 401 |

5 |

|

31C300-503-4-01 |

826 402 |

3 |

|

31C370-503-4-01 |

826 403 |

1 |

|

31C450-503-4-01 |

826 404 |

X |

The special versions for crane control are fitted with the FEA 31C input/output expansion pcb. This option pcb carries the system EPROMs for crane control.

The system EPROMs for the crane control option have the part numbers: 822 246 0.XX LOW 822 247 9.XX HIGH

Functions like hoist and speed control etc. continue to be available without any restrictions.

|

4 |

MOVITRAC ® 31C Crane Control |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

Inverter data and installation

1.2Differences to the MOVITRAC® 31C basic version

MOVITRAC® 31C…-503-4-01 inverters are especially equipped for applications such as trolleys for bridge cranes and hoists.

● Two operating modes are implemented.

The signal level on input TL. 34/35 determines which of the two operating modes is active:

|

TL. 34 |

0…5 V |

= “0″ |

motorized potentiometer mode |

(ground control) |

|

7.5…30 V |

= ”1″ |

fixed setpoint mode |

(radio control) |

|

|

TL. 35 |

jumper with TL. 30 (0V24) |

●A comprehensive limit switch control monitors the preliminary and ultimate (operational) limit switches along the distance of travel of the bridge crane or trolley. To this end, the binary inputs TL. 48/49/50/51 are permanently assigned to limit switch monitoring (low active). Parameters P603…P606 are therefore ineffective.

●External fault detection via TL. 36/37:

The analogue input is used for an “external fault” binary input signal, which is active when low.

|

TL. 36 |

0…5 V |

= “0″ |

external fault |

|

7.5…30 V |

= ”1″ |

no fault |

|

|

TL. 37 |

jumper to TL. 30 |

||

|

Note: |

If this signal input is not used, then TL. 36 — TL. 44 (+24V) and TL. 37 — TL. 30 must |

||

|

be jumpered |

●The following functions of the standard version are no longer available:

—manual operation (P 87_)

—master/slave operation (P 88_)

—setpoint n1 TL. 32/33 with standard function

—setpoint n2 TL. 34/35

—external current limit TL. 36/37

—programming capability of the binary inputs TL. 42-51 (P 60_)

—all functions, activated through binary inputs Exception: fixed setpoints

parameter set selection

—reset via binary input

1.3Wiring of crane control pushbuttons

CW

CCW

|

42 |

41 |

43 |

44 |

||||||

|

CCW |

CW |

Motorized |

+24 V |

||||||

|

Fig. 1: Wiring of crane control pushbuttons |

potentiometer |

00584AEN |

|||||||

MOVITRAC ® 31C Crane Control

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com

1

Inverter data and installation

1.4Wiring diagram

|

RS 485 |

68 |

|||||||||||

|

67 |

||||||||||||

|

0/1= I |

* |

64 |

||||||||||

|

Ref |

63 |

|||||||||||

|

1/0=healthy/Ixt warning* |

||||||||||||

|

0V24 |

30 |

2) |

||||||||||

|

Ref. 48-51 |

60 |

|||||||||||

|

X20: |

CCW preliminary limit switch |

51 |

||||||||||

|

*Factorysetting |

CCW ultimate limit switch |

X8: |

||||||||||

|

50 |

||||||||||||

|

CW preliminary limit switch |

49 |

|||||||||||

|

CW ultimate limit switch |

48 |

|||||||||||

|

0V10 |

0 |

|||||||||||

|

Output current* |

39 |

|||||||||||

|

Output frequency* |

38 |

|||||||||||

|

External fault |

+- |

37 |

||||||||||

|

36 |

||||||||||||

|

31C |

No function |

-+ |

||||||||||

|

33 |

||||||||||||

|

FEA |

32 |

|||||||||||

|

X7: |

||||||||||||

|

0V24 |

30 |

2) |

||||||||||

|

FBG31C |

Keypad option |

X21: |

Ref. 48/49 |

60 |

||||||||

|

CW preliminary limit switch |

X14: |

|||||||||||

|

49 |

||||||||||||

|

CW ultimate limit switch |

48 |

|||||||||||

|

X4: |

1/0 = fault free/fault * |

62 |

||||||||||

|

Brake |

61 |

|||||||||||

|

USS11A |

-(RS232) |

interface option |

X11: |

0V24 |

30 |

3)2) |

||||||

|

eration or setpoint selection 1 |

43 |

|||||||||||

|

Ref. 41-47 |

60 |

|||||||||||

|

Parameter set selection |

47 |

|||||||||||

|

or setpoint selection 2 |

||||||||||||

|

Motorized potentiometer accel- |

||||||||||||

|

setting |

1/0= CCW/ Stop* |

42 |

||||||||||

|

-(RS485) |

1/0= CW/ Stop |

X3: |

||||||||||

|

UST11A |

interface option |

X11: |

Factory* |

41 |

||||||||

|

Output frequency* |

+24V |

65 |

||||||||||

|

44 |

||||||||||||

|

+24V (external) |

40 |

|||||||||||

|

Measurement output |

0V10 |

0 |

||||||||||

|

NDlinechokeoption |

(if4ormoreunitsareconnectedviaacontactor) |

||||||

|

W1 |

W2 |

||||||

|

V1 |

V2 |

||||||

|

U1 |

U2 |

||||||

L1 L2 L3

NF… mains input filter option

L1′ L2′ L3′

|

Mode selection |

+- |

||

|

+10V (3mA) |

|||

|

Processorpcb |

S1 |

left right Isignal Vsignal |

Screenplate |

|

Powersection |

31C |

||

|

R |

|

S1 |

35 |

||

|

34 |

3) |

||

|

31 |

|||

X2:

X0:

|

z |

8 |

1) |

|||

|

+U |

8 |

7/V5 |

|||

|

X1: |

6 |

6/W15/V14/U1 |

optionfilteroutput…HF |

W/W2V/V2U/U2 |

|

|

5 |

|||||

|

4 |

|||||

|

PE |

PE |

|

+24V |

S20 |

||||||||||||||

|

S19 |

|||||||||||||||

|

S18 |

|||||||||||||||

|

S17 |

factoryJumpers,installed;connectbinary |

internalwithref.inputgroundofunit |

|||||||||||||

|

S16 |

seeselectionModeSec.2.5 |

||||||||||||||

|

2) |

3) |

||||||||||||||

|

S15 |

K12 |

Binaryoutputsignals |

forPLCorexternal outputrelay; |

TL.61:max.150mA/3.6W TL.62:max.50mA/1.2W (alternatively:contactorK12 |

forbrakeoperation) |

||||||||||

|

S14 |

|||||||||||||||

|

S13 |

|||||||||||||||

|

S12 |

|||||||||||||||

|

PWM signal TTL |

V |

||||||||||||||

|

S11 |

Connection TL.-503…-HF-8TL.V5 |

forpermissibleOnlyPWM |

andkHz12frequencyhigher |

||||||||||||

|

effectsK11 |

Kl.8 |

1x/2x |

|||||||||||||

|

F16 |

BW… |

Type |

MC31C005- |

MC31C450 |

|||||||||||

|

1) |

|||||||||||||||

|

M |

3phas. |

K12 |

0V10(Referencepotential10V,analoguesignals) |

0V24(Referencepotential24V,binarysignals) |

Protectiveearthconductor(screen) |

||||||||||

|

= |

|||||||||||||||

|

~ |

|||||||||||||||

|

TL.0 |

Kl.30 |

Strip |

|||||||||||||

00556AEN

Terminals X14:48 — X8:48 and X14:49 — X8:49 are OR’d internally, allowing terminals X14:48-49 or X8:48-49 to be used alternatively.

An external voltage +24V can be applied directly to analogue inputs X2:34 and X7:36. The negative output of the external power supply must be connected to 0V24 (TL. 30).

|

6 |

MOVITRAC ® 31C Crane Control |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

Inverter data and

1

installation

1.5Control inputs

1.Motorized potentiometer mode (for ground control) = control by modified motorized potentiometer function. The motorized potentiometer function (P15_) of the MOVITRAC® is automatically activated

|

Terminal |

Function |

Signal status “1″ |

Signal status ”0″ |

|

TL. |

Mode selection |

Fixed setpoint mode |

Motorized potentiometer mode |

|

34/35 |

|||

|

TL. |

External fault detection |

No fault |

External fault |

|

36/37 |

(e.g. TF thermistor) |

||

|

TL. 41 |

Enable + CW |

Ramp UP t11* (P120) to fmin |

Ramp DOWN t4 (P 152) to fmin |

|

Ramp DOWN t11* (P 121) to fstart/stop |

|||

|

TL. 42 |

Enable + CCW |

Ramp UP t11* (P 120) to fmin |

Ramp DOWN t4 (P 152) to fmin |

|

Ramp DOWN t11* (P 121) to fstart/stop |

|||

|

TL. 43 |

Acceleration motorized |

Ramp UP t4 (P 151) to fmax |

Setpoint stays at present value |

|

potentiometer |

|||

|

TL. 47 |

Parameter selection* |

Parameter set 2 |

Parameter set 1 |

|

TL. 48 |

CW ultimate limit switch |

CW ultimate limit switch reached |

|

|

→ rapid stop ramp t13* (P140), |

|||

|

output stage inhibited, brake applied |

|||

|

TL. 49 |

CW preliminary limit |

CW preliminary limit switch reached |

|

|

switch |

Status during travel |

→ rapid stop ramp t13* to fmin |

|

|

TL. 50 |

CCW ultimate limit |

CCW ultimate limit switch reached |

|

|

switchtravel |

→ rapid stop ramp t13*, output stage |

||

|

inhibited, brake applied |

|||

|

TL.51 |

CCW preliminary limit |

CCW preliminary limit switch reached |

|

|

switch |

→ rapid stop ramp t13* to fmin |

||

* The parameters of the 2nd parameter set are activated through the parameter set selection parameter.

2. Fixed setpoint mode (for radio control) = control by internal fixed setpoints

|

Terminal |

Function |

Signal status “1″ |

Signal status ”0″ |

|

TL. 34/35 |

Mode selection |

Fixed setpoint mode |

Motorized potentiometer mode |

|

TL. 36/37 |

External fault detection |

No fault |

External fault |

|

(e.g. TF thermistor) |

|||

|

TL. 41 |

Enable + CW |

Ramp UP t11 (P 120) to fmin |

Ramp DOWN t11 (P 121) to fmin |

|

Ramp DOWN t13 (P 140) to fstop |

|||

|

TL. 42 |

Enable + CCW |

Ramp UP t11 (P 120) to fmin |

Ramp DOWN t11 (P 121) to fmin |

|

Ramp DOWN t13 (P 140) to fstop |

|||

|

TL. 43 |

Internal fixed setpoint n11 |

n11 active |

n11 ineffective |

|

TL. 47 |

Internal fixed setpoint n12 |

n12 active |

n12 ineffective |

|

TL. 43+47 |

Internal fixed setpoint n13 |

n13 active |

n13 ineffective |

|

TL. 48-51 |

Ultimate and preliminary |

See table above |

|

|

limit switches |

|||

If not all limit switch inputs (TL. 48/49/50/51) are used, the open inputs must be connected to +24V (TL. 44) as otherwise the limit switch monitoring will signal a fault (→ Sec. 2.6 Fault signals).

|

MOVITRAC ® 31C Crane Control |

7 |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

1

Inverter data and installation

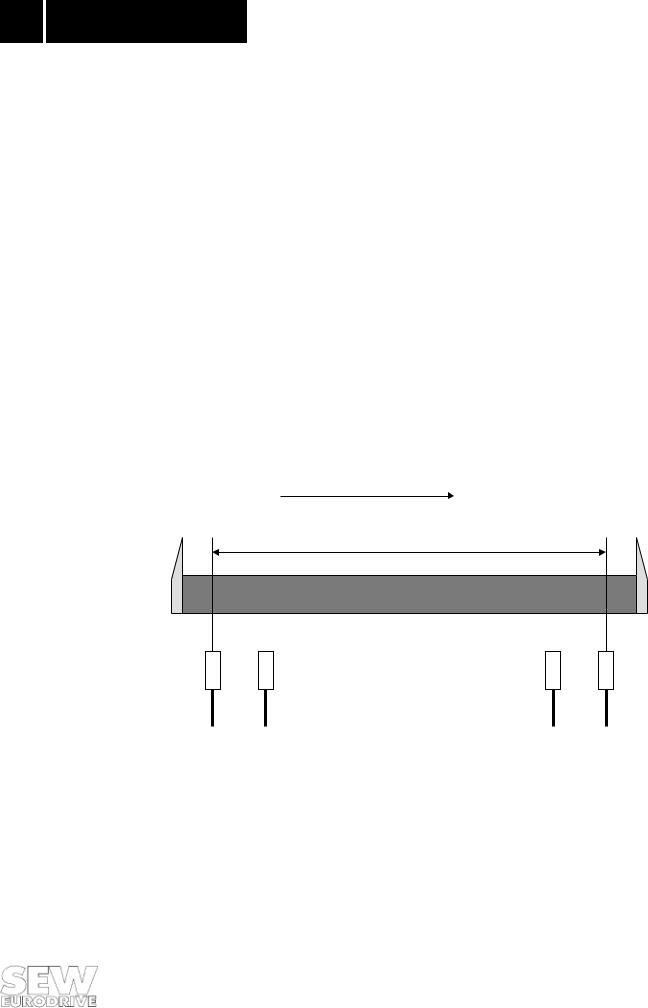

1.6Limit switch connection

The use of end-of-track limit switches for crane control is supported. Altogether four limit switch inputs are available for monitoring the travel and the travel speed. ( → Sec. 1.4 Wiring diagram and Sec. 1.5 Control inputs).

|

— CW ultimate limit switch |

TL. 48 |

|

|

— CW preliminary limit switch |

TL. 49 |

|

|

— |

CCW ultimate limit switch |

TL. 50 |

|

— |

CCW preliminary limit switch |

TL. 51 |

The limit switches must be installed along the distance of travel in accordance with Fig. 4. For safety reasons the limit switches must be implemented as “low active”. When the inverter is enabled the internal limit switch monitoring feature monitors whether both preliminary and ultimate limit switches are connected in accordance with the wiring diagram (→ Sec. 1.4). If only one of the two preliminary or ultimate limit switches is missing no fault signal is issued. The limit switches are not monitored for correct connection.

If not all limit switch inputs (TL. 48/49/50/51) are used, the open inputs must be connected to +24V (TL. 44) otherwise the limit switch monitoring will issue a fault signal (→ Sec. 2.6 Fault signals).

CW frequency inverter

|

CCWultimatelimitswitch |

CCWpreliminarylimitswitch |

CWpreliminarylimitswitch |

CWultimatelimitswitch |

|

Fig. 3: Limit switch installation |

00557AEN |

|

8 |

MOVITRAC ® 31C Crane Control |

|

Phone: 800.894.0412 — Fax: 888.723.4773 — Web: www.clrwtr.com — Email: info@clrwtr.com |

You can only view or download manuals with

Sign Up and get 5 for free

Upload your files to the site. You get 1 for each file you add

Get 1 for every time someone downloads your manual

Buy as many as you need

- Manuals

- Brands

- Sew Eurodrive Manuals

- DC Drives

- MOVITRAC 31C110-503-4-00