-

SEATRACKER

-

Форум

-

Машинная команда

-

Мотористы

20

31-Июл-2016 10:50

Добрый день.

Появился вот такой вот вопрос по системе очистки сточных, фекальных вод на судне (sewage treatment plant). Не будем рассматривать в чьи обязанности входит эксплуатация и ремонт сей установки. Хотелось бы узнать некоторые нюансы работы этого агрегата, а именно:

1. Во всех ли портах запрещен сброс из этой установки?

2. Работает ли эта установка, если используется морская забортная вода? Появилось мнение, что бактерии в морской воде или погибают или не эффективны.

3. Важна ли работа воздушного компрессора? Скажем так в аварийном случае?

4. Как осуществляется контроль работы этой системы?

Спасибо за ответы по теме. Интернет-поиск мне толком не помог.

Если есть возможность поделитесь ссылками или литературой по данной теме.

270

— спустя 7 часов

31-Июл-2016 18:31

Похожие темы

| # | Тема | Форум | Автор |

|---|---|---|---|

|

?? |

У кого что есть по этому ГД — Mitsubishi 6UEC43LSII |

Судомеханики | readline.ua@gmail.com |

|

?? |

Газовоз Нафтомар |

Работа на судах различного типа | Octobrine |

|

RU |

Подруливающее устройство «SCHOTTEL» 100 кВт |

Электромеханики | Petr1508 |

|

?? |

Неразрушающий контроль в судостроении-ремонте |

Ремонт | Shelby |

|

?? |

Bareboat Charters by Mark Davis |

Ищу книгу… | profy23V |

|

?? |

Evac sanitary system MBR 40 C |

Ремонт | andruha2003 |

|

?? |

Срочно ищу доступ к Vessel Monitoring System (SAT-AIS): MarineTraffic, FleetMon, VesselFi… |

Палуба и мостик | d1v3r |

|

?? |

Mitsubishi 6UEC43LSII |

Ищу книгу… | readline.ua@gmail.com |

|

?? |

Мануал SMIT-BOLNES 308HDK |

Судомеханики | RAEM |

|

?? |

Ulstein 600 AGSC Help! |

Ищу книгу… | tanker87 |

-

SEATRACKER

-

Форум

-

Машинная команда

-

Мотористы

- Ответить

Move & Copy & Delete

Модераторы: Breeze, TakeR

- Активные темы

- На страницу 1 2 3 4 5 … 8 След.

|

|

|

Да. А,если другой флаг,то такой журнал не нужен? Просветите,плиз. …Грохот, хохот и дружеская брань висели в воздухе.( Ф. Купер, «Лоцман») |

Откуда: The Volga river Должность: Второй помощник Тип судов: Многоцелевые суда Репутация: 467 |

|

|||||||||||||||||||||||||||||||||||||

Да, но там есть другая зацепка, чтобы нагнуть. Не думаю, что откачка сливов из прачечной или камбуза не изменит цвет окружающей воды, скажем в Норвегии. А там доказывай black или grey это было.

Неужели есть «кадры», которые фиксируют откачку какашек в ORB?

Под голландским раз в дней 10 (для проформы) делали запись в машинном журнале о начале и конце откачки из сборного танка с указанием времени, координат, скорости судна и сброшенном количестве (повторюсь интенсивность сброса должна соответствовать скорости по утверждённой таблице). «Вся наша склонность к оптимизму — от неспособности представить, какого рода завтра клизму судьба решила нам поставить» И.Губерман |

Репутация: 1500 |

|

||||||||||

В курсе. Лады.Спасибо.В общем-то всё тоже самое. …Грохот, хохот и дружеская брань висели в воздухе.( Ф. Купер, «Лоцман») |

Откуда: The Volga river Должность: Второй помощник Тип судов: Многоцелевые суда Репутация: 467 |

|

||||||||||||||||||||||||||||

Администрации большинства удобных флагов руководствуются международными правилами (в которых сточные воды, которые не могут быть отнесены к sewage см. мое сообщение выше не регламентируются никак) и никаких дополнительных журналов для сточных вод я нигде не встречал (еще и заверенных администрацией порта

Бывают и не такие

Я писал про US. Там, кстати, тоже на утверждении лежит куча ужесточающих законов, поэтому нужно держать ухо востро и запрашивать у агентов последние правила, либо не сливать ничего. |

Тип судов: Балкеры Репутация: 1500 |

|

||||||||||

У нас на судне Grey water или за борт, прямиком, или в танк. |

Репутация: 1500 |

|

|

|

Кстати, всё-таки официальное понятие Grey water имеет быть. См.RESOLUTION MEPC.227(64) (бывшая MEPC.159(55)) 2 DEFINITIONS |

Откуда: Ленинград — Мурманск Должность: Старший механик Тип судов: Нефтяные танкера Репутация: 322 |

|

||||||||||

Ничего странного.У нас 1 танк.И — 12 мильная зона.Конкретно — Чёрное,Средиземное.Как в других районах — не вникал. …Грохот, хохот и дружеская брань висели в воздухе.( Ф. Купер, «Лоцман») |

Откуда: The Volga river Должность: Второй помощник Тип судов: Многоцелевые суда Репутация: 467 |

Сударь 17 май 2017, 06:58 |

||||||||||

Местные законы не всегда возможно процитировать. Низзя и все. Из собственной практики — низзя вообще ничего откачивать (ни через аппрувленную фекалку, ни gray water) за борт в портах Бразилии и Турции. В Бразилии так вообще власти опечатывали своими пломбами все отливные клапана и горе тому, кто не успел подготовиться — в душ будет не сходить. Далеко не на каждом судне есть gray water tank или возможность перевести слив gray water через STP. «На ближайшие сто лет нет альтернативы дизелю, как судовому двигателю крупнотоннажных судов.» Компания Sulzer в 80-х годах прошлого века. |

Откуда: Санкт-Петербург Должность: Старший механик Тип судов: Химовозы Репутация: 1500 |

|

||||||||||

В Аргентине тоже такая же песня. Помню что откатывали в один из слопов. Потом ополоснули и всё. |

Репутация: 1500 |

|

|

|

Господа знатоки, такой вопрос. Достался мне в наследство мертвый Sewage Treatment Plant марки Gertsen & Olufsen BR-5500 BG-G, мертвый по причине поступления туда Gray Water с содержанием всякой бытовой химии. Полностью вымыть установку возможности не было, Gray Water перекрыл, сейчас поступает только Black, используем Unitor BTC для туалетов, обслуживание юнита произвожу по мануалу с использованием Gamazyme 700 FN. Прошло 2,5 месяца с начала реанимации. Вопрос в том как без анализов определить работает ли установка и нормальный ли бактериальный баланс, достаточно ли чистая вода в Clean Water танке? |

Должность: Третий механик Тип судов: Heavylifts Репутация: 11 |

|

||||||||||

Нужно дать испить той воды и наблюдать. |

Тип судов: Балкеры Репутация: 1500 |

Culon 01 июн 2017, 09:37 |

|

|

madmax75 «То, что я здесь говорю, разделяют не все, но я скажу, что думаю, и сделаю это с уважением к остальным». Фидель Кастро. |

Откуда: Azov Должность: Старший механик Тип судов: Контейнеровозы Репутация: 704 |

|

|

|

Culon |

Должность: Третий механик Тип судов: Heavylifts Репутация: 11 |

Culon 02 июн 2017, 15:46 |

|

|

madmax75 «То, что я здесь говорю, разделяют не все, но я скажу, что думаю, и сделаю это с уважением к остальным». Фидель Кастро. |

Откуда: Azov Должность: Старший механик Тип судов: Контейнеровозы Репутация: 704 |

|

|

|

Добрый день, |

Должность: Четвертый механик Тип судов: Нефтяные танкера Репутация: 0 |

ifo700 23 июн 2017, 11:22 |

||||||||||

Забортный клапан ниже, а на трубопроводе выполнена петля, которая действительно выше sewage treatment plant. |

Откуда: Тридевятое царство Должность: Старший механик Репутация: 1381 |

|

|||||||||||||||||||

Спасибо |

Должность: Четвертый механик Тип судов: Нефтяные танкера Репутация: 0 |

|

||||||||||

Доброго времени суток , парни! Шампанское и влюблённость — официальные спонсоры глупости. |

Должность: Старший механик Тип судов: Оффшор: вспомогательный флот Репутация: 33 |

Сударь 08 сен 2018, 13:19 |

||||||||||

Нет не поэтому. Просто деды протабанили. Эта таблица должна быть обязательно. Издается Компанией, утверждается классом. Нужна на случай, если у вас СТП выйдет из строя и вам придется сбрасывать необработанные воды. «На ближайшие сто лет нет альтернативы дизелю, как судовому двигателю крупнотоннажных судов.» Компания Sulzer в 80-х годах прошлого века. |

Откуда: Санкт-Петербург Должность: Старший механик Тип судов: Химовозы Репутация: 1500 |

Dexter 08 сен 2018, 23:12 |

|||||||||||||||||||

Извините, что сообщение уже давно было написано, но…у меня этот журнал вернее sewage management plan с записями инспектор DNV GL проверял. Ну и контора требует вести. |

Репутация: 925 |

Сударь 08 сен 2018, 23:35 |

||||||||||

Sewage management plan быть обязан. А вот записи по нему будете вести только если СТП из строя выйдет и в ручном режиме будете откачивать. Как раз тот случай зачем нужна таблица из поста выше. Что именно инспектор проверял если у вас СТП работает в автоматическом режиме? Какие записи? Ну а то, что контора требует, так тут что скажешь. У контор разные прибабахи. Но вопрос остается тот же — Что записывать если у вас одобренная СТП работает в автоматическом режиме? «На ближайшие сто лет нет альтернативы дизелю, как судовому двигателю крупнотоннажных судов.» Компания Sulzer в 80-х годах прошлого века. |

Откуда: Санкт-Петербург Должность: Старший механик Тип судов: Химовозы Репутация: 1500 |

Dexter 09 сен 2018, 01:11 |

|

|

Пишем откачку необработанных вод при ежемесячной мойке УОСВ. Код не помню, вроде С. Мойка по PMS раз в месяц, вот моем, а потом и оформляем. |

Репутация: 925 |

Сударь 09 сен 2018, 05:22 |

|

|

Dexter, круто у вас, ничего не скажешь. «На ближайшие сто лет нет альтернативы дизелю, как судовому двигателю крупнотоннажных судов.» Компания Sulzer в 80-х годах прошлого века. |

Откуда: Санкт-Петербург Должность: Старший механик Тип судов: Химовозы Репутация: 1500 |

|

|

|

Dexter |

Репутация: 1473 |

Dexter 09 сен 2018, 11:07 |

||||||||||

Коды по типу ЖНО, code, item, в SEWAGE MANAGEMENT PLAN указаны. Повторяю, пишем в одну из глав в sewage management plan . Добавлено спустя 55 минут 1 секунду: |

Репутация: 925 |

Dexter 09 сен 2018, 13:04 |

|

|

ciudad Добавлено спустя 14 минут 16 секунд: |

Репутация: 925 |

Dexter 09 сен 2018, 14:22 |

|||||||||||||||||||

http://obrazec.org/14/zhurnal_operacij_ … ednymi.htm Вот нашел ….там есть образец записей для регистрации операций со сточными водами. У нас подобное, только буквы латинские, и вроде 5 кодов могу ошибаться, короче ц нас брлее развернуто. Добавлено спустя 6 минут 44 секунды: https://www.google.ru/url?sa=t&source=w … xPDNtdQAyI Страница 17, пункт 805. Добавлено спустя 17 минут 41 секунду: https://www.google.ru/url?sa=t&source=w … 5j_9lZG2sM |

Репутация: 925 |

|

|

|

То же ведём что то типа журнала, записываем когда сколько зверей засыпали. Когда, где, расстояние до берега — переходы из STP в танк, откачка из танка, переход из танка в STP, но без кодов. Но на моей памяти никто его не проверял. Добавлено спустя 1 минуту 12 секунд: |

Должность: Старший механик Тип судов: Генеральные грузы Репутация: -1 |

|

||||||||||

Странно The discharge of raw sewage into the sea can create a health hazard, while in coastal areas sewage can also lead to oxygen depletion and an obvious visual pollution. MARPOL Annex IV, as adopted in resolution MEPC.115(51), which entered into force on 27th September 2008, applies to ships on international voyages which are: 1. 400gt and greater; or 2. Less than 400gt when certified to carry more than 15 persons, which includes passengers and crew The effluent standards and performance tests, as adopted in resolution MEPC.159(55), which entered into force on 1st January 2010, applies to ships having a sewage effluent plant installed or delivered and ships with a keel laid date on or after 1st January 2010. For vessels visiting countries that have ratified to MARPOL Annex IV, these vessels will need to demonstrate compliance with the regulations, with the relevant certification (ISPPC). ISPCC (International Sewage Pollution Prevention Certificate) are issued upon successful inspection and are valid for 5 years. Non-compliance or failed inspections can result in vessel detention For renewal and random inspections, maintaining the system operating requirements in line with the effluent standards will be required. With this in mind, the Sewage Effluent Test Kit will provide simple and accurate testing for BOD, Chlorine (Free), COD, Coliform Bacteria, pH and Total Suspended Solids. |

Репутация: 1473 |

|

|

|

Статпом, у них и журнал этот нм мостике находттся. |

Должность: Старший механик Тип судов: Балкеры Репутация: 9 |

- Активные темы

- На страницу 1 2 3 4 5 … 8 След.

|

Кто сейчас на конференции Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 3 |

||

Discarding sewage produced onboard on a ship is one of the few tasks on a ship which should be taken utmost care of if one wants to save him and his shipping company from heavy fine. The sewage generated on the ship cannot be stored on the ship for a very long time and it, for this reason, it has to be discharged into the sea.

Though sewage can be discharged into the sea, we cannot discharge it directly overboard as there are some regulations regarding discharging of sewage that needs to be followed. Sewage on the sea is generally the waste produced from toilets, urinals, and WC scuppers. The rules say that the sewage can be discharged into the seawater only after it is treated and the distance of the ship is 4 nautical miles from the nearest land.

But if the sewage is not treated this can be discharged 12 nautical miles away from the nearest land. Also, the discharged sewage should not produce any visible floating solids nor should it cause any discoloration of surrounding water. The details of the sewage discharge regulations can be found in MARPOL Annex IV.

Related Read: MARPOL ANNEX 4 Explained: How to Prevent Pollution from Sewage at Sea

Popular Stories Right now

Generally, ships prefer treating sewage before discharging to save themselves from any type of embarrassment. There are different methods of treating sewage available in the market, but the most common of them is the biological type for it occupies less space for holding tank, unlike those of the other methods. Moreover, the discharge generated from this plant is eco-friendly. It is to note that each sewage treatment system installed onboard has to be certified by classification society and should perform as per their requirement and regulations.

The most preferred type of sewage treatment plant is that involving aerobic bacteria. The Anaerobic bacteria are equally capable of decomposing and breaking down the sludge but during the process, they generate and release harmful gases such as H2S and methane which are toxic and dangerous for aquatic organisms.

Related Read: 4 Important Terms Related to Sewage Treatment Plant on Ships

Component of STP:

Screen Filter:

The screen filter mesh is fitted on the first tank near the entrance of the sewage to the STP. It helps in removing the non-sewage adulteration component such as; toilet paper, plastic paper, other solids etc, which can clog the complete system if went inside.

Biofilter:

The biofilter is also the part of the aeration chamber which treats the sewage passing from the screen filter. The biofilter reactor, with the help of fine air bubbles supplied from the blower, will disperse the contaminated substance diffusing and breaking down the organic matter by the aerobic microorganism. The fine bubble by passing through the diffuser will increase the oxygen transmission rate.

Settling/ Sedimentation Chamber:

The treated sewage water from the biofilter reactor will come to the next chamber which is used for settling purpose. The mixture will be further separated to high-grade water and sediment after being settled in Sedimentation tank. The clarification compartment is usually of the hopper type with sloping sides which prevent the sticking and accumulating of sludge and send it to the suction side of the air lift tube.

The untreated sludge settled in the bottom of the sedimentation tank returns into the Biofilter reactor to break up by microorganism again.

Activated Carbon:

The activated carbon is fitted post the settling chamber to remove Chemical Oxygen Demand (COD) by filtering and absorption. It also helps in treating the Biological Oxygen Demand (BOD) and Suspended Solids.

Chlorinator:

The chlorinator is fitted in the last chamber to treat the final stage water for discharging overboard. The chlorinator can be of tablet dosing type or chemical injection type. Inside the tablet-based chlorinator, clean water comes directly in contacts with the chlorine tablets, making a chlorine solution. The chlorinator comprises cylinders for filling the chlorinator with tablets.

In chemical pump type, a measured set quantity of NaOCl is injected to sterilization/chlorination tank using the diaphragm type reciprocating pump.

Related Read: Different Systems In Ship’s Accommodation Area Explained

Air Blower:

There are usually 2 air blowers installed, in which one acts as stand-by, to supply air (via air bubbles) helping in forming the microorganism in biofilter reactor. It also helps in transferring the sludge from sedimentation tank, supply air to the activated carbon tank and to back flush the sludge.

Discharge Pump:

The discharge pump is provided in a duplex and they are mounted on the last compartment of the STP. They are centrifugal pumps of the non-clog type which are coupled to their respective motors. The pump is run on auto mode controlled by the level switches installed in the sterilization tank. The pump is usually run on manual mode when taking out the sludge from the compartments after the cleaning of the tank insides.

Piping:

- The inlet pipe carrying the sewage to the plant is installed with the proper slope to prevent the clotting and condensation.

- The sewage pipe is such arranged that the inside holes are accessible for cleaning during maintenance.

- Overboard discharging outlet should be placed 200~300mm lower than L.W.L and the discharge pipe is provided with a Non-return valve.

Related Read: Pipes and Bends – An Essential Guide for Second Engineers

Floats and Level Switches:

- Usually, Three float switches, namely – high level, low level, and high alarm level switch are fitted on the chlorination/sterilization chamber.

- This chamber is also fitted with level switches to control the start-stop of the discharge pump.

Working of Biological Sewage Plant:

The basic principle of the working of a biological treatment plant is decomposition of the raw sewage. This process is done by aerating the sewage chamber with fresh air. The aerobic bacteria survive on this fresh air and decompose the raw sewage which can be disposed of in the sea. Air is a very important criterion in the functioning of the biological sewage plant because if air is not present, it will lead to the growth of anaerobic bacteria, which produces toxic gasses that are hazardous to health. Also, after decomposition of the sewage with anaerobic bacteria, a dark black liquid causes discolouration of water which is not accepted for discharging. Thus in a biological sewage treatment plant, the main aim is to maintain the flow of fresh air.

Division of Processes

The biological sewage plant is divided into three chambers:-

Aeration chamber

This chamber is fed with raw sewage which has been grounded to form small particles. The advantage of breaking sewage in small particles is that it increases the area and a high number of bacteria can attack simultaneously to decompose the sewage. The sewage is decomposed into carbon dioxide, water, and inorganic sewage. The air is forced through the diffuser into the air chamber. The pressure of air flow also plays an important role in decomposition of the sewage. If the pressure is kept high then the mixture of air and sewage will not take place properly and it will escape without doing any work required for decomposition. It is for this reason; controlled pressure is important inside the sewage treatment plant as this will help in proper mixing and decomposition by the agitation caused by air bubbles. Generally, the pressure is kept around 0.3-0.4 bars.

Related Read: How Can Ship’s Crew Contribute towards Reducing Waste Production Onboard Ship?

Settling tank

The mixture of liquid and sludge is passed to settling tank from the aeration chamber. In the settling tank, the sludge settles at the bottom and clear liquid on the top. The sludge present at the bottom is not allowed to be kept inside the settling tank as this will lead to the growth of anaerobic bacteria and foul gasses will be produced. The sludge formed is recycled with the incoming sludge where it will mix with the later and assist in the breakdown of sewage.

Chlorination and Collection

In this chamber, the clear liquid produced from the settling tank is overflown and the liquid is disinfected with the help of chlorine. This is done because of the presence of the e-Coli bacteria present in the liquid. To reduce these bacteria to acceptable level chlorination is done. Moreover, to reduce the e-Coli, the treated liquid is kept for a period of at least 60 minutes. In some plants, disinfection is also done with the help of ultraviolet radiation. The collected liquid is discharged to overboard or settling tank depending on the geological position of the ship. If the ship is in restricted or near coastline then the sewage will be discharged into the holding tank; otherwise, the sewage is discharged directly into the sea when a high level is reached and is disposed of automatically until low-level switch activates.

Precautions for efficient operation of STP:

- The aeration blower is installed to run continuously as it helps the microorganism to sustain and grow. Never switch off the blower as it will cause the death of microorganisms, which will, in turn, reduce its clarification efficiency and will take days to grow microorganisms again.

- Never throw any foreign substances such as cigarette buds, paper, rags etc. into toilets as it may choke the pipeline or filter hampering the STP operation

- The toilet tissue used onboard should be free of vinyl components as it affects the growth of bacteria

- Never use unauthorized chemical or detergent to clean toilet

- The grey water inlet pipe must be placed lower than the water level of the inside of S.T.P to decrease the foam generation

- The pH of the samples of effluent shall be in the range of 6 to 8.5

- The Nitrite content is not to exceed 10 mg/ltr NO2.

Related Read: Maintenance and Checks for Sewage Treatment Plant on Ship

Special Area Regulation:

Currently, the Baltic Sea area is the only Special Area under Annex IV. The discharge of sewage from passenger ships within a Special Area is generally be prohibited under the new regulations, except when the ship has in operation an approved sewage treatment plant and additionally meet the nitrogen and phosphorus removal standard.

Related Read: 8 Ways in which Cruise Ships Can Cause Marine Pollution

In accordance with resolution MEPC.275(69), the discharge requirements for Special Areas in regulation 11.3 of MARPOL Annex IV for the Baltic Sea Special Area shall take effect:

1 on 1 June 2019, for new passenger ships;

2 on 1 June 2021, for existing passenger ships other than those specified in 3; and

3 on 1 June 2023, for existing passenger ships en route directly to or from a port located outside the special area and to or from a port located east of longitude 28˚10′ E within the special area that does not make any other port calls within the special area.

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Introduction to Biological Vacuum Sewage Treatment Plant

The biological vacuum sewage treatment plant consists of an integrated vacuum generator and a biological sewage treatment plant. In the sewage treatment plant an aerobic process of the biopopulation convert organic substances existing in waste water to carbon dioxide and water without danger of methane gas production.

All waste water, both black water (toilets, urinals, hospital) and grey water (galley, showers and sinks) can be treated in the biological vacuum sewage treatment plant. The treatment plant can operate in all vessels which are sailing in salt, brackish or fresh water areas.

The biological vacuum sewage treatment plant is fully automatic in normal operation and they require low maintenance.These plants are designed to fulfill the requirements of IMO MARPOL 73/78 Annex IV and USCG 33 CFR Part 159 for inspected vessels which specify discharged waste water from sewage treatment plants.

The effluent quality is as follow:

• BOD5 < 50 ppm

• Suspended solids < 50 ppm (tested on shore) or 100 ppm (tested aboard ship)

• Faecal coliforms < 250 pcs/100ml M. P. N.

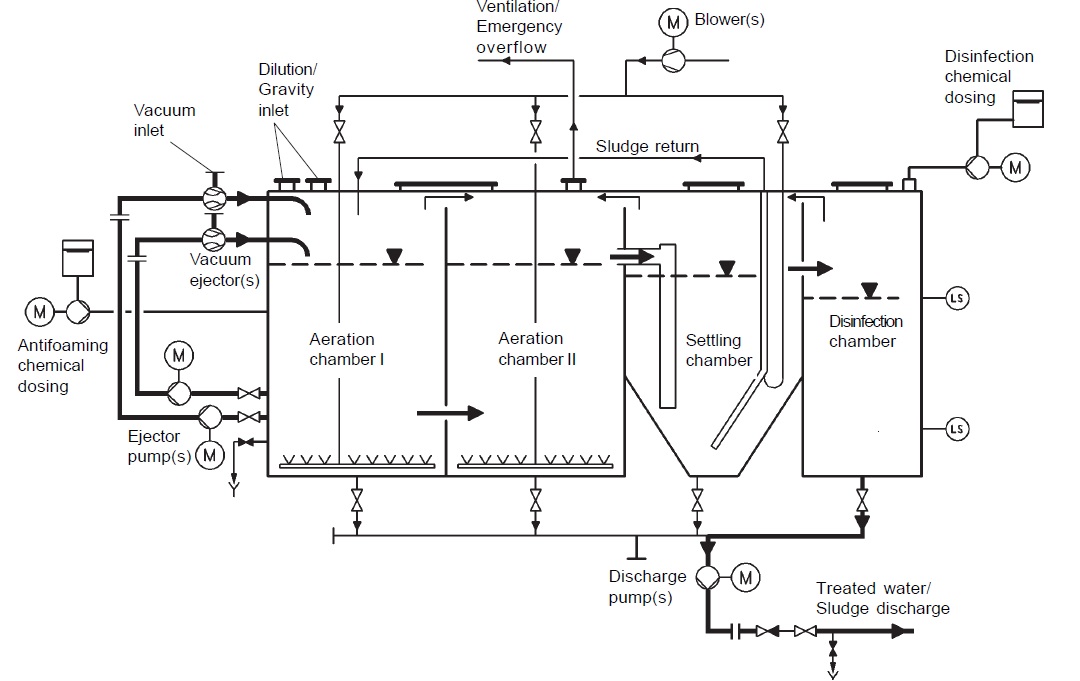

Figure below shows biological vacuum sewage treatment plant normally used on ships.

Operation

Black sewage water is collected by a vacuum ejector system as shown above. Incoming black water must be diluted with technical, grey or sea water. There is a separate dilution/gravity inlet connection built in chamber I. All waste water is led to the aeration chamber I by vacuum from vacuum toilets and by gravity from wash basins. Bacterial growth is stimulated by oxygen of air supplied by the blowers. Required air is produced by the air blowers and led to aeration chambers I and II via air distributors. The aerobic treatment process starts in the aeration chamber I and continues in the aeration chamber II. If treated waste water is coming from a vacuum toilet system, required dilution water must be added into the aeration chamber I.

An activated sludge is separated in the settling chamber by gravity and clarified water floats to the disinfection chamber. The activated sludge is pumped back to the aeration chamber I by an air driven ejector (also called as air lift). A chlorine based disinfection chemical is added by the dosing pump into the clarified water in the disinfection chamber to meet IMO’s requirements regarding presence of coliform bacterias in treated water. Treated water is pumped to sea or ashore by a discharge pump. Disinfection can be also done by UV on some models. A mineralized sludge from activation chambers I and II is pumped at given intervals sea, to on shore facilities or to the vessel’s sludge storing tank. The discharge pump is equipped with an integrated cutting device to prevent blocking.

Vacuum generation

The vacuum generation unit creates vacuum in sewage piping by means of an ejector. The vacuum generation unit consist of ejector, ejector pumps, pressure switch, vacuum gauge, shut-off valves and antifoaming dosing unit. Vacuum generation is controlled by the vacuum switch.

Aeration and blowers

Waste water is led to the aeration chamber I by gravity and vacuum. Bacterial growth is stimulated by oxygen of air. Required air is produced by the air blowers and led to the aeration chamber I and II via installed aerators. An aerobic process continues in the aeration chamber II. Inorganic solids (for instance plastic) are stopped in the aeration chambers I and II. Air flow can be adjusted between chambers I and II using air valves.

Settling of Sludge

Activated sludge is separated in the settling chamber by gravity and clarified water flows to the disinfection chamber. Activated sludge is pumped back to the aeration chamber I by an air driven ejector pump (also called as air lift). Air flow for the sludge ejector is adjusted so that the sludge return from the chamber III is about 1/3 of the pipe section (A transparent hose above tank). Rest of the air flow produced by the blower is used for aeration and divided equally between tanks I and II. Sludge has to be removed frequently from the process to maintain a good biological balance in the sewage treatment unit. Sludge content in process (in chamber I) must be kept between 100ml/l and 500 ml/l. Sludge is removed by the discharge pump.

Disinfection

Disinfection chemical (e.g. Sodium hypochlorite (NaClO), solution, active chlorine 10%) is added to the clarified water in the disinfection chamber to meet IMO’s requirements regarding presence of coliform bacterias in treated water. Residual chlorine must be kept between 2 ppm and 5 ppm. Residual chlorine can be adjusted by the dosing pump’s settings and/or timer settings. Treated water can be pumped to sea or ashore by the discharge pump.

Materials of Construction

- Tank material: Steel S355 EN10025

- Ejector body: Acid proof steel EN 1.4404

- Welded flanges, pipe bend: Acid proof steel EN 1.4404

- Loose flange: Al

- Nozzle: PVC

- Flap: Nature Rubber NR

- Gaskets: Rubber EPDM

Additional Components

The biological vacuum sewage treatment plant may require additional components for optimal operation.

Dilution water

Because the combined treatment plant is processing black water from vacuum toilet system, dilution water must be added into incoming sewage. There are several system options to control and monitor dilution water:

• Flow meter and pressurized fresh or technical water

• Grey water buffer/holding tank and constant flow pump

• Grey water buffer/holding tank and dilution water feeding by gravity with flow meter

Screen or Catcher

If there is a risk that a lot of non organic solids obstacles are entering in the treatment plant, a screen or catcher must

be installed before the treatment plant.

Grease separator

Grease is harmful for treatment process. If there is galley water entering to the treatment unit a grease separator must

be installed before treatment plant.

Reference: EVAC Environmental Solutions Marine Sector Operation Manual

Related Links:

Biological Vacuum Sewage Treatment Plant on Ships

Maintenance of Biological Vacuum Sewage Treatment Plant on Ships

Troubleshooting of Biological Vacuum Sewage Treatment Plant on Ships

Working and Maintenance of Air Ejector, Pressure Switch and Level Switch

Sewage Testing in Biological Vacuum Sewage Treatment Plant

Precautions in Operating Biological Vacuum Sewage Treatment Plant

- Главная

- Статьи на английском

- Engine Room

- Sewage Treatment Plant- Starting, stopping

As mentioned earlier, every machinery system on the ship requires a proper procedure to be followed for starting and stopping and failure to follow this step-by-step procedure will lead to either failure in starting or stopping the machine or to some other fault.

Sewage treatment plant is one of such equipment in the ship’s engine room that requires a step-by-step procedure during starting and stopping.

STARTING

Generally, the sewage plant is running all the time while the ship is sailing. However, the plant might be required to be started manually if it is newly installed.

This is because the new plant needs to be stopped at regular intervals of time for improving its performance and maintenance procedures.

Following are the points that need to be followed for starting a sewage treatment plant:

- Make sure if any maintenance is carried out on the sewage treatment system and all the openings have been closed properly before starting

- The sewage plant is be filled with fresh water inside the chamber

- At this stage, there are no aerobic bacteria inside the chamber, but the sewage would have started coming to the plant. In order to increase the efficiency and starting rate of the plant, a bio-pacis added to the plant by flushing the amount specified in the manual

- This bio-pacis mixed with warm water, which helps in the growth of bacteria and also in efficient functioning of the plant

- If the bio-pacis not added, the plant might take up to 5 to 7 days to become completely functional. However, with the bio-pacit becomes functional within 24 hours

- Start the air compressor or open the air valve as per the design of the plant. The pressure is maintained as per the manual. Generally 0.3-0.4 bars

- Open the sewage overboard valve and close the holding tank valve when the ship is out of restricted waters

- The plant is to be continuously monitored and checked for the flow through the transparent plastic tubes

- Asample is taken for checking for suspended solids and chlorine content

- The test must be performed every week to check the performance of the system

- Some STPs are provided with 7 bar air line with solenoid valve in case the blower has to be stopped

“Do not turn off the power source of the aeration blower under any circumstances. If this happens, the micro-organism will die and thereby reduce the overall effectiveness of the device.”

STOPPING

- Stopping of the sewage treatment plant is generally done either before entering the dry dock or in case some maintenance has to be carried out inside the treatment plant

- For stopping the system, close the inlet valve to the sewage plant, then close the overboard valve and let the sewage go overboard

- Empty all the three chambers of the plant i.e. aeration, settling and chlorination chambers

- If the chambers are not emptied, it will lead to growth of anaerobic bacteria which forms the toxic H2S gas

- If entry has to be made inside the tank, the later should be checked for hydrogen sulphidegas H2S with the help of a dragortube by taking a continuous sample from the plant

- Entry needs to be made wearing mask and rubber gloves

- In case the ship is going to the dry dock, the overboard should be connected to the shore reception facilities

References

The Ultimate Guide to Operating Procedures of Engine Room Machinery. Anish Wankhede [2014]

MirMarine – образовательный морской сайт для моряков.

На нашем сайте вы найдете статьи по судостроению, судоремонту и истории мирового морского флота. Характеристики судовых двигателей, особенности устройства вспомогательных механизмов и систем.

)

)

сразу после тотального маинтенанса. Если со временем не стало сильно хуже, то все хорошо.

сразу после тотального маинтенанса. Если со временем не стало сильно хуже, то все хорошо.

Чего только не услышишь.

Чего только не услышишь.