Инструкции

-

Руководство по эксплуатации SsangYong Actyon (2013 г.в.-в.н.)

-

Руководство по эксплуатации SsangYong Actyon (2011 г.в. — 2013 г.в.)

-

Руководство по эксплуатации SsangYong Kyron (2007 г.в.-н.в.)

-

Руководство по эксплуатации SsangYong Rexton (2013 г.в.-н.в.)

-

Руководство по эксплуатации SsangYong Rexton (2008 г.в.-2012 г.в.)

-

Руководство по эксплуатации SsangYong Actyon Sports (до 2011 г.в.)/ Actyon (до 2010 г.в.)

Руководство по эксплуатации SsangYong Actyon Sports (до 2011 г.в.)/ Actyon (до 2010 г.в.)

Скачать .pdf (10 мб)

-

Руководство по эксплуатации SsangYong Actyon Sports (2012 г.в.-н.в.)

-

Руководство по эксплуатации SsangYong Stavic

-

Руководство пользователя по автомагнитоле DWSY1003 для автомобиля SsangYong Stavic (2013г.в. – н.в.)

Руководство пользователя по автомагнитоле DWSY1003 для автомобиля SsangYong Stavic (2013г.в. – н.в.)

Скачать .pdf (2 мб)

-

Руководство пользователя по автомагнитоле KC3-8600 для автомобиля SsangYong Actyon (2011г.в.-2013г.в.)

Руководство пользователя по автомагнитоле KC3-8600 для автомобиля SsangYong Actyon (2011г.в.-2013г.в.)

Скачать .pdf (5 мб)

-

Руководство пользователя по автомагнитоле KCB-8700 для автомобиля SsangYong Actyon (2011г.в.-2013г.в.)

Руководство пользователя по автомагнитоле KCB-8700 для автомобиля SsangYong Actyon (2011г.в.-2013г.в.)

Скачать .pdf (4 мб)

-

Руководство пользователя по автомагнитоле для автомобиля SsangYong Actyon Sports (2012г.в.-н.в.)

Руководство пользователя по автомагнитоле для автомобиля SsangYong Actyon Sports (2012г.в.-н.в.)

Скачать .pdf (7 мб)

-

Руководство пользователя по автомагнитоле AGC-9145 для автомобиля Rexton (2013г.в.-н.в.)

Руководство пользователя по автомагнитоле AGC-9145 для автомобиля Rexton (2013г.в.-н.в.)

Скачать .pdf (3 мб)

-

Руководство пользователя по автомагнитоле MCD-8200 для автомобиля SsangYong Kyron (2007г.в.-н.в)

Руководство пользователя по автомагнитоле MCD-8200 для автомобиля SsangYong Kyron (2007г.в.-н.в)

Скачать .pdf (4 мб)

- Безопасность

- Мультимедиа

- Комфорт

- Транспортировка

- Все

-

Навигационная система SsangYong

-

Дорожный набор. Инструкция по эксплуатации

-

Механическая противоугонная система

-

Автосигнализация А61

-

Автосигнализация А91

-

Автосигнализация E61

-

Автосигнализации E91, E91GSM

-

Автосигнализация B64

-

Автосигнализации B94, В94GSM, B94GSM/GPS

-

Автосигнализации D94GSM, D94GSM/GPS

-

Поисковый модуль M15

-

Поисковый модуль M17

-

Поисковые модули M21-M31

-

GSM/GPS модуль

-

Интеллектуальные системы помощи при парковке

-

Велокрепление Quickball +

-

Бокс Vista черный 175х95х38 450 л.

-

McKinley лыж.крепление

-

Everest лыж.крепление

-

Грузовая платформа Excursion

-

Грузовая платформа Safari

-

Scott велокрепление

-

Крепление для лодок Sydney

-

Крепление для лодки Galactica

-

Дополнительная секция для Galactica

-

535 Zermatt крепеж для лыж

-

Крепеж для лодки Tahiti

-

Велокрепление на поперечины (прав.) Barracuda

-

Велокрепление на поперечины (лев.) Barracuda

-

Barracuda держатель велосипеда 2 в 1 (правый + левый)

-

Discovery велокрепление правый

-

Discovery велокрепление левый

-

Бокс Triton 350 сереб. черн. 162x88x41 380 л.

-

Бокс Triton 350 черн. черн. 162x88x41 380 л.

-

Бокс Triton 650 серый 224х94х43 620 л. 2-е откр.

-

Бокс Vista 320 135x85x38 320 л.

-

Бокс Vista 380 200х65х45 380 л.

-

Бокс Vista 450 175х95х38 450 л.

-

Бокс Vista 540 200х95х42 540 л.

-

Бокс Triton 450 черн. черн. 197x83x38 430 л., dual-opening, easemount

-

Бокс Triton 450 сереб. черн. 197x83x38 430 л., dual-opening, easemount

-

Багажник на рейлинги, сталь

-

Багажник на рейлинги, Alu

-

Сервисная книжка

-

Тест-драйв SsangYong Actyon Sports

Тест-драйв SsangYong Actyon Sports

Кроссовер Actyon — принципиально новый автомобиль в линейке SsangYong, который призван стать первым шагом на пути к созданию нового модельного ряда.

Cмотреть видео

Главная

>

Сервис

>

Сервис

>

Руководства по эксплуатации

Руководства по эксплуатации

В этом разделе Вы можете скачать сервисную книжку и руководства по эксплуатации для автовладельцев SsangYong в формате pdf.

Руководство по эксплуатации SsangYong Actyon

Скачать (PDF)

Руководство по эксплуатации SsangYong Actyon

Скачать (PDF)

Руководство по эксплуатации SsangYong Kyron

Скачать (PDF)

Руководство по эксплуатации SsangYong Rexton

Скачать (PDF)

Руководство по эксплуатации SsangYong Rexton

Скачать (PDF)

Руководство по эксплуатации SsangYong Actyon Sports/ Actyon

Скачать (PDF)

Сервисная книжка

Скачать (PDF)

Сервис

- Сервис

- Руководства по эксплуатации

- Химчистка и полировка

- Запись на сервис

- Гарантийное обслуживание

- Кузовной ремонт

- Запчасти

- Аксессуары

Руководство на английском языке по техническому обслуживанию и ремонту + схемы электрооборудования автомобиля SsangYong Actyon второго поколения.

- Автор: —

- Издательство: SsangYong

- Год издания: 2012

- Страниц: —

- Формат: PDF

- Размер: 95,2 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту + схемы электрооборудования автомобиля SsangYong Actyon первого поколения.

- Автор: —

- Издательство: SsangYong

- Год издания: 2006-2010

- Страниц: —

- Формат: PDF

- Размер: 1,3 Gb

Руководство по эксплуатации и техническому обслуживанию автомобилей SsangYong Actyon с 2013 года выпуска.

- Автор: —

- Издательство: Automechanic

- Год издания: —

- Страниц: 361

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 347

- Формат: PDF

- Размер: 273,2 Mb

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 356

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong New Actyon и SsangYong Korando C с 2010 года выпуска с дизельным двигателем объемом 2,0 л.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 376

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля SsangYong Actyon 2006-2010 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: 2015

- Страниц: 424

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту + каталог расходных запчастей автомобилей SsangYong Actyon и SsangYong Korando с 2011 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: 2015

- Страниц: 491

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей SsangYong Actyon и SsangYong Actyon Sports с 2006 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 352

- Формат: —

- Размер: —

Сборник руководств по эксплуатации и техническому обслуживанию автомобиля SsangYong Actyon второго поколения.

- Автор: —

- Издательство: SsangYong

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 26,1 Mb

Сборник руководств по эксплуатации и техническому обслуживанию автомобиля SsangYong Actyon первого поколения.

- Автор: —

- Издательство: SsangYong

- Год издания: —

- Страниц: 304/347

- Формат: PDF

- Размер: 19,9 Mb

- Manuals

- Brands

- SSANGYONG Manuals

- Automobile

- Actyon 2008.01

- Manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

GENERAL

1. DIMENSIONS………………………………….

LUBRICANTS………………………………….

CONNECTOR………………………………….

LAYOUT…………………………………………

3

4

6

7

12

13

14

15

17

GENERAL

0000-00

GENERAL

Related Manuals for SSANGYONG Actyon 2008.01

Summary of Contents for SSANGYONG Actyon 2008.01

-

Page 1: Table Of Contents

GENERAL 0000-00 GENERAL GENERAL 1. DIMENSIONS……..2. SPECIFICATIONS……… 3. VEHICLE IDENTIFICATION….4. MAINTENANCE INTERVAL….5. RECOMMENDED FLUIDS AND LUBRICANTS……..6. JACK-UP POINTS (DOTTED CIRCLES). 7. PIN ARRANGEMENT OF DIAGNOSTIC CONNECTOR……..8. ELECTRIC COMPONENTS AND LAYOUT……….9. STANDARD BOLTS SPECIFICATIONS.

-

Page 2

0000-00 GENERAL ACTYON 2008.01… -

Page 3: Dimensions

0000-00 4110-01 GENERAL 1. DIMENSIONS GENERAL ACTYON 2008.01…

-

Page 4: Specifications

0000-00 2. SPECIFICATIONS GENERAL ACTYON 2008.01…

-

Page 5

0000-00 GENERAL ACTYON 2008.01… -

Page 6: Vehicle Identification

Engine Number (D20DT) Certification Label The engine number is stamped on the The certification label is located on lower area of cylinder block in the the driver’s door sill (B pillar). intake manifold side. GENERAL ACTYON 2008.01…

-

Page 7: Maintenance Interval

0000-00 4. MAINTENANCE INTERVAL 1) Diesel Engine * Use only approved Ssangyong genuine parts. Maintenance service and record retention are the owner’s responsibility. You should retain evidence that proper maintenance has been performed on your vehicle in accordance with the scheduled maintenance service chart.

-

Page 8

In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or In hilly or moutainous terrain. Severe Conditions in Air Conditioner Filter — Pollutant area or off-road driving, extended air conditioner or heater operation GENERAL ACTYON 2008.01… -

Page 9

0000-00 2) Gasoline Engine * Use only approved Ssangyong genuine parts. Maintenance service and record retention are the owner’s responsibility. You should retain evidence that proper maintenance has been performed on your vehicle in accordance with the scheduled maintenance service chart. -

Page 10

(5)* Inspect manual transmission fluid every 15,000 km (Inspect the leak of fluid at any time, occasionally), then change every 60,000 km (6)* Change automatic transmission fluid and every 60,000 km if the vehicle is mainly driven under severe conditions. (Inspect the leak of fluid at any time, occasionlly) GENERAL ACTYON 2008.01… -

Page 11

In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or In hilly or moutainous terrain. Severe Conditions in Air Conditioner Filter — Pollutant area or off-road driving, extended air conditioner or heater operation GENERAL ACTYON 2008.01… -

Page 12: Recommended Fluids And Lubricants

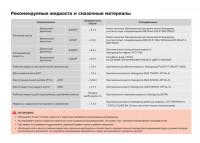

0-12 0000-00 5. RECOMMENDED FLUIDS AND LUBRICANTS Use only Ssangyong recommended fluids and lubricants. Do not mix any different types or brands of oils or fluids. This may cause damages. Keep the specified levels when adding or replacing the fluids.

-

Page 13: Jack-Up Points (Dotted Circles)

0-13 0000-00 6. JACK-UP POINTS GENERAL ACTYON 2008.01…

-

Page 14: Pin Arrangement Of Diagnostic Connector

0-14 0000-00 7. PIN ARRANGEMENT OF DIAGNOSTIC CONNECTOR It is installed under the instrument panel and consists of 16 pins 1) Functions of Terminal GENERAL ACTYON 2008.01…

-

Page 15: Electric Components And Layout

0-15 0000-00 8. ELECTRIC COMPONENTS AND LAYOUT 1) Wiring Harness Arrangement GENERAL ACTYON 2008.01…

-

Page 16

0-16 0000-00 2) Components Locator GENERAL ACTYON 2008.01… -

Page 17: Standard Bolts Specifications

0-17 0000-00 9. STANDARD BOLTS SPECIFICATIONS GENERAL ACTYON 2008.01…

-

Page 18

Determine extra proper tightening torque if tightens with washer or packing. If tightens bolts on the below materials, be sure to determine the proper torque. Aluminum alloy: Tighten to 80 % of above torque table. Plastics: Tighten to 20 % of above torque table. GENERAL ACTYON 2008.01… -

Page 19

ENGINE GENERAL 0000-00 ENGINE GENERAL GENERAL 1. ENGINE ASSEMBLY LAYOUT….2. ENGINE CONTROLS LAYOUT….3. ELECTRICAL COMPONENTS AND PREHEATING SYSTEM….4. INTAKE SYSTEM LAYOUT….5. EXHAUST SYSTEM LAYOUT….6. LUBRICATION SYSTEM LAYOUT..7. COOLING SYSTEM LAYOUT….8. FUEL SYSTEM LAYOUT……. 9. -

Page 21: Engine Assembly Layout

01-3 0000-00 0000-00 ENGINE GENERAL 1. ENGINE ASSEMBLY LAYOUT 1) LH SIDE VIEW 2) RH SIDE VIEW ENGINE GENERAL ACTYON 2008.01…

-

Page 22

01-4 0000-00 3) FRONT VIEW 4) FAN BELT ENGINE GENERAL ACTYON 2008.01… -

Page 23: Engine Controls Layout

Engine oil filler cap Vacuum pump PWM electric fan & fan shroud EGR valve Power steering oil reservoir Vacuum modulator Fuel filter & priming pump Brake fluid reservoir Battery ABS/ESP modulator Fuse box Air cleaner assembly Washer fluid reservoir ENGINE GENERAL ACTYON 2008.01…

-

Page 24

01-6 0000-00 2) Engine And Sensors Camshaft Position Sensor Injector Glow Plug Fuel Pressure Sensor Booster Pressure Sensor Common Rail (Common Rail) ENGINE GENERAL ACTYON 2008.01… -

Page 25

01-7 0000-00 HP Pump Knock Sensor (1 EA) & Crankshaft Vacuum Modulator Water Temperature Sensor Position Sensor Water temp. sensor Knock sensor ENGINE GENERAL ACTYON 2008.01… -

Page 26

01-8 0000-00 3) Engine Accessories Related to ECU IP Interior Fuse Box (Passenger Side) Installed Engine ECU main relay Hazard warning lamp VGT & EGR vacuum modulators, HFM HP pumpIMV Engine ECU Mounting Location ENGINE GENERAL ACTYON 2008.01… -

Page 27

Pump Filter Service Interval (Fuel Filter) Replace every 30,000 km (Draining water from fuel filter: Only whenever replacing the engine oil) Replace every 25,000 km General (Draining water from fuel filter: whenever replacing the engine oil) ENGINE GENERAL ACTYON 2008.01… -

Page 28: Electrical Components And Preheating System

01-10 0000-00 3. ELECTRICAL COMPONENTS AND PRE HEATING SYSTEM Battery Preheat Warning Lamp Glow Plug (Cluster) Engine compartment Alternator Starter motor fuse box PTC / FFH: 12V — 2.2kw 12V — 115A ENGINE GENERAL ACTYON 2008.01…

-

Page 29

No G5 for 4 cylinders (Without D20DT) IG1 power supply terminal Glow plug control signal (ECU113) Ground terminal Battery main wire Preheat completion transmit terminal : No use for vehicle without remote engine start K-line (ECU 34) ENGINE GENERAL ACTYON 2008.01… -

Page 30: Intake System Layout

01-12 0000-00 4. INTAKE SYSTEM Intake outlet hose Air cleaner Front air duct Terbocharger intercooler Supplying Compressed Air with Intake Manifold Turbocharger’s Operation To corresponding cylinders Coolant port Air cleaner Inter cooler Turbo charger From intercooler ENGINE GENERAL ACTYON 2008.01…

-

Page 31

01-13 0000-00 Recirculation of Exhaust Gas when Turbocharger Intercooler EGR Valve Operates EGR valve Intake com pressed air Exhaust gas HFM Sensor Plug-in sensor Temperature Pretension Air cleaner Turbo — charger — Sensor graph ENGINE GENERAL ACTYON 2008.01… -

Page 32: Exhaust System Layout

01-14 0000-00 5. EXHAUST SYSTEM EEGR Pipe Passage for recirculation of exhaust gas DOC (Diesel Catalytic Converter) Exhaust Manifold To turbo — To EGR charger pipe From cylinders ENGINE GENERAL ACTYON 2008.01…

-

Page 33

IP interior fuse duct hose valve that Engine ECU box (RH) opens/closes due to pressure differences (No. 95) No.63(7.5A) between the intake side and crankcase. ENGINE GENERAL ACTYON 2008.01… -

Page 34: Lubrication System Layout

01-16 0000-00 6. LUBRICATION SYSTEM Oil dipstick gauge Cylinder Head Cover Oil Pressure Warning Lamp (Cluster) Oil Pan and Baffle Plate (Integrated Type) Oil Strainer ENGINE GENERAL ACTYON 2008.01…

-

Page 35

Separated oil returns to oil pan via oil drain port and the gas will be burnt again after entering the combustion chamber through duct hose valve that opens/closes due to pressure differences between the intake side and crankcase. ENGINE GENERAL ACTYON 2008.01… -

Page 36: Cooling System Layout

Coolant inlet hose Return hose Coolant outlet hose PWM electric Radiator Coolant Port Water Pump & Pipe Thermostat (inside) Coolant — Cylinder outlet port Radiator block Reservoir (Coolant inlet hose) Radiator Assembly Cooling Fan and Fan Clutch ENGINE GENERAL ACTYON 2008.01…

-

Page 37

01-19 0000-00 Engine Oil Filter & Cooler Oil filter cap Oil cooler cooler filter Oil pressure switch ENGINE GENERAL ACTYON 2008.01… -

Page 38: Fuel System Layout

Fuel filter Connector HP Pump Fuel return port Fuel return port Fuel tempera — ture sensor Venturi IMV connector IMV valve High pres — sure fuel supply port Low pres — sure fuel supply port ENGINE GENERAL ACTYON 2008.01…

-

Page 39

01-21 0000-00 Cylinder Head Fuel return hose Fuel pipe Common rail High pressure fuel pipe Fuel rail pressure sensor ENGINE GENERAL ACTYON 2008.01… -

Page 40: Fuel Supply System

Furthermore, ECU uses signals from coolant temperature sensor and air temperature sensor, booster pressure sensor and barometric sensor as compensation signal to respond to injection starting, pilot injection set values, various operations and variables. ENGINE GENERAL ACTYON 2008.01…

-

Page 41: Cleanness

The core elements of fuel system has very high preciseness that is easily affected by dust or very small foreign material. Therefore, make sure to keep the preliminary works and job procedures in next pages. If not, lots of system problems and claims may arise. ENGINE GENERAL ACTYON 2008.01…

-

Page 42

At this point, thoroughly clean the related area in engine compartment. Clean the engine compartment before starting service works. Tool kit for Took kit for low Removal tool box and high pressure line pressure line cap kits ENGINE GENERAL ACTYON 2008.01… -

Page 43

If not, the injection point may be deviated from correct position, and it may cause engine disorder. Plug the disconnected parts with sealing caps, and remove the caps immediately before replacing the components. ENGINE GENERAL ACTYON 2008.01… -

Page 44

Priming pump filled pump. Check the installed components again and connect the negative battery cable. Start the engine and check the operating status. With SCAN-100, check if there are current faults and erase the history faults. ENGINE GENERAL ACTYON 2008.01… -

Page 45

Due to engine layout, a customer cannot easily drain water from fuel filter directly, so if a customer checks in to change engine oil, be sure to perform water drain from fuel filter. (See fuel system for details.) ENGINE GENERAL ACTYON 2008.01… -

Page 46: Maintenance And Repair

Using oils of any viscosity other than those viscosities recommended could result in engine damage. ▷ Cooling System Service Drain, flush and refill the system with new coolant. Refer to «Recommended Fluids And Lubricants» in this section. ENGINE GENERAL ACTYON 2008.01…

-

Page 47

Check the tires for abnormal wear or damage. To equalize wear and obtain maximum tire life, rotate the tires. If irregular or premature wear exists, check the wheel alignment and check for damaged wheels. While the tires and wheels are removed, inspect the brakes. Tire Rotation (Left-hand Drive Type) ENGINE GENERAL ACTYON 2008.01… -

Page 48: Guidelines For Service Work Safety

Notice means precautions on tool/device or part damages or personal injuries that can occur during service works. However, above references and cautions cannot be inclusive measures, so should have habits of taking concerns and cautions based on common senses. ENGINE GENERAL ACTYON 2008.01…

-

Page 49

LOCK position before work. · Be careful not to touch hot components like catalytic converter, muffler and exhaust pipe when the engine is running or just stopped. They may burn you badly. ENGINE GENERAL ACTYON 2008.01… -

Page 50

While removing engine, drain engine oil, coolant and fuel in fuel system to prevent leakage. During service work of removal/installation, be sure to check each connected portions to engine not to make interference. ENGINE GENERAL ACTYON 2008.01… -

Page 51

When replacing electrical equipment, use the same genuine part and be sure to check whether ground or connecting portions are correctly connected during installation. If ground or connecting portion is loosened, there can be vehicle fire or personal injury. ENGINE GENERAL ACTYON 2008.01… -

Page 52: During Service Work For Inspection

Brake fluid and anti-freeze can damage painted surface of body. So carefully handle them during service work. Use recommended and specified tools to increase efficiency of service work. Use only genuine spare parts. ENGINE GENERAL ACTYON 2008.01…

-

Page 53

(Refer to cleanness.) If remove high pressure fuel supply pipe between HP pump and fuel rail and high pressure fuel pipe between fuel rail and each injector, be sure to replace them with new. ENGINE GENERAL ACTYON 2008.01… -

Page 54: During Service Work For Electric Devices

If lift up the vehicle with safety jack and stand, should be more careful during works. Never be under the vehicle if supported with only jack. If have to be under the vehicle, · be sure to use safety block. Use wheel block in front and rear of every wheel. · ENGINE GENERAL ACTYON 2008.01…

-

Page 55: Owner Inspections And Services

▶ Headlamp Aim Take note of the light pattern occasionally. Adjust the headlights if the beams seem improperly aimed. ENGINE GENERAL ACTYON 2008.01…

-

Page 56

Periodically inspect the surface beneath the vehicle for water, oil, fuel or other fluids, after the vehicle has been parked for a while. Water dripping from the air conditioning system after use is normal. If you notice fuel leaks or fumes, find the cause and correct it at once. ENGINE GENERAL ACTYON 2008.01… -

Page 57

▶ Hood Latch Operation When opening the hood, note the operation of the secondary latch. It should keep the hood from opening all the way when the primary latch is released. The hood must close firmly. ENGINE GENERAL ACTYON 2008.01… -

Page 58

Inspect the hoses. Replace the cracked, swollen, or deteriorated hoses. Tighten the clamps. Clean the outside of the radiator and the air conditioning condenser. Wash the filler cap and the neck. Pressure test the cooling system and the cap in order to help ensure proper operation. ENGINE GENERAL ACTYON 2008.01… -

Page 59: Standard Bolts Specifications

01-41 0000-00 16. STANDARD BOLTS SPECIFICATIONS ENGINE GENERAL ACTYON 2008.01…

-

Page 60

Determine extra proper tightening torque if tightens with washer or packing. If tightens bolts on the below materials, be sure to determine the proper torque. Aluminum alloy: Tighten to 80 % of above torque table. Plastics: Tighten to 20 % of above torque table. ENGINE GENERAL ACTYON 2008.01… -

Page 61

It satisfies the strict emission regulation and provides improved output and maximum torque. Oil separator Coolant (PCV valve) reservoir Engine oil Vacuum dipstick pump Air cleaner assembly Engine oil filler cap VGT Turbo sensor charger Engine ENGINE ASSEMBLY ACTYON 2008.01… -

Page 62

02-3 1212-01 Vacuum modulator ABS/ESP Brake fluid modulator EGR valve reservoir Battery Fuel filter & priming pump Washer fluid reservoir Power steering oil PWM electric reservoir fan & fan shroud ENGINE ASSEMBLY ACTYON 2008.01… -

Page 63

Oil separator (with PCV) VGT Turbo charger EGR pipe Water pump pulley Alternator Crankshaft pulley Oil pan Auto tensioner Air conditioner compressor Auto tensioner pulley Power steering pump pulley Power steering pump EGR valve Idle pulley Viscos clutch pulley ENGINE ASSEMBLY ACTYON 2008.01… -

Page 64

Fuel pressure sensor Water outlet port EGR valve Oil filler Booster pressure sensor Common rail (25 ± 2.5 Nm) Vacuum pump (10 ± 1.0 Nm) Glow plug (15 ± 3 Nm) Cylinder head cover VGT Turbo charger ENGINE ASSEMBLY ACTYON 2008.01… -

Page 65

Air conditioner compressor Engine mounting bracket Vacuum modulator for VGT turbocharger actuator Flywheel Crank position sensor Gap: 0.7 ~ 1.5 mm Vacuum modulator for EGR valve Oil filter & oil cooler Vacuum pump Booster pressure sensor Intake manifold ENGINE ASSEMBLY ACTYON 2008.01… -

Page 66

02-7 1212-01 Left Side View Cylinder head jack valve screw VGT Turbo charger assembly Cylinder block assembly Engine mounting bracket Oil pan Alternator Water pump EGR pipe Oil dipstick gauge Oil separator (with PCV) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 67

02-8 1212-01 2. SPECIFICATIONS AND PERFORMANCE CURVE 1) Specifications ENGINE ASSEMBLY ACTYON 2008.01… -

Page 68

02-9 1212-01 2) Engine Performance Curve (1) Output and Torque (2) Oil Temperature/Pressure and Boost Pressure ENGINE ASSEMBLY ACTYON 2008.01… -

Page 69

02-10 1212-01 3. TIGHTENING TORQUE ENGINE ASSEMBLY ACTYON 2008.01… -

Page 70

02-11 1212-01 ENGINE ASSEMBLY ACTYON 2008.01… -

Page 71

02-12 1212-01 ENGINE ASSEMBLY ACTYON 2008.01… -

Page 72

— Initial cleaning: 5,000 km, Clean or change every 10,000 km as required. However, change every 30,000 km. Service Interval — If the vehicle is operated under severe condition (short distance driving, extensive ldling or driving in dusty condition): More frequent maintenance is required. ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 73

1. Plug-in sensor 2. Cylinder housing 3. Protection grid Plug-in sensor 4. Hybrid cover 5. Measuring duct cover 6. Housing 7. Hybrid 8. Sensor 9. Mounting plate Temperature 10. O-ring Protection grid sensor 11. Temperature sensor ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 74

Turbocharger Intercooler The charging efficiency may be lowered or the knocking may happen as the intake air is heated and the density of air is lowered. The intercooler is the device which cools the supercharged air. ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 75

04-6 2313-01 2) Layout ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 76

The inlet port and coolant outlet port is integrated together. Therefore, be careful not to let the residual coolant in the manifold enter the inlet port when removing the intake manifold. Also, replace the gasket with a new one and tighten it to the specified torque (25 ± 2.5 Nm). ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 77

Intake air Intake air Exhaust gas 1. EGR pipe (RH) 5. Exhaust gas 2. EGR pipe (center) 6. EGR pipe (LH) 3. Coolant emission port 7. Vacuum modulator to the EGR valve 4. Intake air (intercooler) ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 78

Thus, more air is entered the cylinder than the engine only with the turbocharger to give more power. Intercooler For removal and installation procedures, refer to the «Cooling system» section in DI engine service manual. ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 79

04-10 2313-01 2. AIR FLOWS 1) Work Flow of Intake System ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 80

The DI engine ECU receives feedback signal of change in amount of air being passed through the HFM sensor according to the opening amount of the EGR valve. ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 81

Therefore, disregarding the modulator for the EGR valve in DI engine, one must keep in mind that the other modulator is used to control the booster pressure valve in turbo charger. ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 82

EGR Valve and Installation Location Intake air Intake (intercooler) manifold Intake Intake manifold manifold EGR pipe EGR pipe (LH) Exhaust Manifold Exhaust manifold To turbo- To EGR EGR pipe (RH) charger valve Diesel catalytic converter → Muffler ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 83

05-6 1913-01 2) Exhaust Gas Flows ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 84

When operating in dusty, sandy and salty areas In hilly or moutainous terrain When doing frequent trailer towing 2. OIL PRESSURE SWITCH Operating temperature: -40 ~ 140°C Operating pressure: 0.3 ~ 0.55 bar Permissible pressure: 10 bar LUBRICATION SYSTEM ACTYON 2008.01… -

Page 85

Blow-by gas again after entering the combustion chamber (air duct hose) through air duct hose via PCV valve that Inlet port opens/closes due to pressure differences between the intake side and crankcase. Oil (oil gauge pipe) LUBRICATION SYSTEM ACTYON 2008.01… -

Page 86

06-5 1533-01 Oil pressure Warning Lamp Cylinder Head Cover (Cluster) Oil Pan and Baffle Plate Oil Strainer Oil Filter & Oil Cooler (Integrated Type) cooler filter LUBRICATION SYSTEM ACTYON 2008.01… -

Page 87

Main oil gallery: φ 16 Hole to cylinder head: φ 9 Main bearing hole: φ 7 Chain and injection pump: φ 7 Return hole: φ 14 Chain nozzle: φ 1 HP pump bearing: φ 6 Cylinder Block LUBRICATION SYSTEM ACTYON 2008.01… -

Page 88

2. LUBRICATION DIAGRAM Opening pressure of by-pass valve in oil filter: 3 ± 0.4 bar To prevent instant oil shortage after stopping the engine, the return check valve is installed in oil supply line of cylinder head LUBRICATION SYSTEM ACTYON 2008.01… -

Page 89

07-3 2112-01 9210-05 ENGINE COOLING SYSTEM 1. ENGINE COOLING SPECIFICATIONS COOLING SYSTEM ACTYON 2008.01… -

Page 90

07-4 2112-01 1. COMPONENTS ENGINE COOLING Coolant Reservoir Water Pump Cooling Fan and Coolant Radiator Assembly Fan Clutch Temperature Sensor COOLING SYSTEM ACTYON 2008.01… -

Page 91

Cylinder block side · Block #5 → Oil cooler → Heater → Heater water pump inlet pipe → Water pump Cylinder head side · Cylinder head → Coolant outlet port (intake #1) → Radiator → Water pump COOLING SYSTEM ACTYON 2008.01… -

Page 92

It prevents cooling efficiency from decreasing due to coolant separation between · cylinder #4 and #5. In OM 600 engine, the cooling fan is installed with water pump, however, in case of D27DT engine, it is connected to water pump with an additional pulley. COOLING SYSTEM ACTYON 2008.01… -

Page 93

08-3 1451-01 1461-01 ENGINE ELECTRICAL SYSTEM 1.SPECIFICATIONS OF ENGINE ELECTRIC ENGINE ELECTRIC DEVICES ACTYON 2008.01… -

Page 94

08-4 1451-01 1. COMPONENTS OF ELECTRIC IN ENGINE Fuel Pressure Camshaft Position Coolant Temperature Fuel Temperature Sensor Sensor Sensor Sensor Booster Pressure Oil Pressure Switch Crankshaft Position Knock Sensor Sensor Sensor (1 EA) ENGINE ELECTRIC DEVICES ACTYON 2008.01… -

Page 95

08-5 1451-01 2. COMPONENTS OF ELECTRIC DEVICES IN ENGIN Alternator Glow Plug Capacity PTC equipped vehicle : 12V — 140A FFH equipped vehicle : 12V — 115A Air Conditioner Compressor Starter ENGINE ELECTRIC DEVICES ACTYON 2008.01… -

Page 96

08-6 1451-01 3. CIRCUIT DIAGRAM OF PREHEATING SYSTEM 1) Preheating ENGINE ELECTRIC DEVICES ACTYON 2008.01… -

Page 97

08-7 1451-01 4. CIRCUIT DIAGRAM OF STARTING AND ALTERNATOR 1) Starting & Charging ENGINE ELECTRIC DEVICES ACTYON 2008.01… -

Page 98

Water Pump and Pipe Coolant Port Thermostat (inside) Cylinder block Coolant outlet Radiator port Reservior (coolant inlet hose) Engine Oil Filter and Cooler Oil Filter cap Oil cooler Oil cooler Oil filter Oil pressure switch ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 99

09-4 1491-01 2. TOP VIEW Fuel Pressure Sensor Booster Pressure Sensor Injectors (4 EA) Glow Plugs (4 EA) ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 100

09-5 1491-01 3. SIDE VIEW Coolant Temperature Knock Sensors (1 EA) Sensor Fuel Temperature Sensor Fuel Pressure Crankshaft Position Regulating Valve Sensor ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 101

(Water warning light, glow Accelerator sensor plug Vehicle speed sensor indicator light, engine warning Switch input signal light) (IG, brake, clutch, A/C signal, Preheater (auxiliary heater) A/C compressor) K — line CAN communication Self-diagnosis ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 102

Driving mode control If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 103

If the pressure is lower than the demand, current is reduced so that the fuel sent to the high pressure pump is increased. If the pressure is higher than the demand, current is increased so that the fuel sent to the high pressure pump is reduced. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 104

To do this, special mapping is used to determine the injection timing advance as a function of the engine speed and of the water temperature. This requirement only concerns the starting phase, since once the engine has started the system must re-use the mapping and the corrections described previously. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 105

This correction is used to adapt the pilot injection timing as a function of the atmospheric pressure and therefore the altitude. During the starting phase, the pilot injection timing is determined as a function of the engine speed and of the coolant temperature. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 106

This strategy leads to a fuel correction which is added to the total fuel of each cylinder. The correction is determined before each injection as a function of the instantaneous engine speed. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 107

A mapping determines the minimum fuel which can control an injector as a function of the rail pressure. As soon as the main fuel falls below this value, the fuel demand changes to 0 because in any case the injector is not capable of injecting the quantity demand. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 108

The system compares the driver demand with this limit and chooses the smaller of the 2 values. The driver demand is then corrected according to the coolant temperature. This correction is added to the driver demand. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 109

A correction depending on the air temperature and the atmospheric pressure is made in order to increase the supercharge flow during cold starts. It is possible to alter the supercharge flow value by adding a flow offset with the aid of the diagnostic tool. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 110

The cylinder balancing strategy also allows the detection of an injector which has stuck closed. The difference in instantaneous speed between 2 successive injections then exceeds a predefined threshold. In this case, a fault is signaled by the system. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 111

The first MDP value is provided by the C2I. Each resetting then allows the closed loop of the MDP to be updated according to the deviation of the injector. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 112

The recovery modes associated with this fault consist of inhibition of the pilot injection and discharge through the injectors. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 113

The method consists in correcting the pulse that is applied to the injector with an offset that depends on the initial hydraulic map of the injector. So, the pulse should be corrected according to characteristics of each injector. ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 114

When ECU is replaced, C2I code of every injector should be input. If not, cannot accelerate the vehicle even when the accelerator pedal is depressed. C2I Number value (16 digits) For coding of C2I, refer to «Diagnosis» section ※ ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 115

1 ~ 2 mm/str, so precise control of the injector can be difficult if it gets old. So there needs MDP learning to control the very small volume precisely through learning according to getting older injectors. 1) Learning Conditions 2) Trouble Codes ENGINE CONTROL SYSTEM ACTYON 2008.01… -

Page 116

SPECIAL SERVICE TOOLS 0000-00 SPECIAL SERVICE TOOLS GENERAL 1. ENGINE ASSEMBLY……2. ENGINE HOUSING ASSEMBLY SPECIAL TOOLS ANDEQUIPMENT..3. ENGINE INTAKE …….. -

Page 117

10-2 0000-00 SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 118

1. ENGINE ASSEMBLY Injector Puller Glow Plug Wrench Sealing Caps Fuel Pipe Wrench Y99220072B Y99220132B 665 995 5844 Injector Copper Washer Puller Y99220022B Valve Pulley Engine Lock Remover/Installer Lock/Wrench 602 589 00 40 00 Y99220082B Y99220052B SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 119

10-4 0000-00 Glow Plug Socket Removal/Installation Removal/Installation Head Bolt Wrench Socket for High Pressure Device for HP Pump Pipe SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 120

0000-00 2. ENGINE HOUSING ASSEMBLY SPECIAL TOOLS AND EQUIPMENT Name and Part Number Application Y99220092B Compression pressure measuring adapter and gauge Y99220082B Supporting bar and lever Y99220162B Guide pin extractor Y99220112B Intake manifold guide pin SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 121

10-6 0000-00 Name and Part Number Application Y99220152B HLA remover Y99220142B Stem seal installer SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 122

10-7 0000-00 3. ENGINE INTAKE Name and Part Number Application Y99220112B Installation of intake manifold Intake manifold guide pin SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 124

The cruise control system is a supplementary system, which helps the driver to drive the vehicle at a desired speed without using the accelerator pedal under the traffic condition where the vehicle-to-vehicle distance meets the legal requirement. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 125

Use the cruise control system only when driving on motorways or highways. Do not use the cruise control system where the road conditions are as follows: — When there is strong wind or cross wind. — Heavy traffic. — Slippery roads or steep decline. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 126

11-5 8510-23 2. CIRCUIT DIAGRAM 1) Configuration CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 127

Refer to the following pages for details of operation. Never use the cruise control system until you get used to it. Improper use or not fully aware of this function could result in collision and/or personal injuries. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 128

(0.81 mph). For example, if you want to increase the speed 13 km/h (81 mph) more than the previous set speed, tap up the switch lever to ACCEL side ten times without using the accelerator pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 129

(0.62 mph). For example, if you want to decrease the speed 10 km/h (62 mph) lower than the previous set speed, tap down the switch lever to DECEL side ten times without using the brake pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 130

But the driver should know the previous set speed to react to the changed vehicle speed properly. If the vehicle speed increases abruptly, depress the brake pedal to adjust the vehicle speed properly. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 131

Ensure that the braking distance is maintained and use the brake pedal if needed. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 132

1. MAJOR COMPONENTS IN ENGINE AND ENGINE COMPARTMENT The electronically controlled advanced D20DT engine that has high pressure fuel system has been introduced to this vehicle. It satisfies the strict emission regulation and provides improved output and maximum torque. D20DT (EURO) D20DT ENGINE ASSEMBLY ACTYON 2008.01… -

Page 133

01-4 1114-00 1) Engine Assembly Structure Front View Touch idler equipped (for A/T) Top View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 134

01-5 1114-00 Right Side View Left Side View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 135

01-6 1114-00 2. SPECIFICATIONS AND PERFORMANCE CURVE 1) Specifications ENGINE ASSEMBLY ACTYON 2008.01… -

Page 136

01-7 1114-00 2) Engine Performance Curve (1) Output and Torque General (2) Oil Temperature/Pressure and Boost Pressure General ENGINE ASSEMBLY ACTYON 2008.01… -

Page 137

01-8 1114-00 3. TIGHTENING TORQUE ENGINE ASSEMBLY ACTYON 2008.01… -

Page 138

01-9 1114-00 ENGINE ASSEMBLY ACTYON 2008.01… -

Page 139

01-10 1114-00 ENGINE ASSEMBLY ACTYON 2008.01… -

Page 140

Installation order (Based on the number in the picture) 10 → 9 → 8 → 7 → 6 → 5 → 4 → 3 → 2 → 1 → 14 → 13 → 12 → 11 (Reverse order of removal) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 141

4. MAJOR CHANGES IN D20DT (EURO IV) ENGINE (COMPARED TO D20DT) 1) Engine Assembly D20DT (EURO 4) Engine D20DT Engine Front Side View Touch idler equipped (for A/T) Top Side View Right Side View Left Side View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 142

* E-EGR valve: Electric controlled E-EGR valve EGR valve ECU controls the EGR valve directly without any media. It provide more precise EGR control by transmitting the electric signal of EGR valve operating position. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 143

* Reason of changes EGR system layout To satisfy the emission E-EGR valve Throttle regulation, E-EGR valve body cooler adopted. And the layout also has a great difference from D27DT. EGR cooler EGR center pipe EGR valve ENGINE ASSEMBLY ACTYON 2008.01… -

Page 144

Also, mounting location of booster pressure sensor is changed. Water pump For D20DT (EURO4) engine: Additional connecting port for EGR cooler hose Coolant outlet port For D20DT (EURO4) engine: Additional port for coolant of EGR cooler ENGINE ASSEMBLY ACTYON 2008.01… -

Page 145

(It is also installed on the connection of the high pressure fuel supply line of the HP pump.) ENGINE FUEL SYSTEM ACTYON 2008.01… -

Page 146

Also, the engine ECU, HFM sensor and EGR system are changed to control the fuel injection volume and engine more precisely. Fuel high pressure pipe (HP pump → Common rail) ENGINE FUEL SYSTEM ACTYON 2008.01… -

Page 148

(7) Common Rail (Orifice for Preventing Fuel Pulsation Added) Orifice Orifice for HP pump fuel outlet Fuel Supply Rail (Increase in I.D) Fuel pipe Common rail Fuel rail pressure High pressure sensor fuel pipe ENGINE FUEL SYSTEM ACTYON 2008.01… -

Page 149

HP pump Fuel tank HP pump Fuel tank HP Pump Fuel temperature Fuel return Fuel return port sensor port IMV valve Venturi High pressure Low pressure fuel supply port fuel supply port (orifice included) connector ENGINE FUEL SYSTEM ACTYON 2008.01… -

Page 150

02-8 1881-00 2. FUEL FLOW OF D20DT (EURO 4) ENGINE ENGINE FUEL SYSTEM ACTYON 2008.01… -

Page 151

Also, the improved HFM sensor (from HFM5.0 to HFM6.0) has been installed to control the intake air precisely so that the NOx in the exhaust gas can be decreased. ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 152

03-4 2321-01 2. INTAKE SYSTEM LAYOUT Uncompressed air Compressed air VGT Turbo Chargera Air cleaner Ambient air HFM Sensor (ver. 6.0) Temperature sensor Turbo coeaner charger Pretension graph ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 153

To corresponding Coolant Supply power cylinders Ground port Output voltage Compress ed air EGR gas Throttle body Normal: flap open Engine stopped: flap closed Intake duct Intake duct Intercooler Intake manifold Turbo charger (Throttle body) ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 154

Intake manifold Turbocharger intercooler (Intake compressed air) EGR gas (From EGR cooler) Exhaust manifold Throttle bod Turbocharger EGR pipe EGR pipe E-EGR valve EGR cooler Coolant E-EGR valve To EGR cooler Intake manifold Exhaust manifold ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 155

Separated oil returns to oil pan via oil drain port and the gas will be burnt again after entering the combustion chamber through air duct hose via PCV valve that opens/closes due to pressure differences between the intake side and crankcase. ENGINE LUBRICATION SYSTEM ACTYON 2008.01… -

Page 156

If too much oil or particulate material is accumulated, check the followings: 1. Engine oil level 2. EGR valve (exhaust gas leak and operating condition) 3. Turbocharger (oil/gas leak and operating condition) 4. PCV oil separator (installation condition and leak) 5. PCV oil separator (some functions) ENGINE LUBRICATION SYSTEM ACTYON 2008.01… -

Page 157

ENGINE COOLING SYSTEM 2112-00/1520-00 ENGINE COOLING SYSTEM COOLING SYSTEM 1. COMPARISON IN COOLING SYSTEM FOR EACH ENGINE……. WATER PUMP 1. OVERVIEW………. -

Page 158

06-2 0000-00 ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 159

For the D20DT (EURO4) engine, the cooling system is equipped with E-EGR cooler and the water pump which its capacity is improved according to the additional coolant line in the cylinder block. 1) Cooling System for Engine ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 160

The capacity of water pump has been increased due to the EGR cooler, increased engine power and additional coolant port in the cylinder block. For D20DT (EURO4) engine For D20DT engine Port to EGR cooler ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 161

06-5 0000-00 1) Structure of Water Pump for D20DT Engine ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 163

The glow control relay (K-line communication with engine ECU) is deleted. The unit communicates via CAN communication with engine ECU. Also, the number of pins is increased as glow plug’s performance has been improved (1000 C increase in approx. 2 ° seconds). ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 164

07-4 1491-01 2. D20DT (EURO4) ENGINE’S ECU CIRCUIT ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 165

SPECIAL SERVICE TOOLS 0000-00 SPECIAL SERVICE TOOLS GENERAL 1. LOCATION OF ENGINE AND MAJOR SPECIAL SERVICE TOOLS…. -

Page 166

08-2 0000-00 SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 167

1. LOCATION OF ENGINE AND MAJOR SPECIAL SERVICE TOOLS Injector copper washer Injector Puller Glow Plug Socket Puller Sealing Caps (Fuel line) Removal/Installation Device Removal/Installation Socket for Head Bolt Wrench for HP Pump High Pressure Pipe SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 169

The cruise control system is a supplementary system, which helps the driver to drive the vehicle at a desired speed without using the accelerator pedal under the traffic condition where the vehicle-to-vehicle distance meets the legal requirement. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 170

Use the cruise control system only when driving on motorways or highways. Do not use the cruise control system where the road conditions are as follows: — When there is strong wind or cross wind. — Heavy traffic. — Slippery roads or steep decline. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 171

09-5 8510-23 2. CIRCUIT DIAGRAM 1) Configuration CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 172

Refer to the following pages for details of operation. Never use the cruise control system until you get used to it. Improper use or not fully aware of this function could result in collision and/or personal injuries. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 173

(0.81 mph). For example, if you want to increase the speed 13 km/h (81 mph) more than the previous set speed, tap up the switch lever to ACCEL side ten times without using the accelerator pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 174

(0.62 mph). For example, if you want to decrease the speed 10 km/h (62 mph) lower than the previous set speed, tap down the switch lever to DECEL side ten times without using the brake pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 175

But the driver should know the previous set speed to react to the changed vehicle speed properly. If the vehicle speed increases abruptly, depress the brake pedal to adjust the vehicle speed properly. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 176

Ensure that the braking distance is maintained and use the brake pedal if needed. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 177

Battery cables should be disconnected before any major work is performed on the engine. Failure to disconnect cables may result in damage to wire harness or other electrical parts. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 178

Any time the air cleaner is removed, the intake opening should be covered. This will protect against accidental entrance of foreign material, which could follow the intake passage into the cylinder and cause extensive damage when the engine is started. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 179

01-5 1113-01 2. G23D ENGINE ASSEMBLY Front View Rear View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 180

01-6 1113-01 LH Side View RH Side View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 181

01-7 1113-01 3. G23D ENGINE STRUCTURE Front View Side View ENGINE ASSEMBLY ACTYON 2008.01… -

Page 182

Side View FUNCTION FUNCTION Camshaft Adjuster Oil Pump Drive Chain Oil Filler Cap Oil Strainer Engine Hanger Bracket Oil Pump Cooling Fan and Viscous Clutch Ring Gear and Flywheel of Drive Plate Oil Filter Piston Timing Chain ENGINE ASSEMBLY ACTYON 2008.01… -

Page 183

Apply an aerosol-type powder (such as foot powder) to the suspected area. Operate the vehicle under normal operating conditoins. Visually inspect the suspected component. You should be able to trace the leak path over the white powder surface to the source. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 184

The seal bore is damaged (scratched, burred or nicked). The seal is damaged or worn. Improper installation is evident. There are cracks in the components. The shaft surface is scratched, nicked or damaged. A loose or worn bearing is causing excess seal wear. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 185

Measure the compression pressure of the other cylinders in the same way. If measured value is not within the specifications, perform the cylinder pressure leakage test. Discharge the combustion residues in the cylinders before testing the compression pressure. Apply the parking brake before cranking the engine. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 186

Max. 10 % At Piston and Piston Ring Max. 20 % Cylinder Number ▶ 1, 4 OT (TDC) 2, 3 UT (BDC 180 °) ▶ Cylinder Number Cylinder Pressure Bosch, EFAW210A Sun, CLT 228 Leakage Tester ENGINE ASSEMBLY ACTYON 2008.01… -

Page 187

Measure the leakage volume in the completely opening condition of throttle valve by pulling the acceleration cable. Perform the pressure test according to the firing order. Firing Order: 1 — 3 — 4 — 2 Compare the leakage pressure with the specifications. ENGINE ASSEMBLY ACTYON 2008.01… -

Page 188

01-14 1113-01 5. GENERAL DIAGNOSIS ENGINE ASSEMBLY ACTYON 2008.01… -

Page 189

01-15 1113-01 ▶ General Diagnosis (Cont’d) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 190

01-16 1113-01 ▶ General Diagnosis (Cont’d) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 191

01-17 1113-01 ▶ General Diagnosis (Cont’d) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 192

01-18 1113-01 ▶ General Diagnosis (Cont’d) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 193

01-19 1113-01 6. SPECIFICATIONS 1) Engine Specifications MSE : Engine Control Module 3.53D : 4 Cylinder Version ENGINE ASSEMBLY ACTYON 2008.01… -

Page 194

01-20 1113-01 2) Fastener Tightening Specifications ENGINE ASSEMBLY ACTYON 2008.01… -

Page 195

01-21 1113-01 ▶ Fastener Tightening Specifications (Cont’d) ENGINE ASSEMBLY ACTYON 2008.01… -

Page 196

01-22 1113-01 2) Performance Curve ENGINE ASSEMBLY ACTYON 2008.01… -

Page 198

02-3 1713-08 0000-00 ENGINE INTAKE SYSTEM 1. SPECIFICATIONS (1) Fastener Tightening Specifications ENGINE INTAKE SYSTEM ACTYON 2008.01… -

Page 199

03-3 2420-01 2420-01 ENGINE EXHAUST SYSTEM 1. SPECIFICATION (1) Fastener Tightening Specifications ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 200

000~500,000ft3. (10 times of a football field) Generally Alumina (AL2 O3) is used as a raw materialand its 7 phases of gamma, delta, theta have big areas and high stability for the temperature, and nowadays gamma Alumina is used usually. ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 201

HC and CO. Catalytic material supplies Oxygen adheres to catalytic Catalytic material conversion each CO and HC with O2 for process by DOC material : below 180°C their oxidation : above 180°C ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 202

EGR valve is installed on the diesel engine of Musso, Korando, Istana and Rexton. And micro switch is installed together to control EGR valve. The setting method of micro switch is identical with the existing one. ENGINE EXHAUST SYSTEM ACTYON 2008.01… -

Page 203

04-3 2112-01 2110-01 ENGINE COOLING SYSTEM 1. GENERAL SPECIFICATIONS ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 204

04-4 2112-01 2. FASTENER TIGHTENING SPECIFICATIONS ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 205

10. Lower Radiator Insulator 3. Inlet Hose 11. Plate 4. Outlet Hose 12. Clip 5. 3 way Hose 13. Upper Radiator Insulator 6. Clamp 14. Bracket 7. Clamp 15. PWM Electric Fan 8. Bolt (M6, 2 piece) ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 206

This keeps the radiator filled with the coolant to the desired level at all times and increases the cooling efficiency. Maintain the coolant level between the MIN and MAX marks on the coolant reservoir when the system is cold. ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 207

If a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse the damaged part. A bent or damaged fan assembly should always be replaced with a new one to prevent possible injury. ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 208

The Engine Coolant Temperature (ECT) sensor uses a temperature to control the signal voltage to the Engine Control Module (ECM).Coolant Temperature Gauge The coolant temperature gauge controls the instrument panel temperature indicator. The coolant temperature gauge is located with ECT sensor. ENGINE COOLING SYSTEM ACTYON 2008.01…

-

Page 209

1) Function The PWM (Pulse Width Modulation) high capacity electric fan is installed instead of electric condenser fan to enhance the durability and controllability and reduce noise. 2) Mounting Location Fan shroud PWM unit Electric fan ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 210

PWM unit is over 120~150°C. Communication function when failing: The fail signal is transmitted to the ECU when the PWM unit is malfunctioning. Soft start function: The motor speed is gradually increased when the motor is initially operated. ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 211

2.4 kg/cm2. A/C compressor is turned off when the refrigerant pressure is over 30 kg/cm2 and then is turned on when the refrigerant pressure is below 21.4 kg/cm2. ENGINE COOLING SYSTEM ACTYON 2008.01… -

Page 212

05-3 1452-01 0000-00 ENGINE ELECTRIC DEVICES 1. DIAGNOSTIC INFORMATION AND PROCEDURE 1) Ignition System ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 213

05-4 1452-01 2) Ignition System (Cont’d) ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 214

Expressed in minutes, the RC rating is the time required for a fully charged battery, at a temperature of 27°C(80°F) and being discharged at a current of 25 amperes, to reach a terminal voltage of 10.5 volts. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 215

Because the electrolyte is nearly pure water and a poor conductor in a completely discharged battery, the current accepted by the battery is very low at first. Later, as the charging current causes the electrolyte acid content to increase, the charging current will likewise increase. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 216

(AH) to restore the battery to a usable state. If the charge current is still not measurable after using the charging time calculated by · the above method, the battery should be replaced. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 217

Remove the jumper cables by reversing the above sequence exactly, removing the negative cable from the vehicle with the discharged battery first. While removing each clamp, take care that it does not touch any other metal while the other end remains attached. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 218

When the engine starts, pinion overrun protects the armature from excessive speed until the switch is opened, at which time the return spring causes the pinion to disengage. To prevent excessive overrun, the switch should be released immediately after the engine starts. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 219

The starting system circuit consists of the battery, the starter motor, the ignition switch, and all the related electrical wiring. All of these components are connected electrically. ENGINE ELECTRICAL SYSTEM ACTYON 2008.01… -

Page 220

ENGINE SPECIAL SERVICE TOOLS 0000-00 ENGINE SPECIAL SERVICE TOOLS GENERAL 1. SPECIAL SERVICE TOOLS AND… EQUIPMENT FOR ENGINE ASSEMBLY 2. SPECIAL SERVICE TOOLS AND EQUIPMENT FOR ENGINE COOLING SYSTEM………. -

Page 221

06-2 0000-00 ENGINE SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 222

W9911 0010B (102 589 00 15 00) A9917 0111B (111 589 18 61 00) Drift Lever Pusher A9917 0121B (111 589 25 63 00) A9911 0050B (102 589 12 15 00) Thrust Piece Drift ENGINE SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 223

A9911 0060B (601 589 03 14 00) A9912 0080B (617 589 00 10 00) Crankshaft Front Seal Installer Allen Wrench Socket A9910 0150B (602 589 00 40 00) A9911 0012B (DW110-090) Engine Lock Connecting Hose ENGINE SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 224

A9917 0012B (DW110-120) W9911 0020B (601 589 03 43 00) Holding Pin Crankshaft Rear Seal Installer A9910 0150A (603 589 00 40 00) A99120012B (001 589 76 21 00) Fan Clutch Holder Compression Pressure Tester ENGINE SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 225

A9910 0070A (111 589 02 01 00) A9910 0060A (111 589 00 40 00) Open End Wrench Holder A9921 0012A (124 589 15 21 00) A9910 0150A (603 589 00 40 00) Leakage Tester Fan Clutch Holder ENGINE SPECIAL SERVICE TOOLS ACTYON 2008.01… -

Page 226

The cruise control system is a supplementary system, which helps the driver to drive the vehicle at a desired speed without using the accelerator pedal under the traffic condition where the vehicle-to-vehicle distance meets the legal requirement. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 227

Use the cruise control system only when driving on motorways or highways. Do not use the cruise control system where the road conditions are as follows: — When there is strong wind or cross wind. — Heavy traffic. — Slippery roads or steep decline. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 228

07-5 8510-23 2. CIRCUIT DIAGRAM 1) Configuration CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 229

Refer to the following pages for details of operation. Never use the cruise control system until you get used to it. Improper use or not fully aware of this function could result in collision and/or personal injuries. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 230

(0.81 mph). For example, if you want to increase the speed 13 km/h (81 mph) more than the previous set speed, tap up the switch lever to ACCEL side ten times without using the accelerator pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 231

(0.62 mph). For example, if you want to decrease the speed 10 km/h (62 mph) lower than the previous set speed, tap down the switch lever to DECEL side ten times without using the brake pedal. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 232

But the driver should know the previous set speed to react to the changed vehicle speed properly. If the vehicle speed increases abruptly, depress the brake pedal to adjust the vehicle speed properly. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 233

Ensure that the braking distance is maintained and use the brake pedal if needed. CRUISE CONTROL SYSTEM ACTYON 2008.01… -

Page 234

ELECTRIC GENERAL 0000-00 ELECTRIC SYSTEM GENERAL 1. LOCATIONS OF INTERIOR UNITS AND SENSORS ……….2. LOCATION AND COMPARTMENT OF INTERIOR SWITCHES ……3. SWITCHES, UNITS AND SENSORS IN ENGINE COMPARTMENT……4. ELECTRIC COMPONENTS AND LAYOUT ………… 5. DIAGNOSTIC CONNECTOR …. -

Page 235: Locations Of Interior Units And Sensors

01-2 0000-00 0000-00 ELECTRIC GENERAL 1. LOCATIONS OF INTERIOR UNITS AND SENSORS ELECTRIC SYSTEM ACTYON 2008.01…

-

Page 236

01-3 0000-00 ELECTRIC SYSTEM ACTYON 2008.01… -

Page 237: Location And Compartment Of Interior Switches

01-4 0000-00 2. LOCATION AND COMPARTMENT OF INTERIOR SWITCHES ELECTRIC SYSTEM ACTYON 2008.01…

-

Page 238

01-5 0000-00 ELECTRIC SYSTEM ACTYON 2008.01… -

Page 239: Switches, Units And Sensors In Engine Compartment

01-6 0000-00 3. SWITCHES, UNITS AND SENSORS IN ENGINE COMPARTMENT ELECTRIC SYSTEM ACTYON 2008.01…

-

Page 240

01-7 0000-00 ELECTRIC SYSTEM ACTYON 2008.01… -

Page 241: Electric Components And Layout

01-8 0000-00 4. ELECTRIC COMPONENTS AND LAYOUT 1) Wiring Harness Arrangement ELECTRIC SYSTEM ACTYON 2008.01…

-

Page 242

01-9 0000-00 2) Components Locator ELECTRIC SYSTEM ACTYON 2008.01… -

Page 243: Diagnostic Connector

01-10 0000-00 5. DIAGNOSTIC CONNECTOR 1) Pin Arrangement of Diagnostic Connector It is installed under the instrument panel and consists of 16 pins. The REKES key coding should be performed with Scan-100. 2) Functions of Terminal ELECTRIC SYSTEM ACTYON 2008.01…

-

Page 244

There are three fuse and relay boxes in this vehicle (one at each side of instrument panel and one in engine compartment). The designation and capacity of relays and fuses is shown on the fuse and relay box cover. 1) Fuse and Relay Box in Engine Compartment Fuses and Relays Connector Arrangement FUSES AND REALYS ACTYON 2008.01… -

Page 245

8410-02 2) Interior Fuses and Relays Fuse and Relay Box (LH) Fuse and Relay Box (RH) FUSES AND REALYS ACTYON 2008.01… -

Page 246

8410-02 2. DESIGNATION AND CAPACITY OF FUSES AND RELAY 1) Fuses and Relays in Engine FUSES AND REALYS ACTYON 2008.01… -

Page 247

8410-02 2) Designation and Capacity (1) Driver Side FUSES AND REALYS ACTYON 2008.01… -

Page 248

EGR vacuum modulator and HFM. No. 64 fuse (7.5A) ▶ This supplies the power to the HP pump IMV. If this is blown out, IMV opens fully, so too many fuel is delivered. FUSES AND REALYS ACTYON 2008.01… -

Page 249

8410-02 3. POWER DISTRIBUTION For details, refer to the electric circuit diagram. FUSES AND REALYS ACTYON 2008.01… -

Page 250

8410-02 For details, refer to the electric circuit diagram. FUSES AND REALYS ACTYON 2008.01… -

Page 251

0-10 8410-02 4. POWER DISTRIBUTION OF INTERIOR FUSE 1) IP — Interior Fuse (Driver Side) For details, refer to the electric circuit diagram. FUSES AND REALYS ACTYON 2008.01… -

Page 252

0-11 8410-02 2) IP — Interior Fuse (Passenger Side) For details, refer to the electric circuit diagram. FUSES AND REALYS ACTYON 2008.01… -

Page 253

STICS. Theft deterrent condition (according to door status): when engine hood, and front and rear doors are closed. STICS ACTYON 2008.01… -

Page 254

Transmitting frequency: 447.800 ± 0.0125 MHz Channel width: below 12.5 KHz Frequency bandwidth: below 8.5 KHz Modulation method: FSK (Frequency Shift Keying) Receiving distance: Approx. 10 ~ 15 m (In case there are not obstacles around the system) STICS ACTYON 2008.01… -

Page 255

02-5 8710-01 ▶ Rated Load STICS ACTYON 2008.01… -

Page 256

02-6 8710-01 ▶ Input Signals STICS ACTYON 2008.01… -

Page 257

If not indicated, time tolerance will be ± 10%. However, if less than 500 ms, time tolerance will be ± 100 ms. The time indicated in each function does not include chattering processing time from switch input changing point. STICS ACTYON 2008.01… -

Page 258

Control System)), is almost the same as that of ACTYON in terms of its function and role. Due to the removal of tailgate opening switch and rear wiper and washer system, the circuit layout is slightly changed, compared to ACTYON. Door Lock Relay RK STICS REKES key STICS ACTYON 2008.01… -

Page 259

When pulling up the lever, the wiper operates once and the wiper lever returns to the «OFF» position. Stop the operation. AUTO Operates automatically according to the vehicle speed or the amount of rain. Continuous wipe, Continuous wipe, fast operation slow operation. STICS ACTYON 2008.01… -

Page 260

Pull and hold the lever for more than 0.6 seconds: Rear Wiper Stops Three wiping cycles with washer spray Rear Washer and Wiper The rear washer and the wiper operate only while holding the switch. When releasing the switch, it returns to «OFF» position. STICS ACTYON 2008.01… -

Page 261

The wiper relay is turned on at 0.3 seconds (T1) after from the time when the washer switch is turned on for more than 0.6 seconds (T2) with the ignition switch «ON». The wiper relay gets on 3 times immediately after turning off the washer switch. STICS ACTYON 2008.01… -

Page 262

When the washer switch is turned on for more than 0.6 seconds during the wiper operation by INT switch, the operation in step (2) is performed. When it is turned on for a certain period of time (0.1 to 0.59 seconds), the operation in step (1) is performed. STICS ACTYON 2008.01… -

Page 263

ON from the time when the rear washer switch is turned on. It gets OFF when the rear washer switch is turned off. This control is not available while the front washer switch or the auto washer and wiper (AFW: Advanced Fast Washer) is in operation. STICS ACTYON 2008.01… -

Page 264

«OFF», the washer motor output gets ON for 1 second. If the system recognizes the output signal, the wiper relay output gets ON during 4 cycles and the washer motor output gets ON for 1 second. Then, the wiper relay output gets OFF after 3 cycles. STICS ACTYON 2008.01… -

Page 265

The auto washer switch input is overridden during the rear washer operation. The front washer switch input is overridden during the auto washer and wiper (AFW) operation. The auto washer switch input is overridden during the front washer operation. STICS ACTYON 2008.01… -

Page 266

02-16 8710-01 5) Rain Sensor Coupled Wiper and Auto Light Control If equipped with RKSTICS rain sensor, it has following operation system. ▶ System layout STICS ACTYON 2008.01… -

Page 267

FAST ↔ SLOW: Auto delay/Auto speed section (rain sensor mounting section on the control. A position that can control sensitivity windshield) with photodiode (auto light sensor against rains in the windshield and transmits integrated type) wiping demand signal accordingly STICS ACTYON 2008.01… -

Page 268

«ON» and the auto INT switch «ON» in the rain sensing mode. At this moment, the communication with the rain sensor is overridden. However, the washer switch input is overridden during the continuous operation. The operation data is sent to the rain sensor even during the washer coupled wiper’s operation. STICS ACTYON 2008.01… -

Page 269

«ON» position, and the wiper motor is in «Parked» position). However, the wiper motor can be operated only when the rain sensor detects the «Rain Detected» signal. * If the volume sensitivity is changed more than 2 stages within 2 seconds, the wiper motor runs only one cycle. STICS ACTYON 2008.01… -

Page 270

When the parking terminal is fixed to IGN, the wiper system outputs the wiper operating signal for 2 seconds, then continuously outputs the wiper parking signal. * The wiper motor runs only when the rain sensor requires the wiper operation. STICS ACTYON 2008.01… -

Page 271

The wiper relay (LOW) is turned on and the wiper motor runs one cycle when the volume sensitivity is changed to 3 from 4 during receiving the malfunction signal from the rain sensor (while the ignition key is in «ON» position and the wiper switch is in «ON» position). STICS ACTYON 2008.01… -

Page 272

Check whether the variable resistance knob on the multifunction wiper switch is set in «FAST». The «FAST» is the highest stage of the ensitivity and very sensitive to small amount of rain drops. Therefore, change the knob to the low sensitivity. STICS ACTYON 2008.01… -

Page 273

The wiper responses are too fast or slow. Check whether the variable resistance knob on the wiper switch is set in «FAST» or «SLOW». Notify that the customer can select the sensitivity by selecting the variable resistance value. And, select a proper stage. STICS ACTYON 2008.01… -

Page 274

(i.e. the AUTO wiper switch is at the 3rd level, but the wiper operates at the 4th level.) Emitter lense Auto light sensor (Vertical) Auto light sensor (Horizon) STICS ACTYON 2008.01… -

Page 275

The pause time is calculated by the vehicle speed and the VOLUME. If the pause time is below 1.0 second, the wipers operate without pause. · If the pause time is over 1.5 seconds, the wipers operate intermittently · STICS ACTYON 2008.01… -

Page 276

The wiper relay continues to output when the parking terminal is fixed at the ground or IGN while the wiperrelay is «ON» (INT switch = ON or Washer switch = ON) (The output stops immediately after turning off the switch) (The output stops immediately after turning OFF the switch.) STICS ACTYON 2008.01… -

Page 277

When removing the ignition key or closing the driver’s door during chime buzzer operation, the buzzer stops. This function is not available when the ignition switch is in «ON» position. PAS buzzer Chime buzzer STICS ACTYON 2008.01… -

Page 278

If the «UNLOCK» conditions are met, the system outputs «UNLOCK» signal unconditionally. However, if the ignition key is removed after the door lock switch is changed from «UNLOCK» to «LOCK», the system does not output «UNLOCK» signal. STICS ACTYON 2008.01… -

Page 279

If the ignition switch is in the «ON» position or the ignition switch is removed, the above steps are performed. If the key is in the key cylinder, the ignition key reminder function is activated. This function does not work if the vehicle speed is over 10 km/h. STICS ACTYON 2008.01… -

Page 280

The system outputs «UNLOCK» signal for 5 seconds when the driver’s and passenger’s door lock switch is locked (while the tail lamp is turned on and the driver’s door is open). This function is not available when the ignition key is in the «ON» position. STICS ACTYON 2008.01… -

Page 281

The warning light blinks when a door is open while the vehicle speed is over 10 km/h. The warning light goes off when closing the door under step 3. The warning light comes on when the vehicle speed goes below 10 km/h under step 3. STICS ACTYON 2008.01… -

Page 282

Chime Buzzer Chime buzzer The seat belt warning light comes on and the chime buzzer sounds for 6 seconds when turning the ignition key to «ON» from «OFF». After fastening the seat belt, the chime buzzer stops. STICS ACTYON 2008.01… -

Page 283

The warning light comes on and the chime buzzer stops when the vehicle speed goes down below 10 km/h under step 4. This function is not available when the ignition key is turned to the «OFF» position. STICS ACTYON 2008.01… -

Page 284

LOCK button on the remote control key. The luggage room lamp does not have a door coupled operating function. It shoulde be turned on and off by hand. STICS ACTYON 2008.01… -

Page 285

The lamp always comes on while closed. The front and center room lamps the switch is at the other position. come on when pressing the room lamp main switch (3). STICS ACTYON 2008.01… -

Page 286

The output stops when receiving the lock signal from the remote control key (under armed mode). Key cylinder with key hole illumination For diesel and gasoline For diesel engine equipped engine equipped vehicle vehicle Without immobilizer With immobilizer → With key hole illumination → With key hole illumination STICS ACTYON 2008.01… -

Page 287

The output is «ON» only for 6 minutes when turning «ON» the front defogger switch within 10 minutes after completion of output for 12 minutes. This can be done only once. The output is «OFF» when the ignition switch is «OFF». STICS ACTYON 2008.01… -

Page 288

The output is «ON» only for 6 minutes when turning «ON» the rear defogger switch within 10 minutes after completion of output for 12 minutes. This can be done only once. The output is «OFF» when the IGN 2 switch is «OFF». STICS ACTYON 2008.01… -

Page 289

«UNLOCK» signal by other functions. All door lock signals are «UNLOCK» for 0.5 seconds just for once when receiving the «LOCK» signal within 0.5 seconds after closing the driver’s or passenger’s door while the ignition key is removed. STICS ACTYON 2008.01… -

Page 290

0.5 seconds to unlock the tailgate. If any LOCK switch is switched to LOCK position or vehicle speed exceeds 3 Km/h while operating the tailgate open relay, the output of the tailgate relay gets OFF. STICS ACTYON 2008.01… -

Page 291

(However, if the door lock switch (front doors) is at LOCK position, the system outputs UNLOCK signal, and vice versa.) The «LOCK» or «UNLOCK» inputs from the central door lock switch in anti-theft mode are ignored. STICS ACTYON 2008.01… -

Page 292

27) Door LOCK/UNLOCK by Remote Control Key The door lock relay output is «ON» for 0.5 seconds when receiving the remote control lock signal. The door unlock relay output is «ON» for 0.5 seconds when receiving the remote control unlock signal. STICS ACTYON 2008.01… -

Page 293

UNLOCK signal unconditionally when turning the ignition switch to OFF position.) However, when the ignition key is turned to «OFF» position, the lock output conditions will be cancelled. The «FAIL» condition of the door will be erased when the ignition key is turned to «OFF» position. STICS ACTYON 2008.01… -

Page 294

«LOCK» (or «UNLOCK») output is ignored if «LOCK» (or «UNLOCK») output is required while performing the output of «LOCK» (or «UNLOCK»). If the door lock system outputs «LOCK» and «UNLOCK» simultaneously, only the «LOCK» output can be activated. STICS ACTYON 2008.01… -

Page 295

DOOR LOCK: Indicates that all door lock switches (including tailgate) are in LOCK positions. DOOR UNLOCK: Indicates that any of all door lock switches (including tailgate) is in UNLOCK position. Engine hood open warning lamp The warning lamp comes on when the engine hood is open. STICS ACTYON 2008.01… -

Page 296

(RELOCK operation). Also, at this moment, the system blinks hazard warning flasher twice. The armed mode will not be activated except above conditions. Ex) The armed mode will not be activated when the door is locked by the ignition key. STICS ACTYON 2008.01… -

Page 297

3) If the ignition switch is turned to ON position when the warning is activated in armed mode, the warning is cancelled immediately and the warning buzzer stops after 27 seconds (remaining time). Operation when warning is cancelled 1) The theft deterrent horn and hazard warning flasher outputs are «OFF». STICS ACTYON 2008.01… -

Page 298

The front room lamp comes on for 30 seconds when receiving door unlock signal by the remote control key while the front room lamp coupled switch is pressed. It is turned off when receiving the LOCK signal from the remote control key. STICS ACTYON 2008.01… -

Page 299

The system outputs LOCK signal immediately after receiving the door lock message from the remote control key. The system activates the theft deterrent mode when all doors are locked while they are fully closed (the hazard warning lamps blink twice.). STICS ACTYON 2008.01… -

Page 300

36) Auto Door Lock in 30 Seconds after Pressing Door Unlock Button If no door is opened for 30 seconds after inputting remote door unlock, the doors are automatically locked and the armed mode of anti-theft system is activated again. STICS ACTYON 2008.01… -

Page 301

02-51 8710-01 3. CIRCUIT DIAGRAM The circuit diagram below shows the input and output of STICS. 1) STICS Input Singnals and Others STICS ACTYON 2008.01… -

Page 302

02-52 8710-01 2) STICS Output Signals and Others STICS ACTYON 2008.01… -

Page 303

02-53 8710-01 3) Circuit Diagram of Wiper Rear wiper and washer system is not applied, the circuit related to rear wiper and washer is removed from the STICS circuit regarding wiper control. STICS ACTYON 2008.01… -

Page 304

ON or without removing the key. As shown in the figure, STICS monitors the signal of key reminder and controls the vehicle according to the door switch and tail lamp conditions. For details, refer to following information. STICS ACTYON 2008.01… -

Page 305

5) Wiring Circuit of STICS (Related to Seat Belt/Parking Brake Warning) STICS monitors the seat belt fastening status and the parking brake engagement status and warns the driver with the warning light on the instrument panel or chime buzzer. STICS ACTYON 2008.01… -

Page 306

The operating time control and dimming functions of room lamp have been introduced for user convenience. The ignition key reminder warning signal in the circuit is related to the dimming function. Refer to the detailed information in this manual for the control logic. STICS ACTYON 2008.01… -