- Manuals

- Brands

- Snap-On Manuals

- Air Conditioner

- Sun Koolkare Blizzard

- Quick start manual

-

Bookmarks

Quick Links

QUICK

START GUIDE

CHECK OUT OUR VIDEO TUTORIAL AND VISIT:

DIAGNOSTICS.SNAPON.CO.UK/TRAINING

BLIZZARD AIR CONDITIONING UNIT

QUALITY AND SERVICE YOU EXPECT AT A PRICE YOU WOULDN’T

T

I

S

HO

80

EAZ0042N00A

Related Manuals for Snap-On Sun Koolkare Blizzard

Summary of Contents for Snap-On Sun Koolkare Blizzard

-

Page 1

QUICK START GUIDE CHECK OUT OUR VIDEO TUTORIAL AND VISIT: DIAGNOSTICS.SNAPON.CO.UK/TRAINING EAZ0042N00A BLIZZARD AIR CONDITIONING UNIT QUALITY AND SERVICE YOU EXPECT AT A PRICE YOU WOULDN’T… -

Page 2

R134a Set amount: 600g PACKAGING 18126g BOTTLE FILLING AUTOMATIC MANUAL CUSTOM STOP STOP MENU MENU R134a ACTIVATION Check the condition of your delivery, Remove protective cover, Quick Start Release the brake and roll off the pallet. 000000 PQRS WXYZ 11:21 PQRS WXYZ BACK… -

Page 3

Get unlock code R134a ACTIVATION R134a Go to the website ACTIVATION PQRS WXYZ Press OK to PQRS WXYZ www.ac-activation.com BACK BACK Enter the activation code for your machine. Characters and numbers are allowed unlock www.ac-activation.com BACK Press OK to proceed ACTIVATION CODE INSERTING TRACER •… -

Page 4

Press OK to www.ac-activation.com Enter the activation code for your machine. Characters and numbers are allowed unlock PQRS WXYZ BACK PQRS PQRS WXYZ WXYZ BACK PQRS PQRS WXYZ WXYZ Press OK to proceed STOP STOP STOP BACK BACK BACK BACK BACK BACK MENU… -

Page 5

OPTIONAL KOOLKLEAN SET-UP Unpack the Koolklean contents You will require Koolklean fluid. You can Unlock bottle cell Press OK to continue purchase appropriate fluid at: Back to exit www.snaponconsumables.co.uk MENU Have you purchased a PQRS WXYZ SANIFLUX Blizzard Pro or Blizzard Liquid HIGH TEMPERATURE… -

Page 6

Scan this code to view our training and support tools Denney Road, King’s Lynn, Norfolk PE30 4HG tel: +44 (0) 1553 692422 email: ukservice@snapon.com — http://diagnostics.snapon.co.uk…

This manual is also suitable for:

Sun koolkare blizzard proSun koolkare blizzard hfo

4

5

7

8

9

7

7

8

8

9

9

GHI

JKL

1

2

3

PQRS

TUV

WXYZ

BACK

PQRS

PQRS

TUV

TUV

WXYZ

WXYZ

7

8

0

BACK

ABC

DEF

0

0

PQRS

TUV

4

5

6

ESC

ESC

0

GHI

JKL

MNO

15

7

8

9

PQRS

TUV

WXYZ

Connect the appropriate bottle adaptor

0

to the external gas bottle. Once complete

press ‘OK’ on the unit display.

1

2

STOP

ABC

4

5

GHI

JKL

BOTTLE FILLING

BOTTLE FILLING

7

8

Press OK to continue

Press OK to continue

PQRS

TUV

Back to exit

Back to exit

BACK

0

ESC

1

2

3

1

1

2

2

3

3

STOP

ABC

DEF

ABC

ABC

DEF

DEF

4

5

6

MENU

4

4

5

5

6

6

GHI

JKL

MNO

GHI

GHI

JKL

JKL

MNO

MNO

7

8

9

000000

7

7

8

8

9

9

PQRS

TUV

WXYZ

11:21

BACK

PQRS

PQRS

TUV

TUV

WXYZ

WXYZ

0

18

0

0

01/06/17

ESC

Insert the gas quantity between min and

max levels and press ‘OK’, wait for the

system to start the gas filling.

1

2

3

ABC

DEF

MENU

4

5

6

Set amount:

g

GHI

JKL

MNO

Min

600g

7

8

9

Max

18126g

W

PLUS

®

ILT

ATCH

PQRS

TUV

WXYZ

Bottle pressure

3.3 bar(rel)

BOTTLE FILLING

Ext. Bottle Pressure

1.6 bar(rel)

0

319g

DO NOT TILT THIS CARTON

PAST__________ DEGREES

BOTTLE FILLING

1

2

3

ABC

DEF

MENU

4

5

6

GHI

JKL

MNO

1

2

3

7

8

9

ABC

DEF

MENU

4

PQRS

5

TUV

6

WXYZ

21

0

GHI

JKL

MNO

7

8

9

Disconnect the LP/HP coupler.

PQRS

TUV

WXYZ

0

S

W

®

HOCK

ATCH

OR

Bottle pressure

Bottle pressure

3.3 bar(rel)

3.3 bar(rel)

Ext. Bottle Pressure

Ext. Bottle Pressure

1.6 bar(rel)

1.6 bar(rel)

319g

319g

1

2

3

1

2

3

BOTTLE FILLING

BOTTLE FILLING

ABC

DEF

MENU

ABC

DEF

4

5

6

4

5

6

GHI

JKL

MNO

GHI

JKL

MNO

7

8

9

1

1

2

2

3

3

7

8

9

PQRS

TUV

WXYZ

ABC

ABC

DEF

DEF

PQRS

TUV

WXYZ

MENU

MENU

0

4

4

5

5

6

6

0

GHI

GHI

JKL

JKL

MNO

MNO

7

7

8

8

9

9

PQRS

PQRS

TUV

TUV

WXYZ

WXYZ

6

Press OK to

7

unlock

MNO

BACK

PQRS

9

STOP

BACK

BACK

MENU

WXYZ

ESC

BACK

ESC

ESC

16

ESC

PQRS

The display will then prompt you to

BACK

OK to continue

connect and open the LP or HP coupler.

with a vacuum procedure

ESC

Back to exit

3

STOP

DEF

MENU

6

MNO

9

OR

2

3

WXYZ

1

BACK

ESC

1

2

1

STOP

MENU

STOP

STOP

ABC

MENU

4

5

4

1

GHI

JKL

GHI

7

8

7

4

PQRS

TUV

BACK

PQRS

PQRS

19

BACK

BACK

0

GHI

ESC

7

ESC

ESC

The unit will prompt you to close the HP/

PQRS

LP coupler. Once complete click ‘OK’ to

continue

STOP

Min

Max

BACK

ESC

1

1

2

STOP

ABC

4

4

5

GHI

GHI

JKL

STOP

7

7

8

PQRS

1

BACK

PQRS

PQRS

TUV

22

0

ESC

4

Return to the main menu.

GHI

BACK

7

ESC

PQRS

R134a

OR

STOP

1

STOP

MENU

4

GHI

7

STOP

STOP

BACK

BACK

PQRS

PQRS

ESC

ESC

BACK

BACK

4

5

6

www.ac-activation.com

7

8

8

9

9

GHI

JKL

MNO

1

2

3

PQRS

TUV

TUV

WXYZ

WXYZ

Press OK to proceed

7

8

9

ABC

DEF

0

0

MENU

PQRS

TUV

WXYZ

4

5

6

0

GHI

JKL

MNO

7

8

9

TUV

WXYZ

0

BOTTLE FILLING

Press OK to continue

Back to exit

1

2

3

ABC

DEF

4

5

6

GHI

JKL

MNO

7

8

9

OR

OR

PQRS

TUV

WXYZ

3

3

1

Set amount:

0

g

Min

600g

Max

18126g

BOTTLE FILLING

3

1

2

2

3

3

STOP

DEF

ABC

ABC

DEF

DEF

MENU

MENU

MENU

6

4

5

5

6

6

2

3

MNO

GHI

JKL

JKL

MNO

MNO

9

7

ABC

8

8

DEF

9

9

MENU

5

6

WXYZ

TUV

TUV

WXYZ

WXYZ

BACK

JKL

0

0

MNO

8

9

ESC

TUV

WXYZ

0

Set amount:

Set amount:

g

g

OR

Min

600g

600g

Max

18126g

18126g

BOTTLE FILLING

BOTTLE FILLING

AC Pressure

1

2

3

OR

2

3

3

1

2

3

ABC

DEF

STOP

ABC

DEF

MENU

STOP

MENU

ABC

DEF

DEF

4

5

6

4

5

MENU

6

MENU

5

6

6

GHI

JKL

MNO

7

8

9

GHI

JKL

MNO

JKL

MNO

MNO

PQRS

TUV

WXYZ

7

8

9

BACK

0

8

9

9

ESC

TUV

WXYZ

2

3

TUV

WXYZ

WXYZ

0

BACK

0

ABC

DEF

MENU

5

6

ESC

JKL

MNO

Bottle pressure

3.3 bar(rel)

8

Ext. Bottle Pressure

9

1.6 bar(rel)

319g

TUV

WXYZ

0

BOTTLE FILLING

AUTOMATIC

MANUAL

CUSTOM

1

2

3

ABC

DEF

OR

OR

MENU

4

5

6

GHI

JKL

MNO

SETUP

7

8

MAINTENANCE

9

DATA

PQRS

TUV

WXYZ

0

1

2

2

3

3

ABC

ABC

DEF

DEF

MENU

MENU

4

5

5

6

6

GHI

JKL

JKL

MNO

MNO

7

8

8

9

9

TUV

TUV

WXYZ

WXYZ

T

W

PLUS T

W

®

0

0

ILT

ATCH

ILT

S

W

®

HOCK

ATCH

DO NOT TILT THIS CARTON

PAST__________ DEGREES

30°

DAMAGE MAY OCCURR IF CARTON

40°

4

GHI

7

STOP

BACK

BACK

PQRS

BACK

ESC

ESC

17

ESC

Once connected, open the valve on the

BACK

external bottle and position bottle for

ESC

liquid filling.

1

HR

STOP

MENU

4

1

2

3

GHI

ABC

DEF

7

4

5

6

GHI

JKL

MNO

2

2

PQRS

7

8

9

BACK

1

PQRS

TUV

WXYZ

0

ESC

STOP

STOP

1

2

ABC

4

5

STOP

GHI

JKL

7

8

PQRS

TUV

Unlock bottle cell

20

BACK

BACK

0

Press OK to continue

Back to exit

ESC

ESC

Wait for the bottle filling cycle to complete.

BACK

1

2

3

ABC

DEF

ESC

MENU

4

5

6

GHI

JKL

MNO

7

8

9

PQRS

TUV

WXYZ

R134a

0

1

2

AUTOMATIC

ABC

4

5

Bottle pressure

Ext. Bottle Pressure

GHI

JKL

7

8

PQRS

TUV

SETUP

Connect cartridge

0

or refill UV container

Press OK to continue

Back to exit

1

2

1

2

3

STOP

ABC

STOP

ABC

DEF

STOP

MENU

4

5

6

4

5

GHI

JKL

MNO

7

8

9

GHI

JKL

PQRS

TUV

WXYZ

7

8

T

W

BACK

0

ILT

ATCH

ESC

PQRS

TUV

S

W

HOCK

ATCH

BACK

0

BACK

STOP

ESC

ESC

70°

80°

YOUR UNIT IS

30°

BACK

40°

1

ESC

4

GHI

1

7

STOP

4

PQRS

GHI

000000

7

PQRS

11:21

01/06/17

BACK

ESC

STOP

STOP

BACK

BACK

PLUS

®

ATCH

ESC

ESC

5

6

Enter the activation code for your machine. Characters and numbers are allowed

JKL

MNO

8

9

TUV

WXYZ

0

OR

3

2

3

Press

Select CONTAINER

then press OK

ABC

DEF

MENU

5

6

JKL

MNO

STOP

MENU

8

9

TUV

WXYZ

0

BACK

ESC

AC Pressure

3

1

STOP

DEF

MENU

6

4

R134a

MNO

GHI

9

7

WXYZ

Verify vacuum pump

PQRS

BACK

Oil level

ESC

Press OK to continue

Back to exit

AUTOMATIC

Set amount:

1

2

g

3

STOP

ABC

DEF

Min

600g

MENU

4

5

6

Max

18126g

GHI

JKL

MNO

7

8

9

SETUP

BOTTLE FILLING

PQRS

TUV

WXYZ

BACK

0

ESC

3

MANUAL

DEF

CUSTOM

MENU

6

3.3 bar(rel)

1.6 bar(rel)

MNO

000000

9

319g

T

11:21

WXYZ

MAINTENANCE

DATA

01/06/17

BACK

BOTTLE FILLING

S

HOCK

OK to continue

with a vacuum procedure

Back to exit

3

80°

1

2

3

STOP

DEF

MENU

ABC

DEF

MENU

6

4

5

6

GHI

JKL

MNO

MNO

7

8

9

PQRS

TUV

WXYZ

9

PLUS T

W

PLUS

®

®

0

ILT

ATCH

WXYZ

®

BACK

DO NOT TILT THIS CARTON

PAST__________ DEGREES

ESC

30°

OR

DAMAGE MAY OCCURR IF CARTON

40°

50°

IS TILTED PAST INDICATED DEGREES

60°

180°

CONSIGNEE:

IF TILTING HAS OCCURRED

DO NOT REFUSE SHIPMENT

NOTE ON BILL OF LOADING DEGREE OF TILT

50°

NOW READY

60°

S

70°

HOCK

80°

2

3

ABC

DEF

MENU

FOR USE

5

6

JKL

MNO

2

3

8

9

STOP

ABC

DEF

MENU

5

6

TUV

WXYZ

JKL

MNO

8

9

0

TUV

WXYZ

BACK

0

ESC

OR

4

GHI

7

PQRS

BACK

ESC

Unlock bottle cell

Press OK to continue

Back to exit

2

1

1

2

3

ABC

DEF

MENU

4

5

6

GHI

JKL

MNO

7

8

9

PQRS

TUV

WXYZ

0

AC Pressure

STOP

R13

1

2

3

ABC

DEF

MENU

4

5

6

GHI

JKL

MNO

7

8

BACK

9

PQRS

TUV

WXYZ

0

A

ESC

Connect cartridge

or refill UV container

1

2

Press OK to continue

Back to exit

AB

S

4

5

2

3

GHI

JKL

ABC

DEF

MENU

5

6

7

8

JKL

MNO

8

9

PQRS

TU

TUV

WXYZ

C

0

ref

0

P

MANUAL

T

1

2

3

STOP

ABC

DEF

4

5

6

S

GHI

JKL

MNO

7

8

9

MAINTENANCE

PQRS

TUV

WXYZ

BACK

0

ESC

STOP

1

4

G

7

W

PLUS

P

®

ILT

ATCH

1

W

®

ATCH

BOT

Press

ESC

B

30°

4

40°

50°

60°

70°

GHI

180°

1

2

3

7

STOP

ABC

DEF

PQRS

4

5

6

30°

GHI

JKL

MNO

40°

7

8

9

50°

60°

70°

80°

PQRS

TUV

WXYZ

BACK

0

ESC

W

®

ATCH

STOP

BACK

ESC

Bottle pressure

3.3 bar

Ext. Bottle Pressure

1.6 bar

319g

BOTTLE FILL

1

2

3

ABC

DEF

MENU

Kool Kare Blizzard QTech II – полный автомат, позволяет произвести обслуживание кондиционера, работающего на хладагенте R134a за один цикл. Удобная панель и интерактивная система управления помогают оператору автоматически выполнить все операции по обслуживанию в определенной последовательности, т.е. откачку, вакуумирование и зарядку или любую из этих операций.

Особенностью модели Blizzard являются база данных по автомобилям, встроенный принтер и точные весы для хладагента и масла, как откачанного, так и для нового, а также для ультрафиолетового геля. SUN Kool Kare Blizzard является эталоном среди оборудования для диагностики и обслуживания систем кондиционирования воздуха.

Особенности прибора

- Простое интерактивное управление с жидкокристаллическим дисплеем размером 123х40 мм

- Гибкость программирования автоматического выполнения последовательности операций

- Меню на нескольких языках

- Встроенный принтер позволяет распечатывать:

- количество регенерированного и заправленного хладагента;

- количество откачанного и заправленного масла;

- массу и температуру бака с хладагентом;

- заголовок;

- время и дату.

- Встроенные манометры, показывающие давление хладагента в контуре высокого и низкого давления

- Заправка в автоматическом и ручном режиме

- Электронный мониторинг оставшегося срока службы фильтров

- Насос глубокого вакуума с производительностью115 л/мин

- Скорость откачки компрессора 300 грамм жидкого хладагента в минуту

- Приемный бак для извлекаемого хладагента массой22 кг

- Установленные спереди баллоны для слива, подачи масла и УФ геля

- Два отделения для инструмента

- Точность определения массы хладагента +10 г

- Точность определения массы масла +5 г

- Производительность при заправке хладагента – более 1 кг в минуту

Конструкция

- Высокотехнологичный ударопрочный литой корпус современного дизайна

- Четырехстрочный (по 20 символов в строке) жидкокристаллический дисплей с подсветкой

- Встроенные фильтры

- Шланги для хладагента R134а длиной 3 м

- Выбираемые пользователем единицы измерения

- Выбираемый пользователем язык меню

- Шланги и клапаны управления в комплекте

Технические характеристики:

| Точность измерительных приборов |

Класс 1, точность 1% |

|

Диапазон измерения |

0,1 mbar вакуум до 25 bar |

|

Количество заправляемого хладагента |

0-22 кг |

|

Количество хладагента в баллоне |

0-22 кг |

|

Производительность компрессора |

115 л/мин |

|

Вакуум |

0,1 mbar (абсолютное значение) |

|

Размеры (Высота-Ширина-Глубина), см |

103х57х63 |

|

Питание |

230В», 50 Гц |

Балансировочный стенд с электроприводом B100Комплект для ремонта винила и кожи 15400

Установки для обслуживания кондиционеров

АКЦИЯ!!! СНИЖЕНЫ ЦЕНЫ НА 14-30%

( подробности узнавайте у наших консультантов по тел +38 0675313086)

| Фото | Код | Описание | Цена | ||||||||||

|

KOOLKARE Breeze |

|

2750€ | ||||||||||

|

KOOLKARE Blizzard |

|

3880€ | ||||||||||

|

KONFORT 610 Evolution |

|

3480€ | ||||||||||

| RA16352EU | Ультрафиолетовый детектор утечки хладагента

Состоит из: |

350€ | |||||||||||

| RA16600 | Электронный детектор утечки хладагента

Портативный, эргономичный. Размеры 220х80х50 мм. Вес 520 гр. |

360€ | |||||||||||

|

ACT500-SFK-B | Набор для очистки системы кондиционирования Набор состоит из аксессуаров и адаптеров, необходимых для подключения установок Robinair к системе кондиционирования автомобиля в режиме очистки. |

1125€ |

Технологический процесс обслуживания кондиционера происходит следующим образом. Для того, чтобы выяснить в каком состоянии находится автомобильный кондиционер – необходимо произвести диагностику. Сначала состояние узлов и агрегатов кондиционера проверяется визуально – нет ли механических повреждений, подтеков, пятен масла и т.п. Диагност проверяет наличие посторонних шумов и биений при работе автокондиционера. Для измерения давления хладагента в системе, к заправочным портам подключаются шланги манометрического коллектора, и по показаниям манометров специалист оценивает давление хладагента на стороне нагнетания и всасывания. Как правило, наибольшее количество неисправностей в автомобильных кондиционерах связано с утечкой хладагента. В этом случае главная задача диагноста – обнаружить утечку и выявить, что является причиной ее возникновения. Следующий этап работы – устранение утечки, проверка на герметичность системы и заправка кондиционера.

Перед заправкой хладагента необходимо произвести вакуумирование системы, для удаления атмосферного воздуха и влаги. Только после этой процедуры можно заправлять в систему хладагент. Заправка производится при помощи манометрического коллектора или автоматической заправочной станции.

Robinair, TEXA, SUN Установки для обслуживания кондиционеров, чистка кондиционера, автомобильные кондиционеры,Электронный детектор утечки хладагента, Ультрафиолетовый детектор утечки хладагента, Набор для очистки системы кондиционирования

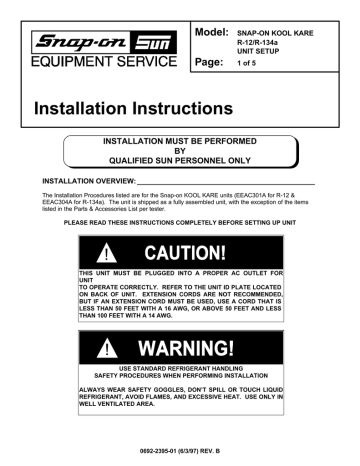

Model: SNAP-ON KOOL KARE R-12/R-134a UNIT SETUP Page: 1 of 5 Installation Instructions INSTALLATION MUST BE PERFORMED BY QUALIFIED SUN PERSONNEL ONLY INSTALLATION OVERVIEW: _____________________________________________ The Installation Procedures listed are for the Snap-on KOOL KARE units (EEAC301A for R-12 & EEAC304A for R-134a). The unit is shipped as a fully assembled unit, with the exception of the items listed in the Parts & Accessories List per tester. PLEASE READ THESE INSTRUCTIONS COMPLETELY BEFORE SETTING UP UNIT ! THIS UNIT MUST BE PLUGGED INTO A PROPER AC OUTLET FOR UNIT TO OPERATE CORRECTLY. REFER TO THE UNIT ID PLATE LOCATED ON BACK OF UNIT. EXTENSION CORDS ARE NOT RECOMMENDED, BUT IF AN EXTENSION CORD MUST BE USED, USE A CORD THAT IS LESS THAN 50 FEET WITH A 16 AWG, OR ABOVE 50 FEET AND LESS THAN 100 FEET WITH A 14 AWG. ! USE STANDARD REFRIGERANT HANDLING SAFETY PROCEDURES WHEN PERFORMING INSTALLATION ALWAYS WEAR SAFETY GOGGLES, DON’T SPILL OR TOUCH LIQUID REFRIGERANT, AVOID FLAMES, AND EXCESSIVE HEAT. USE ONLY IN WELL VENTILATED AREA. 0692-2395-01 (6/3/97) REV. B Page 2 of 5 PARTS & ACCESSORIES LIST FOR EEAC301A: ____________________________ PART NUMBER 0001006701 0119038401 0647019601 0647019701 0647019901 0647020001 0692183401 0692239501 4211000101 7009244703 EAH0013C00A SS1386VHS DESCRIPTION Wrench, Separator Bowl Literature Kit Adapter, GM Adapter, Quick-Disconnect, GM/Ford Adapter, Quick-Disconnect, Large GM Adapter, Ford Questionnaire, SEL 1403C Installation instructions Envelope Recovery Tank Assembly Gauge Set, Uniweld Video, Snap-on Kool Kare QTY 1 1 1 1 1 1 1 1 1 1 1 1 PARTS & ACCESSORIES LIST FOR EEAC304A: ____________________________ PART NUMBER 0001006701 0119038401 0647028709 0647028710 0692183401 0692239801 4211000101 7009244701 ARG04040 EAH0014C01A SS1386VHS DESCRIPTION Wrench, Separator Bowl Literature Kit Adapter, Vehicle, High Side Adapter, Vehicle, Low Side Questionnaire, SEL 1403C Installation Instructions Envelope Recovery Tank Assembly Kit, Vehicle Adapter O-Ring Gauge Set, R134a Video, Snap-on Kool Kare QTY 1 1 1 1 1 1 1 1 1 1 1 REQUIRED TOOLS: ____________________________________________________ ù ù ù Screwdriver (Flat Blade and Phillips) Safety Goggles (0001-5005) Refrigerant Oil (Mineral) or Superlube (0681-0193-02 or -03) UNPACKING UNIT AND ACCESSORIES: ___________________________________ 1. Cut Straps (A), and slide the carton (B) off the pallet (C). A 2. Remove the top of the carton (D), and packing foam (E) from unit. Split the corners of the base carton (F). D E 3. Remove all boxes (G) and packing material (H) from scale/tank compartment. G 5. Lean one side of unit (I) so packing foam (J) can be removed. Repeat for other side. B H 4. Lean the unit (I) so it can be rolled off the base carton (F). PL AC ED OV ER SC AL E 6. Inventory all items using the Parts & Accessories list and inspect for damage. I J F C FIGURE 1 UNIT PACKAGE 0692-2395-01 (6/3/97) REV. B Page 3 of 5 PARTS & ACCESSORIES SETUP: ________________________________________ 1. Remove the Gauge Set Assembly (EAH0013C00A or EAC0014C01A) from the gauge set box and place on gauge set bracket. 2. Remove the Blue and Red Hoses from the gauge set box and OIL the seals on each end. 3. Connect the open end of the Blue and Red Hoses to the Gauge Set respectively. 4. For the EEAC301A, place the four adapters in the Storage Compartment. 5. For the EEAC304A, connect the Red and Blue adapters (0647028709 and 0647028710) to the Red and Blue Hoses from the Gauge Set respectively. 6. For the EEAC304A, place the O-Ring Kit (ARG04040) in the Storage Compartment. 7. Place the Separator Bowl Wrench (0001006701) in the Storage Compartment. 8. Remove the User's Manual from the Literature Kit, and place the remainder of the Literature Kit (0119038401) in the Storage Compartment. BE SURE TO REVIEW THE USER'S MANUAL WITH THE CUSTOMER DURING TRAINING. Then before installing the User's Manual Envelope, ask where the customer would like the envelope installed. There is also a Video Tape (SS1386VHS) supplied and can be viewed at the customer's convenience. 9. Peel the backing from the User's Manual Envelope (4211000101) and apply the envelope, with the open end on top, to either side of the unit, or in the location designated by the customer. 10. Place the User's Manual in the Envelope. 11. Remove Recovery Tank (7009244701 or 7009244703) from its box. Remove cardboard wrap from Recovery Tank. Set on floor in front of unit. PREPARING NEW RECOVERY TANK: _____________________________________ 1. Refering to FIGURE 2, open the BLUE valve on Recovery Tank to release ALL COMPRESSED AIR. 2. Remove the Particle Filter from the Recovery Tank. OIL seal, and re-attach to Recovery Tank. (BLUE SIDE) 3. Remove the Yellow Hose from the gauge set box. OIL the seals on each end of hose. 4. Attach open end of Yellow Hose to BLUE valve of Recovery Tank. Attach other end of Yellow Hose to service port on front of unit. Open ball valve on yellow hose. 5. Plug AC Cord to a 115VAC outlet. Turn unit on using the front power switch. FIGURE 2 RECOVERY TANK ! THIS UNIT MUST BE PLUGGED IN TO A PROPER AC OUTLET FOR UNIT TO OPERATE CORRECTLY. REFER TO UNIT ID PLATE LOCATED ON BACK OF UNIT. EXTENSION CORDS ARE NOT RECOMMENDED, BUT IF AN EXTENSION CORD MUST BE USED, USE A CORD THAT IS LESS THAN 50 FEET WITH A 16 AWG, OR ABOVE 50 FEET AND LESS THAN 100 FEET WITH A 14 AWG. 0692-2395-01 (6/3/97) REV. B Page 4 of 5 PREPARING NEW RECOVERY TANK continued: 6. Following the displays in FIGURE 3, program a 10 minute vacuum time. STARTING SCREEN Enter time to pull Vacuum on vehicle: 10 minutes UP DOWN Enter time to hold Vacuum: 00 minutes UP DOWN YES ENTER Will you Recycle from Vehicle this sequence? YES Will you be pulling a Vacuum this sequence? YES NO NO Will you be charging this sequence? YES ENTER NO FIGURE 3 VACUUM MODE 7. Once completed, close Recovery Tank valve (BLUE) and remove Yellow Hose from Recovery Tank. 8. Re-OIL seal on Yellow Hose and connect to center port on Gauge Set. 9. Place Recovery Tank on scale. Tank fittings should face straight out the back of unit. Connect velcro strap and tighten belt. 10. Remove bubble wrap from Red and Blue Hoses on unit 11. OIL seals on the anti-blow back valves on Red and Blue Hoses from unit. Connect respectively to Recovery Tank. Refer to FIGURE 4 FIGURE 4 INSTALLING TANK 0692-2395-01 (6/3/97) REV. B Page 5 of 5 CHARGING RECOVERY TANK: __________________________________________ NOTE: THIS PROCEDURE IS USED TO SETUP THE UNIT FOR CHARGING. RECOVERY TANK SHOULD HAVE AT LEAST A 25” VACUUM. THIS PROCEDURE IS DONE WHEN RECOVERY TANK IS ON THE SCALE. 1. Be sure Recovery Tank valves (B) are closed. Refer to FIGURE 5 2. Disconnect the Red and Blue hoses from the Recovery Tank. 3. Disconnect and Re-Oil both the seals on Yellow hose (C). Connect the long side of the Yellow Hose to the Virgin Tank (A). 4. Connect the short side of the Yellow Hose to the Red Valve on the Recovery Tank (B). A 5. Open the Red Valve on the Recovery Tank. 6. Invert the Virgin Tank and open valve. Open Hand Valve (D) on the Yellow Hose to allow the refrigerant to flow. D C 7. Raise the Virgin Tank to a higher level than the Recovery Tank. Gravity and vacuum will transfer the liquid refrigerant to the Recovery Tank faster than reclaiming it. 8. Press <AMOUNT> to display the amount of refrigerant that has been transferred. 9. After the desired amount of refrigerant has been transferred, close valves on Virgin Tank and Recovery Tank. Set Virgin Tank on ground upright. 10. Close Hand Valve on Yellow Hose. Disconnect Yellow Hose from Recovery Tank. B FIGURE 5 CHARGING TANK 11. Re-Oil seals on anti-blow back valves on Red and Blue Hoses from unit and connect to Recovery Tank. Open Recovery Tank valves. 12. Re-Oil seal on Yellow Hose and connect to service port on front of unit. Open Hand Valve on Yellow Hose. 13. Following the displays in FIGURE 6, perform a recover mode. This will reclaim the refrigerant from STARTING the hose. (Optional: Opening Virgin Tank valve will SCREEN reclaim rest of refrigerant.) Will you Recycle from Vehicle this sequence? YES Will you be pulling a Vacuum this sequence? YES 14. Once complete, disconnect Yellow Hose from Virgin Tank. 15. Re-Oil seals on Yellow Hose and connect to center port on Gauge Set. NO NO Will you be charging this sequence? REMEMBER TO OIL O-RINGS AND SEALS WHEN ATTACHING HOSES OR FITTINGS YES FIGURE 6 RECOVER MODE INSTALLATION COMPLETE/SETUP COMPLETE 0692-2395-01 (6/3/97) REV. B NO