Hide thumbs

Also See for KS0077:

- Manual (109 pages)

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

keyestudio

Super Learning Kit for Arduino

www.keyestudio.com

1

Related Manuals for Keyestudio KS0077

Summary of Contents for Keyestudio KS0077

-

Page 1

Super Learning Kit for Arduino www.keyestudio.com… -

Page 2: Table Of Contents

Content 1. Introduction……………………….. 3 2. Component List……………………..3 3. Project List……………………….9 4. Project Details……………………..10 Project 1: Hello World…………………..10 Project 2: LED Blinking………………….13 Project 3: PWM…………………….15 Project 4: Traffic Light………………….20 Project 5: LED Chasing Effect………………..23 Project 6: Button-Controlled LED……………….. 25 Project 7: Active Buzzer………………….28…

-

Page 3: Introduction

1. Introduction keyestudio super learning kit is suitable for Arduino enthusiasts. This kit includes 32 projects with detailed tutorials, starting from the basics to more complex projects. Different from other kits, it adds some functional modules, such as RFID, temperature and humidity module. There is connection diagram and code for each project, making it easy for you to learn.

-

Page 4

220 Ω Resistor 10K Ω Resistor 1K Ω resistor 10K Ω Potentiometer Buzzer (Active) Buzzer (Passive) Large Button Switch www.keyestudio.com… -

Page 5

Ball Tilt Sensor Photo Resistor Flame Sensor LM35 Temp Sensor IC 74HC595N 16-pin DIP 7-seg LED Segment Display 7-seg LED Segment Display 8*8 LED Matrix www.keyestudio.com… -

Page 6

2×16 LCD display IR Receiver IR Remote Control Servo Motor Stepper Driver Stepper Motor Joystick Module www.keyestudio.com… -

Page 7

Relay Module PIR Motion Sensor Analog Gas Sensor ADXL345 Three Axis Acceleration Module HC-SR04 Ultrasonic Sensor DS3231 Clock Module www.keyestudio.com… -

Page 8

DHT11 Temperature and Humidity Sensor Soil Humidity Sensor RC522 RFID Module RFID Card Access Key Pin Headers www.keyestudio.com… -

Page 9: Project List

830-hole Breadboard Dupont Wire Jumper Wire 6-cell AA Battery Case USB Cable 3. Project List Project 1: Hello World Project 2: LED Blinking Project 3: PWM Project 4: Traffic Light Project 5: LED Chasing Effect Project 6: Button-controlled LED Project 7: Active Buzzer www.keyestudio.com…

-

Page 10: Project Details

Project 8: Passive Buzzer Project 9: RGB LED Project 10: Photo Resistor Project 11: Flame Sensor Project 12: LM35 Temperature Sensor Project 13: Tilt Switch Project 14: IR Remote Control Project 15: Analog Value Reading Project 16: 74HC595 Project 17: 1-digit LED Segment Display…

-

Page 11

Sample Code After installing driver for Arduino, let’s open Arduino software and compile code that enables Arduino to print «Hello World!» under your instruction. Of course, you can compile code for Arduino to continuously echo «Hello World!» without instruction. A simple If () statement will do the instruction trick. -

Page 12

Test Result Click to open the serial monitor, input an “ R”, LED 13 will blink once, PC will receive the information from Arduino: Hello World After choosing the proper port, the experiment is easy for you! www.keyestudio.com… -

Page 13: Project 2: Led Blinking

Project 2: LED Blinking Introduction Blinking LED experiment is quite simple. In the «Hello World!» program, we have come across LED. This time, we are going to connect an LED to one of the digital pins rather than using LED13 soldered to the board.

-

Page 14

Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

Page 15: Project 3: Pwm

Sample Code ////////////////////////////////////////////////////////// int ledPin = 10; // define digital pin 10. void setup() pinMode(ledPin, OUTPUT);// define pin with LED connected as output. void loop() digitalWrite(ledPin, HIGH); // set the LED on. delay(1000); // wait for a second. digitalWrite(ledPin, LOW); // set the LED off.

-

Page 16

Introduction PWM, short for Pulse Width Modulation, is a technique used to encode analog signal level into digital ones. A computer cannot output analog voltage but only digital voltage values such as 0V or 5V. So we use a high resolution counter to encode a specific analog signal level by modulating the duty cycle of PMW. -

Page 17

1. The amplitude of pulse width (minimum / maximum) 2. The pulse period (The reciprocal of pulse frequency in one second) 3. The voltage level(such as:0V-5V) There are 6 PMW interfaces on Arduino, namely digital pin 3, 5, 6, 9, 10, and 11. In previous experiments, we have done «button-controlled LED», using digital signal to control digital pin,… -

Page 18

Connection for 2560 R3: Sample Code In the program compiling process, we will use the analogWrite (PWM interface, analog value) function. In this experiment, we will read the analog value of the potentiometer and assign the value to PWM port, so there will be corresponding change to the brightness of the LED. One final part will display the analog value on the screen. -

Page 19

Serial.println(val);// display value of val analogWrite(ledpin,val/4);// turn on LED and set up brightness ( maximum output of PWM is 255) delay(10);// wait for 0.01 second… -

Page 20: Project 4: Traffic Light

Project 4: Traffic Light Introduction In the previous program, we have done the LED blinking experiment with one LED. Now, it’s time to up the stakes to do a bit more complicated experiment-traffic light. Actually, these two experiments are similar. While in this traffic light experiment, we use three LEDs with different colors rather than an LED.

-

Page 21

Circuit Connection Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

Page 22

Sample Code Since it is a simulation of traffic lights, the blinking time of each LED should be the same with those in traffic lights system. In this program, we use Arduino delay () function to control delay time, which is much simpler than C language. -

Page 23: Project 5: Led Chasing Effect

Project 5: LED Chasing Effect Introduction We can see many billboards composed of colorful LEDs. They are constantly changing to form various effects. In this experiment, we compile a program to simulate chase effect. Hardware Required Red LED*6 220Ω Resistor *6…

-

Page 24

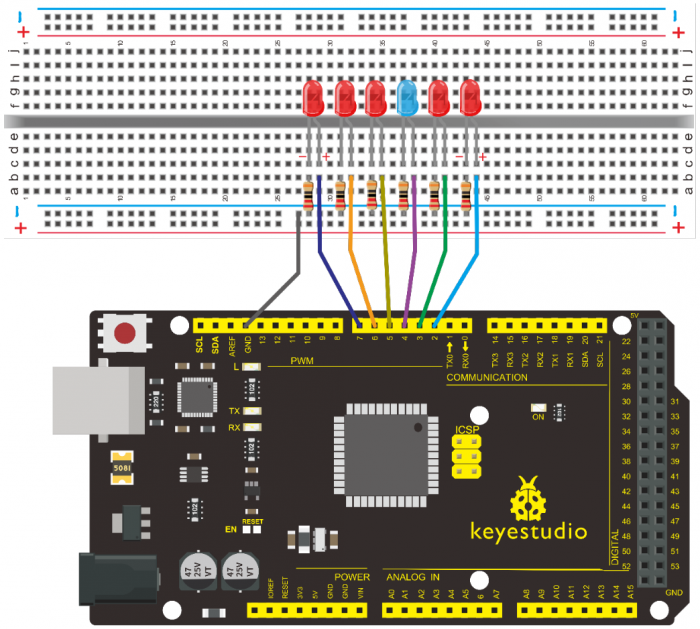

Connection for 2560 R3: Sample Code ////////////////////////////////////////////////////////// int BASE = 2 ; // the I/O pin for the first LED int NUM = 6; // number of LEDs void setup() for (int i = BASE; i < BASE + NUM; i ++) pinMode(i, OUTPUT);… -

Page 25: Project 6: Button-Controlled Led

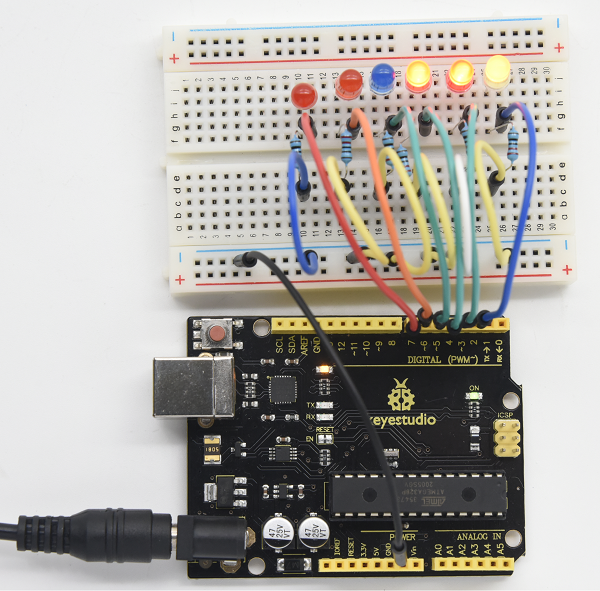

(int i = BASE; i < BASE + NUM; i ++) digitalWrite(i, HIGH); // set I/O pins as “high”, turn on LEDs one by one delay(200); // delay ////////////////////////////////////////////////////////// Result You can see the LEDs blink by sequence.

-

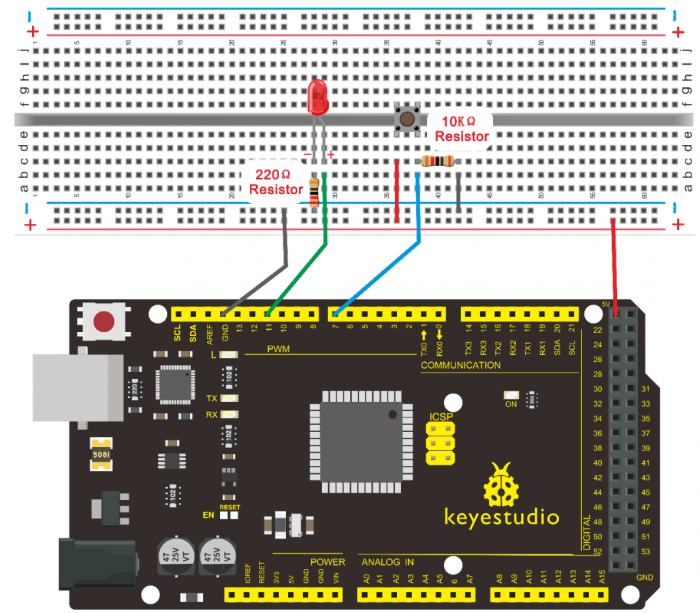

Page 26

Hardware Required Button switch*1 Red M5 LED*1 220ΩResistor*1 10KΩ Resistor*1 Breadboard*1 Breadboard Jumper Wires Circuit Connection Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

Page 27

Sample Code Now, let’s begin the compiling. When the button is pressed, the LED will be on. Based on the previous study, the coding should be easy for you. In this program, we add a statement of judgment. Here, we use an if () statement. -

Page 28: Project 7: Active Buzzer

7 and assign if to val if(val==LOW)// check if the button is pressed, if yes, turn on the LED { digitalWrite(ledpin,LOW);} else { digitalWrite(ledpin,HIGH);} ////////////////////////////////////////////////////////// Test Result When the button is pressed, LED is on, otherwise, LED remains off. In this way, the button controlled LED experiment is completed.

-

Page 29

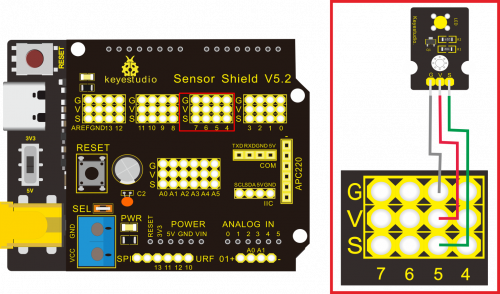

Hardware Required Buzzer*1 Key *1 Breadboard*1 Breadboard Jumper Wires Circuit Connection Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

Page 30

When connecting the circuit, pay attention to the positive and negative poles of the buzzer. In the photo, you can see there are red and black lines. When the circuit is finished, you can begin the programming. Sample Code Program is simple. -

Page 31: Project 8: Passive Buzzer

Project 8: Passive Buzzer Introduction We can use Arduino to make many interactive works. The most commonly used one is acoustic-optic display. All the previous experiment has something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer but not a speaker while buzzer is more simpler and easier to use.

-

Page 32

Connection for 2560 R3: www.keyestudio.com… -

Page 33

Sample Code ////////////////////////////////////////////////////////// int buzzer=8;// select digital IO pin for the buzzer void setup() pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output void loop() { unsigned char i,j;//define variable while(1) { for(i=0;i<80;i++)// output a frequency sound { digitalWrite(buzzer,HIGH);// sound delay(1);//delay1ms… -

Page 34: Project 9: Rgb Led

Project 9: RGB LED Introduction Tricolor principle to display various colors; PWM controlling ports to display full color; Can be driven directly by Arduino PWM interface. Hardware Required Arduino Board* 1 USB Cable * 1 RGB LED * 1…

-

Page 35

Circuit Connection Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

Page 36

Sample Code ////////////////////////////////////////////////////////// int redpin = 11; //select the pin for the red LED int bluepin =10; // select the pin for the blue LED int greenpin =9;// select the pin for the green LED int val; void setup() { pinMode(redpin, OUTPUT);… -

Page 37: Project 10: Photo Resistor

Project 10: Photo Resistor Introduction After completing all the previous experiments, you may acquire some basic understanding and knowledge about Arduino application. We have introduced digital input and output, analog input and PWM. Now, let’s begin the learning of sensor applications.

-

Page 38

Hardware Required Photo Resistor*1 Red M5 LED*1 10KΩ Resistor*1 220Ω Resistor*1 Breadboard*1 Breadboard Jumper Wires Circuit Connection Connection for UNO R3: www.keyestudio.com… -

Page 39

Connection for 2560 R3: Sample Code After wiring, let’s begin the program compiling. The program is similar to the PWM. For change detail, please refer to the Sample Code below. ////////////////////////////////////////////////////////// int potpin=0;// initialize analog pin 0, connected with photovaristor int ledpin=11;// initialize digital pin 11, output regulating the brightness of LED… -

Page 40: Project 11: Flame Sensor

0.01 ////////////////////////////////////////////////////////// Test Result After downloading the program, you can change the light strength around the photovaristor, and see the corresponding brightness change of the LED. Photovaristors has various applications in our everyday. You can make other interesting interactive projects based on this one.

-

Page 41

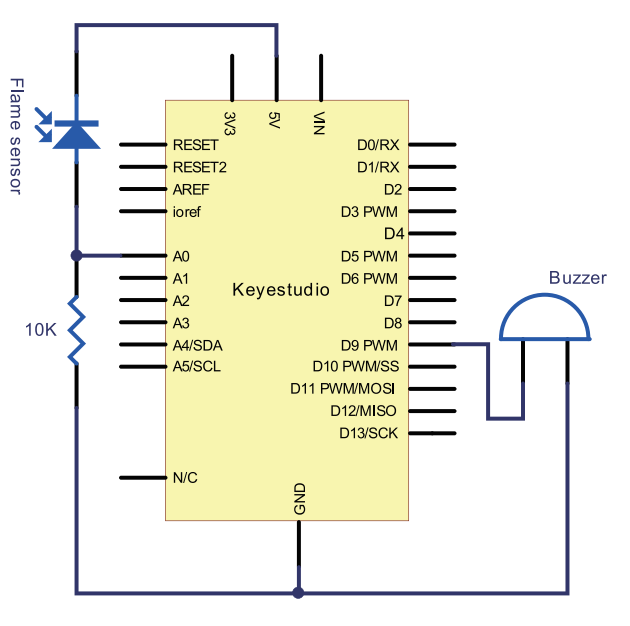

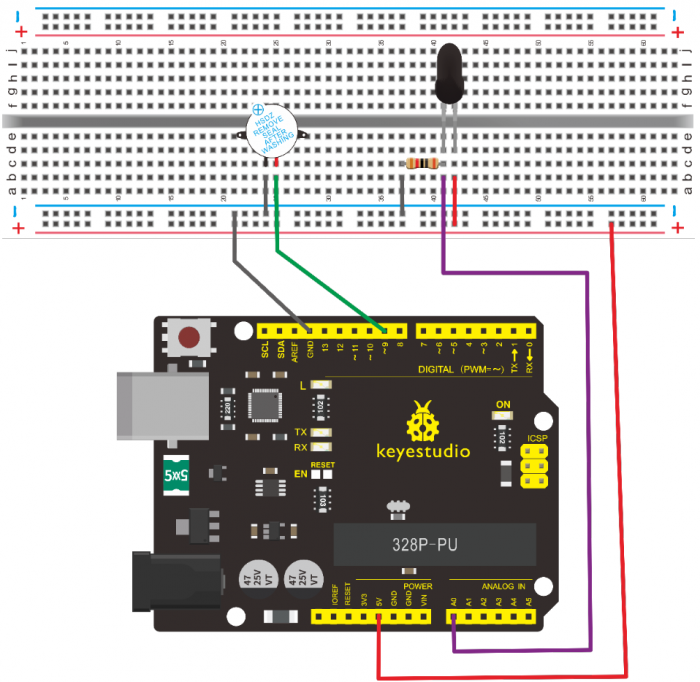

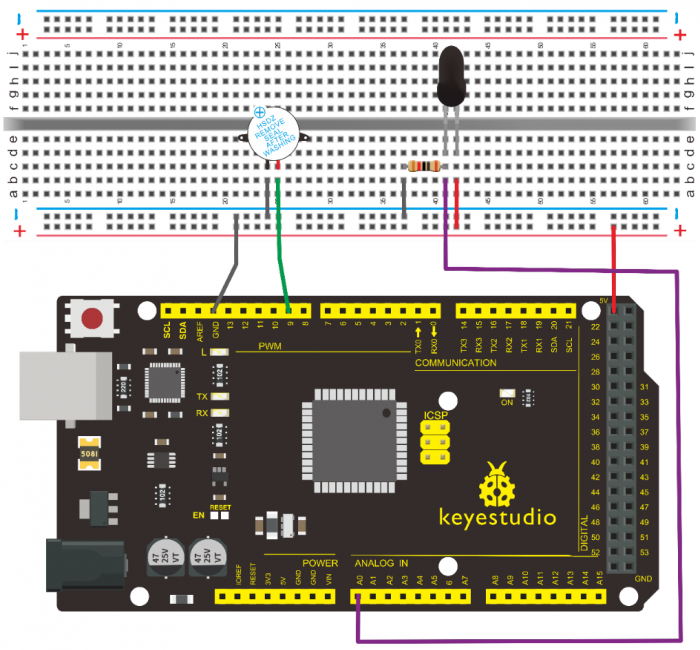

Hardware Required Flame Sensor *1 Buzzer *1 10K Resistor *1 Breadboard Jumper Wires Circuit Connection 1)Connecting buzzer: Connect the controller board, prototype board, breadboard and USB Cable according to the Arduino tutorial. Connect the buzzer to digital pin 8. -

Page 42

Connection for MEGA 2560: www.keyestudio.com… -

Page 43

Experiment Principle When it’s approaching a fire, the voltage value read from the analog port will differ. If you use a multimeter, you can see that when there is no fire approaching, the voltage it reads is around 0.3V;… -

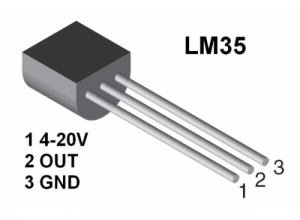

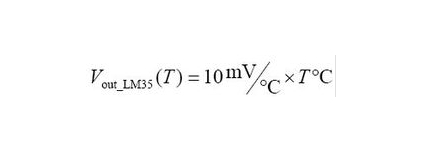

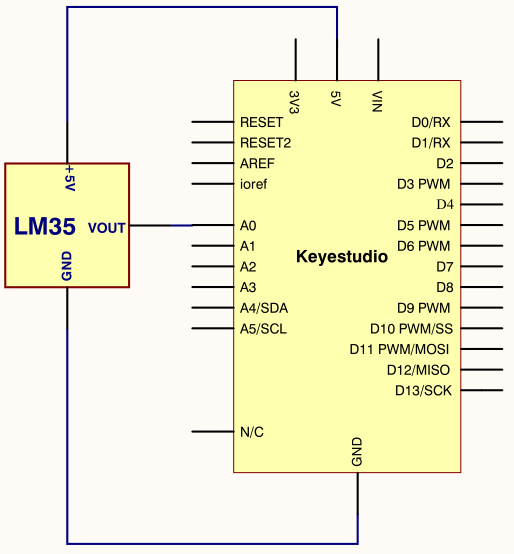

Page 44: Project 12: Lm35 Temperature Sensor

Project 12: LM35 Temperature Sensor Introduction LM35 is a common and easy-to-use temperature sensor. It does not require other hardware. You just need an analog port to make it work. The difficulty lies in compiling the code to convert the analog value it reads into Celsius temperature.

-

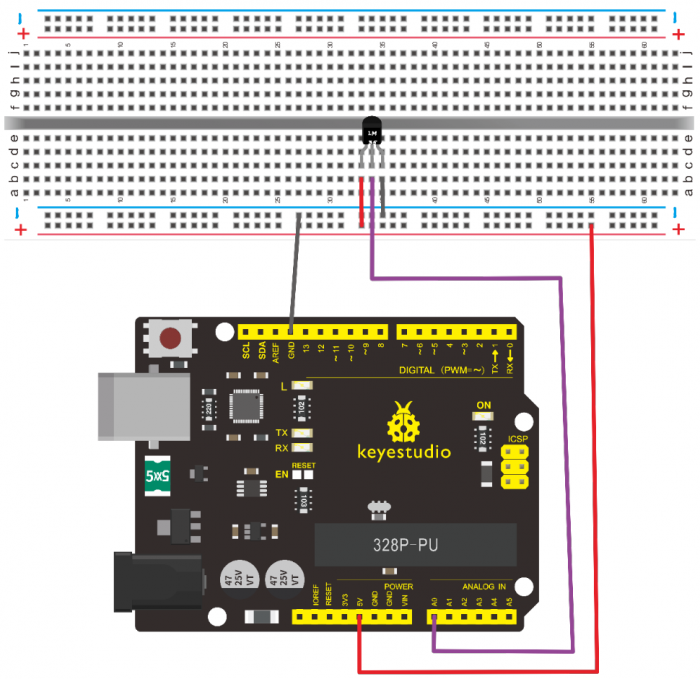

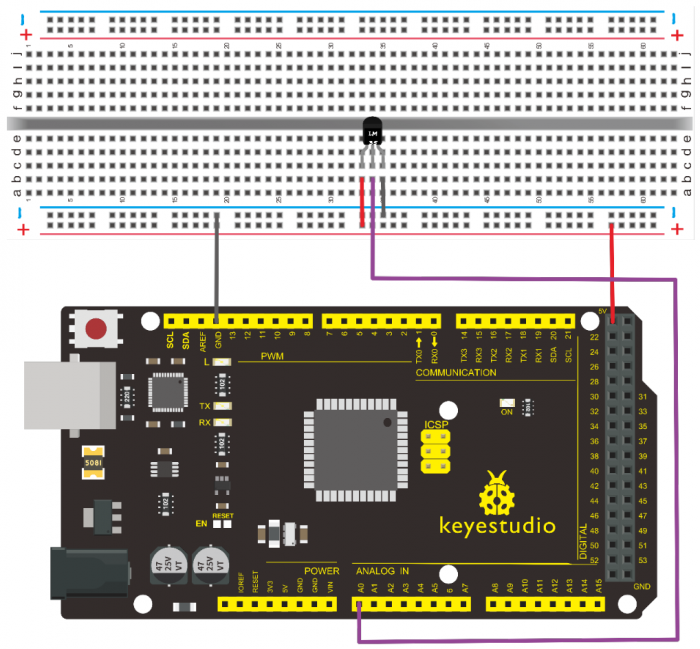

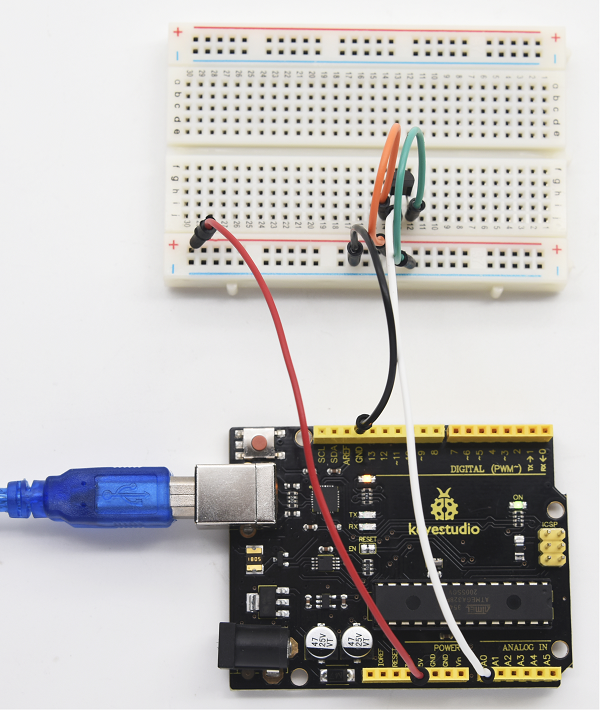

Page 45

Connection for UNO R3: Connection for 2560 R3: www.keyestudio.com… -

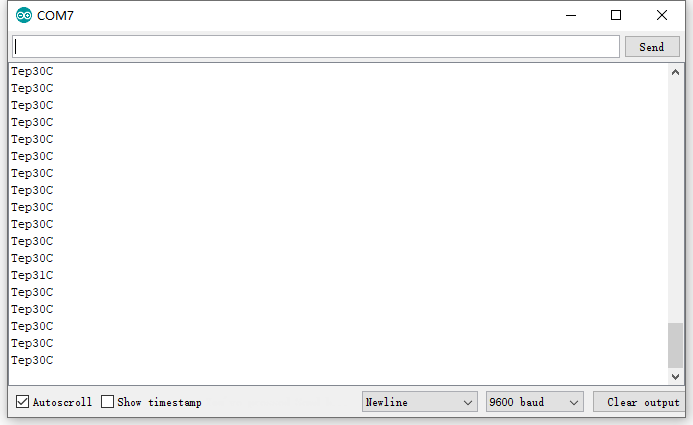

Page 46

Sample Code ////////////////////////////////////////////////////////// int potPin = 0; // initialize analog pin 0 for LM35 temperature sensor void setup() Serial.begin(9600);// set baud rate at”9600” void loop() int val;// define variable int dat;// define variable val=analogRead(0);// read the analog value of the sensor and assign it to val dat=(125*val)>>8;// temperature calculation formula… -

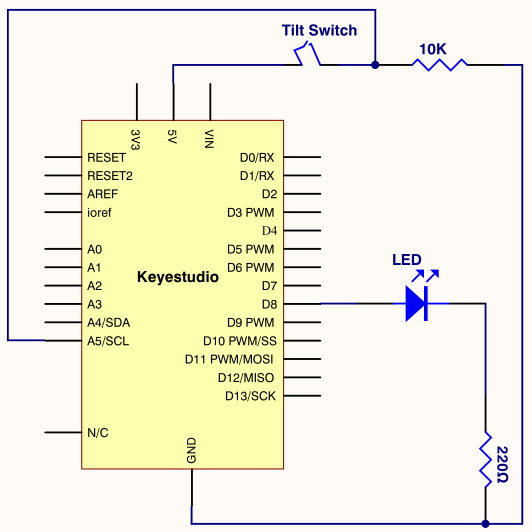

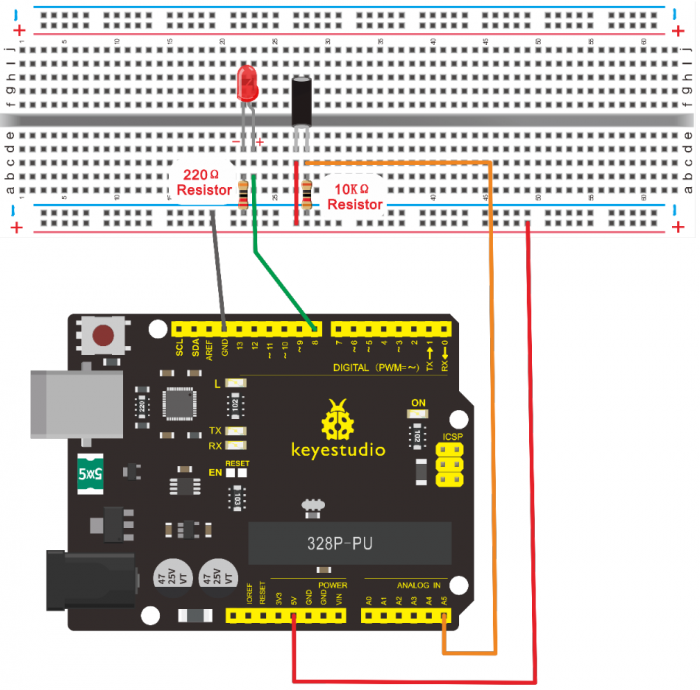

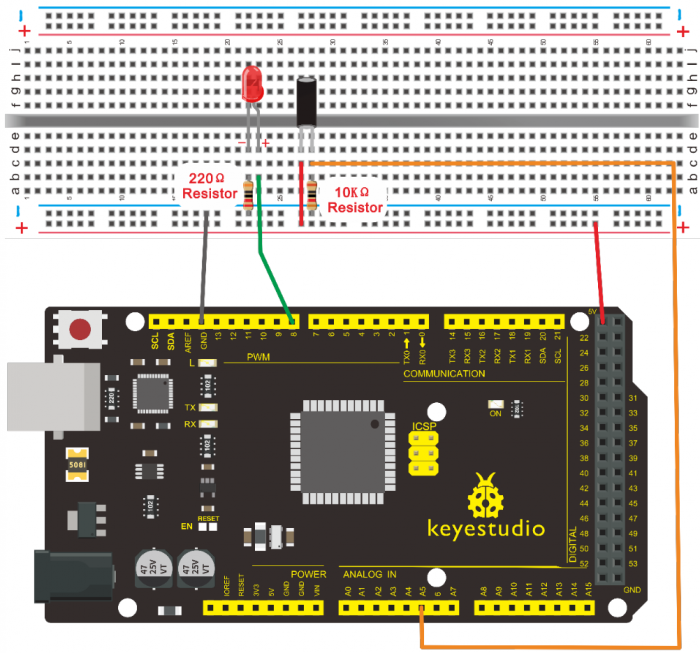

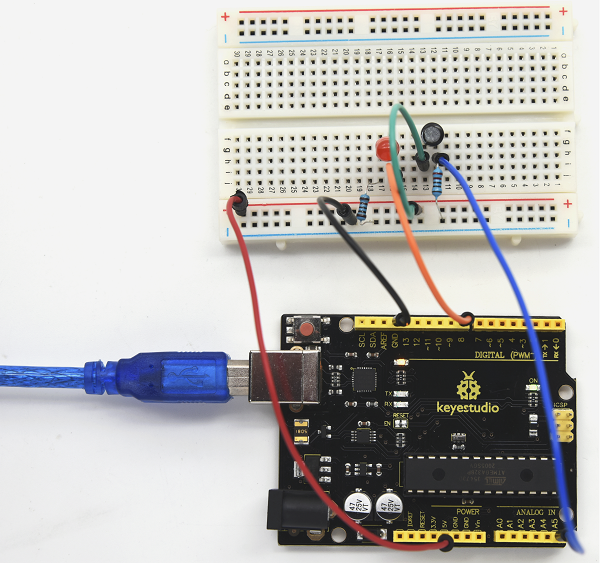

Page 47: Project 13: Tilt Switch

Project 13: Tilt Switch Introduction Tilt switch controlling the LED on and off. Hardware Required Ball switch*1 Led *1 220Ω Resistor*1 10KΩ resistor*1 Breadboard Jumper Wires Circuit Connection Connection for R3: www.keyestudio.com…

-

Page 48

Connection for 2560 R3: Connect the controller board, shield, breadboard and USB cable according to Arduino tutorial. Connect the LED to digital pin 8, ball switch to analog pin 5. Experiment Principle When one end of the switch is below horizontal position, the switch is on. The voltage of the analog port is about 5V (1023 in binary). -

Page 49: Project 14: Ir Remote Control

5 if(i>512)// if larger that 512(2.5V) digitalWrite(8,LOW);// turn on LED else// otherwise digitalWrite(8,HIGH);// turn off LED ////////////////////////////////////////////////////////// Test Result Hold the breadboard with your hand. Tilt it to a certain extent, the LED will be on. If there is no tilt, the LED will be off.

-

Page 50

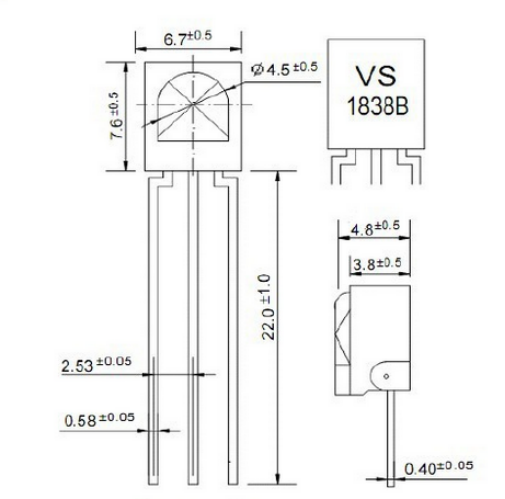

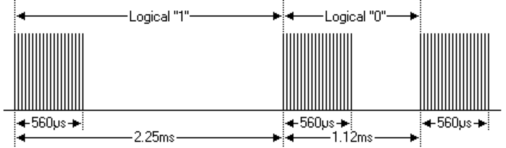

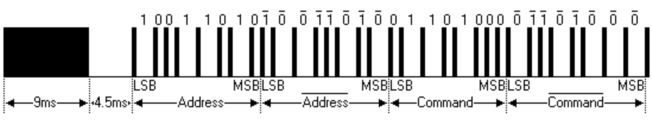

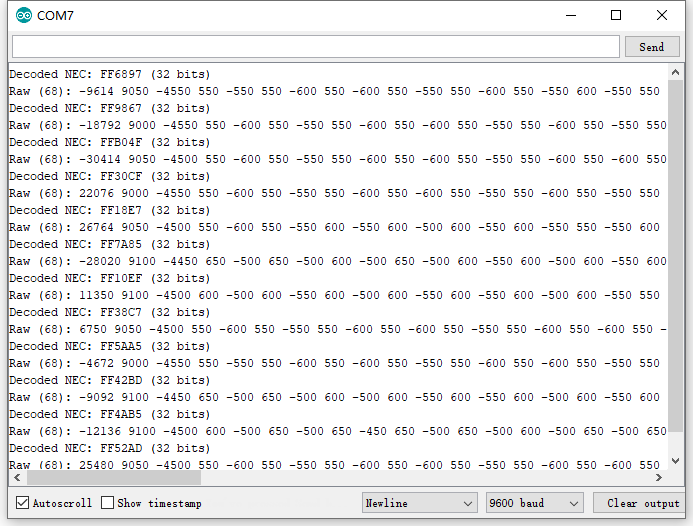

Introduction What is an infrared receiver? The signal from the infrared remote controller is a series of binary pulse code. To avoid the other infrared signal interference during the wireless transmission, the signal is pre-modulate at a specific carrier frequency and then send out by an infrared emission diode. The infrared receiving device needs to filter out other waves and receive signals at that specific frequency and to modulate it back to binary pulse code, known as demodulation. -

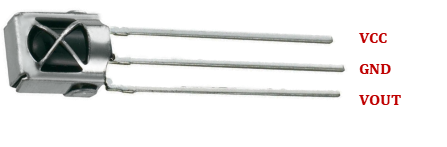

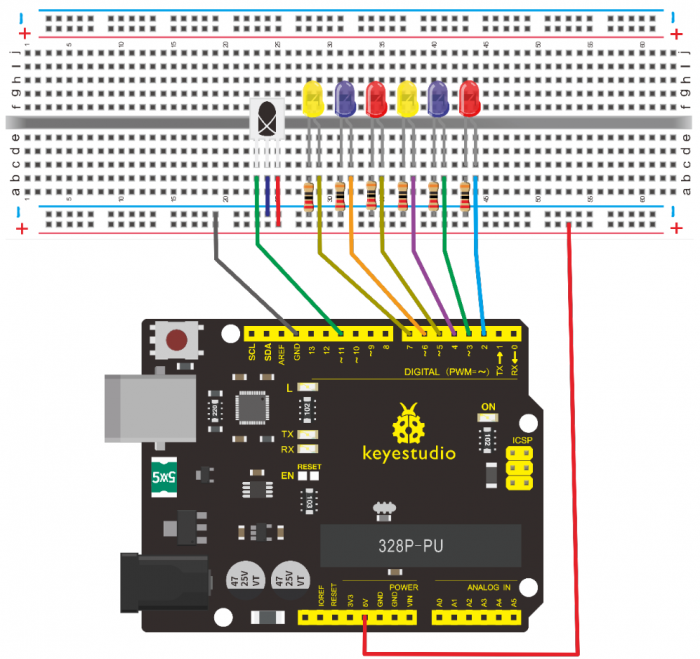

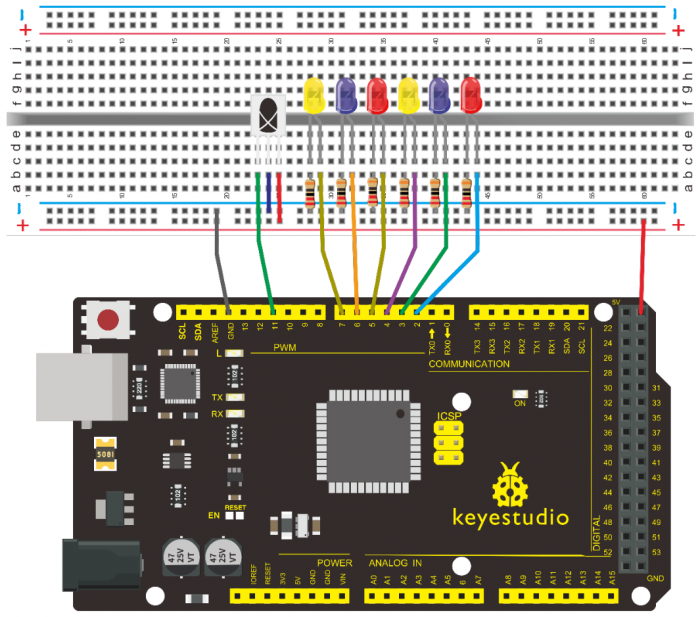

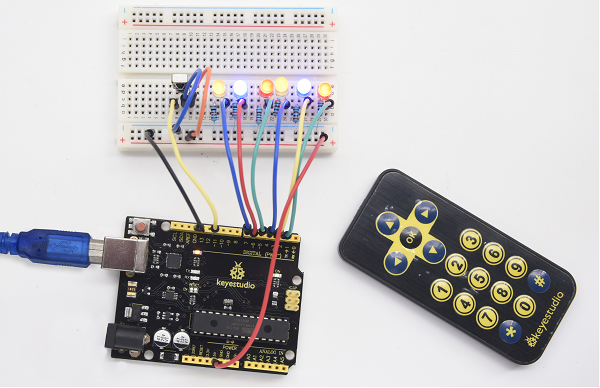

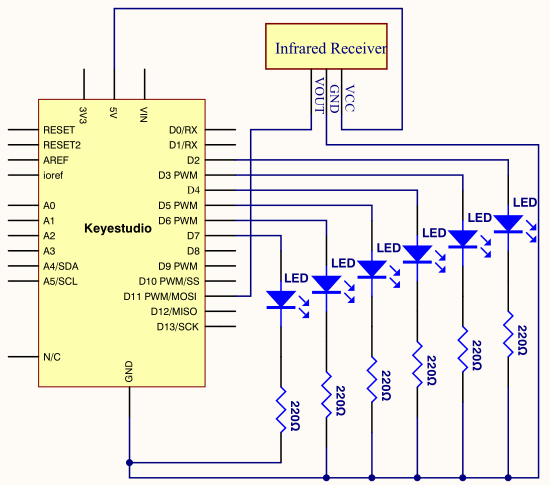

Page 51

Hardware Required Infrared Remote Controller *1 Infrared Receiver *1 LED *6 220ΩResistor *6 Multi-color Breadboard Wires Circuit Connection First, connect the controller board; then connect the infrared receiver as the above mentioned, connect VOUT to digital pin 11, connect the LEDs with resistors and connect the resistors to pin 2,3,4,5,6,7. -

Page 52

Connection for 2560 R3: Experimental Principle If you want to decode the code from the remote controller, you must first know how it’s coded. The coding method we use here is NEC protocol. Below is a brief introduction. • NEC protocol: Features:… -

Page 53

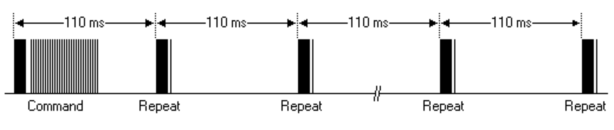

• Pulse transmitted when button is pressed and immediately released The picture above shows a typical pulse train of the NEC protocol. With this protocol the LSB is transmitted first. In this case Address $59 and Command $16 is transmitted. A message is started by a 9ms AGC burst, which was used to set the gain of the earlier IR receivers. -

Page 54

Sample Code ////////////////////////////////////////////////////////// #include <IRremote.h> int RECV_PIN = 11; int LED1 = 2; int LED2 = 3; int LED3 = 4; int LED4 = 5; int LED5 = 6; int LED6 = 7; long on1 = 0x00FF6897; long off1 = 0x00FF9867;… -

Page 55

Serial.print(«Decoded SONY: «); else if (results->decode_type == RC5) Serial.print(«Decoded RC5: «); else if (results->decode_type == RC6) Serial.print(«Decoded RC6: «); Serial.print(results->value, HEX); Serial.print(» («); Serial.print(results->bits, DEC); Serial.println(» bits)»); Serial.print(«Raw («); Serial.print(count, DEC); Serial.print(«): «); for (int i = 0; i < count; i++) if ((i % 2) == 1) { Serial.print(results->rawbuf[i]*USECPERTICK, DEC);… -

Page 56

Serial.begin(9600); irrecv.enableIRIn(); // Start the receiver int on = 0; unsigned long last = millis(); void loop() if (irrecv.decode(&results)) // If it’s been at least 1/4 second since the last // IR received, toggle the relay if (millis() — last > 250) on = !on;… -

Page 57

LOW); last = millis(); irrecv.resume(); // Receive the next value ////////////////////////////////////////////////////////// Note:add IRremote folder into installation directory Arduinocompiler libraries, or you will fail to compile it. Infrared remote library: https://github.com/shirriff/Arduino-IRremote Program Function Decode the coded pulse signal emitted by the remote controller, then execute corresponding action according to the results of the decoding. -

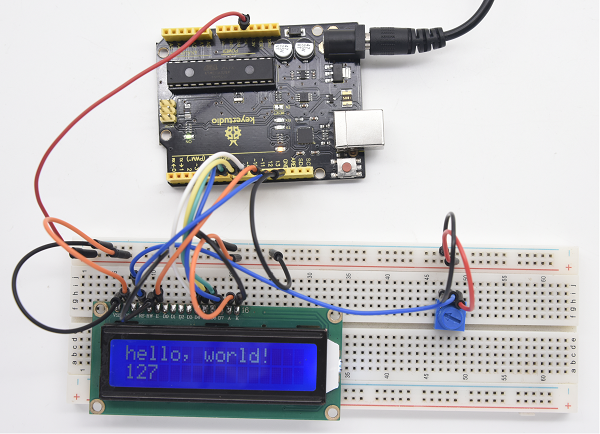

Page 58: Project 15: Analog Value Reading

Project 15: Analog Value Reading Introduction In this experiment, we will begin the study of analog I/O interfaces. On an Arduino, there are 6 analog interfaces numbered from 0 to 5. These 6 interfaces can also be used as digital ones numbered as 14-19.

-

Page 59

Connection for 2560 R3: www.keyestudio.com… -

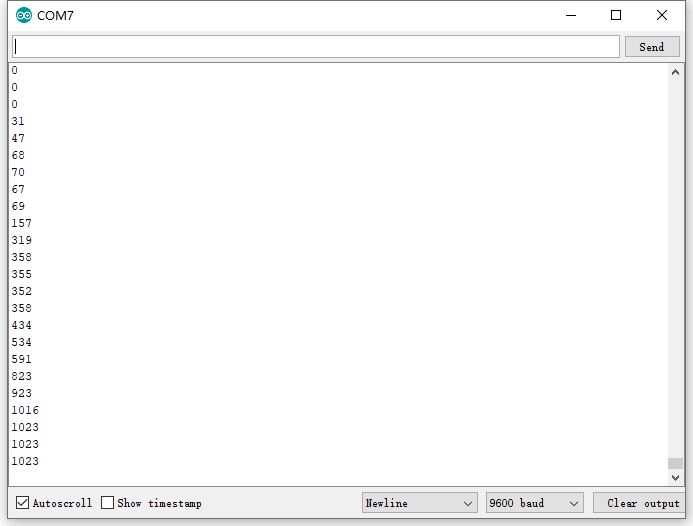

Page 60

Sample Code The program compiling is simple. An analogRead () Statement can read the value of the interface. The A/D acquisition of Arduino 328 is in 10 bits, so the value it reads is among 0 to 1023. One difficulty in this project is to display the value on the screen, which is actually easy to learn. -

Page 61

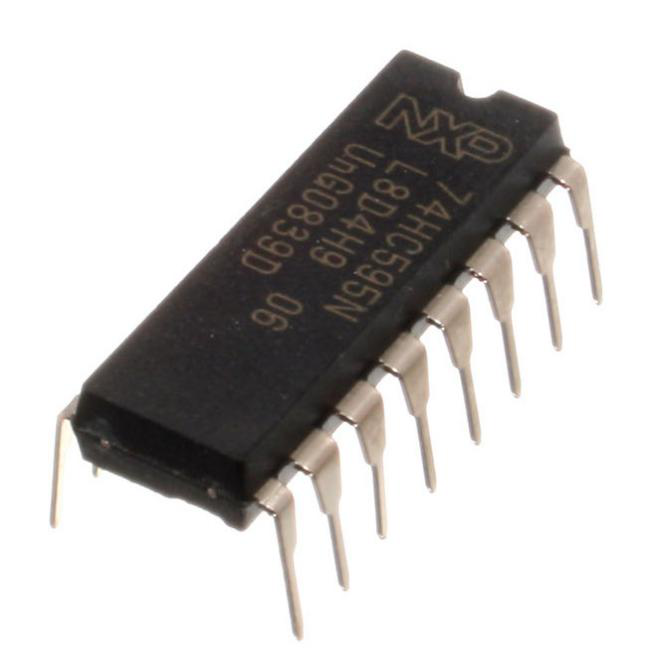

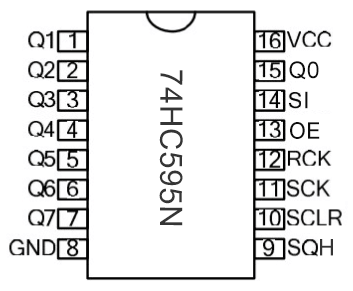

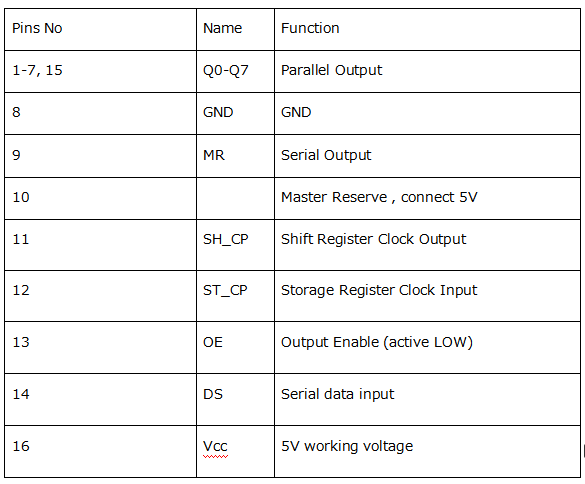

The experiment is now completed. Thank you! ******************************************************************************* Project 16: 74HC595 Introduction To put it simply, 74HC595 is a combination of 8-digit shifting register, memorizer and equipped with tri-state output. Here, we use it to control 8 LEDs. You may wonder why use a 74HC595 to control LED? Well, think about how many I/O it takes for an Arduino to control 8 LEDs? Yes, 8. -

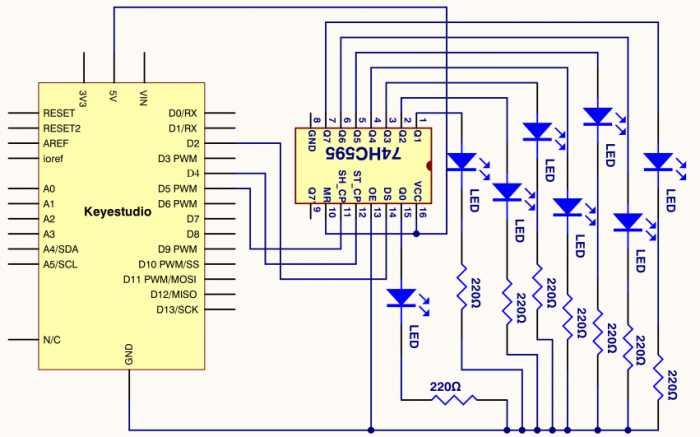

Page 62

Hardware Required 74HC595 chip*1 Red M5 LED*4 Green M5 LED*4 220Ω Resistor*8 Breadboard*1 Breadboard Jumper Wires Circuit Connection Connection for UNO R3: Note: for pin 13 OE port of 74HC595, it should be connected to GND. www.keyestudio.com… -

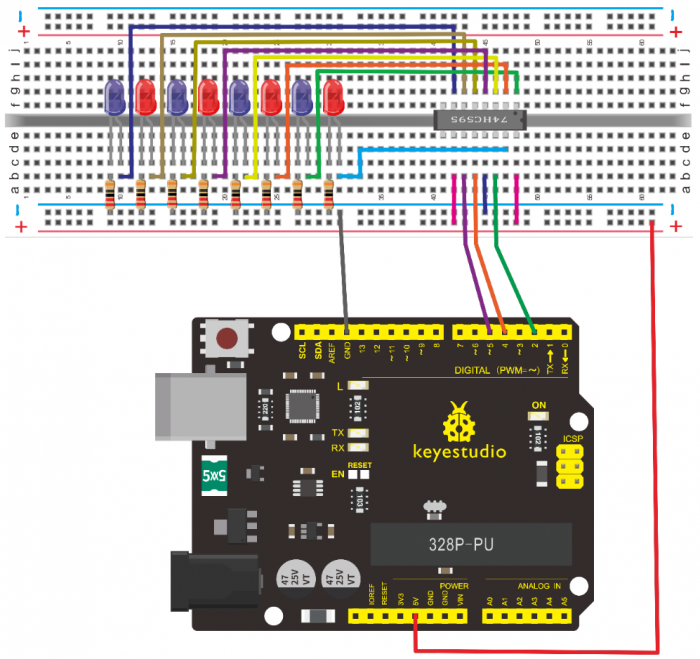

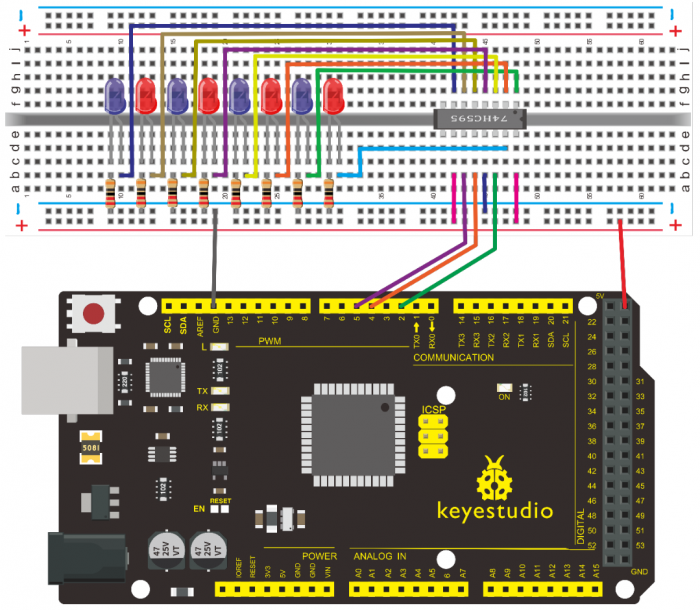

Page 63

Connection for 2560 R3: The circuit may seem complicated, but once you wire it in order, you will find it more easier! Sample Code ////////////////////////////////////////////////////////// int data = 2;// set pin 14 of 74HC595as data input pin SI int clock = 5;// set pin 11 of 74hc595 as clock pin SCK int latch = 4;// set pin 12 of 74hc595 as output latch RCK… -

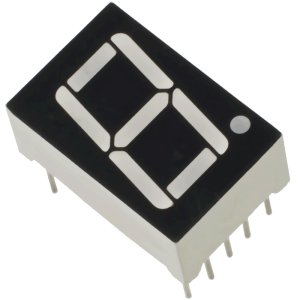

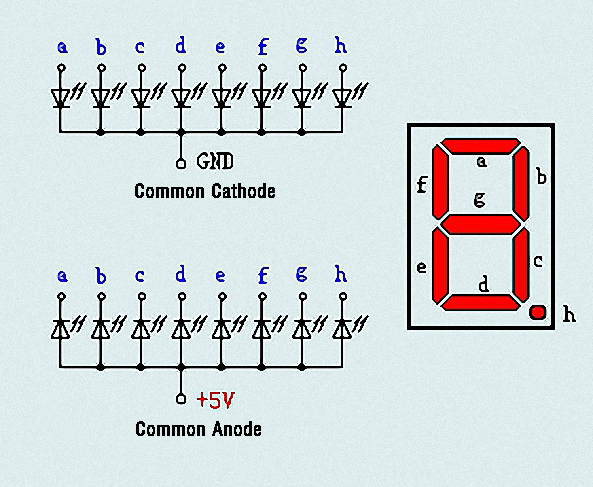

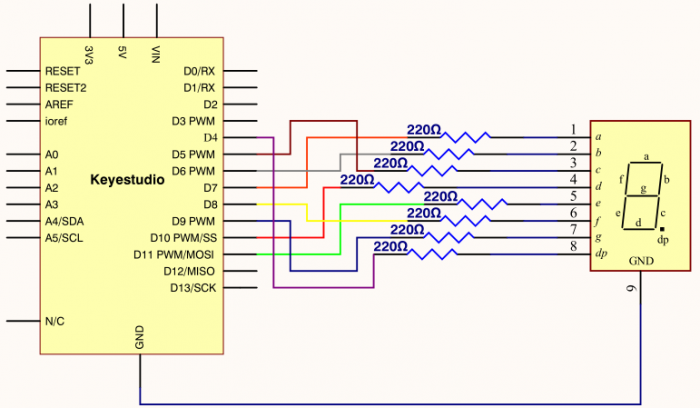

Page 64: Project 17: 1-Digit Led Segment Display

= 0; i < 256; i++) updateLEDs(i); delay(500); void updateLEDs(int value) digitalWrite(latch, LOW);// shiftOut(data, clock, MSBFIRST, ~value);// serial data “output”, high level first digitalWrite(latch, HIGH);// latch ////////////////////////////////////////////////////////// Test Result After downloading the program, you can see 8 LEDs display 8-bit binary number.

-

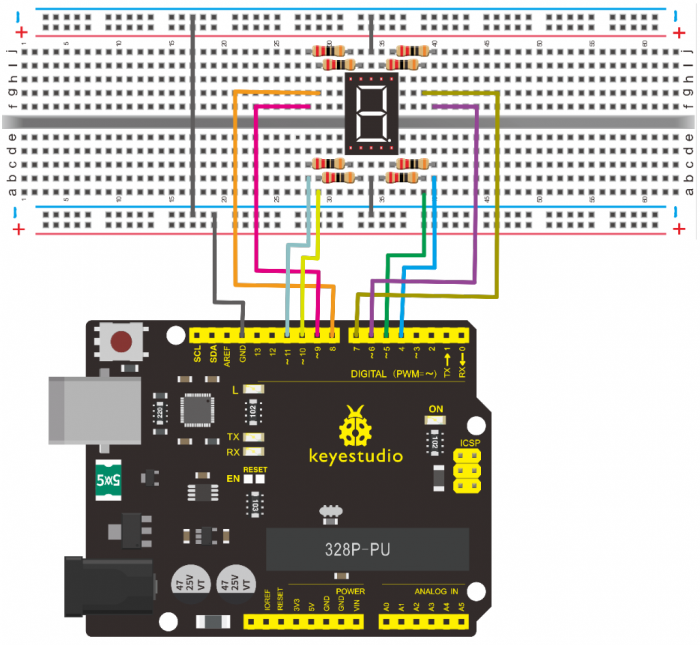

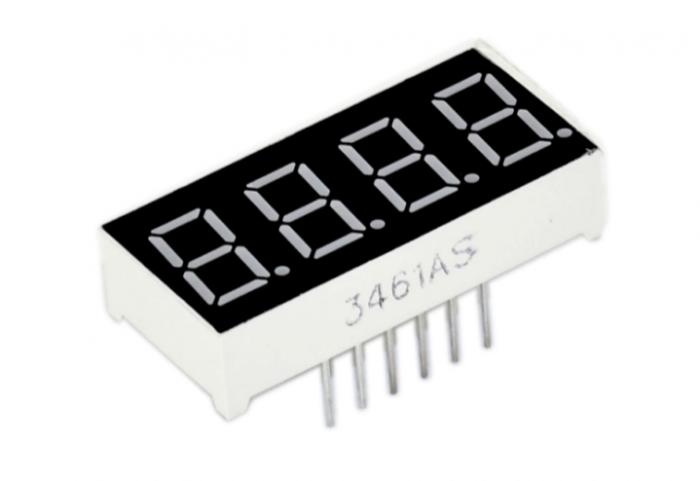

Page 65

8-segment display has one more LED unit ( for decimal point display) than 7-segment one. According to the wiring method of LED units, LED segment display can be divided into common anode display and common cathode display. Common anode display refers to the one that combine all the anodes of LED units into one common anode (COM). -

Page 66

Connection for 2560 R3: www.keyestudio.com… -

Page 67

Sample Code There are seven segments for numerical display, one for decimal point display. Corresponding segments will be turned on when displaying certain numbers. For example, when displaying number 1, b and c segments will be turned on. We compile a subprogram for each number, and compile the main program to display one number every 2 seconds, cycling display number 0 ~ 9. -

Page 68

// display number 3 {digitalWrite(g,HIGH); digitalWrite(a,HIGH); digitalWrite(b,HIGH); digitalWrite(c,HIGH); digitalWrite(d,HIGH); digitalWrite(dp,LOW); digitalWrite(f,LOW); digitalWrite(e,LOW); void digital_4(void) // display number 4 {digitalWrite(c,HIGH); digitalWrite(b,HIGH); digitalWrite(f,HIGH); digitalWrite(g,HIGH); digitalWrite(dp,LOW); digitalWrite(a,LOW); digitalWrite(e,LOW); digitalWrite(d,LOW); void digital_5(void) // display number 5 unsigned char j;… -

Page 69

// display number 7 unsigned char j; for(j=5;j<=7;j++) digitalWrite(j,HIGH); digitalWrite(dp,LOW); for(j=8;j<=11;j++) digitalWrite(j,LOW); void digital_8(void) // display number 8 unsigned char j; for(j=5;j<=11;j++) digitalWrite(j,HIGH); digitalWrite(dp,LOW); void digital_9(void) // display number 5 unsigned char j;… -

Page 70

0 delay(1000);// wait for 1s digital_1();// display number 1 delay(1000);// wait for 1s digital_2();// display number 2 delay(1000); // wait for 1s digital_3();// display number 3 delay(1000); // wait for 1s digital_4();// display number 4 delay(1000);… -

Page 71: Project 18: 4-Digit Led Segment Display

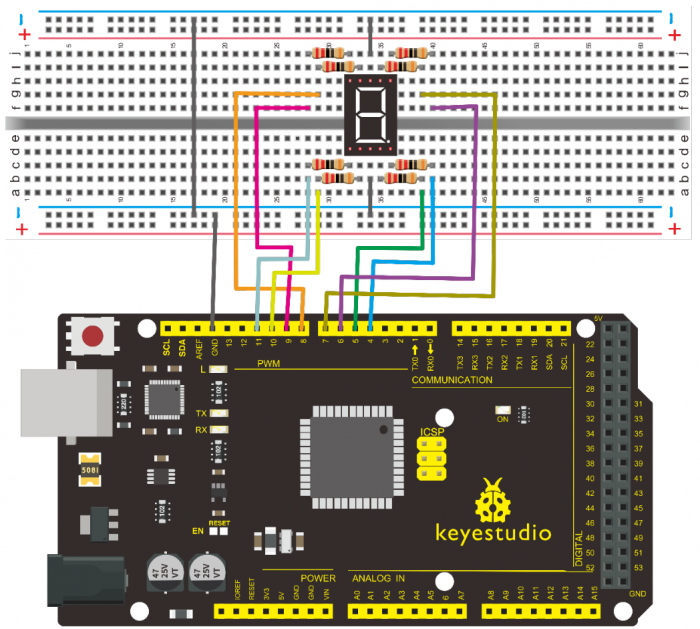

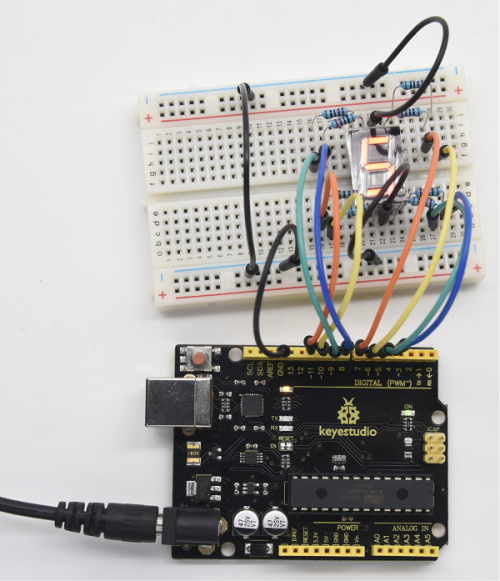

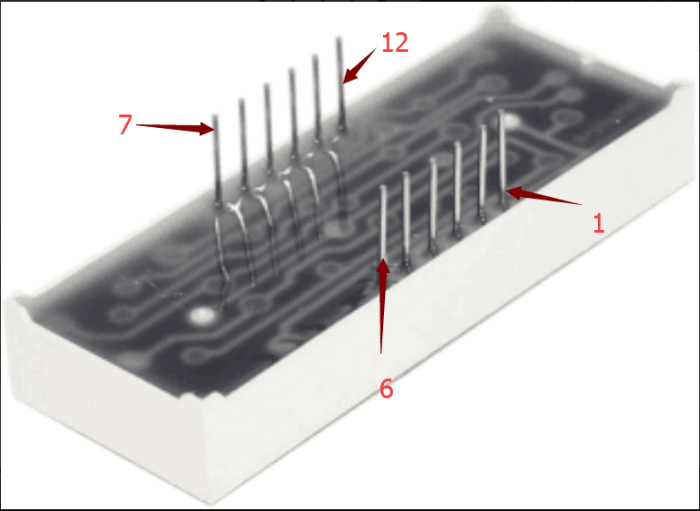

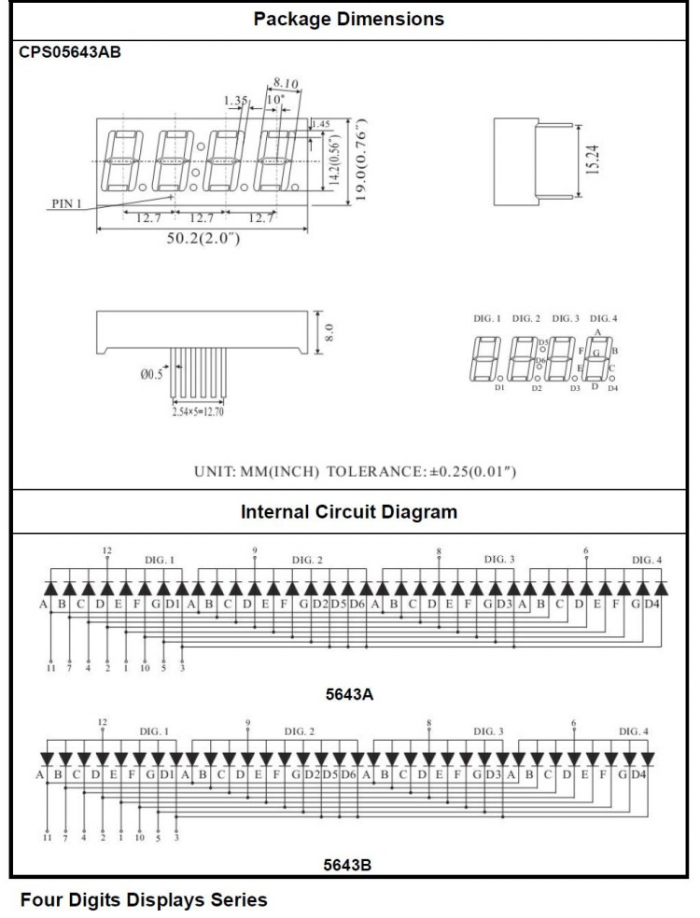

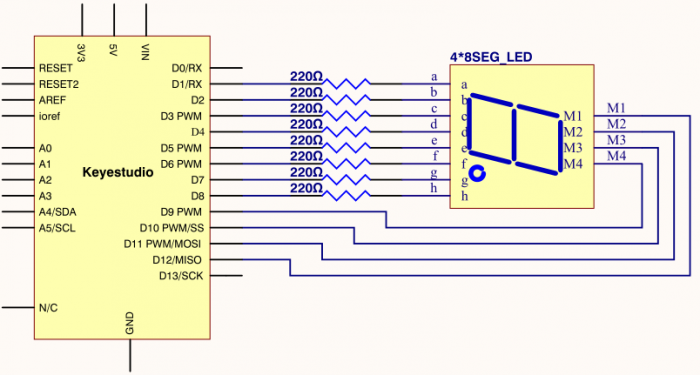

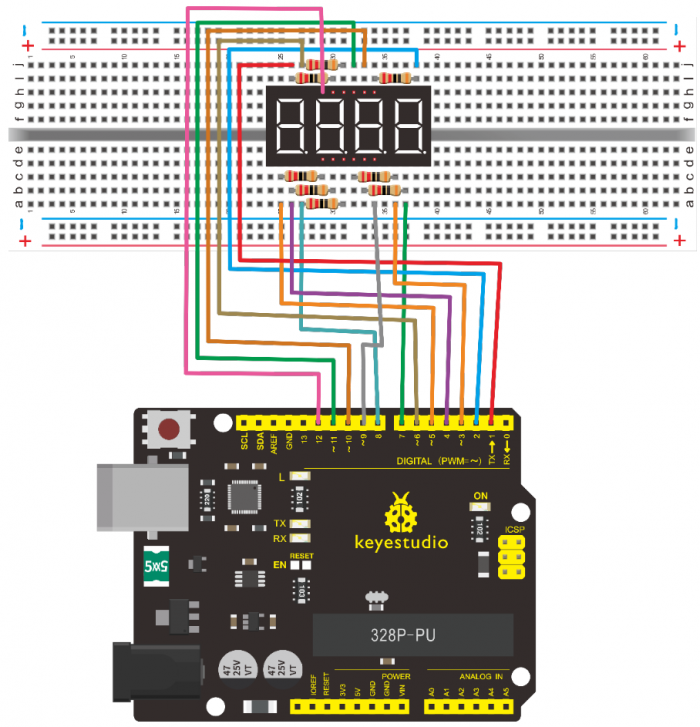

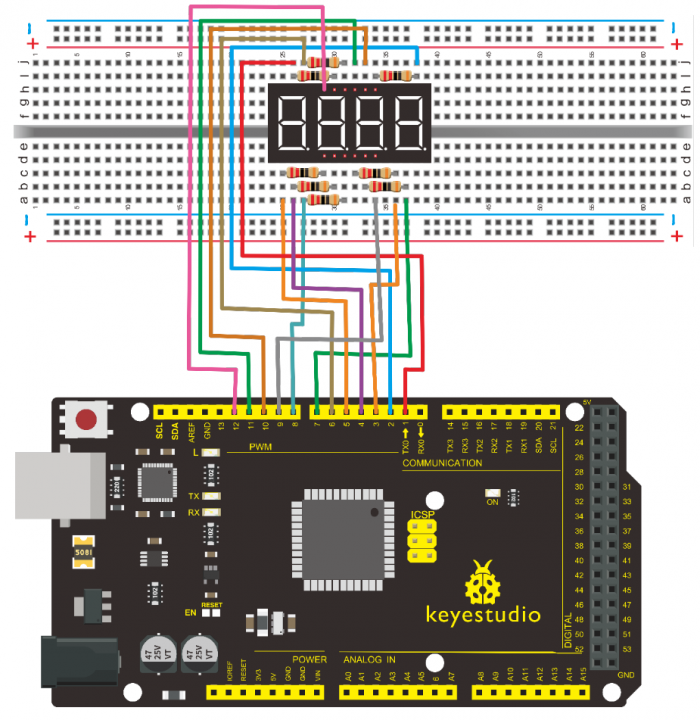

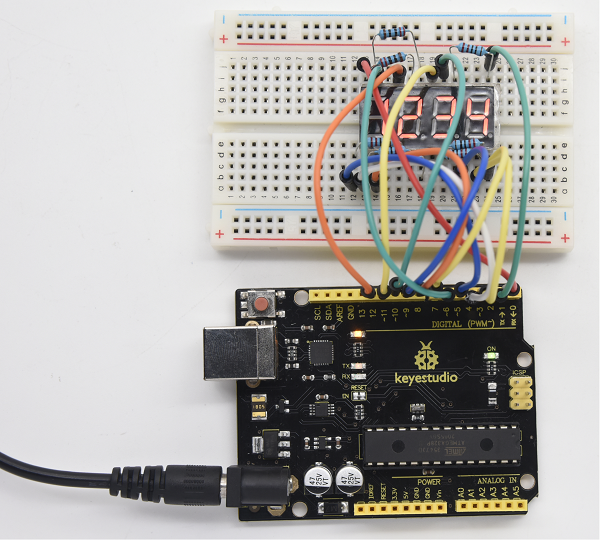

Project 18: 4-digit LED Segment Display Introduction In this experiment, we use an Arduino to drive a common cathode, 4-digit, 7-segment LED display. For LED display, current-limiting resistors are indispensable. There are two wiring methods for Current-limiting resistor. One is to connect one resistor for each cathode end, 4 in total for d1-d4 cathode.

-

Page 72

Manual for LED Segment Display: Connection for UNO R3: www.keyestudio.com… -

Page 73

Connection for 2560 R3: Sample Code ////////////////////////////////////////////////////////// // display 1234 // select pin for cathode int a = 1; int b = 2; int c = 3; int d = 4; int e = 5; int f = 6;… -

Page 74

OUTPUT); pinMode(d, OUTPUT); pinMode(e, OUTPUT); pinMode(f, OUTPUT); pinMode(g, OUTPUT); pinMode(dp, OUTPUT); ///////////////////////////////////////////////////////////// void loop() Display(1, 1); Display(2, 2); Display(3, 3); Display(4, 4); /////////////////////////////////////////////////////////////// void WeiXuan(unsigned char n)// switch(n) case 1: digitalWrite(d1,LOW); digitalWrite(d2, HIGH); digitalWrite(d3, HIGH); digitalWrite(d4, HIGH); break;… -

Page 75

HIGH); digitalWrite(d4, LOW); break; default : digitalWrite(d1, HIGH); digitalWrite(d2, HIGH); digitalWrite(d3, HIGH); digitalWrite(d4, HIGH); break; void Num_0() digitalWrite(a, HIGH); digitalWrite(b, HIGH); digitalWrite(c, HIGH); digitalWrite(d, HIGH); digitalWrite(e, HIGH); digitalWrite(f, HIGH); digitalWrite(g, LOW); digitalWrite(dp,LOW); void Num_1() digitalWrite(a, LOW); digitalWrite(b, HIGH);… -

Page 76

Num_3() digitalWrite(a, HIGH); digitalWrite(b, HIGH); digitalWrite(c, HIGH); digitalWrite(d, HIGH); digitalWrite(e, LOW); digitalWrite(f, LOW); digitalWrite(g, HIGH); digitalWrite(dp,LOW); void Num_4() digitalWrite(a, LOW); digitalWrite(b, HIGH); digitalWrite(c, HIGH); digitalWrite(d, LOW); digitalWrite(e, LOW); digitalWrite(f, HIGH); digitalWrite(g, HIGH); digitalWrite(dp,LOW); void Num_5() digitalWrite(a, HIGH);… -

Page 77

HIGH); digitalWrite(g, HIGH); digitalWrite(dp,LOW); void Num_7() digitalWrite(a, HIGH); digitalWrite(b, HIGH); digitalWrite(c, HIGH); digitalWrite(d, LOW); digitalWrite(e, LOW); digitalWrite(f, LOW); digitalWrite(g, LOW); digitalWrite(dp,LOW); void Num_8() digitalWrite(a, HIGH); digitalWrite(b, HIGH); digitalWrite(c, HIGH); digitalWrite(d, HIGH); digitalWrite(e, HIGH); digitalWrite(f, HIGH); digitalWrite(g, HIGH); digitalWrite(dp,LOW);… -

Page 78

LOW); digitalWrite(e, LOW); digitalWrite(f, LOW); digitalWrite(g, LOW); digitalWrite(dp,LOW); void pickNumber(unsigned char n)// select number switch(n) case 0:Num_0(); break; case 1:Num_1(); break; case 2:Num_2(); break; case 3:Num_3(); break; case 4:Num_4(); break; case 5:Num_5(); break; case 6:Num_6(); break; case 7:Num_7();… -

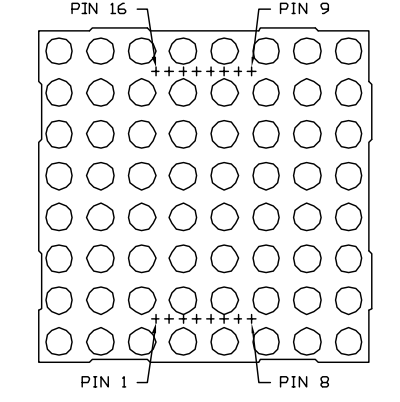

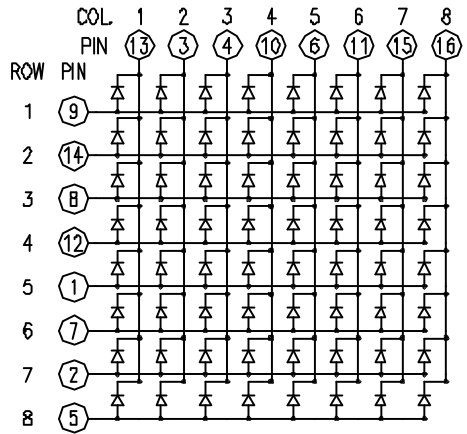

Page 79: Project 19: 8*8 Led Matrix

Result Download the above code to the controller board, you can see the LED display shows the number 1234. Note: if it’s not displaying correctly, check the wiring. The experiment is over. Thank you! ****************************************************************************** Project 19: 8*8 LED Matrix…

-

Page 80

The external view of a dot-matrix is shown as follows: The display principle of the 8*8 dot-matrix: The 8*8 dot-matrix is made up of sixty-four LEDs, and each LED is placed at the cross point of a row and a column. When the electrical level of a certain row is 1 and the electrical level of a certain column is 0, the corresponding LED will lighten. -

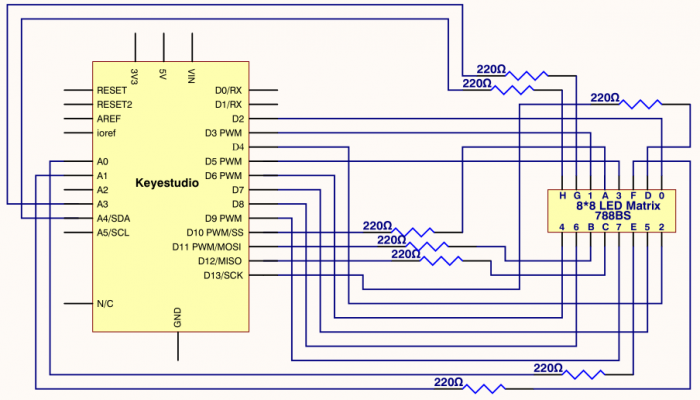

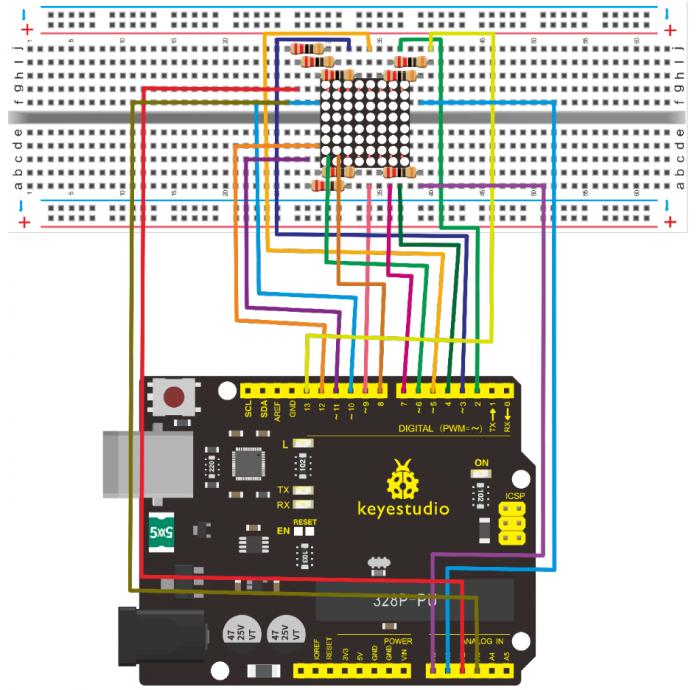

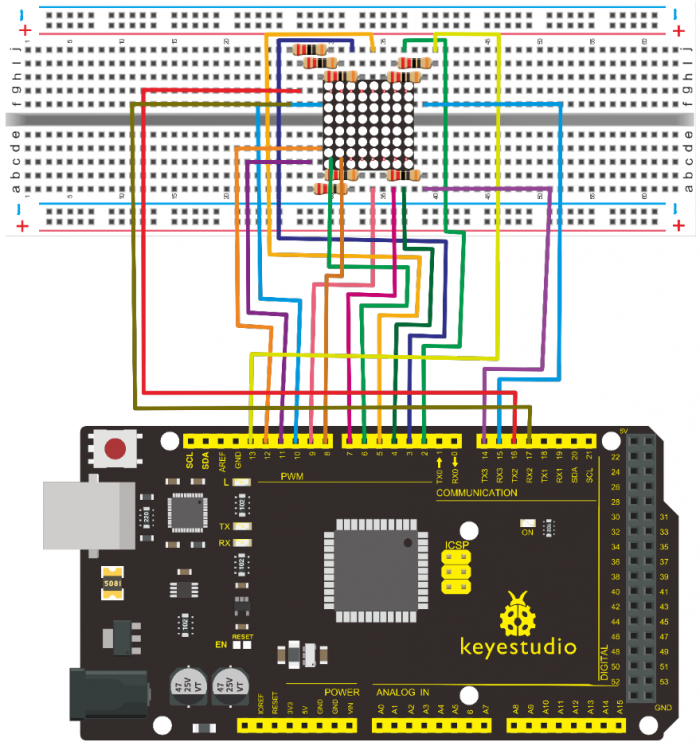

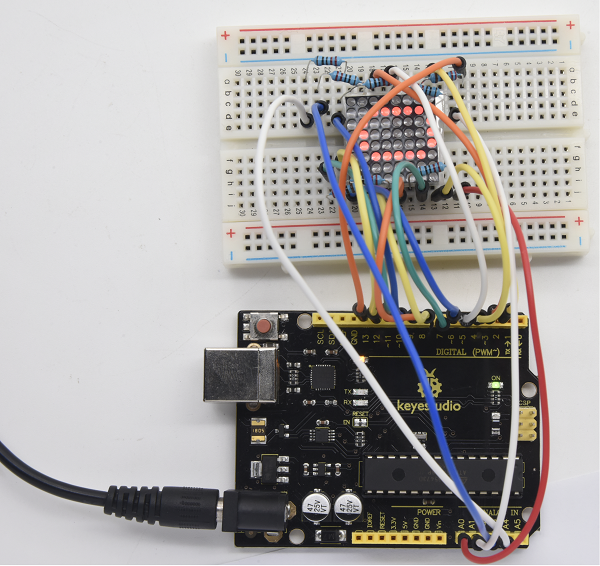

Page 81

Connection for UNO R3: Connection for 2560 R3: Sample Code for displaying “0” ////////////////////////////////////////////////////////// // set an array to store character of “0” unsigned char Text[]={0x00,0x1c,0x22,0x22,0x22,0x22,0x22,0x1c}; void Draw_point(unsigned char x,unsigned char y)// point drawing function { clear_(); digitalWrite(x+2, HIGH);… -

Page 82

& 0x01)Draw_point(j,i); data>>=1; void setup(){ int i = 0 ; for(i=2;i<18;i++) pinMode(i, OUTPUT); clear_(); void loop() { show_num(); void clear_(void)// clear screen {for(int i=2;i<10;i++) digitalWrite(i, LOW);… -

Page 83: Project 20: 1602 Lcd

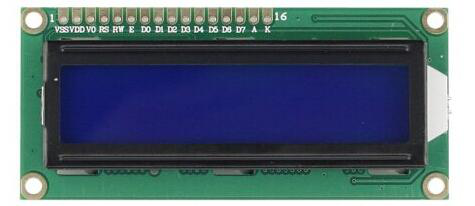

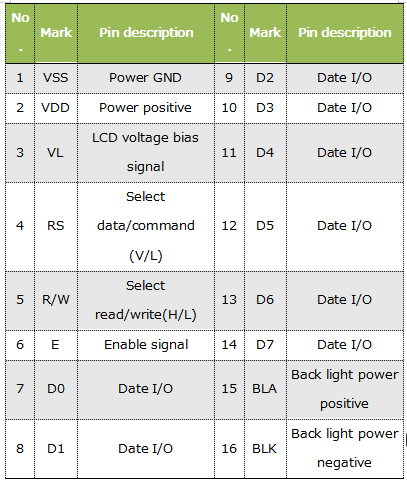

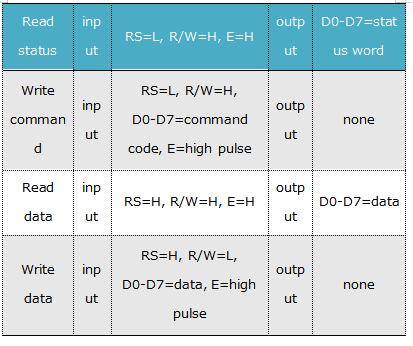

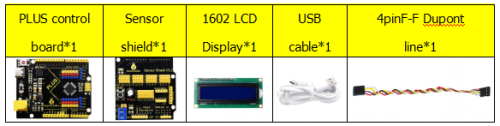

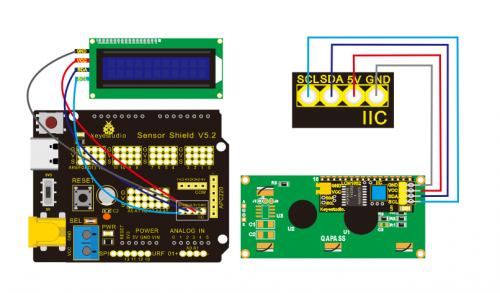

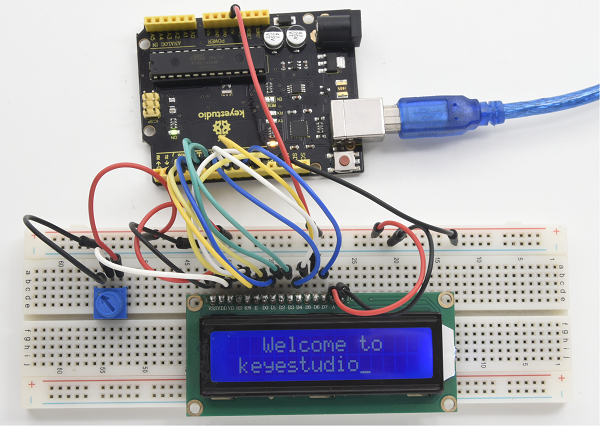

Project 20: 1602 LCD Introduction In this experiment, we use an Arduino to drive the 1602 LCD. 1602 LCD has wide applications. In the beginning, 1602 LCD uses a HD44780 controller. Now, almost all 1602 LCD module uses a compatible IC, so their features are basically the same.

-

Page 84

Interface Description: 1. two power sources, one for module power, another one for back light, generally use 5V. In this project, we use 3.3V for back light. 2. VL is the pin for adjusting contrast ratio; it usually connects a potentiometer(no more than 5KΩ) in series for its adjustment. -

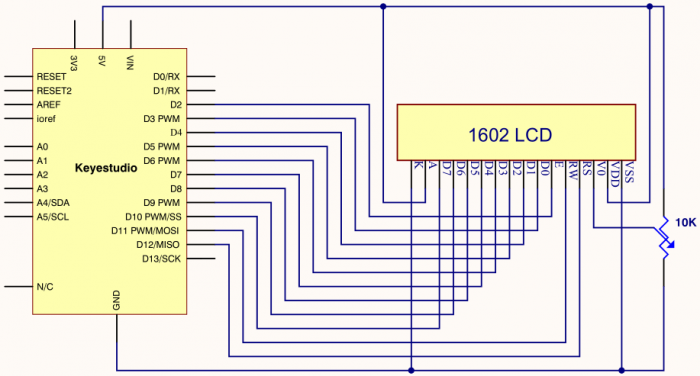

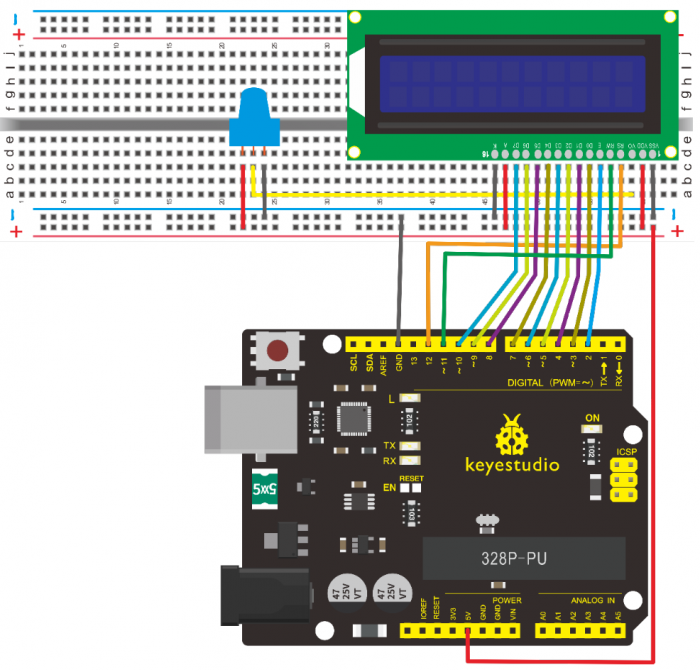

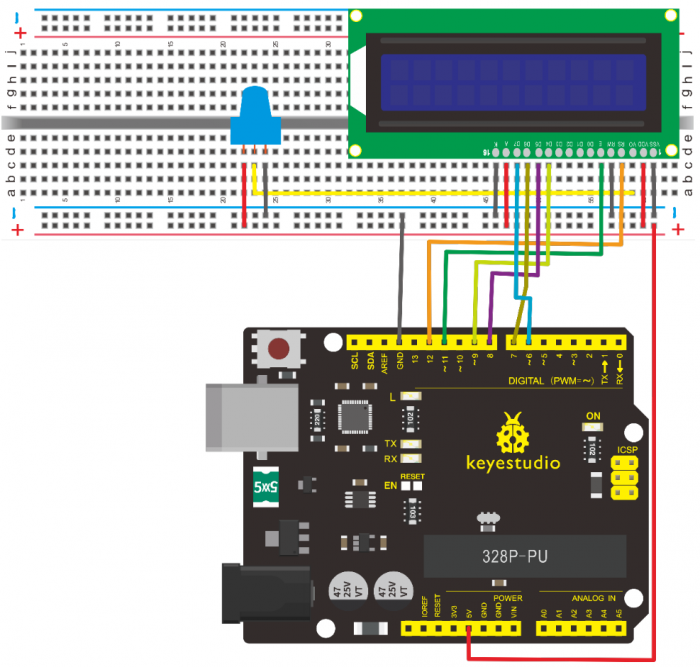

Page 85

8-bit Connection Method: Connection for UNO R3: www.keyestudio.com… -

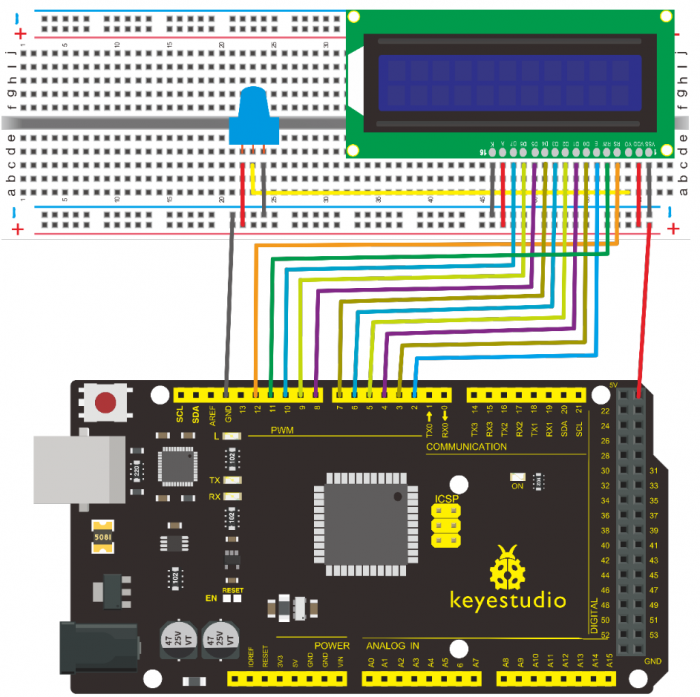

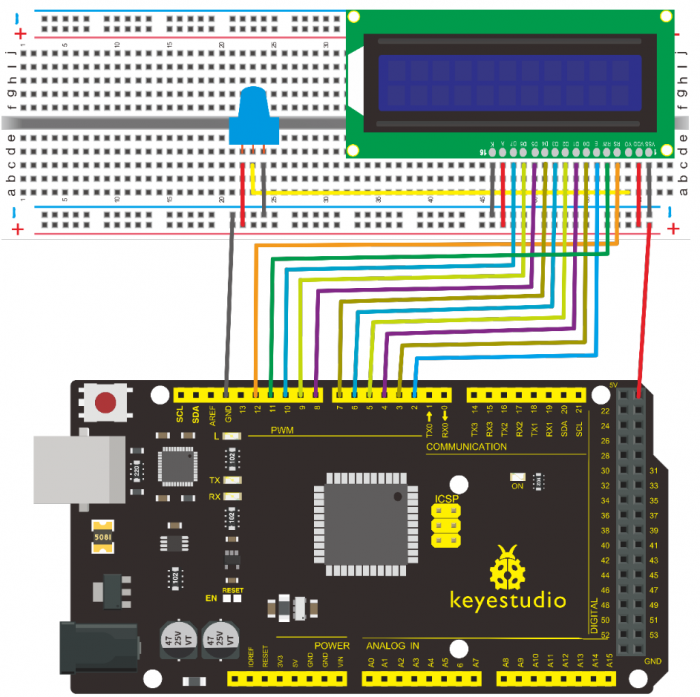

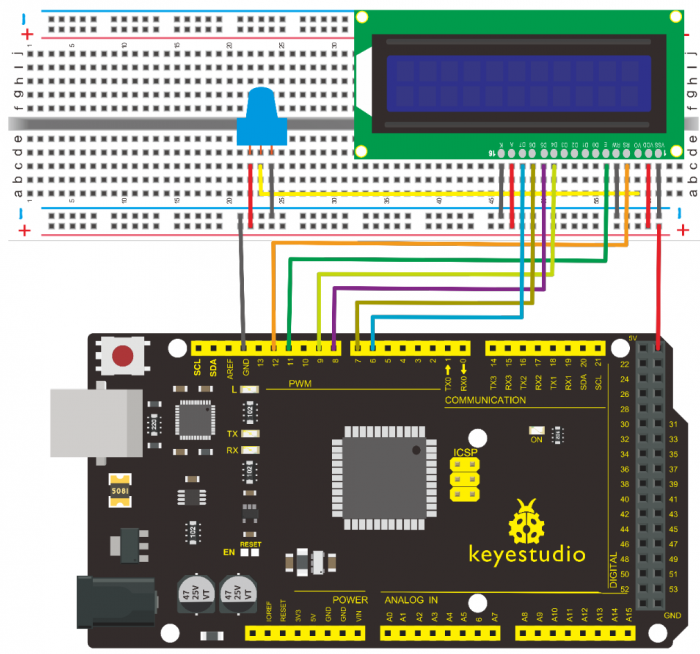

Page 86

Connection for 2560 R3: Sample Code A: ////////////////////////////////////////////////////////// int DI = 12; int RW = 11; int DB[] = {3, 4, 5, 6, 7, 8, 9, 10};// use array to select pin for bus int Enable = 2; void LcdCommandWrite(int value) { // define all pins int i = 0;… -

Page 87

HIGH); digitalWrite(RW, LOW); for (i=DB[0]; i <= DB[7]; i++) { digitalWrite(i,value & 01); value >>= 1; digitalWrite(Enable,LOW); delayMicroseconds(1); digitalWrite(Enable,HIGH); delayMicroseconds(1); digitalWrite(Enable,LOW); delayMicroseconds(1); // wait for 1ms void setup (void) { int i = 0; for (i=Enable; i <= DI; i++) { pinMode(i,OUTPUT);… -

Page 88

(void) { LcdCommandWrite(0x01); // clear the scree, cursor position returns to 0 delay(10); LcdCommandWrite(0x80+3); delay(10); // write in welcome message LcdDataWrite(‘W’); LcdDataWrite(‘e’); LcdDataWrite(‘l’); LcdDataWrite(‘c’); LcdDataWrite(‘o’); LcdDataWrite(‘m’); LcdDataWrite(‘e’); LcdDataWrite(‘ ‘); LcdDataWrite(‘t’); LcdDataWrite(‘o’); delay(10); LcdCommandWrite(0xc0+1); // set cursor position at second line, second position delay(10);… -

Page 89

LcdDataWrite(‘n’); LcdDataWrite(‘g’); LcdDataWrite(‘y’); LcdDataWrite(‘i’); delay(3000); LcdCommandWrite(0x02); // set mode as new characters replay old ones, where there is no new ones remain the same delay(10); LcdCommandWrite(0x80+5); // set cursor position at first line, sixth position delay(10); LcdDataWrite(‘t’); LcdDataWrite(‘h’); LcdDataWrite(‘e’);… -

Page 90

Connection for 2560 R3: After the connection, upload below code to the controller board and see how it goes. Sample Code B: ////////////////////////////////////////////////////////// LiquidCrystal Library — Hello World Demonstrates the use a 16×2 LCD display. The LiquidCrystal library works with all LCD displays that are compatible with the Hitachi HD44780 driver. -

Page 91

* 10K resistor: * ends to +5V and ground * wiper to LCD VO pin (pin 3) Library originally added 18 Apr 2008 by David A. Mellis library modified 5 Jul 2009 by Limor Fried (http://www.ladyada.net) example added 9 Jul 2009… -

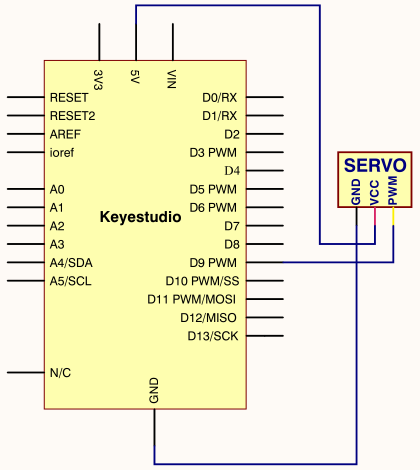

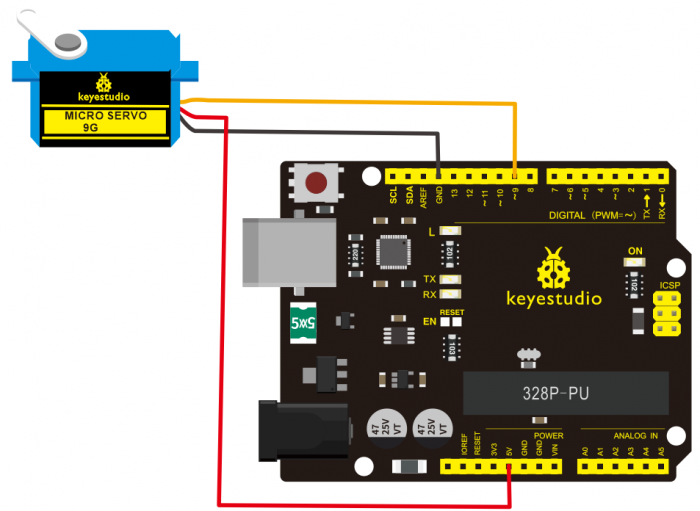

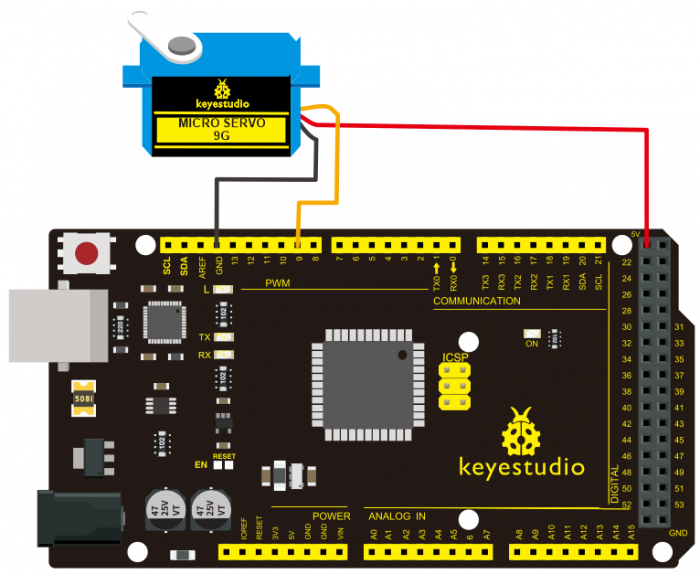

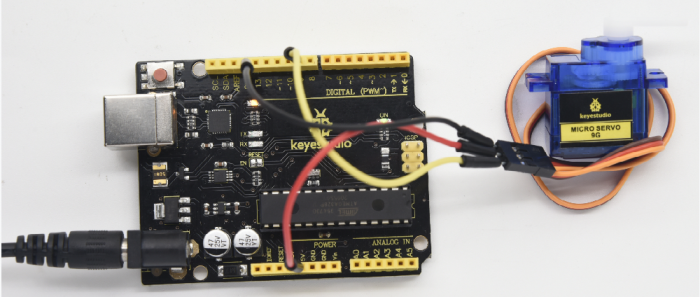

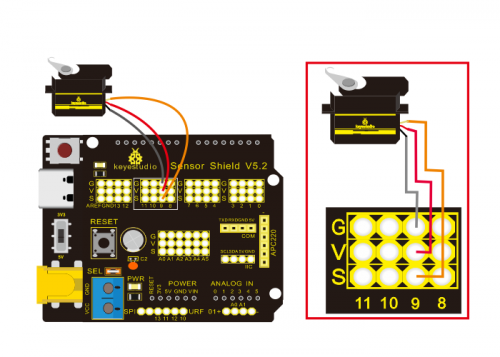

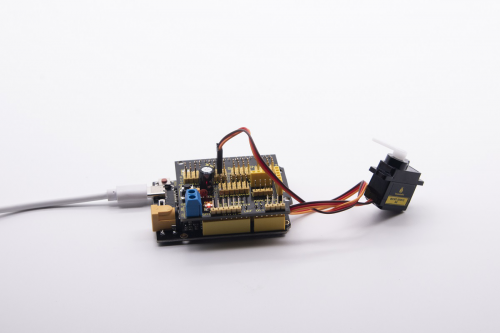

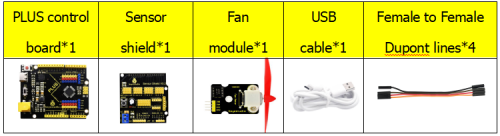

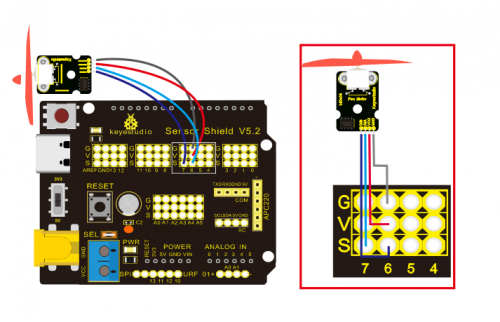

Page 92: Project 21: 9G Servo Control

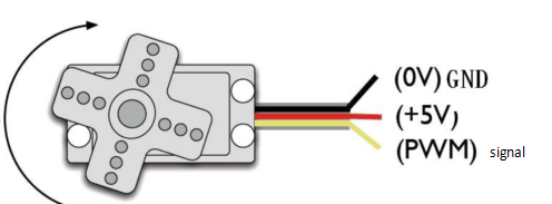

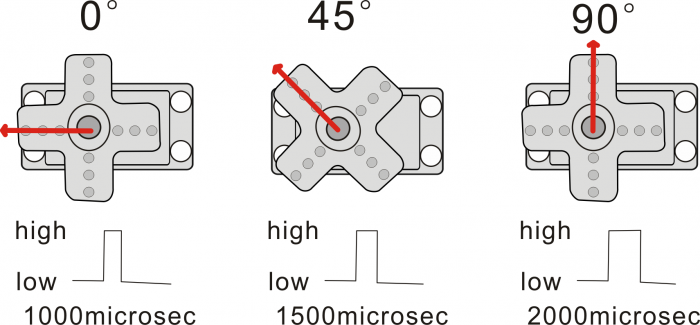

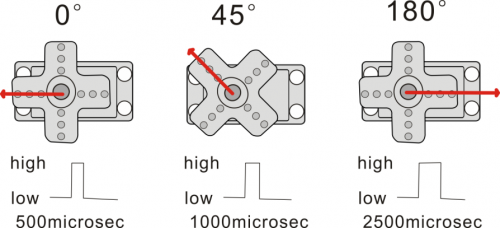

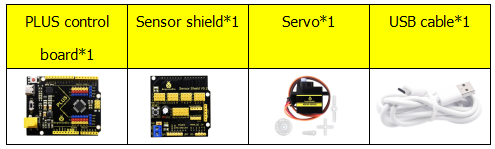

Project 21: 9g Servo Control Introduction Servomotor is a position control rotary actuator. It mainly consists of housing, circuit board, core-less motor, gear and position sensor. The receiver or MCU outputs a signal to the servomotor. The motor has a built-in reference circuit that gives out reference signal, cycle of 20ms and width of 1.5ms.

-

Page 93

The rotate angle of the servo motor is controlled by regulating the duty cycle of the PWM(Pulse-Width Modulation) signal. The standard cycle of the PWM signal is 20ms(50Hz). Theoretically, the width is distributed between 1ms-2ms, but in fact, it’s between 0.5ms-2.5ms. -

Page 94

Connection for 2560 R3: Connect the motor to digital pin 9. www.keyestudio.com… -

Page 95

Compile a program to control the motor to rotate in the commanded angle, and display the angle on the screen. Sample Code A ////////////////////////////////////////////////////////// int servopin=9;// select digital pin 9 for servomotor signal line int myangle;// initialize angle variable int pulsewidth;// initialize width variable… -

Page 96

Method 2: Let’s first take a look at the Arduino built-in servo function and some common statements. 1. attach(interface)——select pin for servo, can only use pin 9 or 10. 2. write ( angle) ——used to control the rotate angle of the servo, can set the angle among 0 degree to 180 degree. -

Page 97: Project 22: 5V Stepper Motor

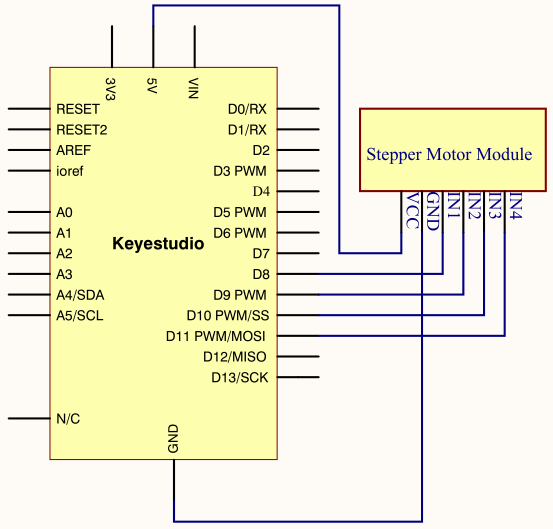

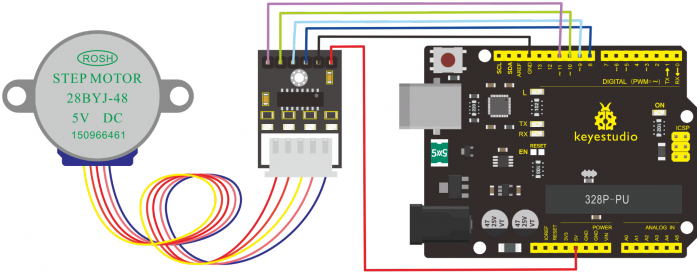

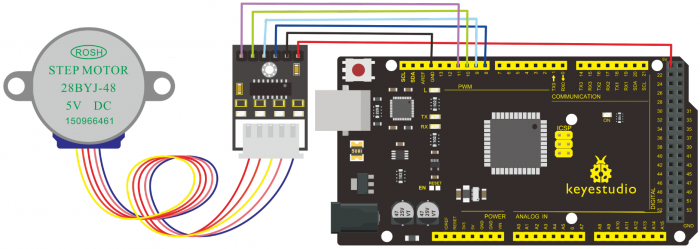

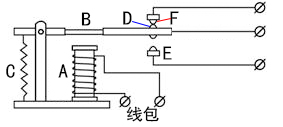

Project 22: 5V Stepper Motor Introduction A stepper motor is an electromechanical device which can convert electrical pulses into discrete mechanical movements. The shaft or spindle of a stepper motor rotates in discrete step increments when electrical command pulses are applied to it in the proper sequence. The motors rotation has several direct relationships to these applied input pulses.

-

Page 98

• A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses. Parameters of Stepper Motor 28BYJ-48 Model: 28BYJ-48 Rated Voltage: 5VDC Number of Phase: 4 Speed Variation Ratio: 1/64 Stride Angle: 5.625°… -

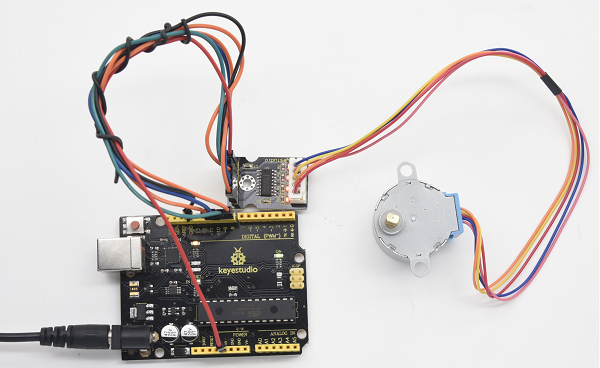

Page 99

Connection for 2560 R3: Sample Code ////////////////////////////////////////////////////////// #include <Stepper.h> #define STEPS 100 Stepper stepper(STEPS, 8, 9, 10, 11); int previous = 0; void setup() stepper.setSpeed(90); void loop() int val = analogRead(0); stepper.step(val — previous); previous = val; ////////////////////////////////////////////////////////// www.keyestudio.com… -

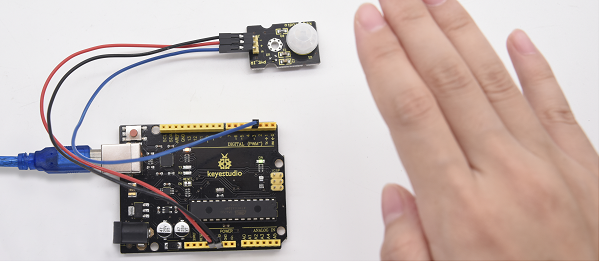

Page 100: Project 23: Pir Motion Sensor

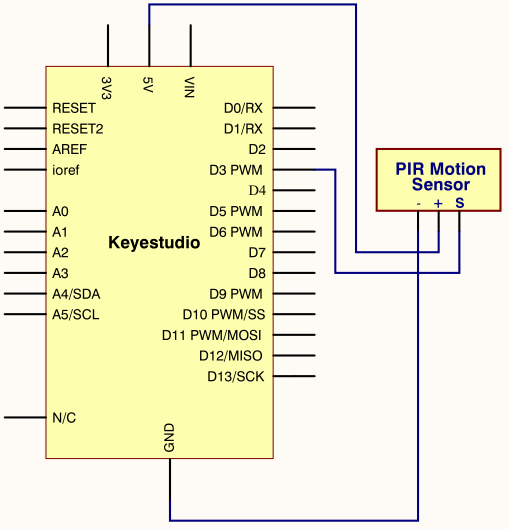

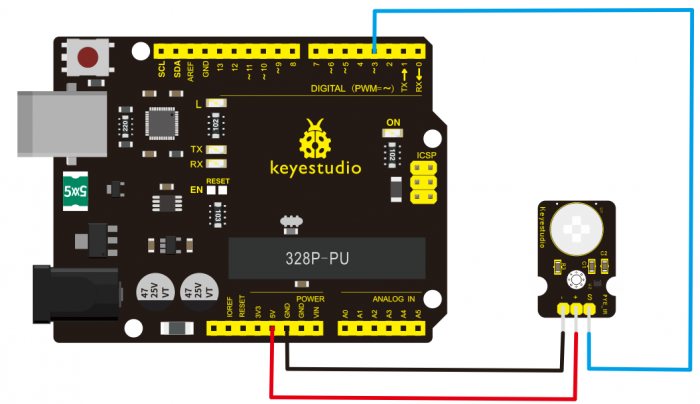

Project 23: PIR Motion Sensor Introduction Pyroelectric infrared motion sensor can detect infrared signals from a moving person or moving animal, and output switching signals. It can be applied to a variety of occasions to detect the movement of human body. Conventional pyroelectric infrared sensors require body pyroelectric infrared detector, professional chip, complex peripheral circuit, so it is more bigger with complex circuit, and lower reliability.

-

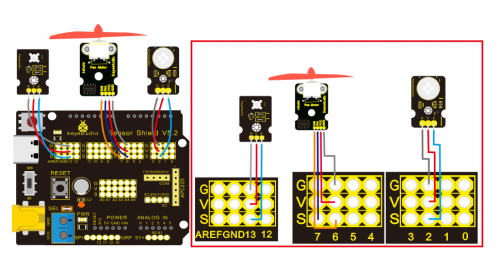

Page 101

Connection for UNO R3: Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// byte sensorPin = 3; byte indicator = 13; void setup() pinMode(sensorPin,INPUT); pinMode(indicator,OUTPUT); Serial.begin(9600); www.keyestudio.com… -

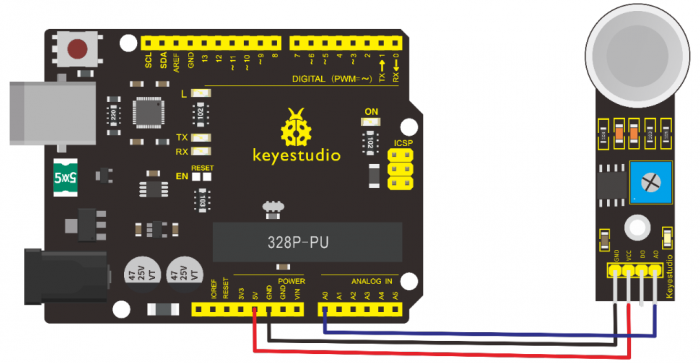

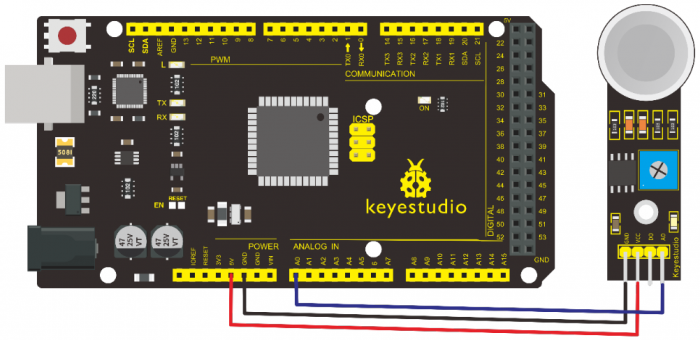

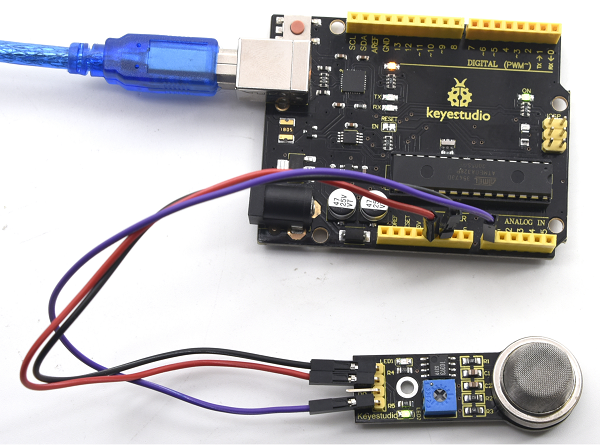

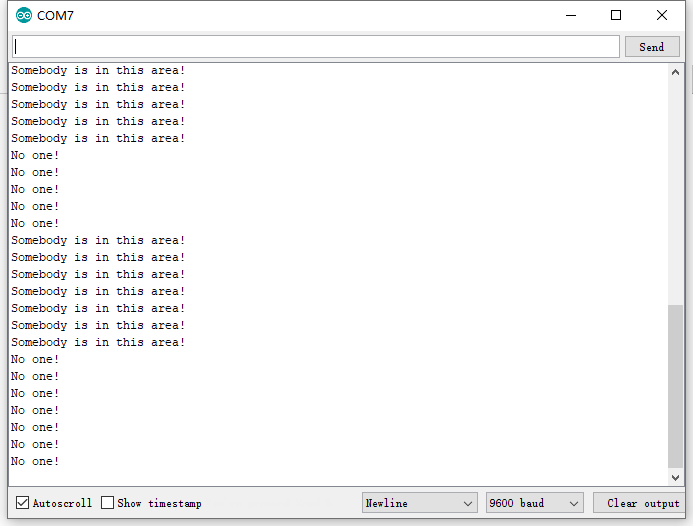

Page 102: Project 24: Analog Gas Sensor

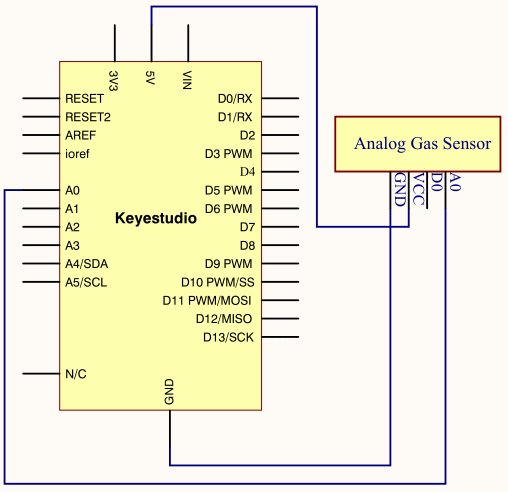

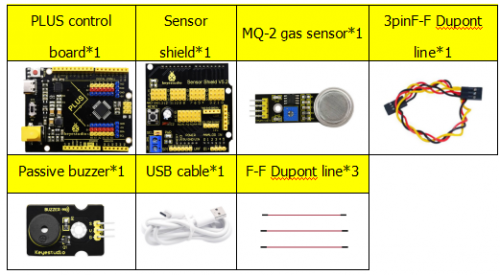

= digitalRead(sensorPin); digitalWrite(indicator,state); if(state == 1)Serial.println(«Somebody is in this area!»); else if(state == 0)Serial.println(«No one!»); delay(500); ////////////////////////////////////////////////////////// Project 24: Analog Gas Sensor Introduction This analog gas sensor — MQ2 is used in gas leakage detecting equipment in consumer electronics and industrial markets.

-

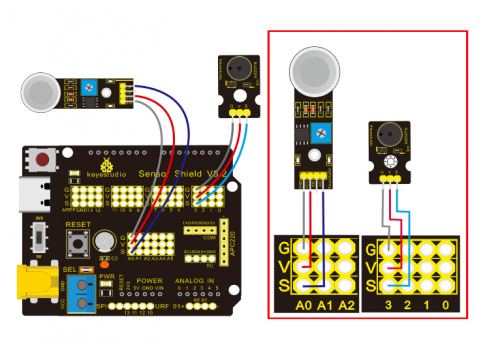

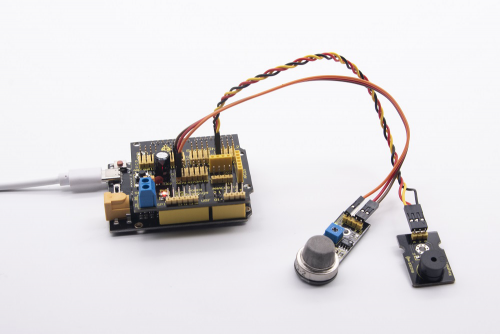

Page 103

Stable and long lifespan Size: 49.7*20mm Weight: 8g Circuit Connection Connection for UNO R3: Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// void setup() Serial.begin(9600); //Set serial baud rate to 9600 bps www.keyestudio.com… -

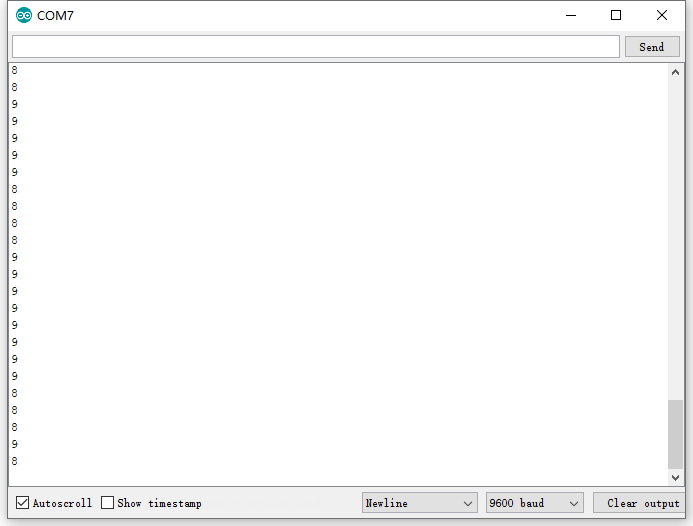

Page 104: Project 25: Adxl345 Three Axis Acceleration Module

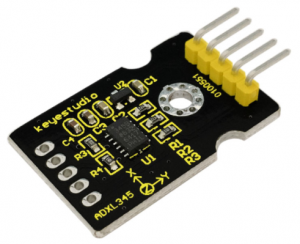

{int val; val=analogRead(0);//Read Gas value from analog 0 Serial.println(val,DEC);//Print the value to serial port delay(100); ////////////////////////////////////////////////////////// Project 25: ADXL345 Three Axis Acceleration Module Introduction The ADXL345 is a small, thin, low power, 3-axis MEMS accelerometer with high resolution (13-bit) measurement at up to +-16 g.

-

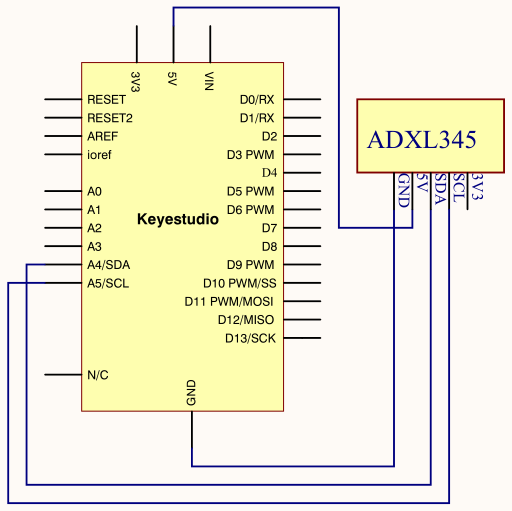

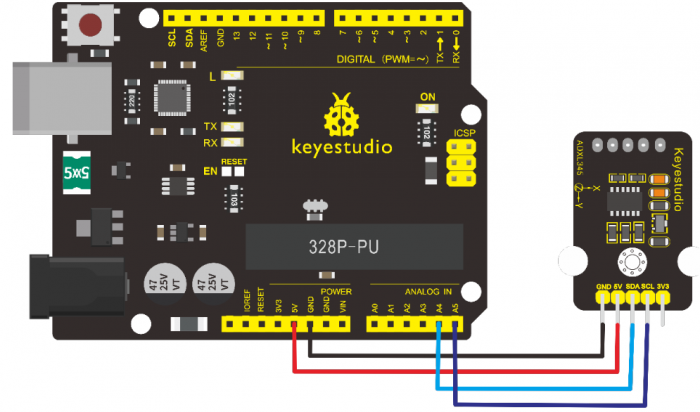

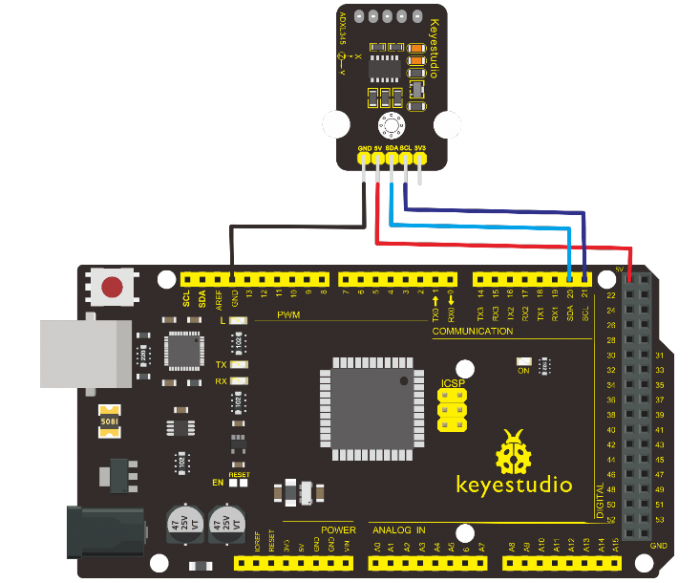

Page 105

Circuit Connection Connection for UNO R3: Connection for MEGA 2560 R3: www.keyestudio.com… -

Page 106

Sample Code /////////////////////////////////////////////////////////////////////////////////////////////////////////////////// The circuit: VCC: 5V GND: ground SCL: UNO SLC SDA: UNO SDA This example code is in the public domain. #include <Wire.h> // Registers for ADXL345 #define ADXL345_ADDRESS (0xA6 >> 1) // address for device is 8 bit but shift to the… -

Page 107

// Connect to device Wire.beginTransmission(address); // Request data from slave // Count stands for number of bytes to request Wire.requestFrom(address, count); while(Wire.available()) // slave may send less than requested char c = Wire.read(); // receive a byte as character data[i] = c;… -

Page 108

// initialise and start everything void setup() { Wire.begin(); Serial.begin(9600); for(int i=0; i<3; ++i) { accelerometer_data[i] = 0; init_adxl345(); void loop() { read_adxl345(); Serial.print(«ACCEL: «); Serial.print(float(accelerometer_data[0])*3.9/1000);//3.9mg/LSB scale factor in 13-bit mode Serial.print(«t»); Serial.print(float(accelerometer_data[1])*3.9/1000); Serial.print(«t»); Serial.print(float(accelerometer_data[2])*3.9/1000); Serial.print(«n»); delay(100); //////////////////////////////////////////////////////////////////////////////////////////////////////////////////// www.keyestudio.com… -

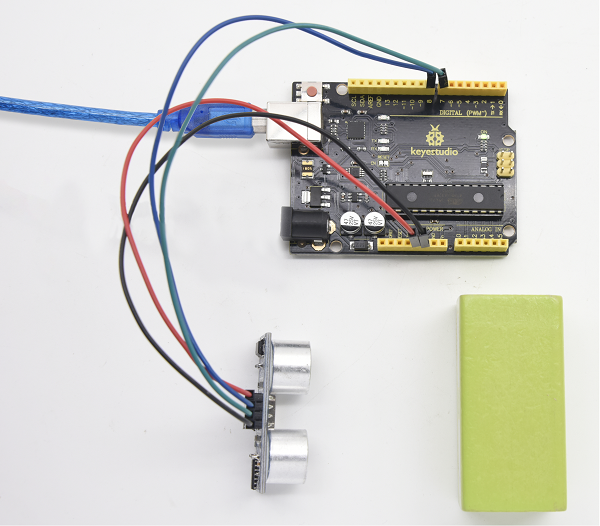

Page 109: Project 26: Hc-Sr04 Ultrasonic Sensor

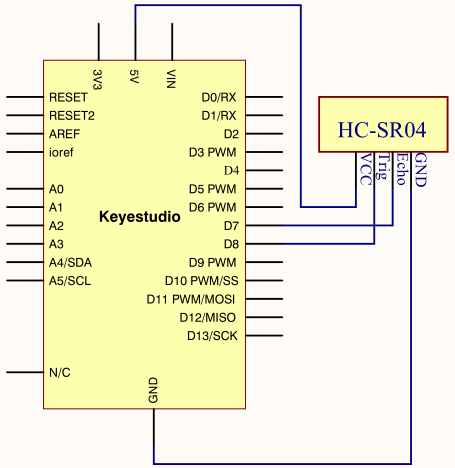

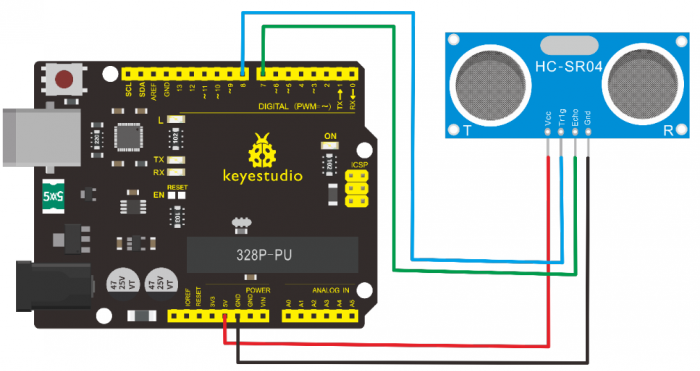

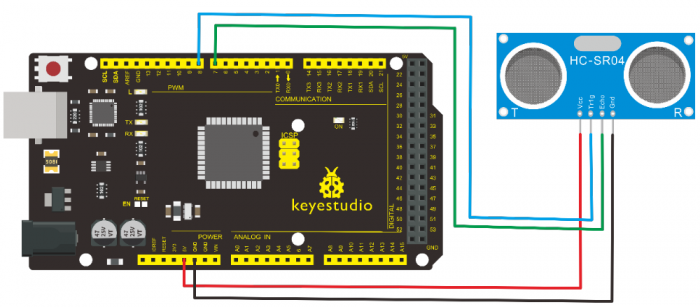

Project 26: HC-SR04 Ultrasonic Sensor Introduction The HC-SR04 Ultrasonic Sensor is a very affordable proximity/distance sensor that is mainly used for object avoidance in various robotics projects. It essentially gives your Arduino eyes / spacial awareness and can prevent your robot from crashing or falling off a table. It has also been used in turret applications, water level sensing, and even as a parking sensor.

-

Page 110

Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// VCC to arduino 5v GND to arduino GND Echo to Arduino pin 7 Trig to Arduino pin 8 #define echoPin 7 // Echo Pin #define trigPin 8 // Trigger Pin #define LEDPin 13 // Onboard LED int maximumRange = 200;… -

Page 111

// Duration used to calculate distance void setup() { Serial.begin (9600); pinMode(trigPin, OUTPUT); pinMode(echoPin, INPUT); pinMode(LEDPin, OUTPUT); // Use LED indicator (if required) void loop() { /* The following trigPin/echoPin cycle is used to determine the distance of the nearest object by bouncing soundwaves off of it. -

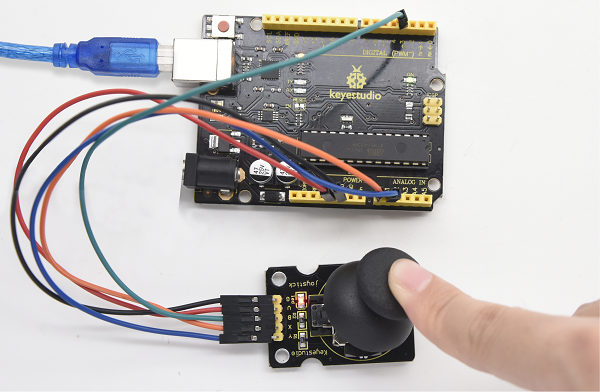

Page 112: Project 27: Joystick Module

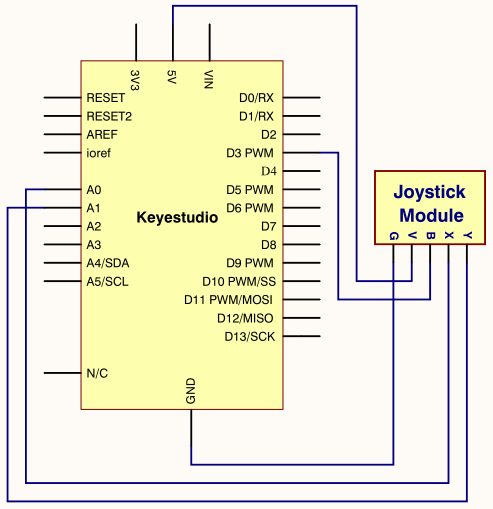

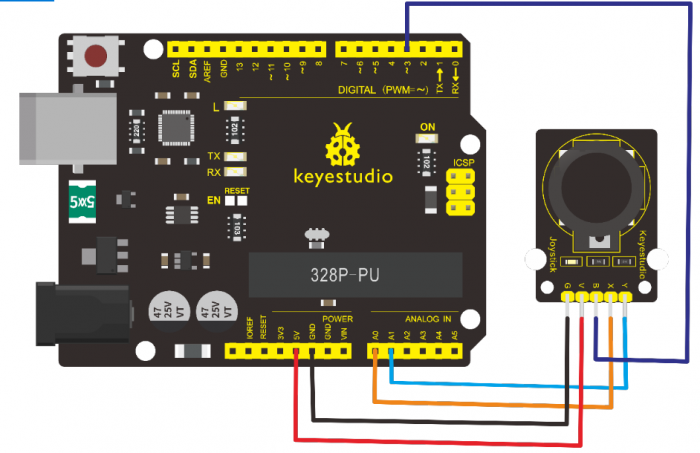

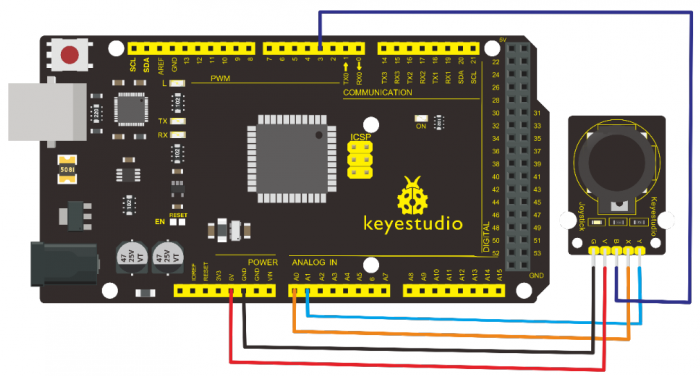

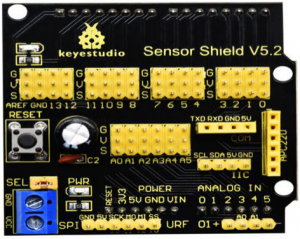

Project 27: Joystick Module Introduction Lots of robot projects need joystick. This module provides an affordable solution. By simply connecting to two analog inputs, the robot is at your commands with X, Y control. It also has a switch that is connected to a digital pin. This joystick module can be easily connected to Arduino by IO Shield.

-

Page 113

Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// int JoyStick_X = 0; //x int JoyStick_Y = 1; //y int JoyStick_Z = 3; //key void setup() pinMode(JoyStick_Z, INPUT); Serial.begin(9600); // 9600 bps void loop() int x,y,z; x=analogRead(JoyStick_X); y=analogRead(JoyStick_Y); z=digitalRead(JoyStick_Z); Serial.print(x ,DEC);… -

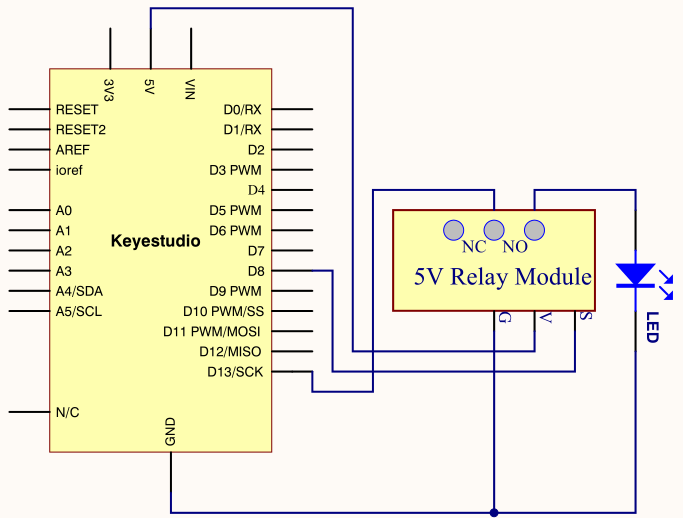

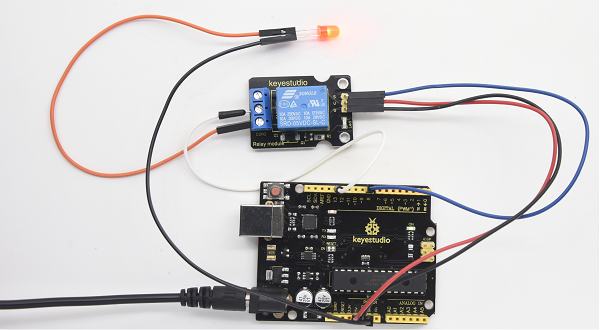

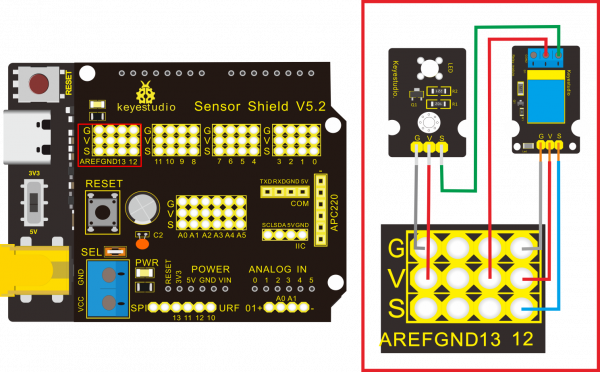

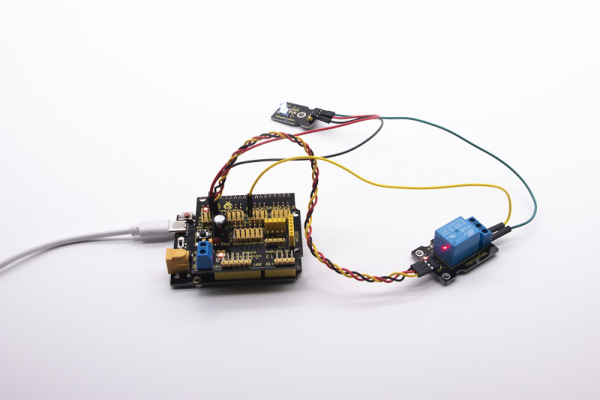

Page 114: Project 28: 5V Relay Module

Project 28: 5V Relay Module Introduction This single relay module can be used in interactive projects. This module uses SONGLE 5v high-quality relay. It can also be used to control the lighting, electrical and other equipment. The modular design makes it easy to expand with the Arduino Board (not included).

-

Page 115

Connection for UNO R3: Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// int Relay = 8; void setup() pinMode(13, OUTPUT); //Set Pin13 as output digitalWrite(13, HIGH); //Set Pin13 High www.keyestudio.com… -

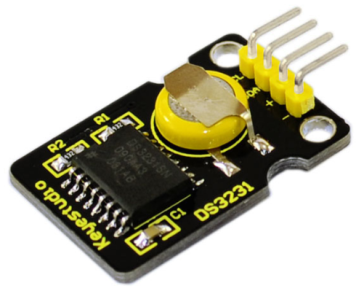

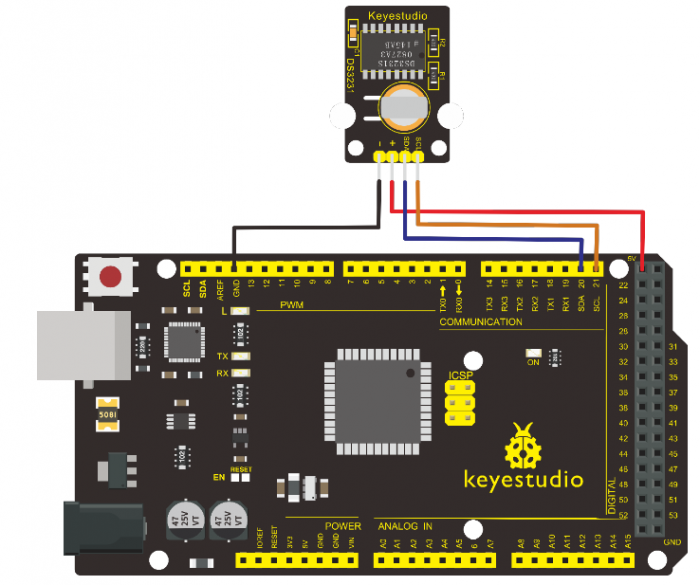

Page 116: Project 29: Ds3231 Clock Module

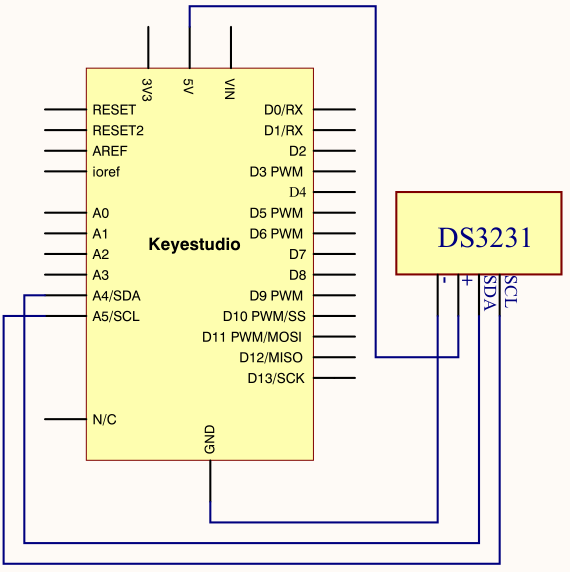

OUTPUT); //Set Pin3 as output void loop() digitalWrite(Relay, HIGH); //Turn off relay delay(2000); digitalWrite(Relay, LOW); //Turn on relay delay(2000); ////////////////////////////////////////////////////////// Project 29: DS3231 Clock Module Introduction DS3231 is equipped with integrated TCXO and crystal, which makes it a cost-effective I2C real time clock with high precision.

-

Page 117

Specification • Temperature Range: -40 to +85; • Timing Accuracy : ± 5ppm (±0.432 seconds / day) • Provide battery backup for continuous timing • Low power consumption • Device package and function compatible with DS3231 • Complete clock calendar function contains seconds and minutes, hour, week, date, month, and year timing and provides leap year compensation until 2100. -

Page 118

Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// #include <Wire.h> #include «DS3231.h» DS3231 RTC; //Create the DS3231 object char weekDay[][4] = {«Sun», «Mon», «Tue», «Wed», «Thu», «Fri», «Sat» }; //year, month, date, hour, min, sec and week-day(starts from 0 and goes to 6) //writing any non-existent time-data may interfere with normal operation of the RTC. -

Page 119

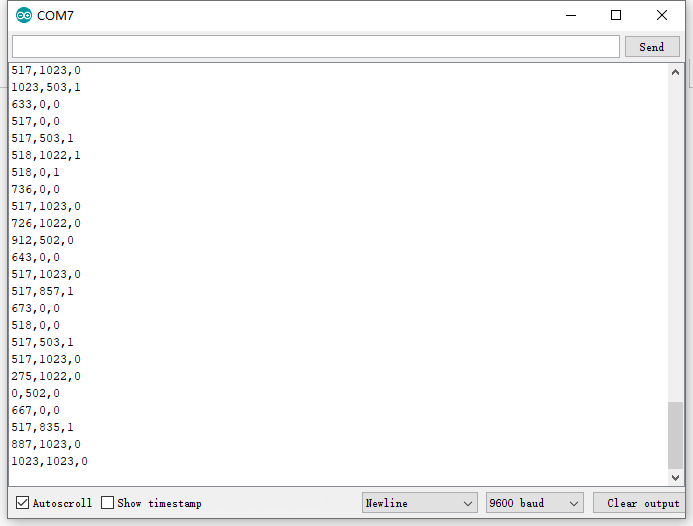

Serial.print(now.minute(), DEC); Serial.print(‘:’); Serial.print(now.second(), DEC); Serial.println(); Serial.print(weekDay[now.dayOfWeek()]); Serial.println(); delay(1000); ////////////////////////////////////////////////////////// Before compiling the code, you’d better put DS3231 library under file into Arduino catalogue. Test Result Done uploading the code to arduino, open the serial monitor and get the following results:… -

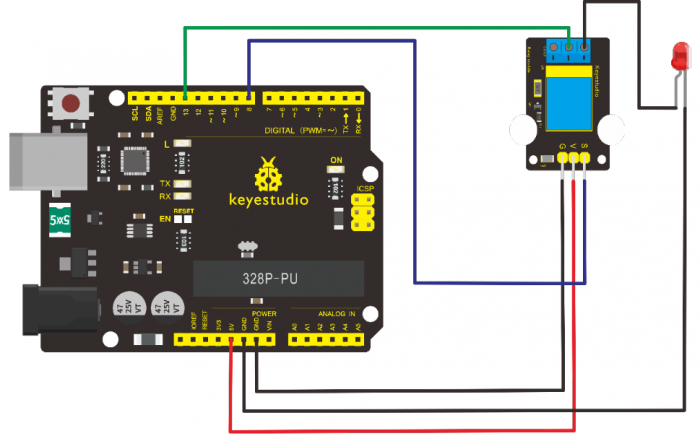

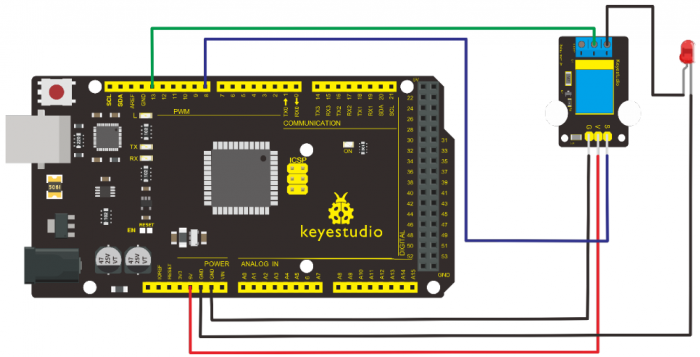

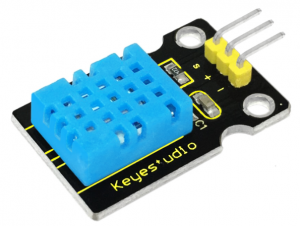

Page 120: Project 30: Dht11 Temperature And Humidity Sensor

Project 30: DHT11 Temperature and Humidity Sensor Introduction This DHT11 Temperature and Humidity Sensor features calibrated digital signal output with the temperature and humidity sensor complex. Its technology ensures high reliability and excellent long-term stability. A high-performance 8-bit microcontroller is connected.

-

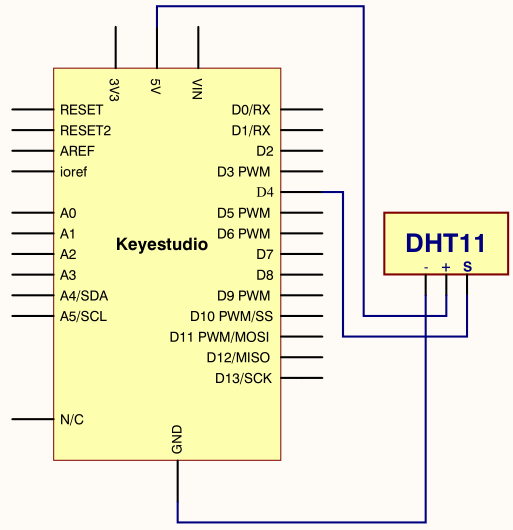

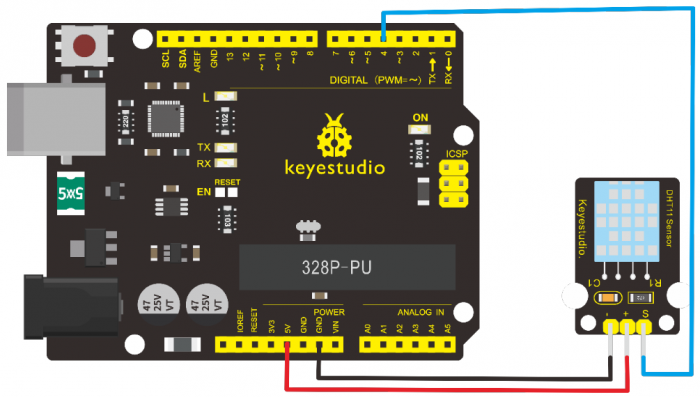

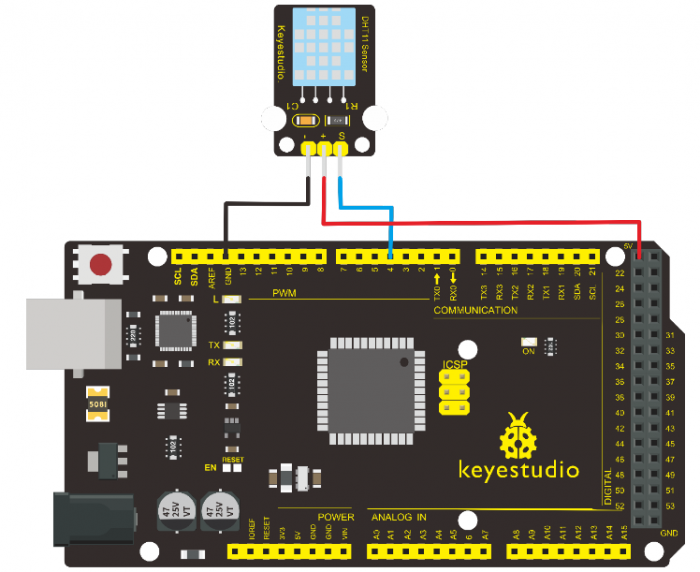

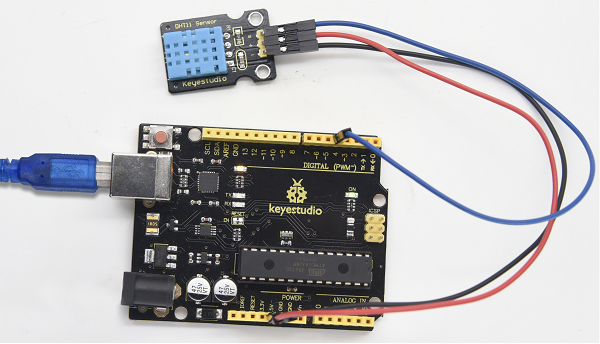

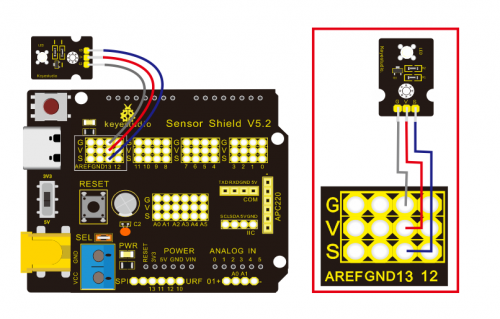

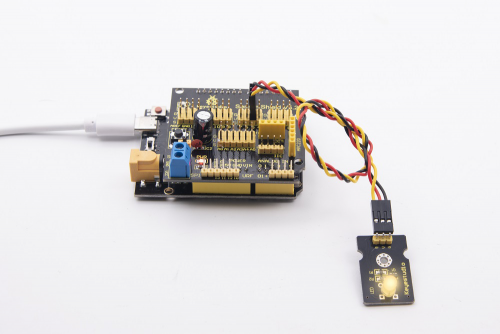

Page 121

Circuit Connection Connection for UNO R3: Connection for MEGA 2560 R3: Sample Code Please download the DHT11Lib firstly. Or see the website ////////////////////////////////////////////////////////// #include <dht11.h> dht11 DHT; #define DHT11_PIN 4 void setup(){ Serial.begin(9600); Serial.println(«DHT TEST PROGRAM «); Serial.print(«LIBRARY VERSION: «);… -

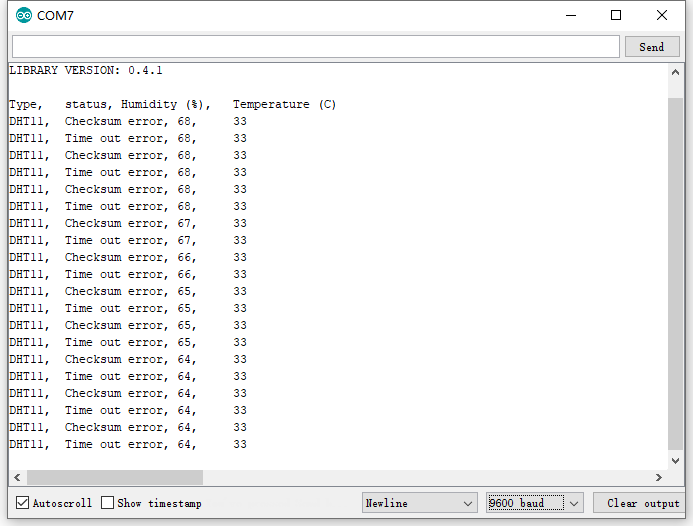

Page 122

Serial.println(«Type,tstatus,tHumidity (%),tTemperature (C)»); void loop(){ int chk; Serial.print(«DHT11, t»); chk = DHT.read(DHT11_PIN); // READ DATA switch (chk){ case DHTLIB_OK: Serial.print(«OK,t»); break; case DHTLIB_ERROR_CHECKSUM: Serial.print(«Checksum error,t»); break; case DHTLIB_ERROR_TIMEOUT: Serial.print(«Time out error,t»); break; default: Serial.print(«Unknown error,t»); break; // DISPLAT DATA Serial.print(DHT.humidity,1);… -

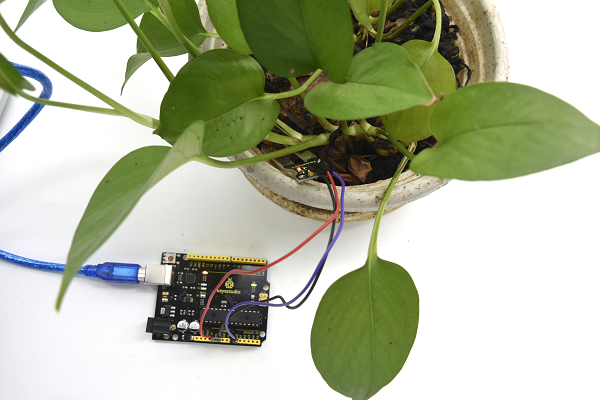

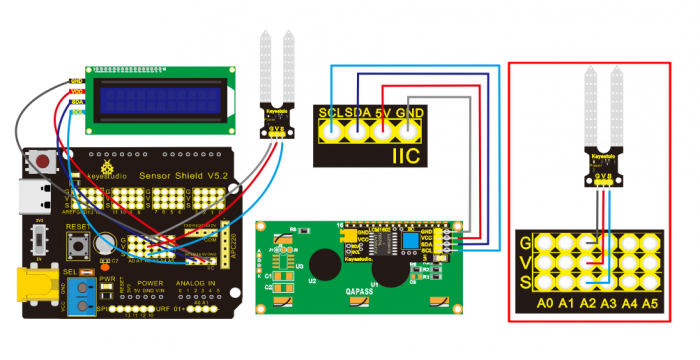

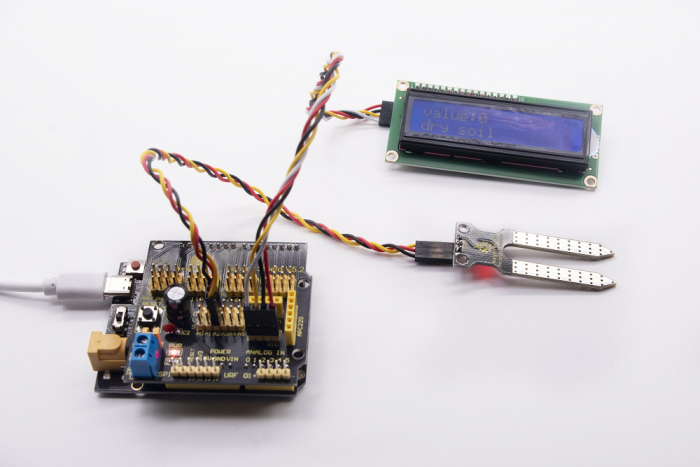

Page 123: Project 31: Soil Humidity Sensor

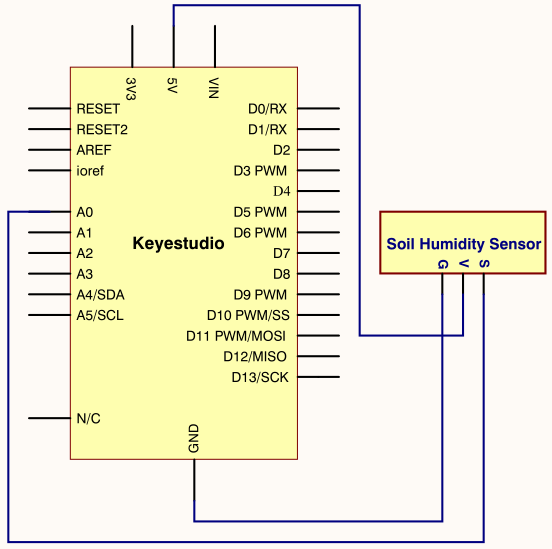

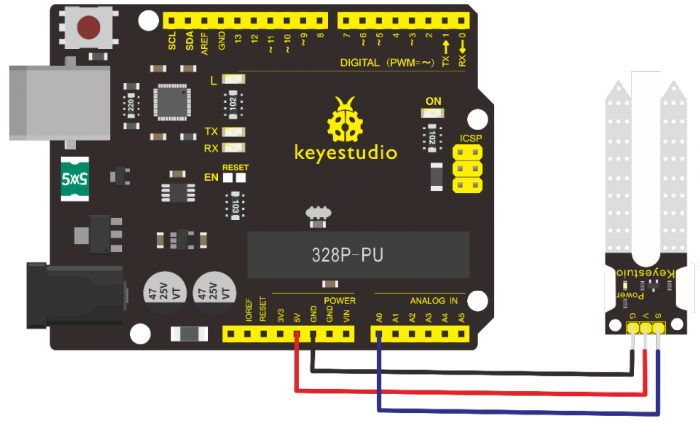

Project 31: Soil Humidity Sensor Introduction This is a simple soil humidity sensor aims to detect the soil humidity. If the soil is lack of water, the analog value output by the sensor will decrease; otherwise, it will increase. If you use this sensor to make an automatic watering device, it can detect whether your botany is thirsty so as to prevent it from withering when you go out.

-

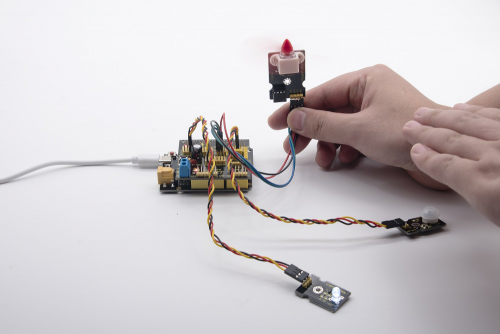

Page 124

Circuit Connection Connection for UNO R3: Connection for MEGA 2560 R3: Sample Code ////////////////////////////////////////////////////////// # 0 ~300 dry soil # 300~700 humid soil # 700~950 in water void setup(){ www.keyestudio.com… -

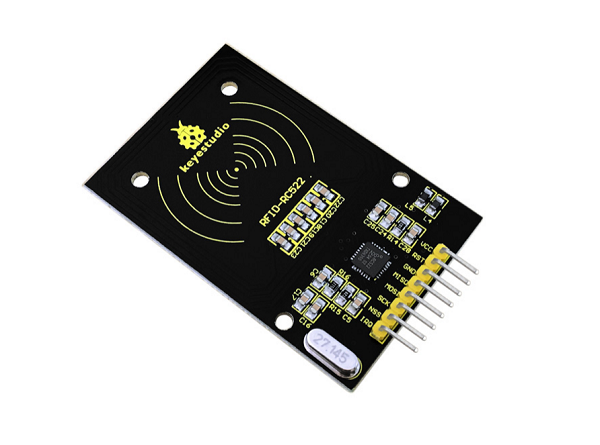

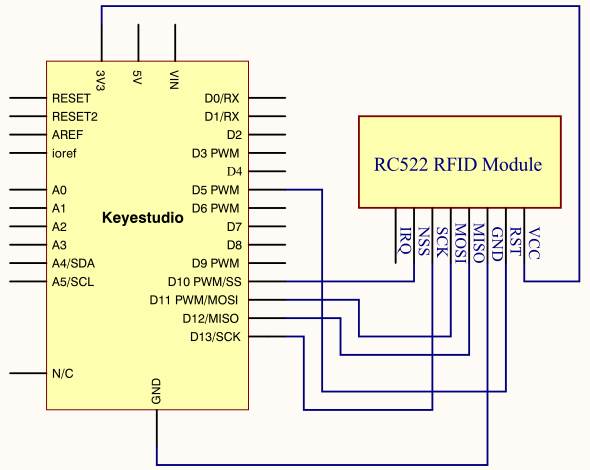

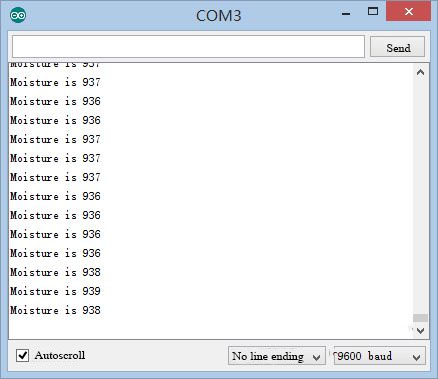

Page 125: Project 32: Rc522 Rfid Module

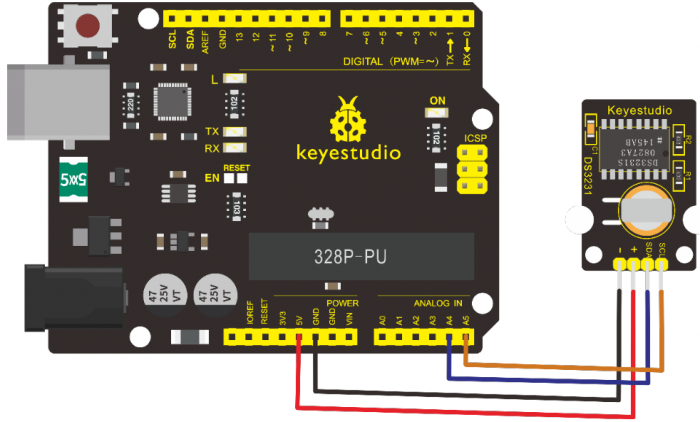

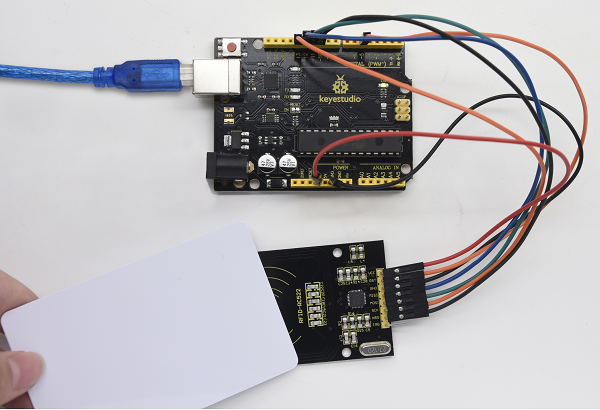

Serial.begin(57600); void loop(){ Serial.print(«Moisture Sensor Value:»); Serial.println(analogRead(0)); delay(100); ////////////////////////////////////////////////////////// Project 32: RC522 RFID Module Introduction MF522-AN module adopts Philips MFRC522 original reader circuit chip design, easy to use, low cost, suitable for equipment development, development of advanced applications, the need for the user of RF card terminal design / production.

-

Page 126

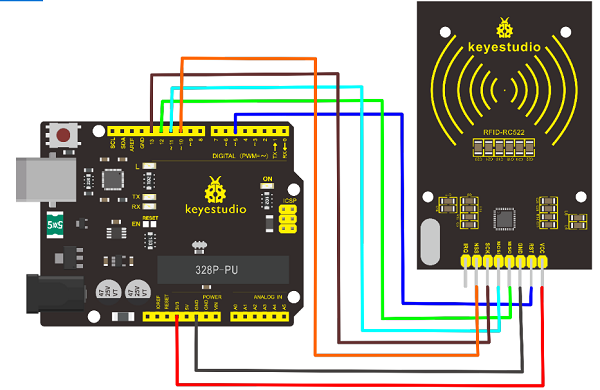

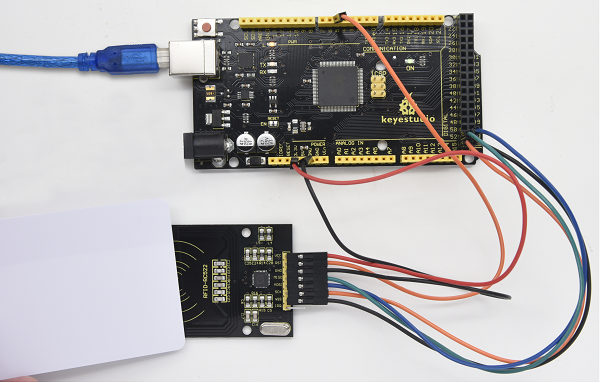

Supported card types: mifare1 S50, mifare1 S70, mifare UltraLight, mifare Pro, mifare Desfire Dimension: 40mm * 60mm Environmental Operating Temperature: -20-80 degrees Celsius Environment Storage Temperature: -40-85 degrees Celsius 10. Relative Humidity: 5% -95% Circuit Connection Connection for UNO R3:… -

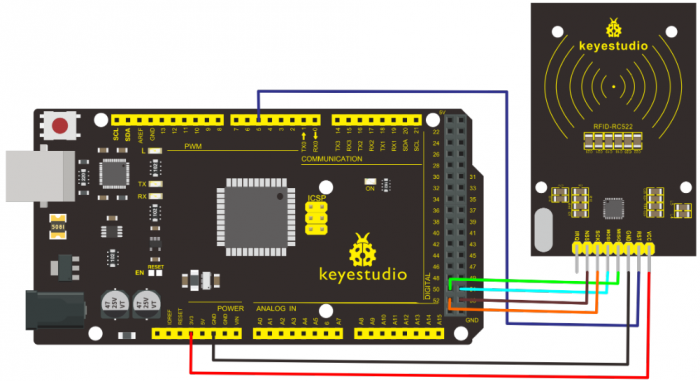

Page 127

Connection for 2560 R3: Sample Code ////////////////////////////////////////////////////////// #include <SPI.h> #define uchar unsigned char #define uint unsigned int #define MAX_LEN 16 const int chipSelectPin = 10;//if the controller is UNO,328,168 const int NRSTPD = 5; //MF522command word #define PCD_IDLE 0x00 //NO action;concel current command… -

Page 128

#define PICC_READ 0x30 // Reader Module #define PICC_WRITE 0xA0 // letter block #define PICC_DECREMENT 0xC0 #define PICC_INCREMENT 0xC1 #define PICC_RESTORE 0xC2 //Transfer data to buffer #define PICC_TRANSFER 0xB0 //Save buffer data #define PICC_HALT 0x50 //Dormancy //MF522 Error code returned when communication… -

Page 129

#define RxThresholdReg 0x18 #define DemodReg 0x19 #define Reserved11 0x1A #define Reserved12 0x1B #define MifareReg 0x1C #define Reserved13 0x1D #define Reserved14 0x1E #define SerialSpeedReg 0x1F //Page 2:CFG #define Reserved20 0x20 #define CRCResultRegM 0x21 #define CRCResultRegL 0x22 #define Reserved21 0x23 #define… -

Page 130

={‘T’, ‘e’, ‘n’, ‘g’, ‘ ‘, ‘B’, ‘o’, 0, 0, 0, 0, 0, 0, 0, 0,0}; uchar sectorKeyA[16][16] = {{0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF}, {0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF}, {0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF},… -

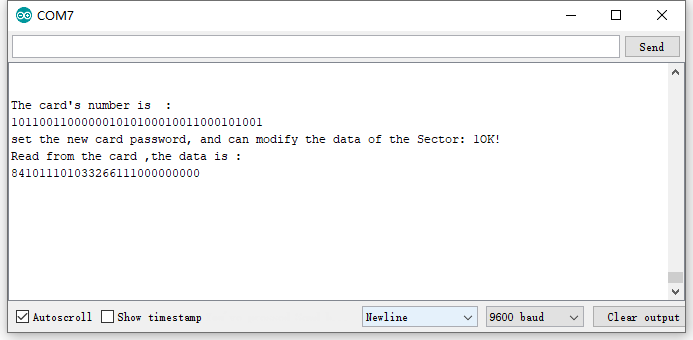

Page 131

= MFRC522_Anticoll(str); memcpy(serNum, str, 5); if (status == MI_OK) Serial.println(«The card’s number is : «); Serial.print(serNum[0],BIN); Serial.print(serNum[1],BIN); Serial.print(serNum[2],BIN); Serial.print(serNum[3],BIN); Serial.print(serNum[4],BIN); Serial.println(» «); // select card, return card capacity RC_size = MFRC522_SelectTag(serNum); if (RC_size != 0) // write data card blockAddr = 7;… -

Page 132

// read card blockAddr = 7; // data block 7 status MFRC522_Auth(PICC_AUTHENT1A, blockAddr, sectorNewKeyA[blockAddr/4], serNum); // authentication if (status == MI_OK) // read data blockAddr = blockAddr — 3 ; status = MFRC522_Read(blockAddr, str); if (status == MI_OK) Serial.println(«Read from the card ,the data is : «);… -

Page 133

SPI.transfer(((addr<<1)&0x7E) | 0x80); val =SPI.transfer(0x00); digitalWrite(chipSelectPin, HIGH); return val; void SetBitMask(uchar reg, uchar mask) uchar tmp; tmp = Read_MFRC522(reg); Write_MFRC522(reg, tmp | mask); // set bit mask void ClearBitMask(uchar reg, uchar mask) uchar tmp; tmp = Read_MFRC522(reg); Write_MFRC522(reg, tmp & (~mask)); // clear bit mask void AntennaOn(void) uchar temp;… -

Page 134

MFRC522_Reset(void) Write_MFRC522(CommandReg, PCD_RESETPHASE); void MFRC522_Init(void) digitalWrite(NRSTPD,HIGH); MFRC522_Reset(); //Timer: TPrescaler*TreloadVal/6.78MHz = 24ms Write_MFRC522(TModeReg, 0x8D); //Tauto=1; f(Timer) = 6.78MHz/TPreScaler Write_MFRC522(TPrescalerReg, 0x3E); //TModeReg[3..0] + TPrescalerReg Write_MFRC522(TReloadRegL, 30); Write_MFRC522(TReloadRegH, 0); Write_MFRC522(TxAutoReg, 0x40); //100%ASK Write_MFRC522(ModeReg, 0x3D); //CRC initial value AntennaOn(); // open antenna uchar MFRC522_Request(uchar reqMode, uchar *TagType) uchar status;… -

Page 135

MFRC522_ToCard(uchar command, uchar *sendData, uchar sendLen, uchar *backData, uint *backLen) uchar status = MI_ERR; uchar irqEn = 0x00; uchar waitIRq = 0x00; uchar lastBits; uchar n; uint i; switch (command) case PCD_AUTHENT: // card key authentication irqEn = 0x12;… -

Page 136

Write_MFRC522(CommandReg, command); if (command == PCD_TRANSCEIVE) SetBitMask(BitFramingReg, 0x80); //StartSend=1,transmission of data starts // wait for the completion of data receiving i = 2000; // adjust i according to clock frequency, maximum waiting time of operating M1 is 25ms //CommIrqReg[7..0] //Set1 TxIRq RxIRq IdleIRq HiAlerIRq LoAlertIRq ErrIRq TimerIRq n = Read_MFRC522(CommIrqReg);… -

Page 137

(n == 0) n = 1; if (n > MAX_LEN) n = MAX_LEN; // read data which FIFO received for (i=0; i<n; i++) backData[i] = Read_MFRC522(FIFODataReg); else status = MI_ERR; //SetBitMask(ControlReg,0x80); //timer stops //Write_MFRC522(CommandReg, PCD_IDLE); return status; uchar MFRC522_Anticoll(uchar *serNum) uchar status;… -

Page 138

(status == MI_OK) // verify card sequence number for (i=0; i<4; i++) serNumCheck ^= serNum[i]; if (serNumCheck != serNum[i]) status = MI_ERR; //SetBitMask(CollReg, 0x80); //ValuesAfterColl=1 return status; void CalulateCRC(uchar *pIndata, uchar len, uchar *pOutData) uchar i, n; ClearBitMask(DivIrqReg, 0x04);… -

Page 139

// read CRC calculation result pOutData[0] = Read_MFRC522(CRCResultRegL); pOutData[1] = Read_MFRC522(CRCResultRegM); uchar MFRC522_SelectTag(uchar *serNum) uchar i; uchar status; uchar size; uint recvBits; uchar buffer[9]; //ClearBitMask(Status2Reg, 0x08); //MFCrypto1On=0 buffer[0] = PICC_SElECTTAG; buffer[1] = 0x70; for (i=0; i<5; i++) buffer[i+2] = *(serNum+i);… -

Page 140

// Verification commands + block address + sector password + card sequence number buff[0] = authMode; buff[1] = BlockAddr; for (i=0; i<6; i++) buff[i+2] = *(Sectorkey+i); for (i=0; i<4; i++) buff[i+8] = *(serNum+i); status = MFRC522_ToCard(PCD_AUTHENT, buff, 12, buff, &recvBits);… -

Page 141

= PICC_WRITE; buff[1] = blockAddr; CalulateCRC(buff, 2, &buff[2]); status = MFRC522_ToCard(PCD_TRANSCEIVE, buff, 4, buff, &recvBits); if ((status != MI_OK) || (recvBits != 4) || ((buff[0] & 0x0F) != 0x0A)) status = MI_ERR;… -

Page 142

CalulateCRC(buff, 2, &buff[2]); status = MFRC522_ToCard(PCD_TRANSCEIVE, buff, 4, buff,&unLen); ////////////////////////////////////////////////////////// Note: if you want to use MEGA 2560 R3, please in the code change const int chipSelectPin = 10;//if the controller is UNO,328,168 into const int chipSelectPin = 53;//if the controller is UNO,328,168…

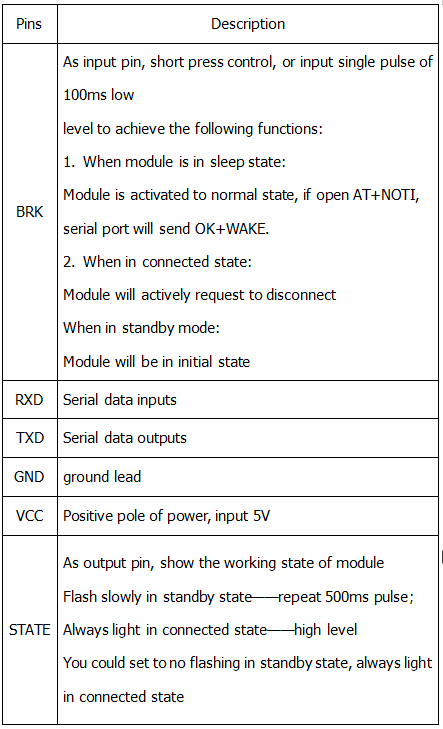

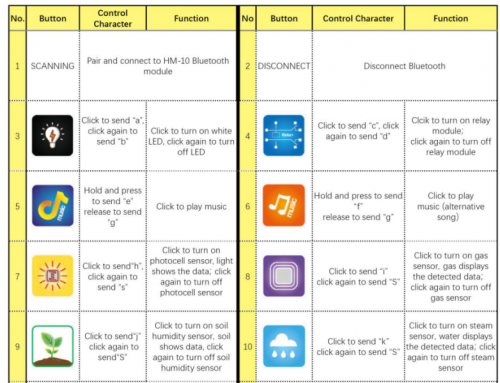

Introduction

keyestudio super learning kit is suitable for Arduino enthusiasts. This kit includes 32 projects with detailed tutorials, starting from the basics to more complex projects.

Different from other kits, it adds some functional modules, such as RFID, temperature and humidity module. There is connection diagram and code for each project, making it easy for you to learn.

At the same time, each project has Scratch graphic programming and Arduino C language programming, so that you can access the underlying code.

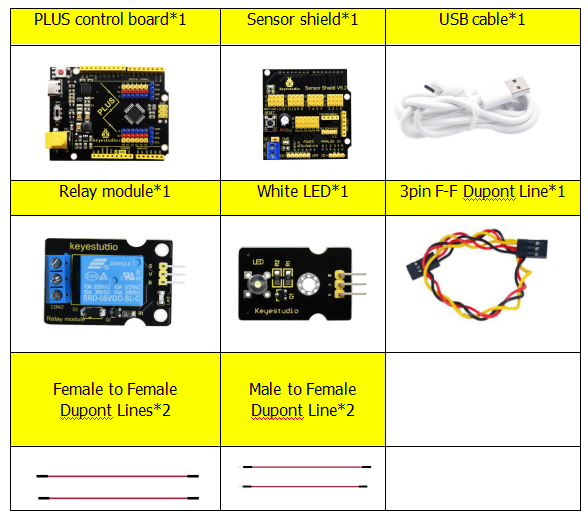

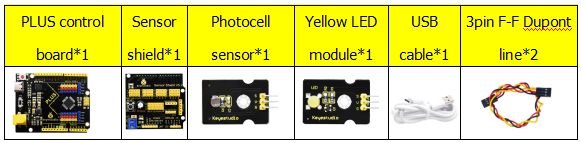

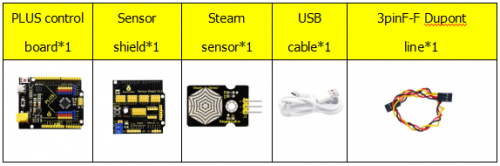

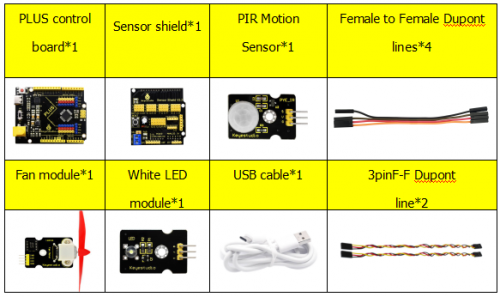

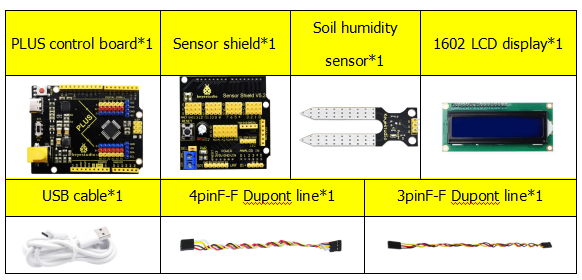

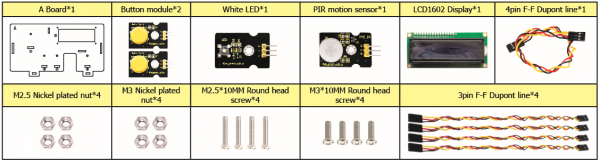

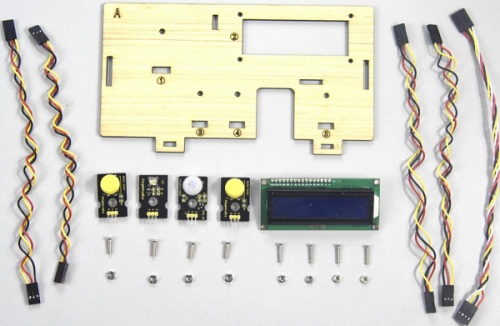

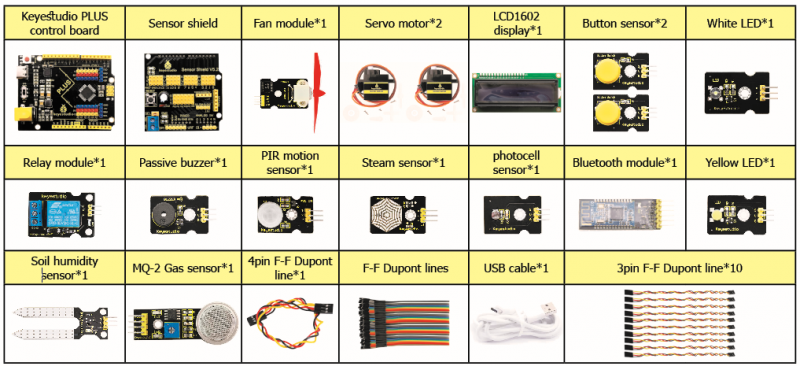

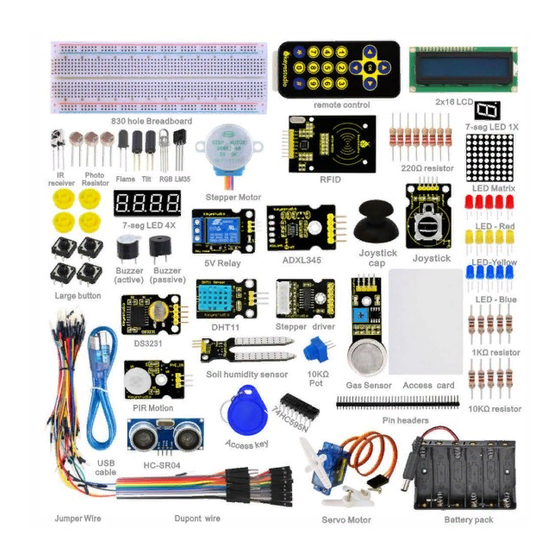

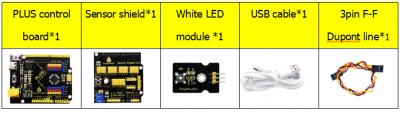

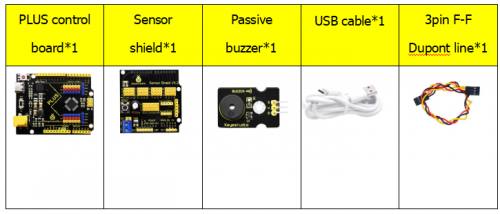

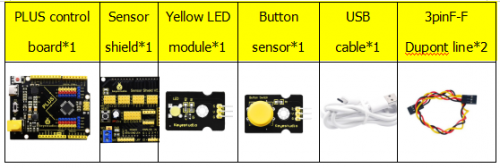

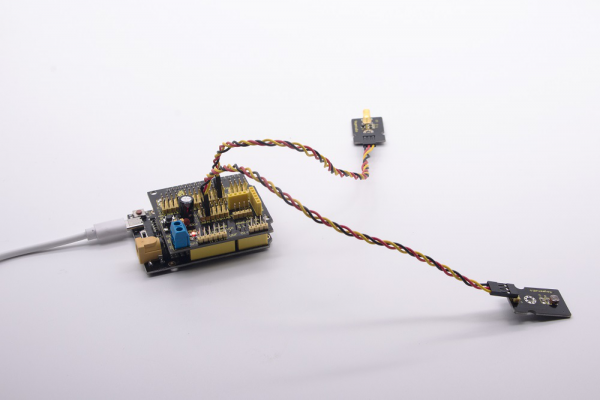

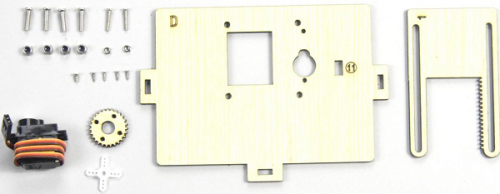

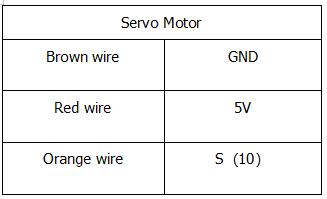

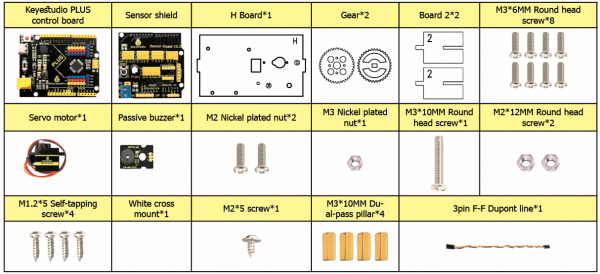

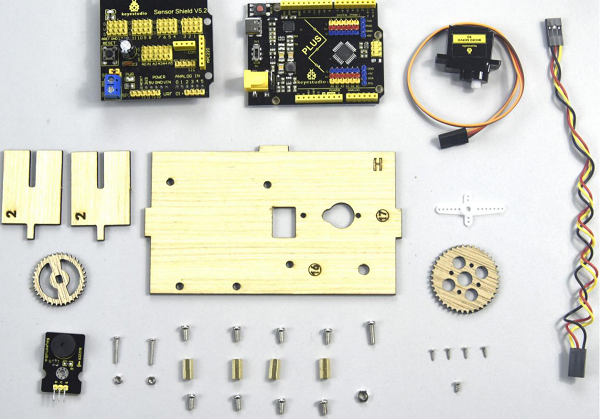

Component List

NOTE: KS0077 Kit doesn’t include a mainboard; KS0078 Kit includes V4.0 board; KS0079 Kit includes MEGA 2560 board:

Install Arduino IDE and Driver

Download software

When we get control board, we need to download Arduino IDE and driver firstly.

You could download Arduino IDE from the official website:

https://www.arduino.cc/, click the SOFTWARE on the browse bar, click “DOWNLOADS” to enter download page, as shown below:

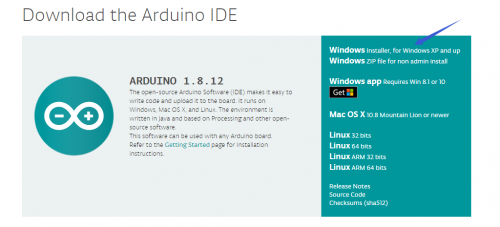

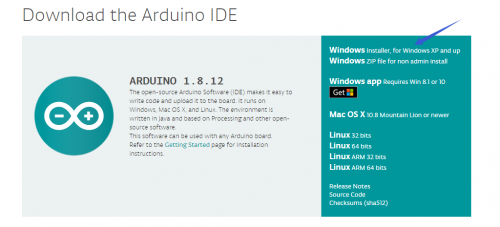

There are various versions for Arduino, just download a suitable version for your system, we will take WINDOWS system as an example to show you how to download and install.

There are two versions for WINDOWS system, one is installed version, another one is download version, you just need to download file to computer directly and unzip it. These two versions can be used normally. Choose one and download on your computer.

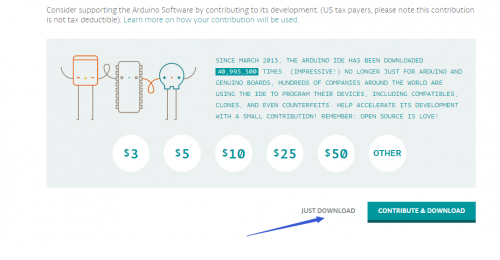

You just need to click JUST DOWNLOAD, then click the downloaded file to install it. And when the ZIP file is downloaded, you can directly unzip and start it.

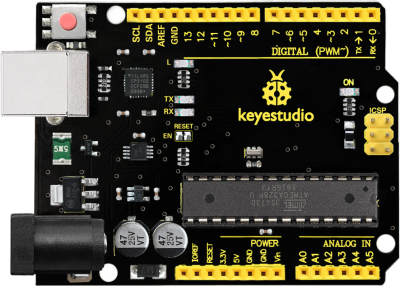

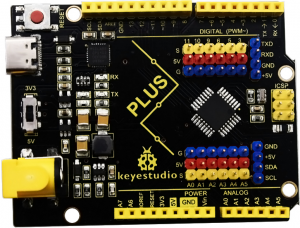

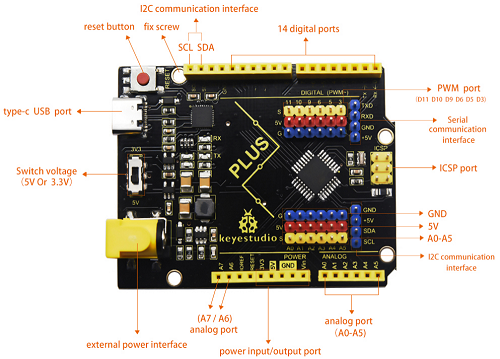

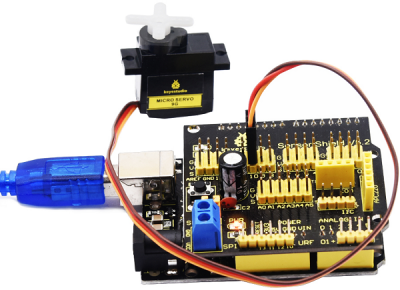

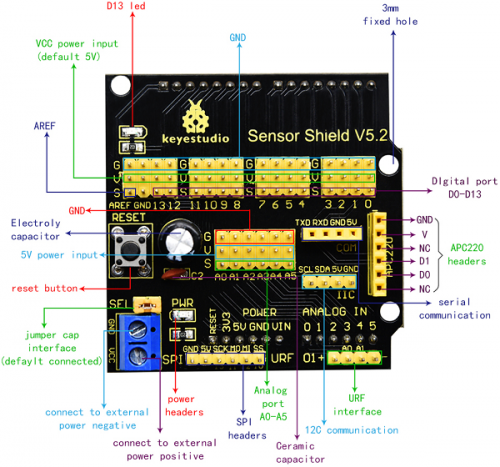

Keyestudio V4.0 Development Board

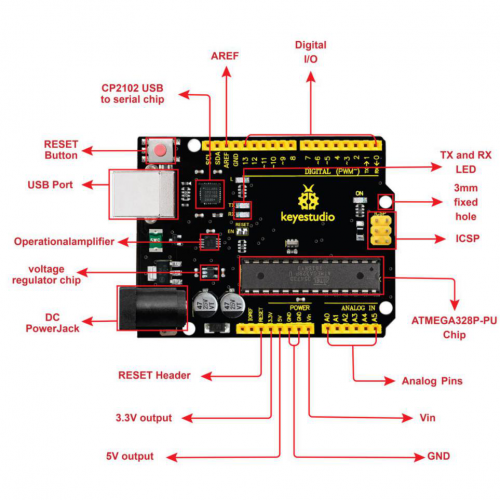

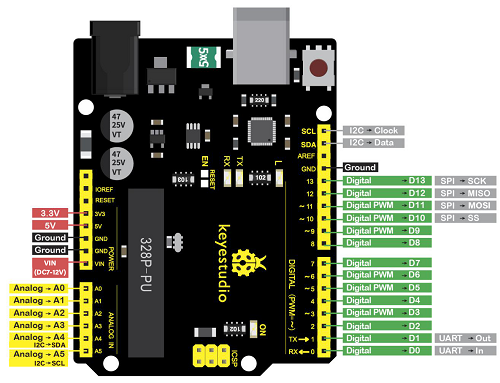

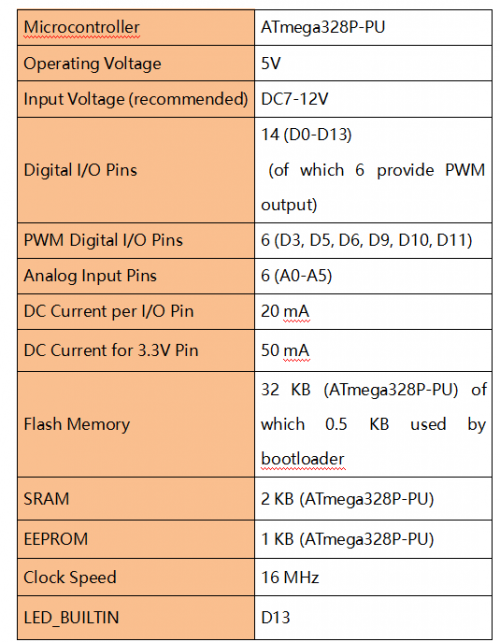

We need to know keyestudio V4.0 development board, as a core of this smart car.

keyestudio V4.0 development board is an Arduino uno-compatible board, which is based on ATmega328P MCU, and with a cp2102 Chip as a UART-to-USB converter.

It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

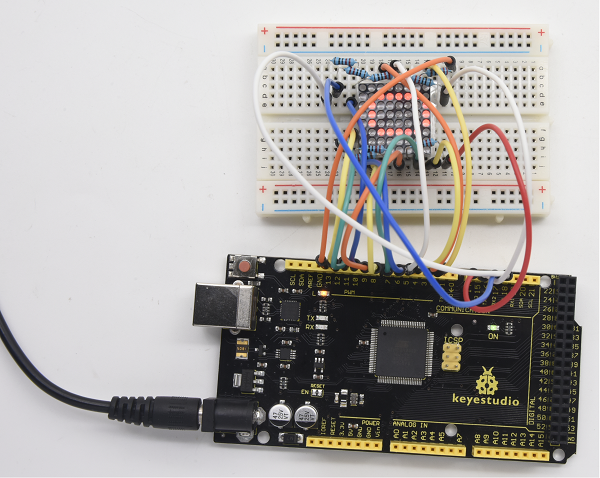

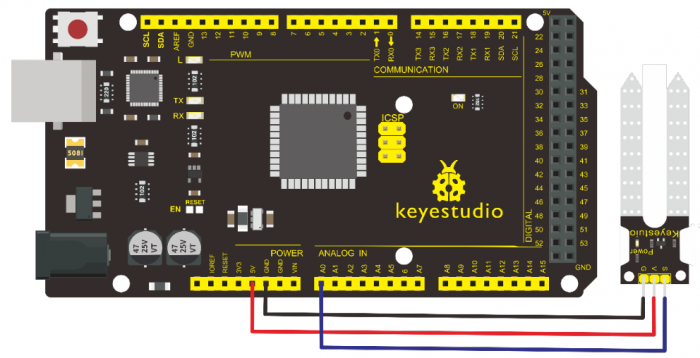

Keyestudio MEGA 2560 Board

Keyestudio Mega 2560 R3 is a microcontroller board based on the ATMEGA2560-16AU , fully compatible with ARDUINO MEGA 2560 R3.

It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, 1 ICSP header, and a reset button. The built-in ICSP port can burn the firmware for ATMEGA2560-16AU directly. This chip is burnt the firmware well before leaving the factory, therefore, we hardly use it. We can power on by USB wire, DC head and Vin GND pins. To facilitate wiring, a 0.5 m USB wire is provided for you.

Specialized Functions of Some Pins:

1. Serial Communication: D0 (RX0) and D1 (TX1); Serial 1: D19 (RX1) and D18 (TX1); Serial 2: D17 (RX2) and D16 (TX2); Serial 3: D15 (RX3) and D14 (TX3). Used to receive (RX) and transmit (TX) TTL serial data. Pins 0 and 1 are also connected to the corresponding pins of the CP2102 USB-to-TTL Serial chip.

2. PWM Pins (Pulse-Width Modulation): D2 to D13, and D44 to D46. Provide 8-bit PWM output with the analogWrite() function.

3. External Interrupts: D2 (interrupt 0), D3 (interrupt 1), D18 (interrupt 5), D19 (interrupt 4), D20 (interrupt 3), and D21 (interrupt 2). These pins can be configured to trigger an interrupt on a low level, a rising or falling edge, or a change in level. See the attachInterrupt() function for details.

4. SPI communication: D53 (SS), D52 (SCK), D51 (MOSI), D50 (MISO). These pins support SPI communication using theSPI library. The SPI pins are also broken out on the ICSP header, which is physically compatible with the Arduino Uno.

5. IIC communication: D20 (SDA); D21 (SCL). Support TWI communication using the Wire library.

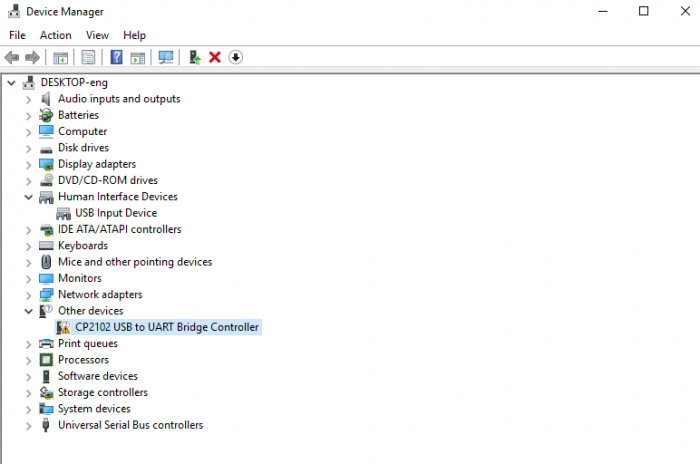

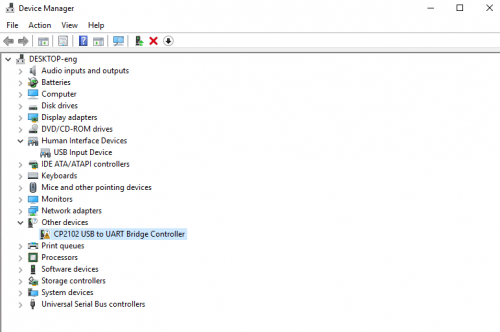

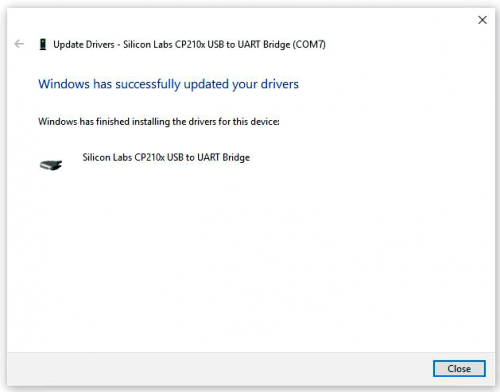

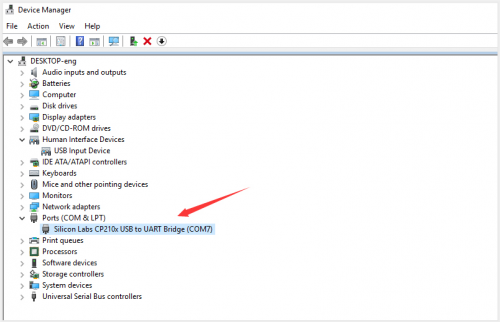

Installing driver

Let’s install the driver of keyestudio PLUS control board. The USB-TTL chip on PLUS board adopts CP2102 serial chip. The driver program of this chip is included in Arduino 1.8 version and above, which is convenient. Plug on USB port of board, the computer can recognize the hardware and automatically install the driver of CP2102.

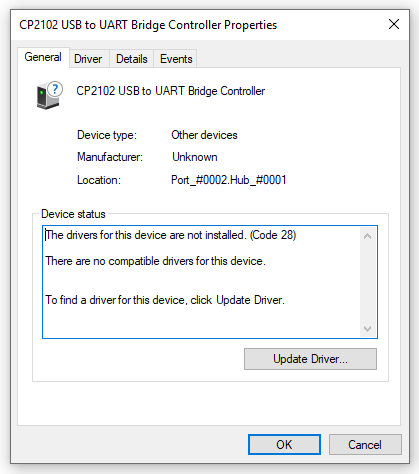

If install unsuccessfully, or you intend to install manually, open the device manager of computer. Right click Computer—— Properties—— Device Manager.

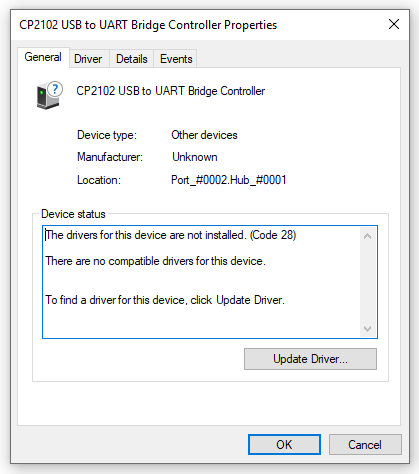

There is a yellow exclamation mark on the page, which implies installing the driver of CP2102 unsuccessfully. Then we double click the hardware and update the driver.

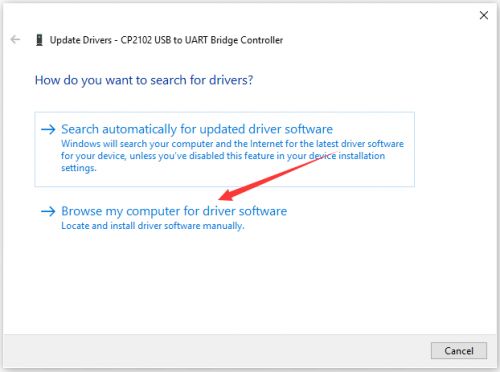

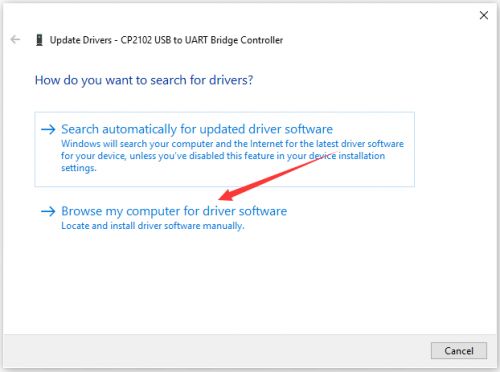

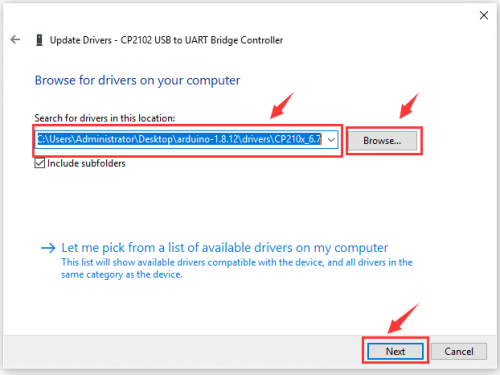

Click “OK” to enter the following page, click “browse my computer for updated driver software”, find out the installed or downloaded ARDUINO software. As shown below:

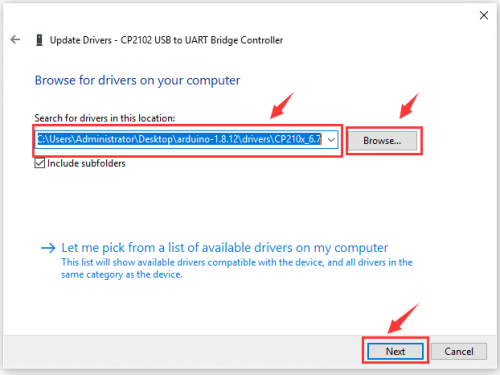

There is a DRIVERS folder in Arduino software installed package(), open driver folder and you can see the driver of CP210X series chips.

We click “Browse”, then find out the driver folder, or you could enter “driver” to search in rectangular box, then click “next”, the driver will be installed successfully. (I place Arduino software folder on the desktop, you could follow my way)

Open device manager, we will find the yellow exclamation mark disappear. The driver of CP2102 is installed successfully.

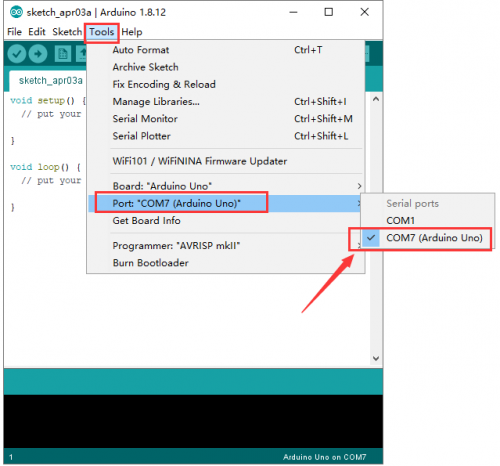

Arduino IDE Setting

Click

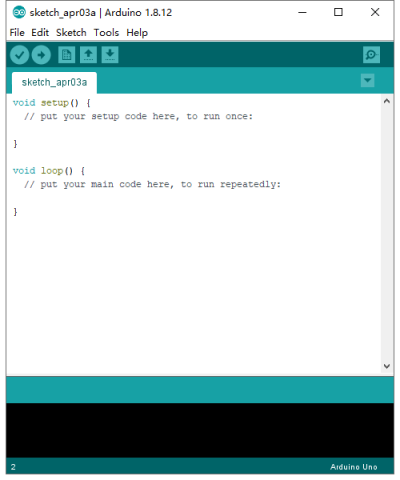

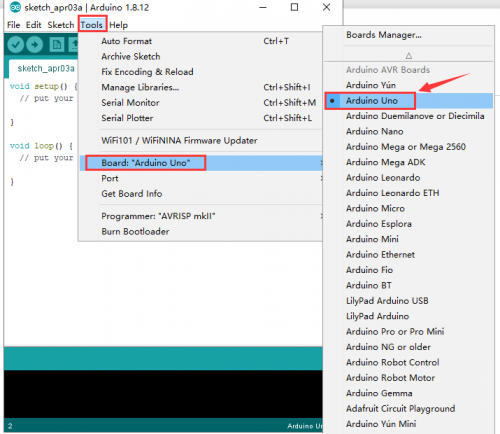

To avoid the errors when uploading the program to the board, you need to select the correct Arduino board that matches the board connected to your computer.

Then come back to the Arduino software, you should click Tools→Board, select the board. (as shown below)

Then select the correct COM port (you can see the corresponding COM port after the driver is successfully installed)

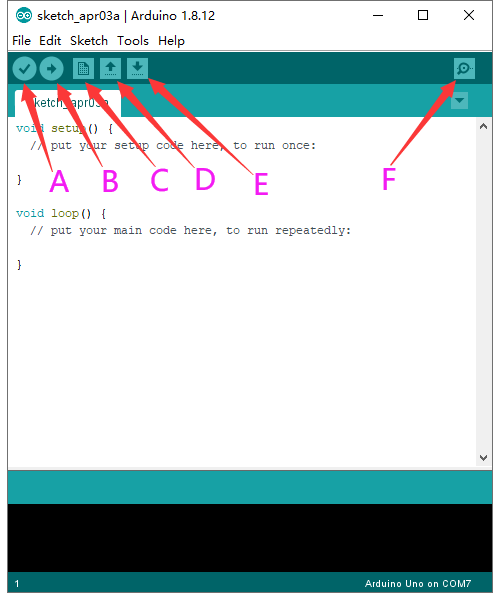

Before uploading the program to the board, let’s demonstrate the function of each symbol in the Arduino IDE toolbar.

A- Used to verify whether there is any compiling mistakes or not.

B- Used to upload the sketch to your Arduino board.

C- Used to create shortcut window of a new sketch.

D- Used to directly open an example sketch.

E- Used to save the sketch.

F- Used to send the serial data received from board to the serial monitor.

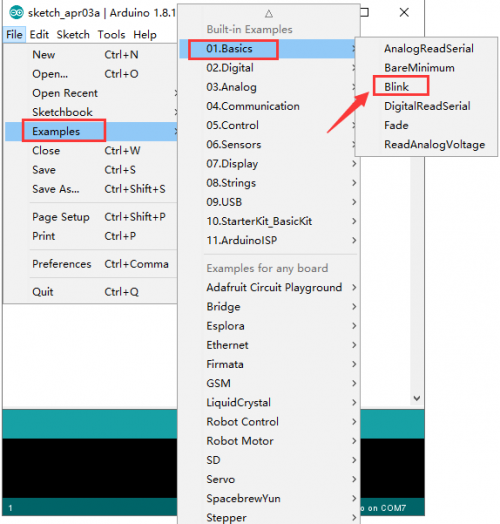

Start your first program

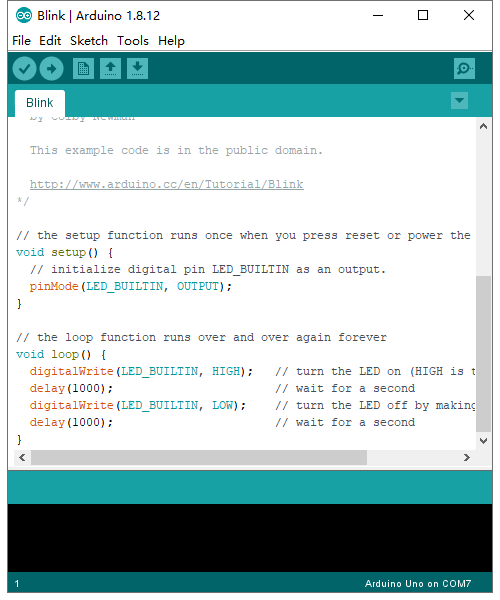

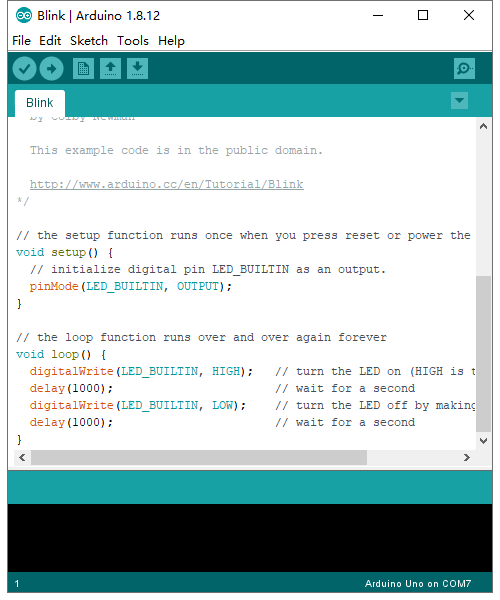

Open the file to select Example, choose BLINK from BASIC, as shown below:

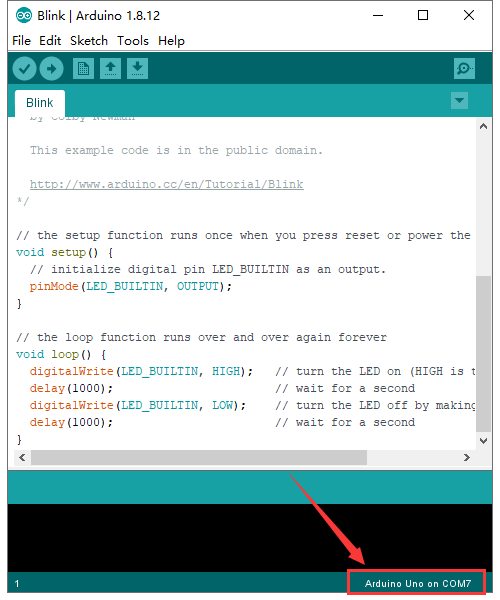

Set board and COM port, the corresponding board and COM port are shown on the lower right of IDE.

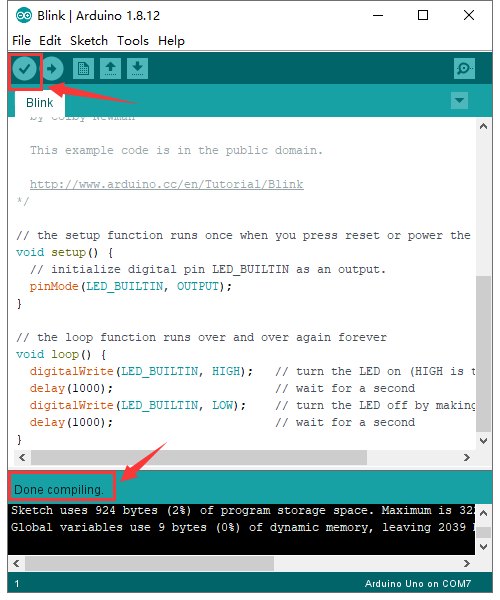

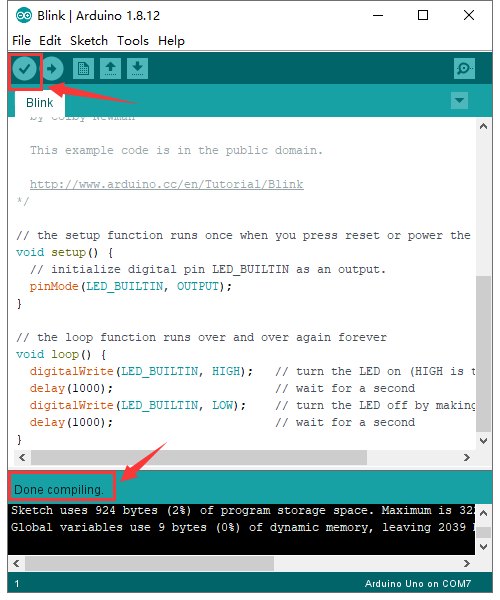

Click to start compiling the program, check errors.

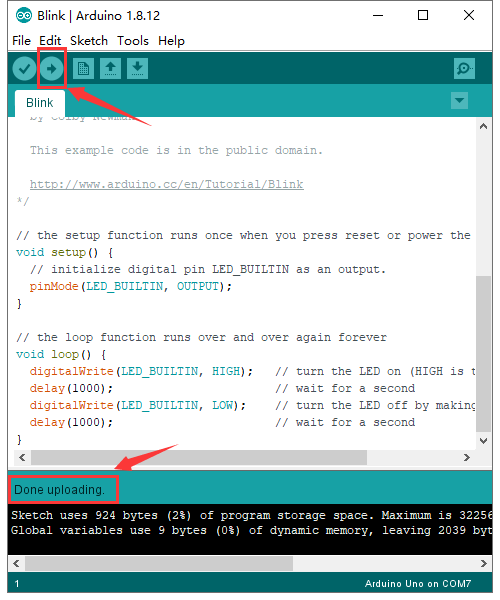

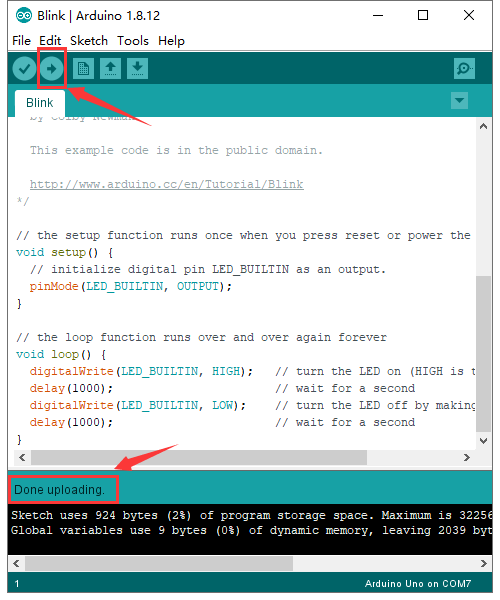

Click to upload the program, upload successfully.

Upload the program successfully, the onboard LED lights on for 1s, lights off for 1s. Congratulation, you finish the first program.

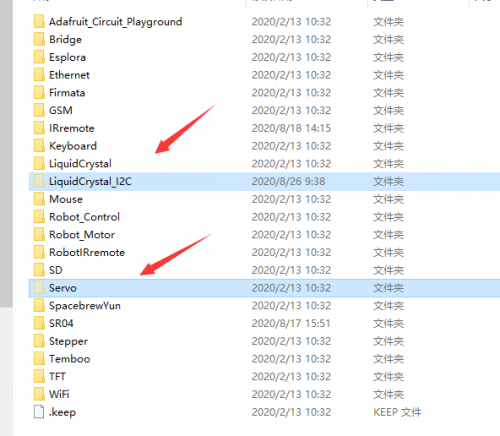

Add Project Libraries

What are Libraries ?

Libraries are a collection of code that makes it easy for you to connect to a sensor,display, module, etc.

For example, the built-in LiquidCrystal library helps talk to LCD displays. There are hundreds of additional libraries available on the Internet for download.

The built-in libraries and some of these additional libraries are listed in the reference.

How to Install a Library ?

Here we will introduce the most simple way for you to add libraries.

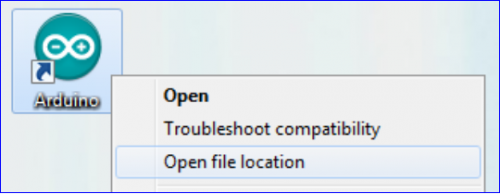

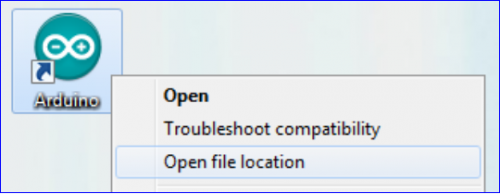

Step 1:After downloading well the Arduino IDE, you can right-click the icon of Arduino IDE.

Find the option «Open file location» shown as below:

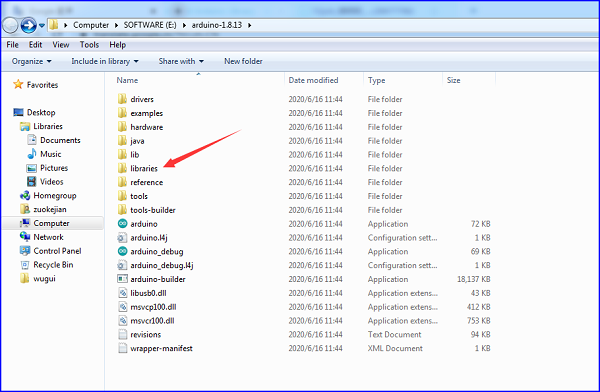

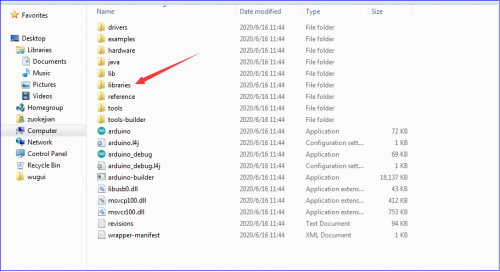

Step 2: Enter it to find out libraries folder which is the library file of Arduino.

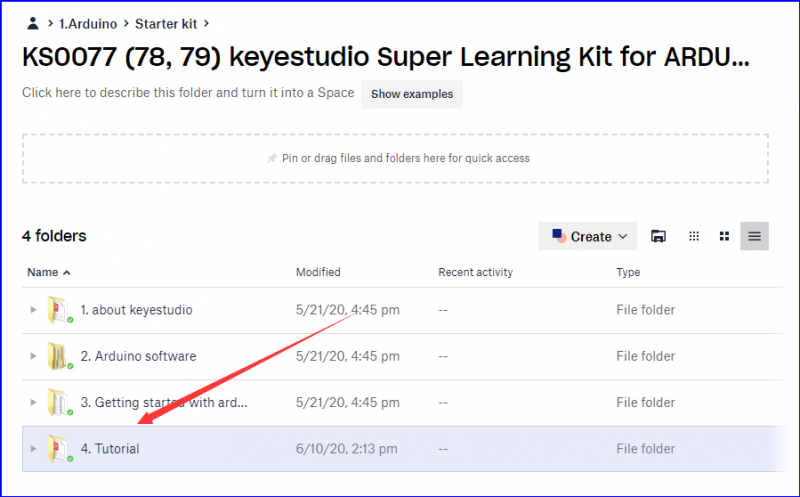

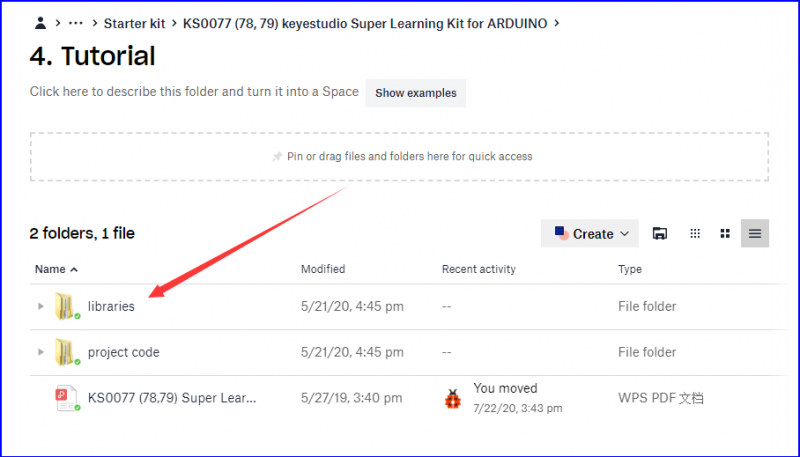

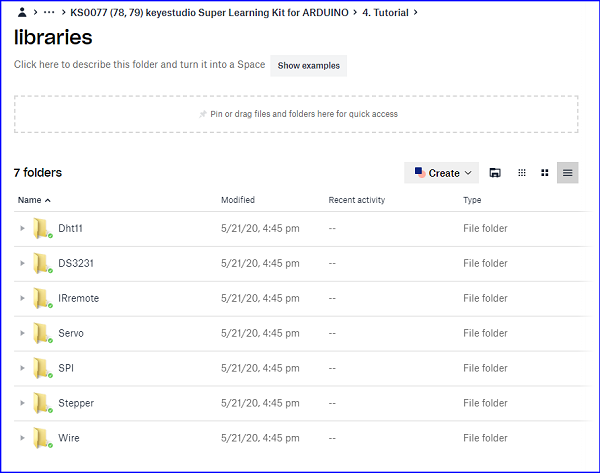

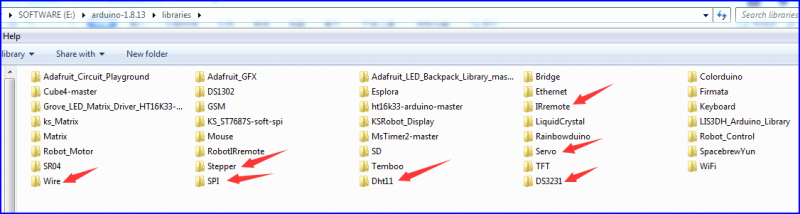

Step 3 Next to find out the “libraries” folder of this kit(seen in the link https://fs.keyestudio.com/KS0077-78-79)

You just need to replicate and paste above libraries into the libraries folder of Arduino IDE.

Then the libraries of this kit are installed successfully, as shown below

Note the Arduino software download and the driver installation of keyetudio Mega 2560 R3 board is similar to arduino V4.0 board.

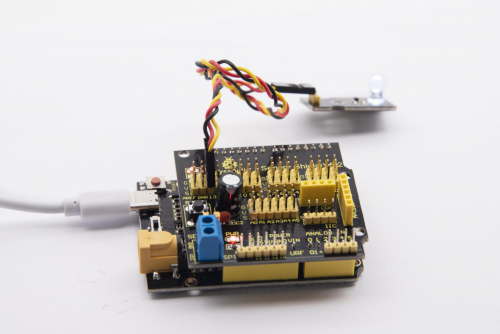

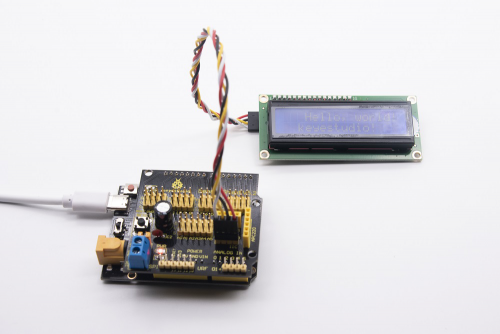

Project Details

Project 1: Hello World

1.Introduction

As for starters, we will begin with something simple. In this project, you only need an Arduino and a USB Cable to start the «Hello World!» experiment. It is not only a communication test of your Arduino and PC, but also a primer project for you to have your first try in the Arduino world!

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB cable*1

3.Sample Code

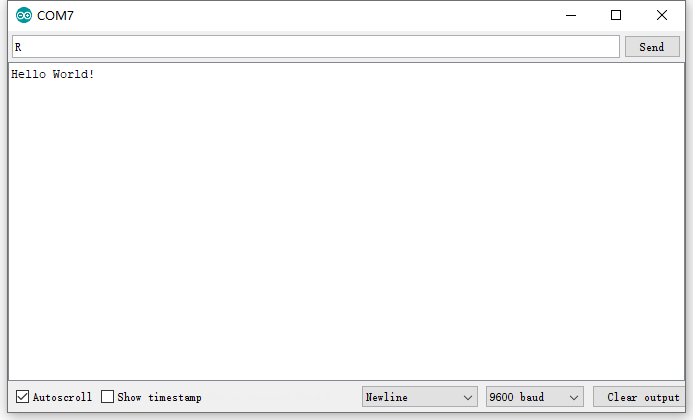

After installing driver for Arduino, let’s open Arduino software and compile code that enables Arduino to print «Hello World!» under your instruction. Of course, you can compile code for Arduino to continuously echo «Hello World!» without instruction.

A simple If () statement will do the instruction trick. when Arduino gets an instruction and then to print «Hello World!”.

/*

keyestudio super learning kit

Project 1

Hello World

http//www.keyestudio.com

- /

int val;//define variable val

void setup()

{

Serial.begin(9600);// set the baud rate at 9600 .

}

void loop()

{

val=Serial.read();// read the instruction or character from PC to Arduino, and assign them to Val.

if(val=='R')// determine if the instruction or character received is “R”.

{ // if it’s “R”,

Serial.println("Hello World!");// display“Hello World!”string.

}}//

///////////////////////////////////////////////////////////////

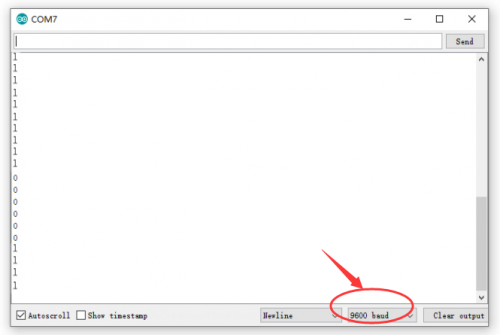

4.Test Result

Click to open the serial monitor, input an “R”, PC will receive the information from Arduino Hello World!

After choosing the proper port, the experiment is easy for you!

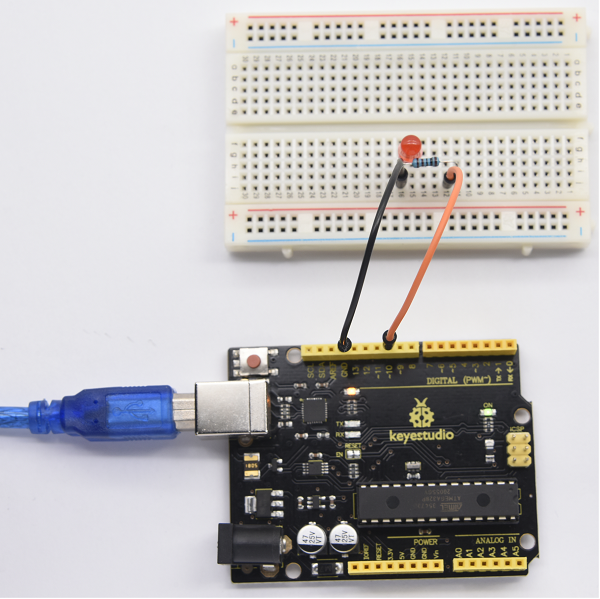

Project 2: LED Blinking

1.Introduction

Blinking LED experiment is quite simple. In the «Hello World!» program, we have come across LED. This time, we are going to connect an LED to one of the digital pins rather than using LED13 soldered to the board. Apart from an Arduino and a USB cable, you will need extra parts as below

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red M5 LED*1

- 220Ω Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

3.Little Knowledge

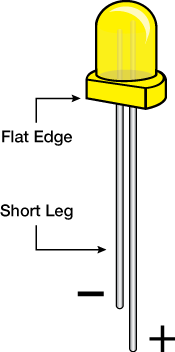

LED is a type of semiconductor called «Light Emitting Diode «which is an electronic device made of semiconductor materials (silicon, selenium, germanium, etc.). It is dubbed indicator, digital and word display in circuit and device. It has positive and negative poles. The short leg is negative pole, the long one is positive pole.

Resistor:Resistor is the electronic component in the circuit, which limits and regulates current flow. Its unit is (Ω).

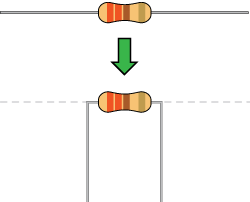

The units larger than ohms are kiloohms (KΩ) and megaohms (MΩ). When in use, in addition to the size of the resistance, you must also pay attention to its power. In the project, the leads at both ends of the resistor should be bent at a 90° angle to fit the breadboard properly. If the lead is too long, it can be cut to an appropriate length.

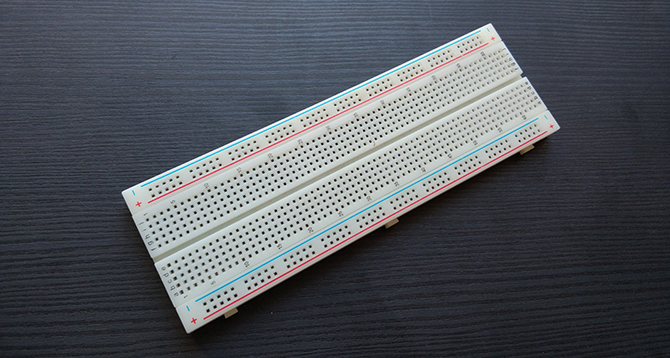

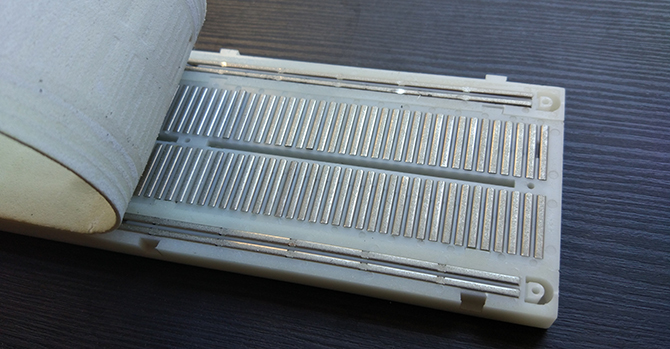

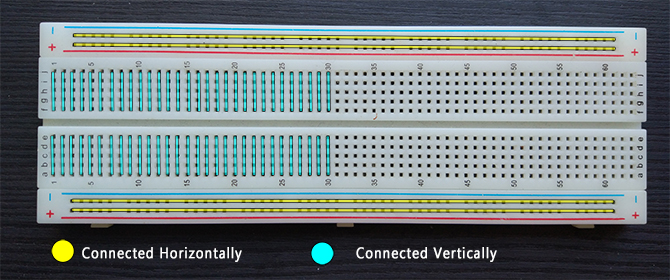

A breadboard is used to build and test circuits quickly before finalizing any circuit design. The breadboard has many holes into which circuit components like ICs and resistors can be inserted. A typical breadboard is shown below:

The bread board has strips of metal which run underneath the board and connect the holes on the top of the board. The metal strips are laid out as shown below. Note that the top and bottom rows of holes are connected horizontally while the remaining holes are connected vertically.

To use the bread board, the legs of components are placed in the holes. Each set of holes connected by a metal a strip underneath forms anode

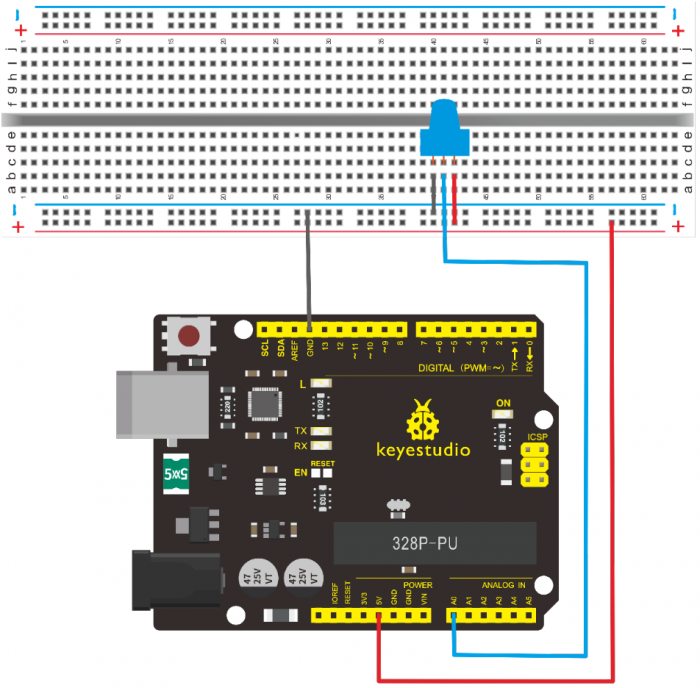

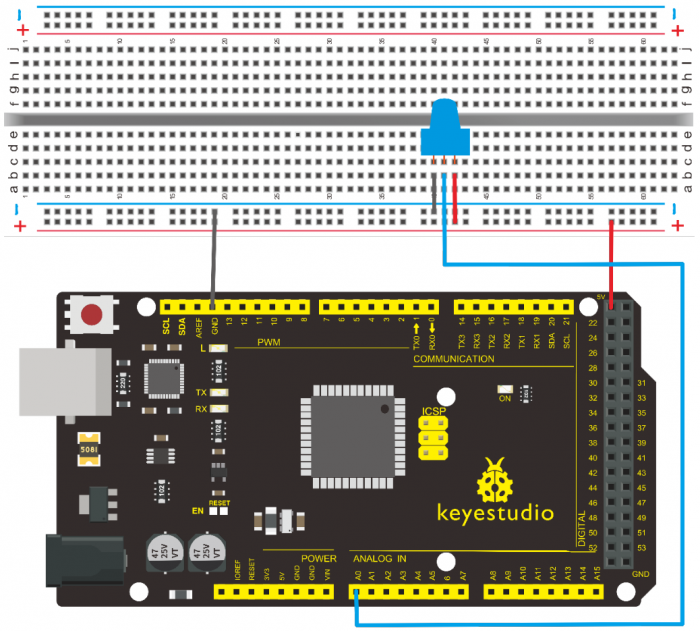

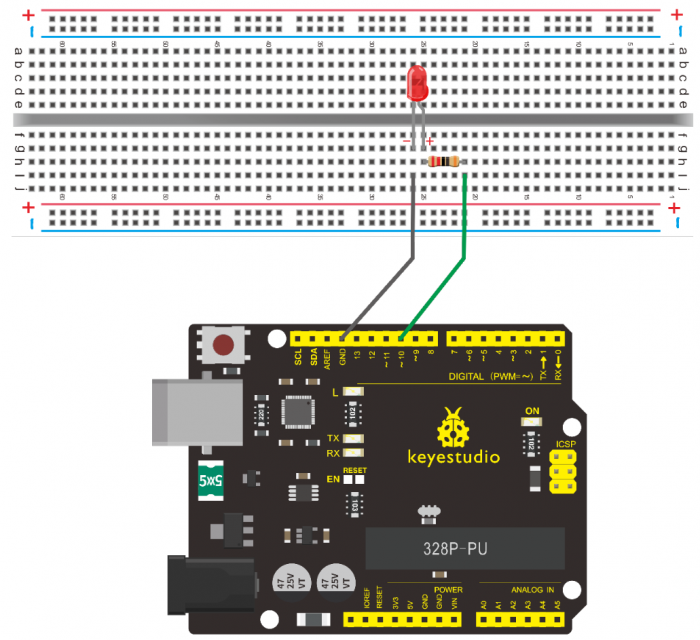

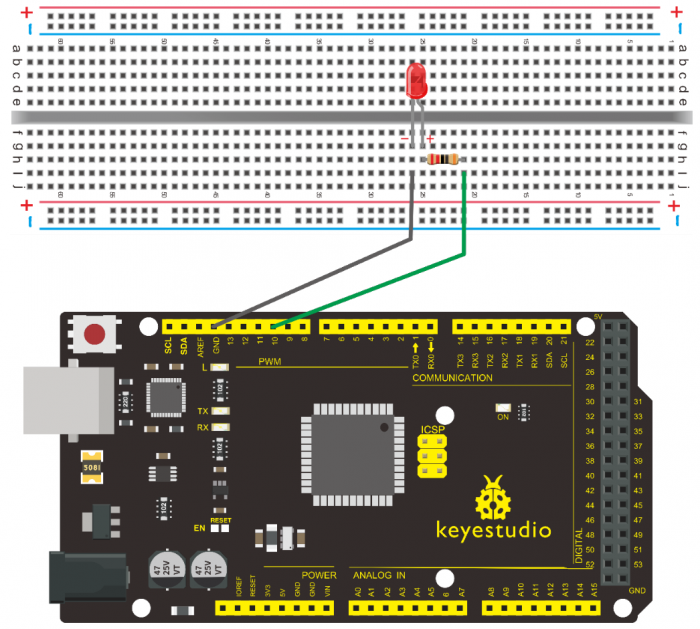

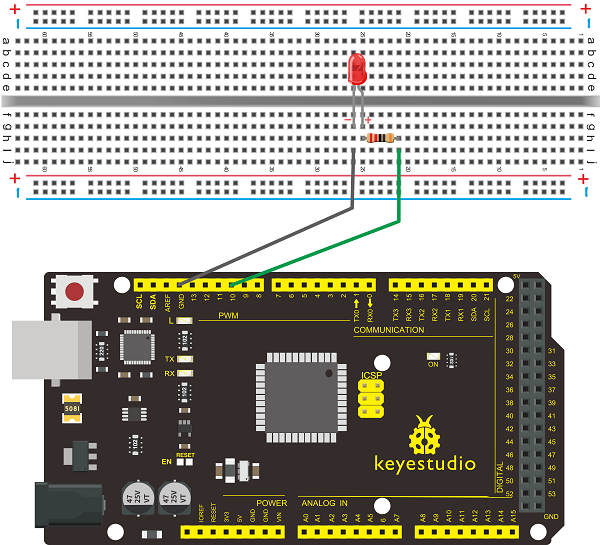

4.Circuit Connection

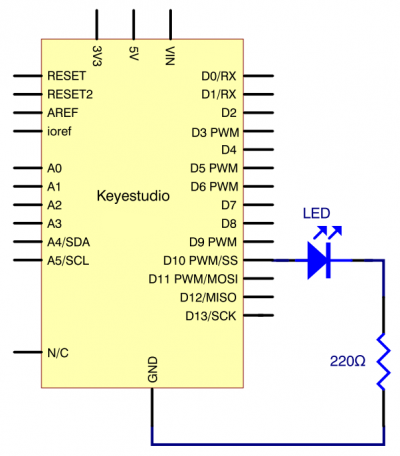

We follow below diagram from the experimental schematic link. Here we use digital pin 10. We connect LED to a 220 ohm resistor to avoid high current damaging the LED.

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 2

Blink

http//www.keyestudio.com

- /

int ledPin = 10; // define digital pin 10.

void setup()

{

pinMode(ledPin, OUTPUT);// define pin with LED connected as output.

}

void loop()

{

digitalWrite(ledPin, HIGH); // set the LED on.

delay(1000); // wait for a second.

digitalWrite(ledPin, LOW); // set the LED off.

delay(1000); // wait for a second

}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading this program, in the experiment, you will see the LED connected to pin 10 turning on and off, with an interval of approximate one second.

In this way, blinking LED experiment is now completed. Thank you!

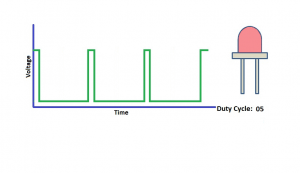

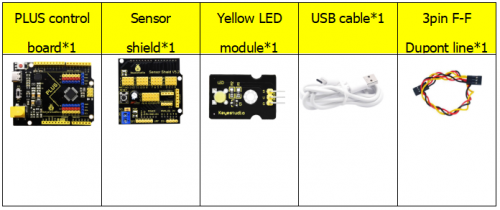

Project 3: PWM

1.Introduction

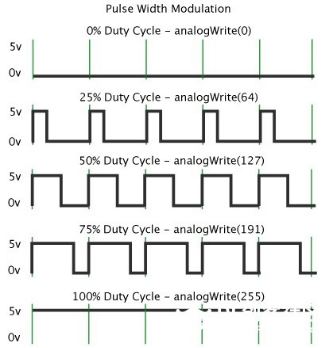

PWM, short for Pulse Width Modulation, is a technique used to encode analog signal level into digital ones. A computer cannot output analog voltage but only digital voltage values such as 0V or 5V. So we use a high resolution counter to encode a specific analog signal level by modulating the duty cycle of PMW.

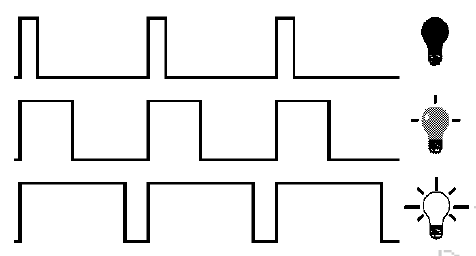

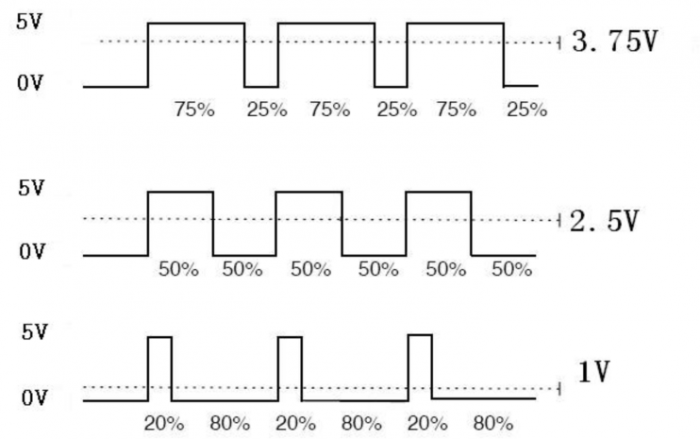

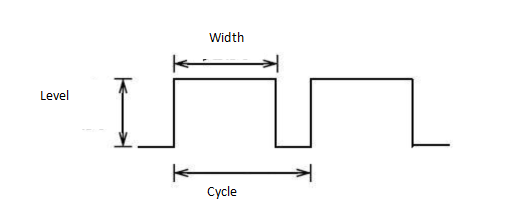

2.Working Principle

The PWM signal is also digitalized because in any given moment, fully on DC power supply is either 5V (ON), or 0V (OFF). The voltage or current is fed to the analog load (the device that uses the power) by repeated pulse sequence being ON or OFF. Being on, the current is fed to the load; being off, it’s not. With adequate bandwidth, any analog value can be encoded using PWM. The output voltage value is calculated via the on and off time.

Output voltage = (turn on time/pulse time) * maximum voltage value.

PWM has many applications lamp brightness regulating, motor speed regulating, sound making, etc.

The following are the three basic parameters of PMW.

- 1.The amplitude of pulse width (minimum / maximum)

- 2. The pulse period (The reciprocal of pulse frequency in one second)

- 3. The voltage level(such as 0V-5V)

- There are 6 PMW interfaces on Arduino, namely digital pin 3, 5, 6, 9, 10, and 11.

- In previous experiments, we have done «button-controlled LED», using digital signal to control digital pin, also one about potentiometer.

- This time, we will use a potentiometer to control the brightness of the LED.

3.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red M5 LED*1

- 220Ω Resistor

- Breadboard*1

- Breadboard Jumper Wire*6

- USB cable*1

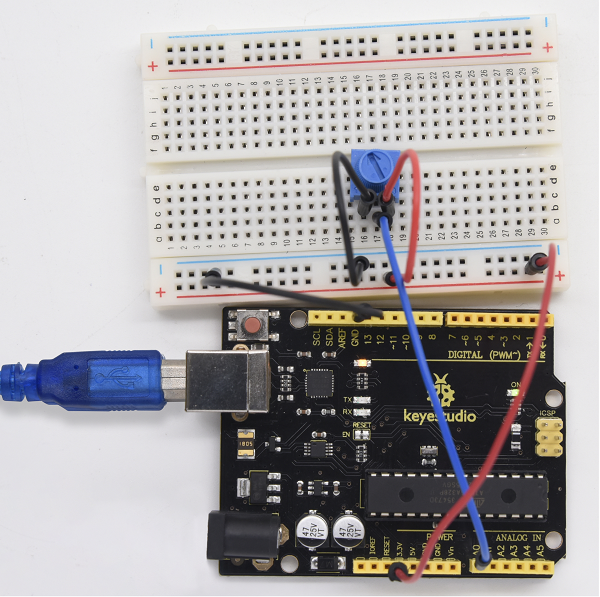

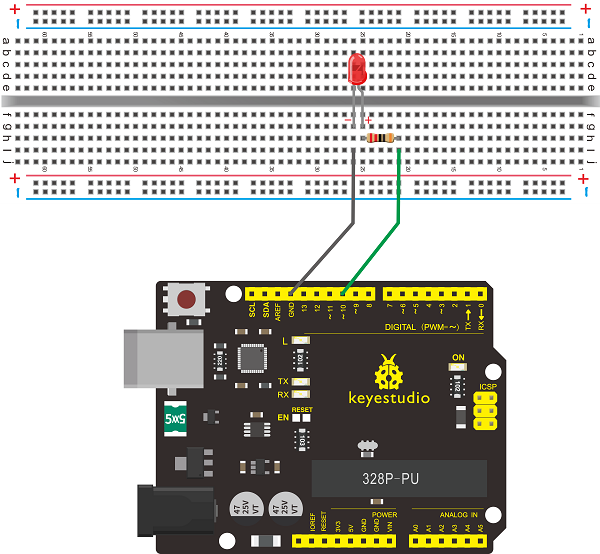

4.Circuit Connection

Connection for V4.0

Connection for 2560 R3

5.Sample Code

/*

keyestudio super learning kit

Project 3

pwm

http//www.keyestudio.com

*/

int ledPin = 10;

void setup() {

pinMode(ledPin,OUTPUT);

}

void loop(){

for (int value = 0 ; value < 255; value=value+1){

analogWrite(ledPin, value);

delay(5);

}

for (int value = 255; value >0; value=value-1){

analogWrite(ledPin, value);

delay(5);

}

}

//////////////////////////////////////////////////////////////////

6.Test Result

Hook up via connection diagram, upload the code and plug in power. The external LED lights up then gets dark gradually, which looks like human breath.

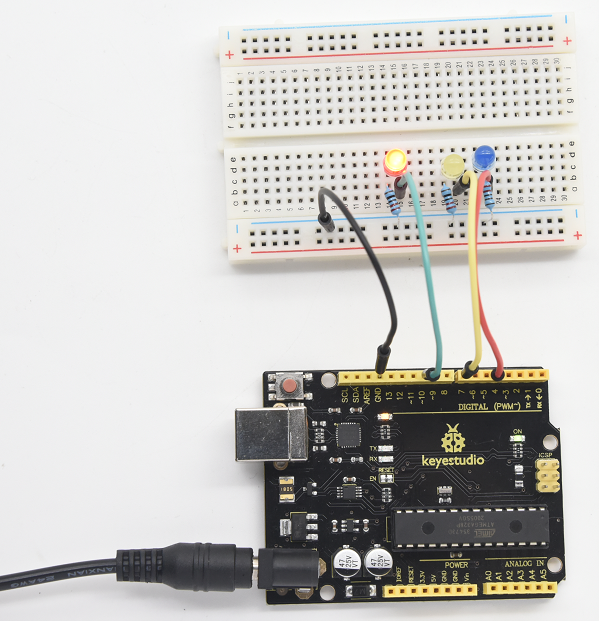

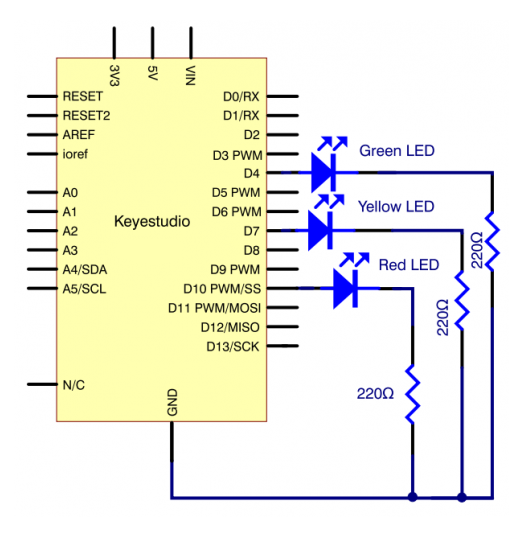

Project 4: Traffic Light

1.Introduction

In the previous program, we have done the LED blinking experiment with one LED. Now, it’s time to up the stakes to do a bit more complicated experiment-traffic light. Actually, these two experiments are similar. While in this traffic light experiment, we use three LEDs with different colors rather than an LED.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB Cable *1

- Red M5 LED*1

- Yellow M5 LED*1

- Blue M5 LED*1

- 220Ω Resistor *3

- Breadboard*1

- Breadboard Jumper Wire *4

3.Circuit Connection

Connection for V4.0

Connection for 2560

4.Sample Code

Since it is a simulation of traffic lights, the blinking time of each LED should be the same with those in traffic lights system.

In this program, we use Arduino delay () function to control delay time, which is much simpler than C language.

/*

keyestudio super learning kit

Project 4

traffic light

http//www.keyestudio.com

*/

int redled =10; // initialize digital pin 10.

int yellowled =7; // initialize digital pin 7.

int blueled =4; // initialize digital pin 4.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(blueled, OUTPUT); // set the pin with blue LED as “output”

}

void loop()

{

digitalWrite(blueled, HIGH);//// turn on blue LED

delay(5000);// wait 5 seconds

digitalWrite(blueled, LOW); // turn off blue LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 second

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 second

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 second

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 second

digitalWrite(redled, LOW);// turn off red LED

}

//////////////////////////////////////////////////////////////////

5.Test Result

When the uploading process is completed, you can see traffic lights of your own design. Note this circuit design is very similar with the one in LED chasing effect.

The blue light will be on for 5 seconds, and then off, followed by the yellow light blinking for 3 times, and then the red light is on for 5 seconds, repeatedly forming a cycle.

Experiment is now completed, thank you!

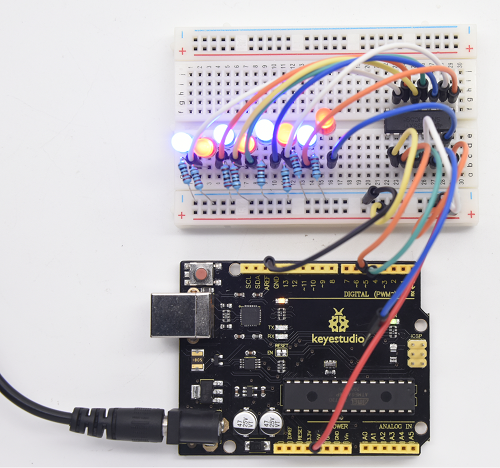

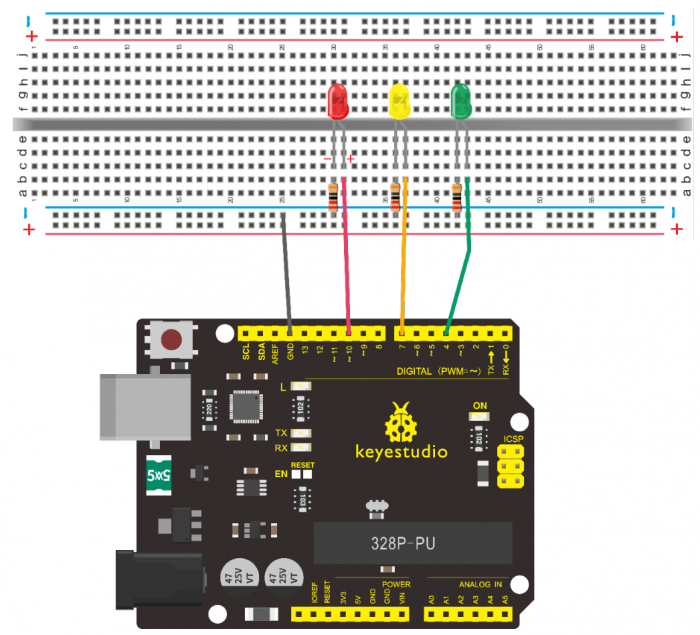

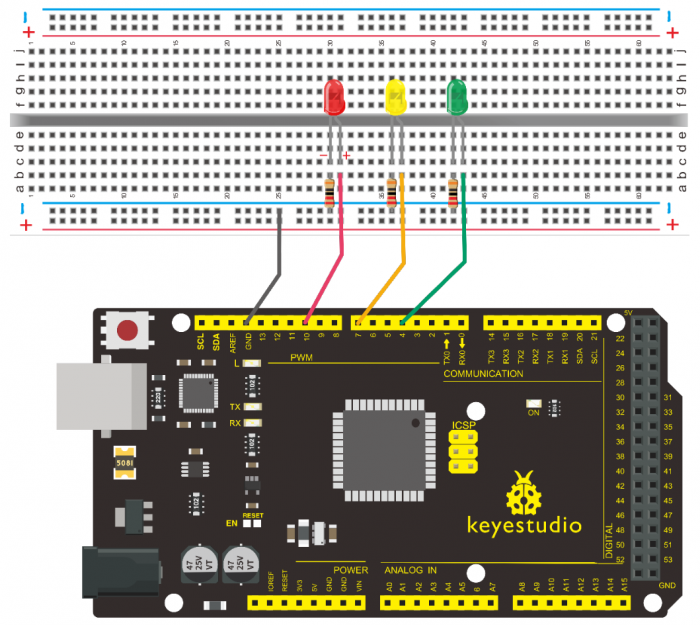

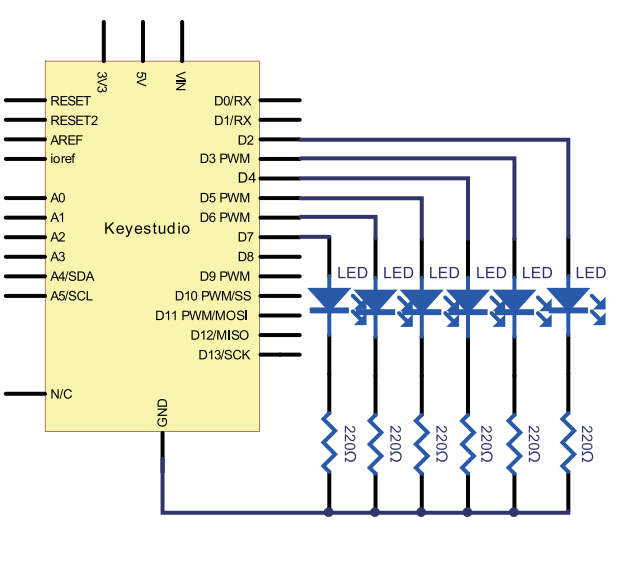

Project 5: LED Chasing Effect

1.Introduction

We can see many billboards composed of colorful LEDs. They are constantly changing to form various effects. In this experiment, we compile a program to simulate chase effect.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Red LED*6

- 220Ω Resistor *6

- Breadboard Jumper Wire*12

- USB cable*1

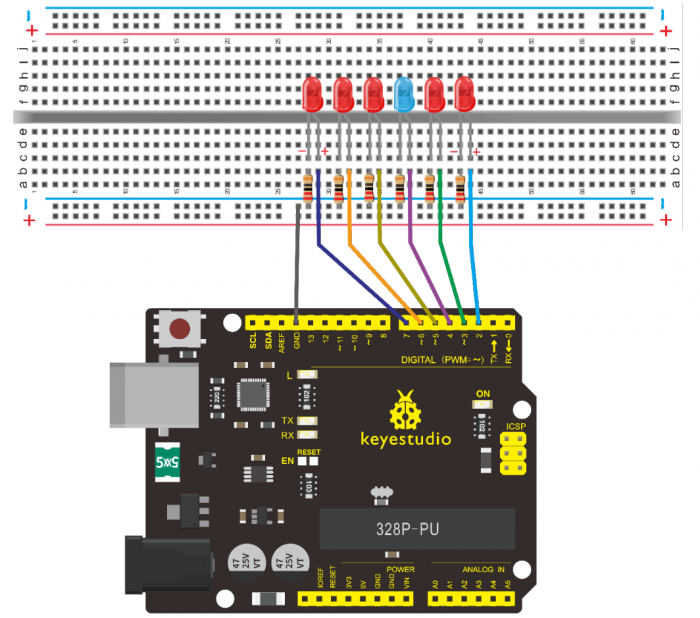

3.Circuit Connection

Connection for V4.0

Connection for 2560

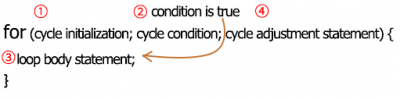

4.Sample Code

/*

keyestudio super learning kit

Project 5

LED Chasing Effect

http//www.keyestudio.com

*/

int BASE = 2 ; // the I/O pin for the first LED

int NUM = 6; // number of LEDs

void setup()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

pinMode(i, OUTPUT); // set I/O pins as output

}

}

void loop()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, LOW); // set I/O pins as “low”, turn off LEDs one by one.

delay(200); // delay

}

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, HIGH); // set I/O pins as “high”, turn on LEDs one by one

delay(200); // delay

}

}

//////////////////////////////////////////////////////////////////

5.Test Result

You can see the LEDs blink by sequence.

Project 6: Button-Controlled LED

1.Introduction

I/O port means interface for INPUT and OUTPUT. Up to now, we have only used the OUTPUT function.

In this experiment, we will try to use the INPUT function, which is to read the output value of device connecting to it.

We use 1 button and 1 LED using both input and output to give you a better understanding of the I/O function.

Button switch, familiar to most of us, is a switch value (digital value) component. When it’s pressed, the circuit is in closed (conducting) state.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Button switch*1

- Red M5 LED*1

- 220ΩResistor*1

- 10KΩ Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*6

- USB cable*1

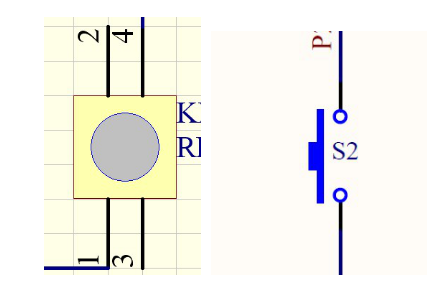

3. Little Knowledge

I believe that button switch is common and popular for people. It belongs to switch quantity( digital quantity)component. Composed of normally open contact and normally closed contact,its working principle is similar with ordinary switch.

When the normally open contact bears pressure, the circuit is on state ; however, when this pressure disappears, the normally open contact goes back to initial state, that is, off state. The pressure is the act we switch the button.

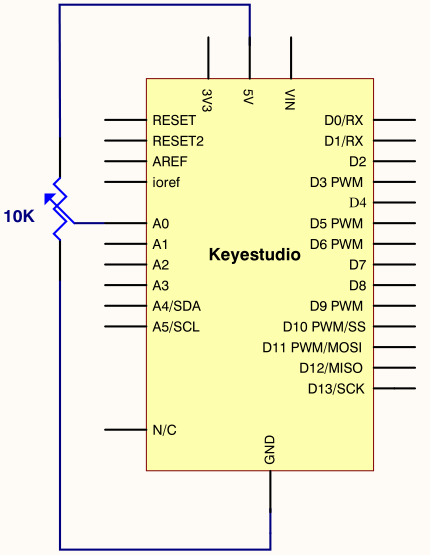

Schematic Diagrams:

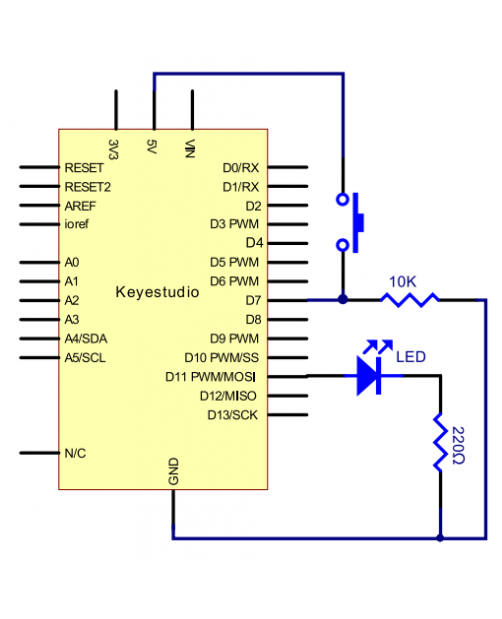

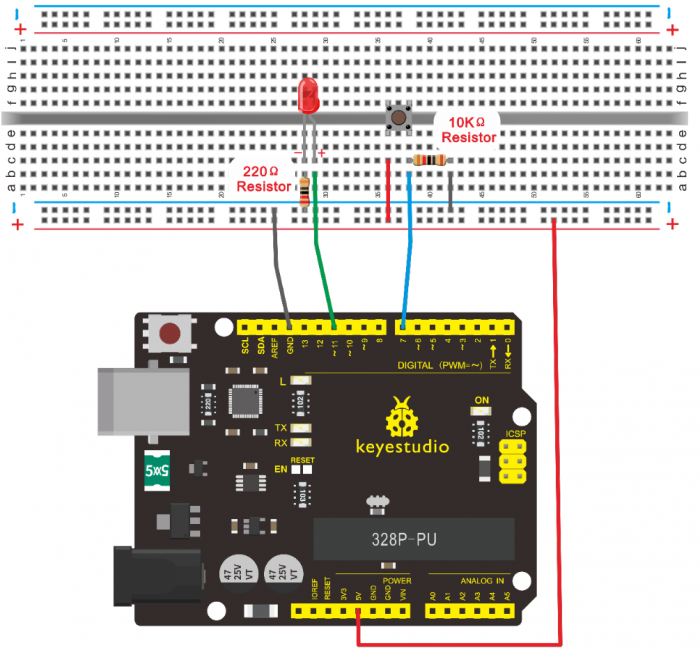

4. Circuit Connection

Connection for V4.0

Connection for 2560

5.Sample Code

Now, let’s begin the compiling. When the button is pressed, the LED will be on. Based on the previous study, the coding should be easy for you.

In this program, we add a statement of judgment. Here, we use an if () statement.

Arduino IDE is based on C language, so statements of C language such as while, switch etc. can certainly be used for Arduino program.

When we press the button, pin 7 will output high level. We can program pin 11 to output high level and turn on the LED. When pin 7 outputs low level, pin 11 also outputs low level and the LED remains off.

/*

keyestudio super learning kit

Project 6

Button

http//www.keyestudio.com

*/

int ledpin=11;// initialize pin 11

int inpin=7;// initialize pin 7

int val;// define val

void setup()

{

pinMode(ledpin,OUTPUT);// set LED pin as “output”

pinMode(inpin,INPUT);// set button pin as “input”

}

void loop()

{

val=digitalRead(inpin);// read the level value of pin 7 and assign if to val

if(val==LOW)// check if the button is pressed, if yes, turn on the LED

{ digitalWrite(ledpin,LOW);}

else

{ digitalWrite(ledpin,HIGH);}

}

//////////////////////////////////////////////////////////////////

6.Test Result

When the button is pressed, LED is on, otherwise, LED remains off. In this way, the button controlled LED experiment is completed.

The simple principle of this experiment is widely used in a variety of circuit and electric appliances. You can easily come across it in your daily life. One typical example is when you press a certain key on your phone, the backlight will be on.

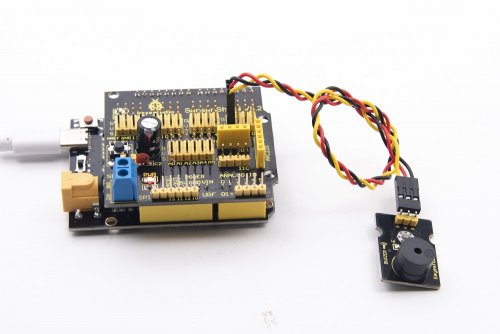

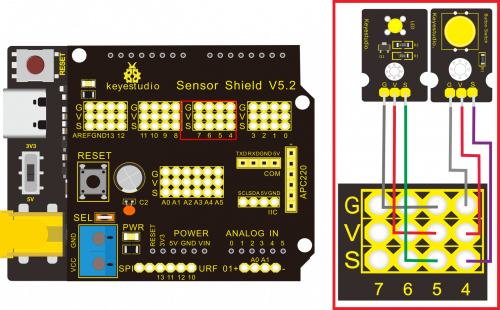

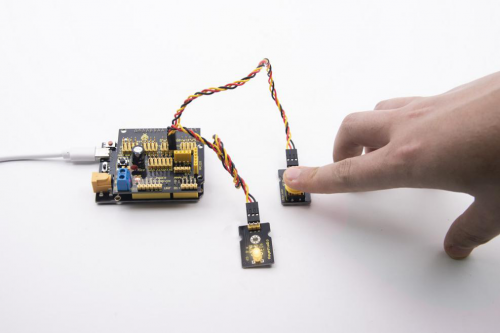

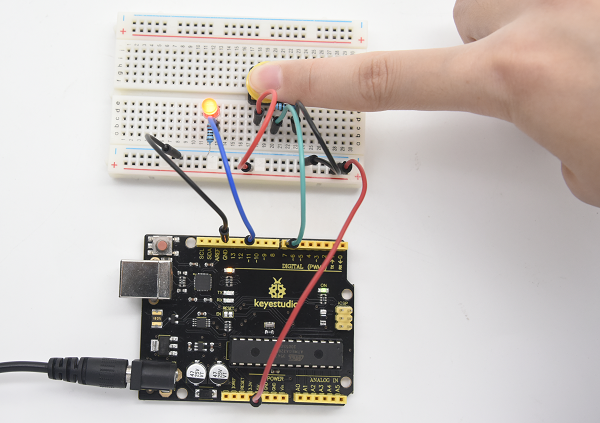

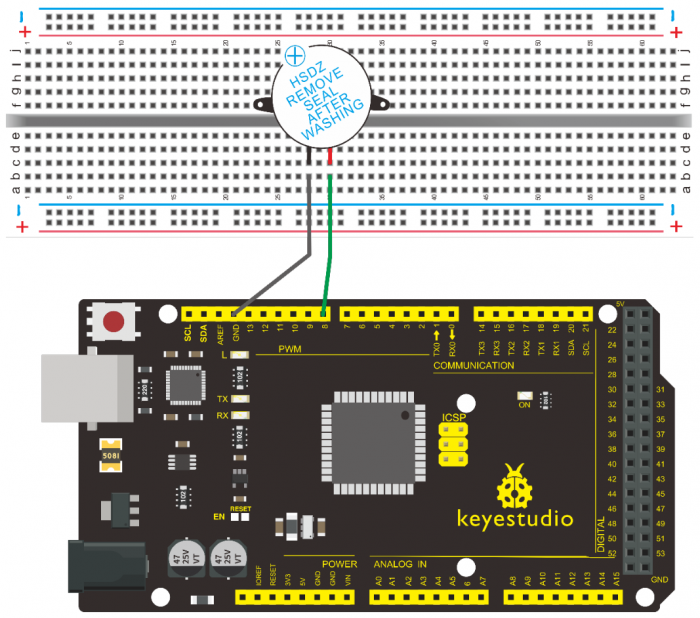

Project 7: Active Buzzer

1.Introduction

Active buzzer is widely used as a sound making element on computer, printer, alarm, electronic toy, telephone, timer and more. It has an inner vibration source. Simply connect it with 5V power supply, it can buzz continuously.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

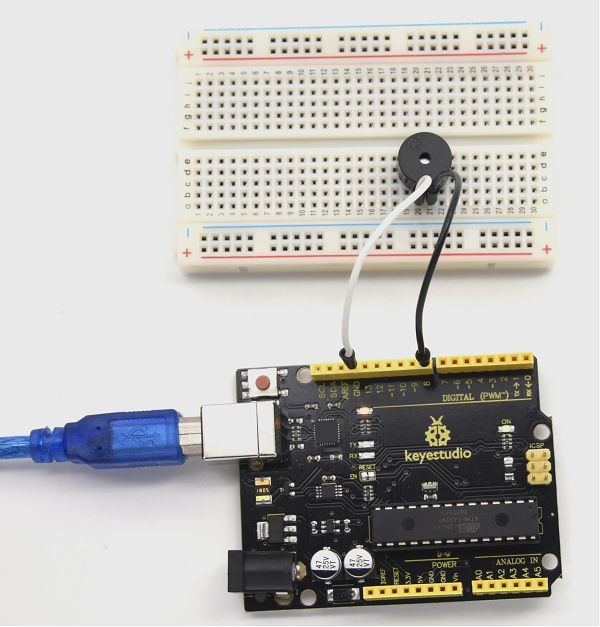

- Buzzer*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

3. Little Knowledge

There are two kinds of buzzer, active buzzer and passive buzzer. In this lesson, we will use Micro:bit to drive an active buzzer. The active buzzer inside has a simple oscillator circuit which can convert constant direct current into a certain frequency pulse signal. Once active buzzer receives a high level, it will produce an audible beep.

4.Circuit Connection

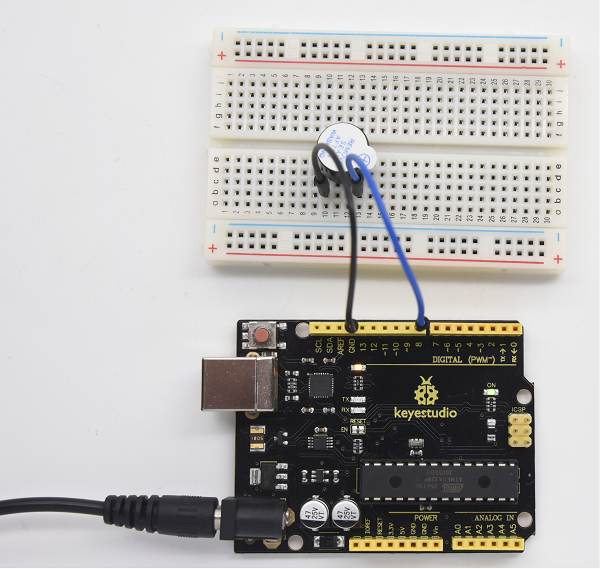

Connection for V4.0

Connection for 2560

When connecting the circuit, pay attention to the positive and negative poles of the buzzer. In the photo, you can see there are red and black lines. When the circuit is finished, you can begin the programming.

5.Sample Code

Program is simple. You control the buzzer by outputting high/low level.

/*

keyestudio super learning kit

Project 7

Active Buzzer

http//www.keyestudio.com

*/

int buzzer=8;// initialize digital IO pin that controls the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set pin mode as “output”

}

void loop()

{

digitalWrite(buzzer, HIGH); // produce sound

}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading the program, the buzzer experiment is completed. You can see the buzzer is ringing.

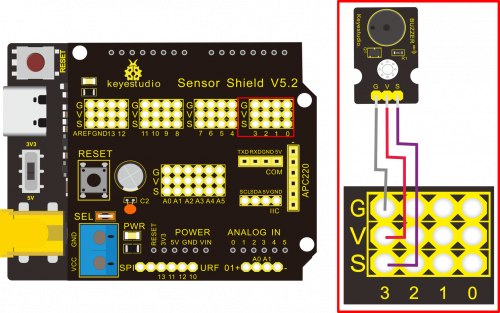

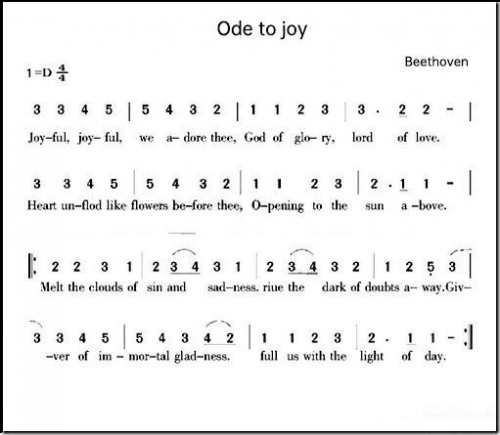

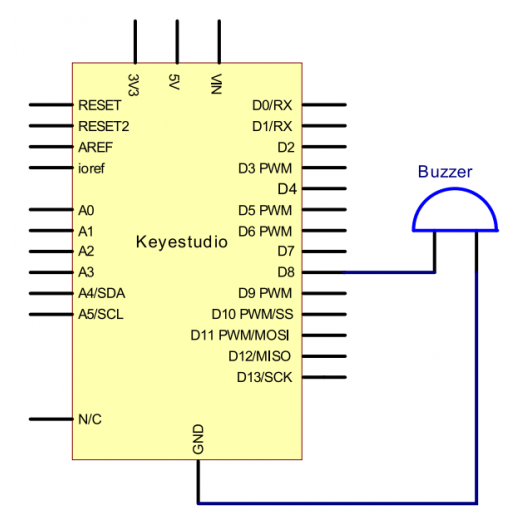

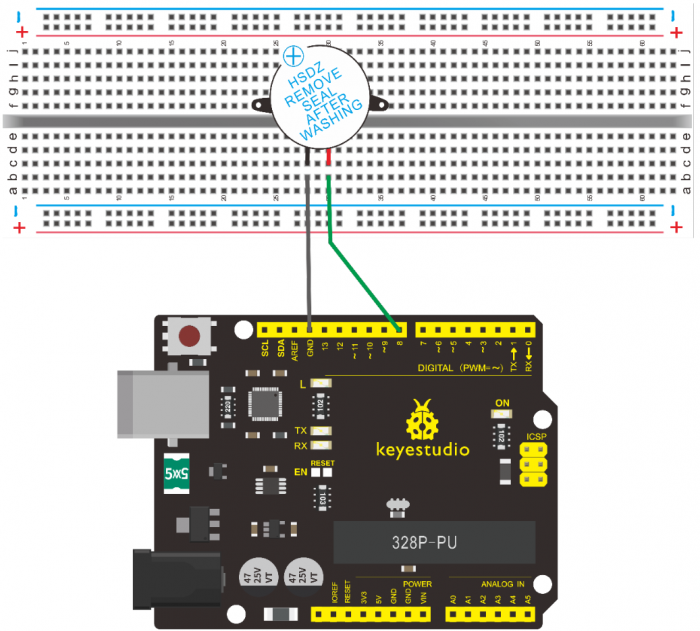

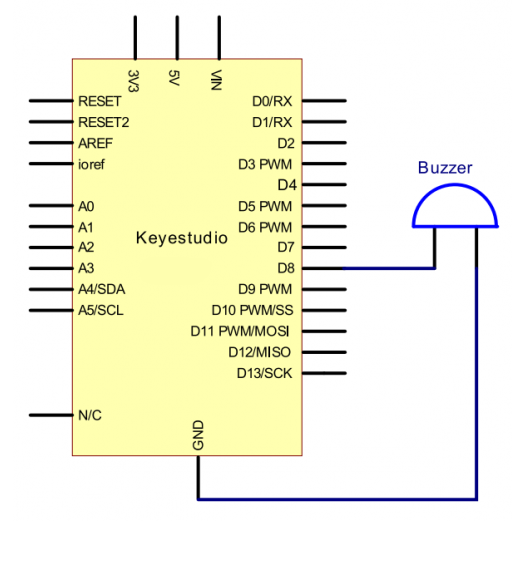

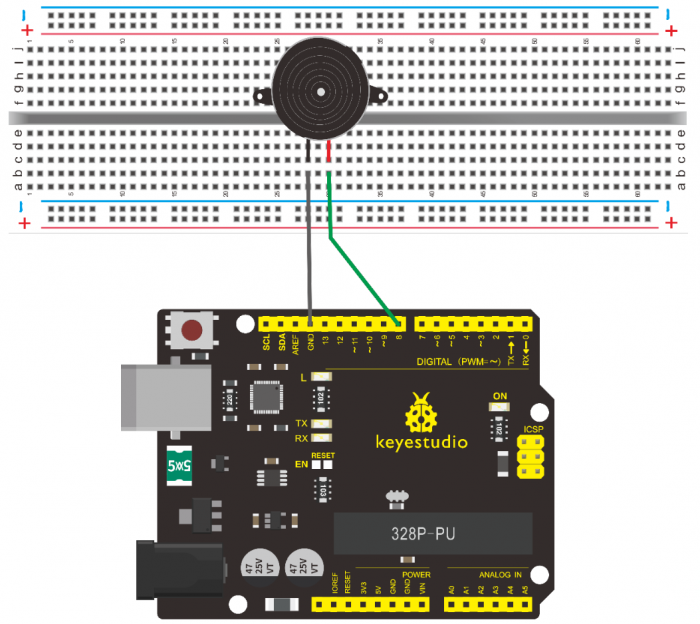

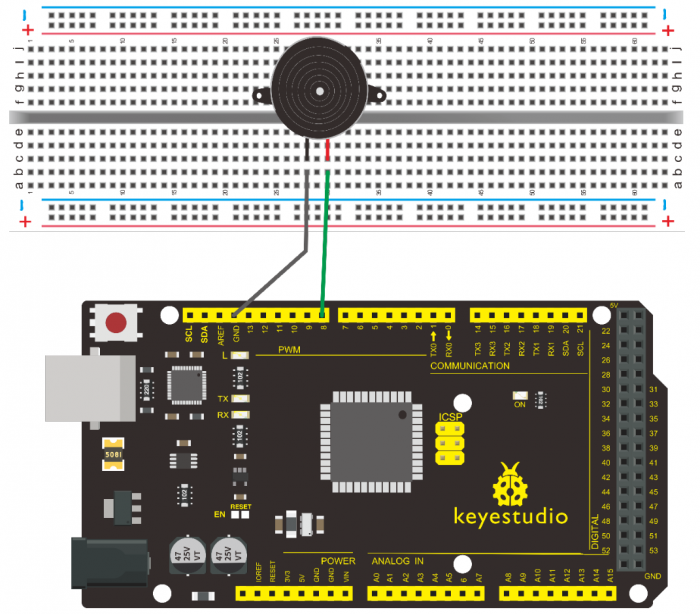

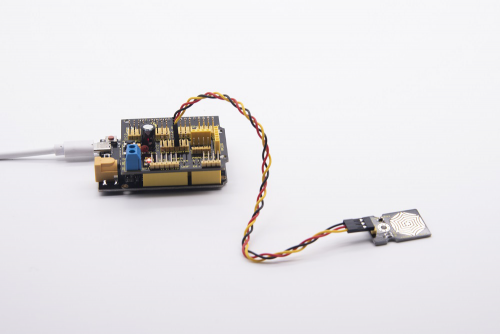

Project 8: Passive Buzzer

1.Introduction

We can use Arduino to make many interactive works. The most commonly used one is acoustic-optic display. All the previous experiment has something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer but not a speaker while buzzer is more simpler and easier to use.

The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequency produces different sound. We can use Arduino to code the melody of a song, which is quite fun and simple.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Passive Buzzer*1

- Breadboard*1

- Breadboard Jumper Wire*2

- USB cable*1

3. Little knowledge

Passive buzzer is an integrated electronic buzzer without vibration source inside. It must be driven by 2K-5K square wave instead of direct current signals. There is little difference between the two buzzers, but when the pins of the two buzzers are placed up, the passive buzzer comes with green circuit board, and the one sealed with vinyl is an active buzzer.

4.Circuit Connection

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 8

Passive Buzzer

http//www.keyestudio.com

*/

int buzzer=8;// select digital IO pin for the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output

}

void loop()

{ unsigned char i,j;//define variable

while(1)

{ for(i=0;i<80;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(1);//delay1ms

digitalWrite(buzzer,LOW);//not sound

delay(1);//ms delay

}

for(i=0;i<100;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(2);//2ms delay

digitalWrite(buzzer,LOW);//not sound

delay(2);//2ms delay

}}}

//////////////////////////////////////////////////////////////////

6.Test Result

After uploading the program, buzzer experiment is finished, you can hear the buzzer sound.

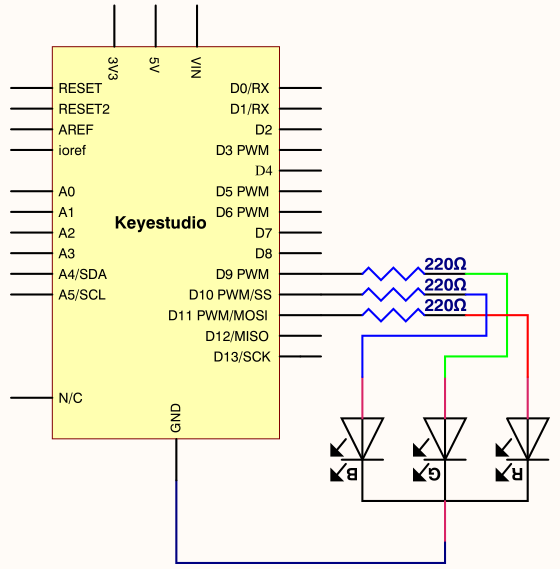

Project 9: RGB LED

1.Introduction

The RGB color mode is a color standard in the industry. It obtains various colors by changing the three color channels of red (R), green (G), and blue (B) and integrating them. RGB denotes the three colors of red, green and blue.

In this project, we use Arduino to mix these three colors in equal amounts to produce white light.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- USB Cable * 1

- RGB LED * 1

- Resistor *3

- Breadboard jumper wire*5

3. Little Knowledge

The monitors mostly adopt the RGB color standard, and all the colors on the computer screen are composed of the three colors of red, green and blue mixed in different proportions.

RGB is inclusive of common cathode RGB and common anode RGB.

And we could adjust the LED brightness by PWM

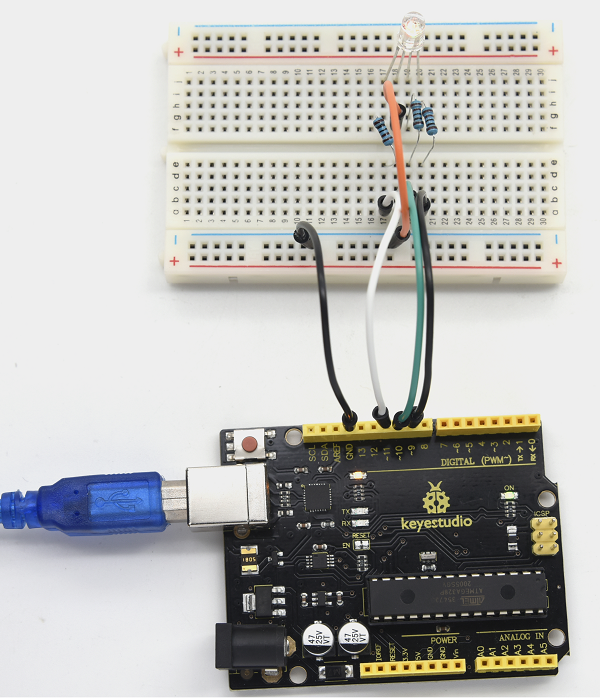

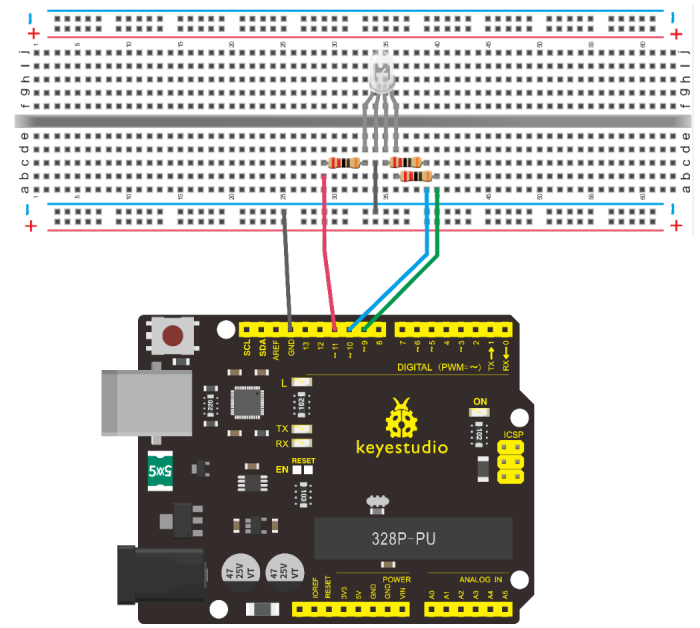

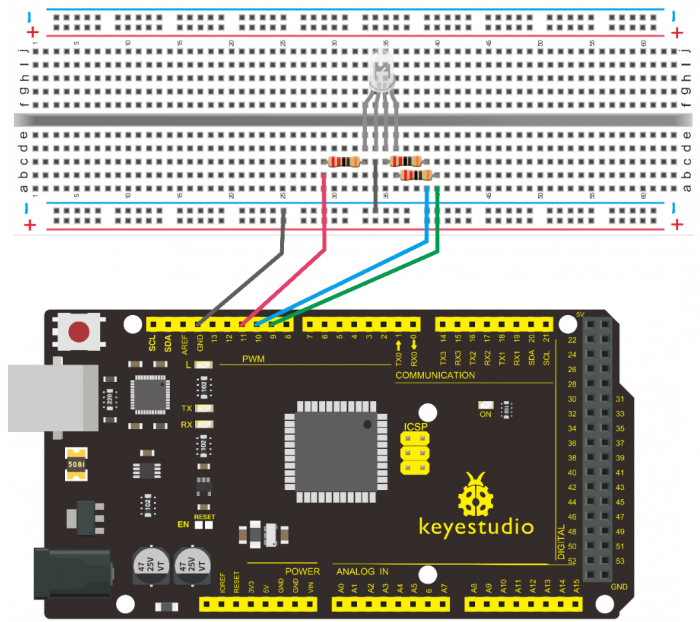

4.Circuit Connection

Connection for V4.0

Connection for 2560

5.Sample Code

/*

keyestudio super learning kit

Project 9

RGB

http//www.keyestudio.com

*/

int redpin = 11; //select the pin for the red LED

int bluepin =10; // select the pin for the blue LED

int greenpin =9;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

Serial.begin(9600);

}

void loop()

{

for(val=255; val>0; val--)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val<255; val++)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

Serial.println(val, DEC);

}

//////////////////////////////////////////////////////////////////

6.Test Result

Directly copy the above code into arduino IDE, and click upload, wait for a few seconds, you can see a full-color LED.

Project 10: Photo Resistor

1.Introduction

After completing all the previous experiments, you may acquire some basic understanding and knowledge about Arduino application. We have introduced digital input and output, analog input and PWM.

Now, let’s begin the learning of sensor applications.

Photo Resistor (Photovaristor) is a resistor whose resistance varies from different incident light strength. It’s based on the photoelectric effect of semiconductor. If the incident light is intense, its resistance reduces; if the incident light is weak, the resistance increases.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Photo Resistor*1

- Red M5 LED*1

- 10KΩ Resistor*1

- 220Ω Resistor*1

- Breadboard*1

- Breadboard Jumper Wire*5

- USB cable*1

3.Little Knowledge

Photovaristor is commonly applied in the measurement of light, light control and photovoltaic conversion (convert the change of light into the change of electricity).

Photo resistor is also being widely applied to various light control circuit, such as light control and adjustment, optical switches, etc.

We will start with a relatively simple experiment regarding to photovaristor application.

Photovaristor is an element that can change its resistance as light strength changes. So need to read the analog value. You can refer to the PWM experiment, replacing the potentiometer with photovaristor. When there is change in light strength, it will make corresponding change on the LED.

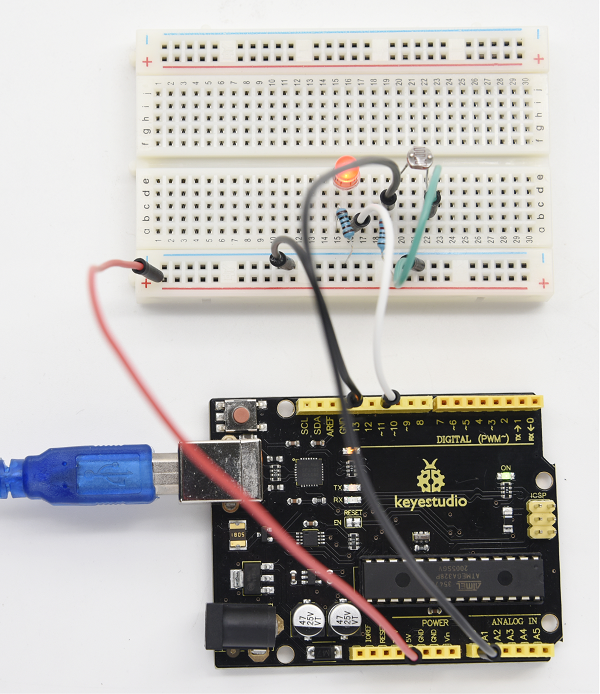

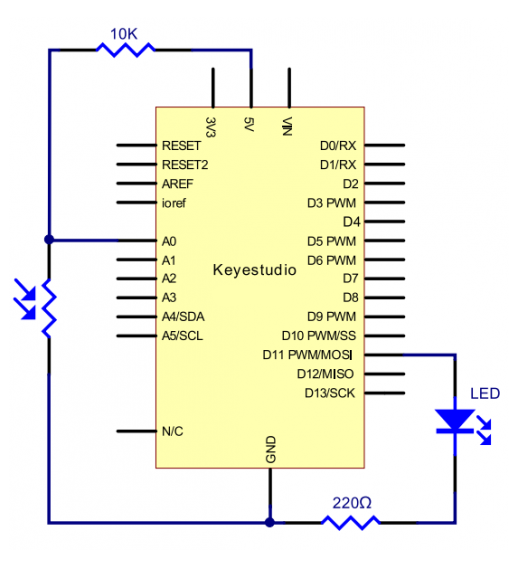

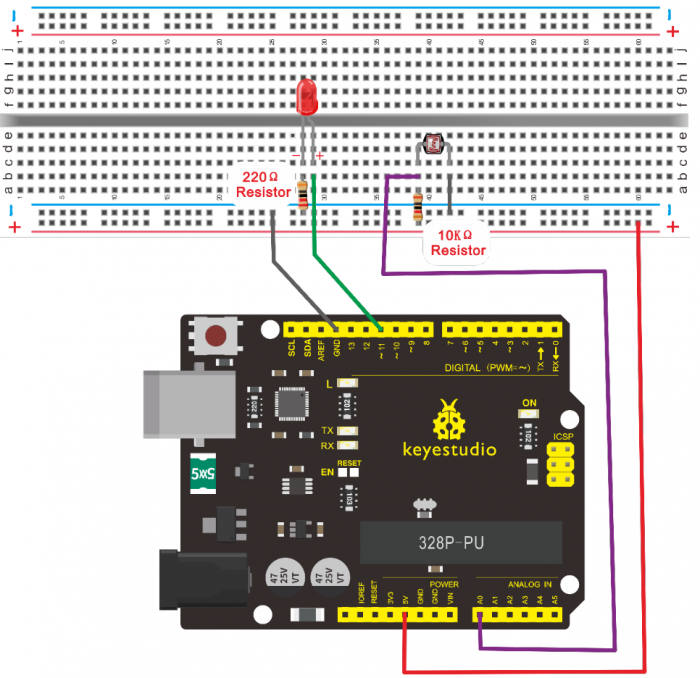

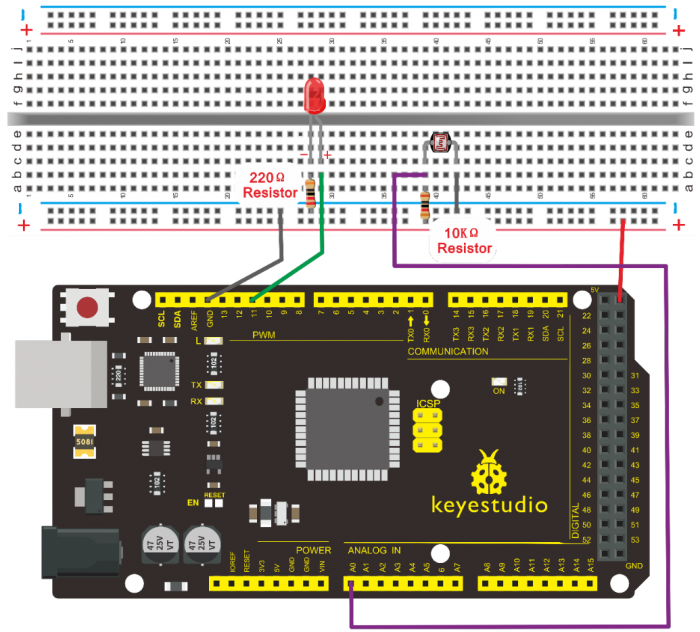

4.Circuit Connection

Connection for V4.0

Connection for 2560

5.Sample Code

After wiring, let’s begin the program compiling. The program is similar to the PWM.

For change detail, please refer to the Sample Code below.

/*

keyestudio super learning kit

Project 10

Photo Resistor

http//www.keyestudio.com

*/

int potpin=0;// initialize analog pin 0, connected with photovaristor

int ledpin=11;// initialize digital pin 11,

int val=0;// initialize variable va

void setup()

{

pinMode(ledpin,OUTPUT);// set digital pin 11 as “output”

Serial.begin(9600);// set baud rate at “9600”

}

void loop()

{

val=analogRead(potpin);// read the value of the sensor and assign it to val

Serial.println(val);// display the value of val

analogWrite(ledpin,val/4);// set up brightness(maximum value 255)

delay(10);// wait for 0.01

}

//////////////////////////////////////////////////////////////////

6.Test Result

After downloading the program, you can change the light strength around the photovaristor, and see the corresponding brightness change of the LED.

Photovaristors has various applications in our everyday. You can make other interesting interactive projects based on this one.

Project 11: Flame Sensor

1.Introduction

Flame sensor (infrared receiving triode) is specially used for robots to find the fire source. This sensor is of high sensitivity to flame.

2.Hardware Required

- V4.0 Board or MEGA 2650 Board*1

- Flame Sensor *1

- Buzzer *1

- 10K Resistor *1

- Breadboard Jumper Wire*6

- USB cable*1

3. Little Knowledge

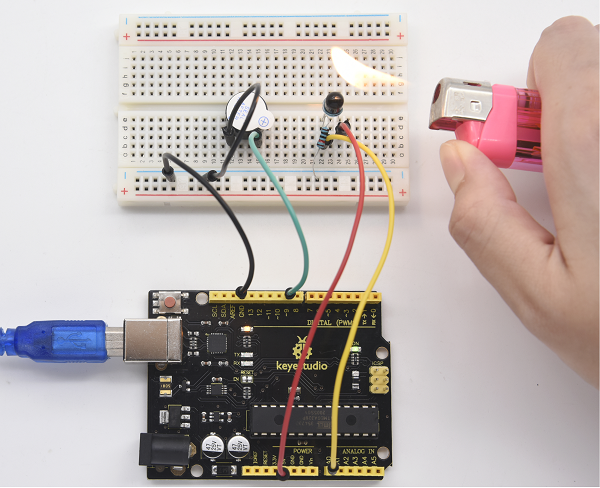

Flame sensor is based on the principle that infrared ray is highly sensitive to flame. It has an infrared receiving tube specially designed to detect fire, and then to convert the flame brightness into fluctuating level signal. The signals are then input into the central processor and be dealt with accordingly.

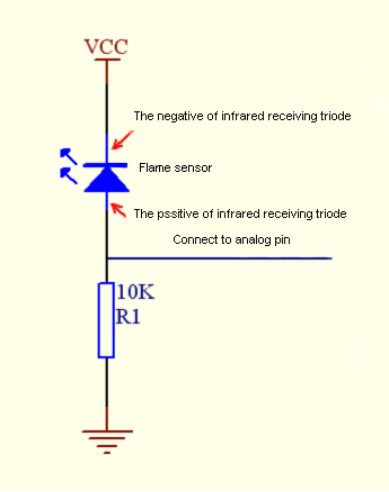

The shorter lead of the receiving triode is for negative, the other one for positive. Connect negative to 5V pin, positive to resistor; connect the other end of the resistor to GND, connect one end of a jumper wire to a clip which is electrically connected to sensor positive, the other end to analog pin. As shown below

4.Experiment Principle