Инструкция для тахеометров Nikon Nivo 3.M+, Nivo 5.M+ и Nivo 5.MW+

Руководство по эксплуатации тахеометров Nikon Nivo 3.M+, Nivo 5.M+ и Nivo 5.MW+.

| Имя файла: | nikon_nivo_3m+_5m+_5mw+.pdf |

| Размер файла: | 3.79 MB |

| Тип файла: | application/pdf |

| Посещений: | 8289 Посещений |

| Дата последнего обновления: | 15-12-15 |

-

Скачать -

Просмотр

Бренд Nikon выпускает серии тахеометров – электронных приборов для инженерных работ в сфере геодезии. Производитель гарантирует эффективное использование инструмента при условии предварительного изучения руководства пользователя. Подробная инструкция для тахеометра Nikon является обязательным компонентом комплектации. Но возможны ситуации, когда бумажную версию мануала невозможно найти и применить. Причины могут быть разными, а выход один: скачать бесплатную копию руководства к нужной модели в этом разделе.

Если у вас был старый прибор, и вы думаете, что прежняя инструкция к тахеометру Nikon подойдёт к новой линейке, то это неверно. Каждое поколение инструментов расширяет спектр функций и возможностей применения. Приборы отличаются точностью угловых измерений, появляются специальные модели с маркировкой «W» для работы при низких температурах, внедряются новаторские функции. У каждого прибора есть особенности, поэтому использование инструкций от других производителей или моделей снижает эффективность работы и отражается на безопасности персонала.

Бесплатная инструкция по эксплуатации тахеометра Nikon содержит актуальную информацию. Здесь вы найдёте ответы на все вопросы: от описания внешнего вида прибора до разбора возможных ошибок в работе и способов их устранения. Оглавление к руководству помогает быстро найти нужную функцию и приступить к выполнению задачи. Например, если вам нужно изменить настройки проекта, то сразу перейдите в нужный раздел электронной версии и прочитайте пошаговые рекомендации. Специалисты рекомендуют всегда держать руководство пользователя для тахеометра Nikon под рукой для достижения максимальной точности измерений. Также отсутствие инструкции может привести к поломкам оборудования.

Поэтому не рискуйте вывести из строя дорогостоящий инженерный прибор. Просто скачайте бесплатную версию инструкции от официального производителя Nikon и используйте все возможности современной техники.

Рекомендуем аналог

Описание

Характеристики

Файлы

Оформить заказ

Штатив для тахеометра В ПОДАРОК!!! По промокоду #Штатив в подарок# (Сообщите менеджеру при заказе) Уточняйте подробности 8-800-551-11-01

Экспертные мнения

Экспертные мнения

Радиостанции

Трегеры RGK

Рюкзаки и сумки RGK

Вехи RGK

Минипризмы RGK

Отражатель на веху

Трегеры GeoMax

Вехи SECO

Рюкзаки Vega

Аккумуляторные батареи

Рюкзаки и кейсы Geobond

Трегеры GEOBOND

Подставки для штативов

Переходники для штативов

Винты становые

Круговые отражатели

Чехлы для штативов

Штативы GeoBond

Окуляры для тахеометра

Призменные системы

Вехи GEOBOND

Минипризмы GEOBOND

Плёночные отражатели Geobond

Минипризмы Leica

Рулетки

Деревянные штативы GeoBond

Резьба станового винта — 5/8″;

Стандарт — WILD.

Подробнее

Резьба станового винта — 5/8″;

Стандарт — WILD;

Отвес — оптический (4Х).

Подробнее

- Резьба станового винта — 5/8″;

Подробнее

- Резьба станового винта — 5/8″;

- Стандарт -WILD;

- Отвес — оптический (4Х) .

Подробнее

- Резьба станового винта — 5/8″;

- Стандарт -WILD;

- Отвес — лазерный.

Подробнее

- Для тахеометров всех типов и аксессуаров;

Подробнее

- Назначение — для траиссоискателей Ridgid SR-20/24

- Габариты — 60*36*23 см

- Масса — 2,5 кг

Подробнее

- Назначение — для тахеометров

- Вес — 3,99 кг

Подробнее

- Высота — 2,5 м.

- Резьбовое соединение — 5/8»;

- Зажим — винт типа барашек;

Подробнее

- Высота — 3,6 м.

- Резьбовое соединение — 5/8»;

- Пузырьковый уровень;

- Зажим — винт типа барашек;

Подробнее

- Высота — 4,6 м.

- Резьбовое соединение — 5/8»;

- Пузырьковый уровень;

- Зажим — винт типа барашек;

Подробнее

- Высота — до 2,5 м;

- Масса — 1,09 кг;

- Тип зажима — винт;

- Материал — карбон.

Подробнее

- Высота — 5 м;

- Масса — 2,7 кг;

- Тип зажима — винт.

Подробнее

- Высота — 2.5 м;

- Масса — 0.93 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 2.

Подробнее

- Высота — 3.6 м;

- Масса — 1.29 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 3.

Подробнее

- Высота — 4.6 м;

- Масса — 1,99 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 4.

Подробнее

- Диаметр — 25 мм;

- Постоянная призмы (офсет) — 0 мм;

- Высота вехи — 1,3 м.

Подробнее

- Диаметр — 23 мм;;

- Высота вехи — 1,8 м.

- Вертикальное перемещение по вешке

Подробнее

Диаметр Ø=38 мм;

Постоянная призмы (офсет) К=0 мм;

Подробнее

- Диаметр — 35 мм.;

- Коэффициент — 30 мм. (0 мм.);

- Длина минивехи — 0.5-1.5 м;

- возможность вертикального перемещения по вешке

Подробнее

Постоянная призмы — 9 мм.

Подробнее

Постоянная призмы — 2 мм

Подробнее

- Винтовая резьба крепления — 5/8″;

- Диаметр призмы — Ø=64 мм;

- Константа = 0мм / -30мм.

Подробнее

- Винтовая резьба крепления — 5/8″;

- Константа =0мм / -30мм

- Подсветка отражателя

Подробнее

- Постоянная призмы — 30 мм / 0 мм;

- Диаметр призмы — 64 мм;

- Винтовая резьба крепления — 5/8″;

- Увеличенная марка

Подробнее

- Постоянная призмы — 30 мм / 0 мм;

- Диаметр призмы — 64 мм;

- Винтовая резьба крепления — 5/8″.

Подробнее

2,6 м, универсальная, TLV механизм (США)

Подробнее

фиберглассовая (вес 0,88 кг) , 2,6 м TLV механизм (США)

Подробнее

3.6м, универсальная (США)

Подробнее

фиберглассовая (вес 1,13 кг) , 3,6 м TLV механизм (США)

Подробнее

4.6м, универсальная (США)

Подробнее

для GNSS приемников

Подробнее

Материал: Алюминий

Подробнее

- Тип крепления:Резьба 5/8″

- Резьба в основании:5/8″

Подробнее

- Тип крепления:Leica

- Резьба в основании:5/8″

Подробнее

Резьба станового винта:5/8″

Подробнее

Отражатель круговой, призма круговая, призма 360

Подробнее

- Бренд:Geobond

- Коэффициент:23,1 мм

- Крепление на веху:Leica

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:64 мм

- Крепление на веху:5/8″

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:64 мм

- Крепление на веху:5/8″

Подробнее

- Длина: 130 см

- Материал: Нейлон

Подробнее

- Материал: Алюминий

- Рабочая высота: 1.55 м

Подробнее

- Материал:Алюминий

- Рабочая высота:1.6 м

- Длина в сложенном виде:1 м

Подробнее

- Материал:Алюминий

- Рабочая высота:1.55 м

Подробнее

Для тахеометров: Topcon GTS/GPT

Подробнее

Для тахеометров: Sokkia

Подробнее

Для тахеометров:Leica (кроме FlexLine и TS02 plus), GeoMax (кроме Zoom20 Pro, Zoom25, Zoom30 Pro)

Подробнее

Диаметр призмы:25 мм

Подробнее

Наконечник для вех Geobond серии ВК

Подробнее

Наконечник для вех Geobond серии SK

Подробнее

Съемный уровень для вех

Подробнее

- Материал: Карбон

- Рабочая высота: 2.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:2.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:3.6 м

- Длина в сложенном виде:1.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:5 м

- Длина в сложенном виде:1.6 м

Подробнее

- Бренд:Geobond

- Коэффициент:30 мм

- Диаметр призмы:22 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

- Бренд:Geobond

- Коэффициент:17.5 мм (0 мм)

- Диаметр призмы:25 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:35 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

30 м / 13 мм / Сталь

Подробнее

Трегеры RGK

Резьба станового винта — 5/8″;

Стандарт — WILD.

Подробнее

Резьба станового винта — 5/8″;

Стандарт — WILD;

Отвес — оптический (4Х).

Подробнее

- Резьба станового винта — 5/8″;

Подробнее

- Резьба станового винта — 5/8″;

- Стандарт -WILD;

- Отвес — оптический (4Х) .

Подробнее

- Резьба станового винта — 5/8″;

- Стандарт -WILD;

- Отвес — лазерный.

Подробнее

Рюкзаки и сумки RGK

- Для тахеометров всех типов и аксессуаров;

Подробнее

- Назначение — для траиссоискателей Ridgid SR-20/24

- Габариты — 60*36*23 см

- Масса — 2,5 кг

Подробнее

- Назначение — для тахеометров

- Вес — 3,99 кг

Подробнее

Вехи RGK

- Высота — 2,5 м.

- Резьбовое соединение — 5/8»;

- Зажим — винт типа барашек;

Подробнее

- Высота — 3,6 м.

- Резьбовое соединение — 5/8»;

- Пузырьковый уровень;

- Зажим — винт типа барашек;

Подробнее

- Высота — 4,6 м.

- Резьбовое соединение — 5/8»;

- Пузырьковый уровень;

- Зажим — винт типа барашек;

Подробнее

- Высота — до 2,5 м;

- Масса — 1,09 кг;

- Тип зажима — винт;

- Материал — карбон.

Подробнее

- Высота — 5 м;

- Масса — 2,7 кг;

- Тип зажима — винт.

Подробнее

- Высота — 2.5 м;

- Масса — 0.93 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 2.

Подробнее

- Высота — 3.6 м;

- Масса — 1.29 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 3.

Подробнее

- Высота — 4.6 м;

- Масса — 1,99 кг;

- Резьбовое соединение — 5/8»;

- Тип — телескопическая;

- Количество секций — 4.

Подробнее

Минипризмы RGK

- Диаметр — 25 мм;

- Постоянная призмы (офсет) — 0 мм;

- Высота вехи — 1,3 м.

Подробнее

- Диаметр — 23 мм;;

- Высота вехи — 1,8 м.

- Вертикальное перемещение по вешке

Подробнее

Диаметр Ø=38 мм;

Постоянная призмы (офсет) К=0 мм;

Подробнее

- Диаметр — 35 мм.;

- Коэффициент — 30 мм. (0 мм.);

- Длина минивехи — 0.5-1.5 м;

- возможность вертикального перемещения по вешке

Подробнее

Постоянная призмы — 9 мм.

Подробнее

Постоянная призмы — 2 мм

Подробнее

Отражатель на веху

- Винтовая резьба крепления — 5/8″;

- Диаметр призмы — Ø=64 мм;

- Константа = 0мм / -30мм.

Подробнее

- Винтовая резьба крепления — 5/8″;

- Константа =0мм / -30мм

- Подсветка отражателя

Подробнее

- Постоянная призмы — 30 мм / 0 мм;

- Диаметр призмы — 64 мм;

- Винтовая резьба крепления — 5/8″;

- Увеличенная марка

Подробнее

- Постоянная призмы — 30 мм / 0 мм;

- Диаметр призмы — 64 мм;

- Винтовая резьба крепления — 5/8″.

Подробнее

Вехи SECO

2,6 м, универсальная, TLV механизм (США)

Подробнее

фиберглассовая (вес 0,88 кг) , 2,6 м TLV механизм (США)

Подробнее

3.6м, универсальная (США)

Подробнее

фиберглассовая (вес 1,13 кг) , 3,6 м TLV механизм (США)

Подробнее

4.6м, универсальная (США)

Подробнее

Рюкзаки и кейсы Geobond

для GNSS приемников

Подробнее

Подставки для штативов

Материал: Алюминий

Подробнее

Переходники для штативов

- Тип крепления:Резьба 5/8″

- Резьба в основании:5/8″

Подробнее

- Тип крепления:Leica

- Резьба в основании:5/8″

Подробнее

Винты становые

Резьба станового винта:5/8″

Подробнее

Круговые отражатели

Отражатель круговой, призма круговая, призма 360

Подробнее

- Бренд:Geobond

- Коэффициент:23,1 мм

- Крепление на веху:Leica

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:64 мм

- Крепление на веху:5/8″

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:64 мм

- Крепление на веху:5/8″

Подробнее

Чехлы для штативов

- Длина: 130 см

- Материал: Нейлон

Подробнее

Штативы GeoBond

- Материал: Алюминий

- Рабочая высота: 1.55 м

Подробнее

- Материал:Алюминий

- Рабочая высота:1.6 м

- Длина в сложенном виде:1 м

Подробнее

- Материал:Алюминий

- Рабочая высота:1.55 м

Подробнее

Окуляры для тахеометра

Для тахеометров: Topcon GTS/GPT

Подробнее

Для тахеометров: Sokkia

Подробнее

Для тахеометров:Leica (кроме FlexLine и TS02 plus), GeoMax (кроме Zoom20 Pro, Zoom25, Zoom30 Pro)

Подробнее

Призменные системы

Диаметр призмы:25 мм

Подробнее

Вехи GEOBOND

Наконечник для вех Geobond серии ВК

Подробнее

Наконечник для вех Geobond серии SK

Подробнее

Съемный уровень для вех

Подробнее

- Материал: Карбон

- Рабочая высота: 2.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:2.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:3.6 м

- Длина в сложенном виде:1.5 м

Подробнее

- Материал:Алюминий

- Рабочая высота:5 м

- Длина в сложенном виде:1.6 м

Подробнее

Минипризмы GEOBOND

- Бренд:Geobond

- Коэффициент:30 мм

- Диаметр призмы:22 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

- Бренд:Geobond

- Коэффициент:17.5 мм (0 мм)

- Диаметр призмы:25 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

- Бренд:Geobond

- Коэффициент:-30 мм (0 мм)

- Диаметр призмы:35 мм

- Длина минивехи:0.3 — 1.25 м

Подробнее

Плёночные отражатели Geobond

Рулетки

30 м / 13 мм / Сталь

Подробнее

Деревянные штативы GeoBond

Купить Тахеометр Nikon Nivo 5M+ LP в Тюмени легко — просто позвоните по телефону:: 8-800-551-11-01

Total Station Nivo Series

Nivo3.M and Nivo5.M

Instruction Manual

Version A 1.0.0

Part Number C231E

July 2009

www.trimble.com

Contact Information

Trimble Navigation Limited Engineering and Construction Division 5475 Kellenburger Road

Dayton, Ohio 45424-1099 USA

800-538-7800 (toll free in USA)

+1-937-245-5600 Phone

+1-937-233-9004 Fax www.trimble.com

Legal Notices

Copyright and Trademarks

© 2007-2009, Nikon-Trimble Co. Limited. All rights reserved. All trademarks are the property of their respective owners.

It is prohibited to alter this manual in part or whole without express permission.

The contents of this manual are subject to change without notice. Although every effort has been made to ensure the accuracy of this manual, please contact your dealer if you find anything in it that is incorrect or unclear.

Release Notice

This is the July 2009 (Revision A) release of the Total Station Nivo Series Instruction Manual. It applies to software release version 1.0.0 for the Total Station Nivo series.

Manufacturer

Nikon-Trimble Co., Ltd. Technoport Mituiseimei Bldg.

16-2, Minamikamata 2-chome, Ota-ku Tokyo 144-0035 Japan

Notices

USA

FCC 15B Class B satisfied.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

–Consult the dealer or an experienced radio/TV technician for help.

|

C |

Warning – This equipment has been certified to |

|

comply with the limits for a Class B personal |

|

|

computer and peripherals, pursuant to Subpart B of |

|

|

Part 15 of FCC Rules. Only peripherals (computer |

|

|

input/output devices, terminals, printers, etc.) |

|

|

certified to comply with the Class B limits may be |

|

|

attached to this equipment. Operation with |

|

|

non-certified personal computer and/or peripherals |

|

|

is likely to result in interference to radio and TV |

|

|

reception. The connection of a non-shielded |

|

|

equipment interface cable to this equipment will |

|

|

invalidate the FCC Certification of this device and |

|

|

may cause interference levels which exceed the |

|

|

limits established by the FCC for this equipment. |

|

|

You are cautioned that changes or modifications not |

|

|

expressly approved by the party responsible for |

|

|

compliance could void your authority to operate the |

|

|

equipment. |

|

European Union

EU EMC Directive satisfied.

Authorized Representative in Europe

Trimble GmbH Am Prime Parc 11

65479 Raunheim, Germany

Canada

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Class B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Taiwan

Battery Recycling Requirements

The product contains a removable battery. Taiwanese regulations require that waste batteries are recycled.

Notice to Our European Union Customers

For product recycling instructions and more information, please go to:

www.trimble.com/environment/summary.html

Recycling in Europe

To recycle Trimble WEEE, call: +31 497 53 2430,

and ask for the “WEEE associate,”

or mail a request for recycling instructions to:

Trimble Europe BV

c/o Menlo Worldwide Logistics Meerheide 45

5521 DZ Eersel, NL

For optional Bluetooth unit

USA

FCC Part 15 Subpart C/RSS-210, OET bulletin 65 supplement C satisfied

|

C |

Caution – Any changes or modifications not |

|

expressly approved by the party responsible for |

|

|

compliance could void the user’s authority to |

|

|

operate the equipment. |

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

–Consult the dealer or an experienced radio/TV technician for help.

Canada

RSS-210 Low Power Device

Operation is subject to the following two conditions: (1) This device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device.

European Union countries, Iceland, Norway, Liechtenstein, Turkey, Swiss

EN300 328v1.7.1, EN50360 satisfied

Hereby, Nikon-Trimble Co., Ltd., declares that this instrument is in compliance with the essential requirements and other relevant provisions of Directive 1999/5/EC.

Declaration of Conformity available at http://www.nikon-trimble.com/

RF exposure compliance

1)To comply with FCC/IC RF exposure compliance requirements, a separation distance of at least 20 cm must be maintained between the antenna of this device and all persons.

2)This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

Safety

In this chapter:

QIntroduction

QWarnings and Cautions

QLaser Safety

Total Station Nivo Series Instruction Manual iii

Safety

Introduction

For your safety, read this instruction manual carefully and thoroughly before using the Total Station Nivo series. Although Nikon products are designed for maximum safety, using them incorrectly or disregarding the instructions can cause personal injury or property damage.

You should also read the documentation for any other equipment that you use with a Nivo series instrument.

Note – Always keep the manual near the instrument for easy reference.

Warnings and Cautions

The following conventions are used to indicate safety instructions:

C C

WARNING – Warnings alert you to situations that could cause death or serious injury.

CAUTION – Cautions alert you to situations that could cause injury or property damage.

Always read and follow the instructions carefully.

Warnings

C C

Before using the instrument, read the following warnings and follow the instructions that they provide:

WARNING – Never look at the sun through the telescope. If you do, you may damage or lose your eyesight.

WARNING – Nivo series instruments are not designed to be explosion-proof. Do not use the instrument in coal mines, in areas contaminated with coal dust, or near other flammable substances.

|

C |

WARNING – Never disassemble, modify, or repair the instrument yourself. If you do, you may |

|

receive electric shocks or burns, or the instrument may catch fire. You may also impair the |

|

|

accuracy of the instrument. |

|

|

C |

|

|

WARNING – Use only the battery charger and AC adapter that are supplied with the |

|

|

instrument. Do not use any other charger or you may cause the battery pack to catch fire or |

|

|

rupture. |

|

iv Total Station Nivo Series Instruction Manual

|

Safety |

|

|

C |

|

|

WARNING – Do not cover the battery charger and AC adapter while the battery pack is being |

|

|

recharged. The charger must be able to dissipate heat adequately. Coverings such as blankets |

|

|

or clothing can cause the charger to overheat. |

|

|

C |

|

|

WARNING – Avoid recharging the battery pack in humid or dusty places, in direct sunlight, or |

|

|

near heat sources. Do not recharge the battery pack when it is wet. If you do, you may receive |

|

|

electric shocks or burns, or the battery pack may overheat or catch fire. |

|

|

C |

|

|

WARNING – Although the battery pack has an auto-reset circuit breaker, you should take care |

|

|

not to short circuit the contacts. Short circuits can cause the battery pack to catch fire or burn |

|

|

you. |

|

C C

WARNING – Never burn or heat the battery. Doing so may cause the battery to leak or rupture. A leaking or ruptured battery can cause serious injury.

WARNING – Before storing the battery pack or battery charger, cover the contact points with insulation tape. If you do not cover the contact points, the battery pack or charger may short circuit, causing fire, burns, or damage to the instrument.

|

C |

WARNING – The battery is not itself waterproof. Do not get the battery wet when it is removed |

|

from the instrument. If water seeps into the battery, it may cause a fire or burns. |

|

Cautions

C C C

Before using the instrument, read the following cautions and follow the instructions that they provide:

CAUTION – Use of controls, adjustments, or performance of procedures other than those specified herein may result in hazardous radiation exposure.

CAUTION – The tops of the tripod ferrules are very sharp. When handling or carrying the tripod, take care to avoid injuring yourself on the ferrules.

CAUTION – Before carrying the tripod or the instrument in the carrying case, check the shoulder strap and its clasp. If the strap is damaged or the clasp is not securely fastened, the carrying case may fall, causing personal injury or instrument damage.

|

C |

CAUTION – Before setting up the tripod, make sure that no-one’s hands or feet are underneath |

|

it. When the legs of the tripod are being driven into the ground, they could pierce hands or feet. |

|

Total Station Nivo Series Instruction Manual v

Safety

|

C |

CAUTION – After mounting the instrument on the tripod, securely fasten the thumb screws on |

|

|

the tripod legs. If the thumb screws are not securely fastened, the tripod may collapse, causing |

||

|

personal injury or instrument damage. |

||

|

C |

||

|

CAUTION – After mounting the instrument on the tripod, securely fasten the clamp screw on |

||

|

the tripod. If the clamp screw is not securely fastened, the instrument may fall off the tripod, |

||

|

causing personal injury or instrument damage. |

||

|

C |

||

|

CAUTION – Securely fasten the tribrach clamp knob. If the knob is not securely fastened, the |

||

|

tribrach may come loose or fall off when you lift the instrument, causing personal injury or |

||

|

instrument damage. |

||

|

C |

||

|

CAUTION – Do not stack objects on the plastic carrying case, or use it as a stool. The plastic |

||

|

carrying case is unstable and its surface is slippery. Stacking or sitting on the plastic carrying |

||

|

case may cause personal injury or instrument damage. |

||

|

C |

||

|

CAUTION – The system in the instrument may stop functioning in order to avoid any errors in |

||

|

measurement when the instrument detects strong electromagnetic wave(s). If this is the case, |

||

|

turn off the instrument and remove the source of the electromagnetic wave(s). Then turn on the |

||

|

instrument to resume the work. |

||

Rechargeable Lithium-ion (Li-ion) batteries |

||

|

C |

||

|

WARNING – Do not damage the rechargeable Lithium-ion battery. A damaged battery can |

||

|

cause an explosion or fire, and can result in personal injury and/or property damage. |

||

|

To prevent injury or damage: |

||

|

– Do not use or charge the battery if it appears to be damaged. Signs of damage include, but |

||

|

are not limited to, discoloration, warping, and leaking battery fluid. |

||

|

– Do not expose the battery to fire, high temperature, or direct sunlight. |

||

|

– Do not immerse the battery in water. |

||

|

– Do not use or store the battery inside a vehicle during hot weather. |

||

|

– Do not drop or puncture the battery. |

||

|

– Do not open the battery or short-circuit its contacts. |

||

|

C |

||

|

WARNING – Avoid contact with the rechargeable Lithium-ion battery if it appears to be leaking. |

Battery fluid is corrosive, and contact with it can result in personal injury and/or property damage.

To prevent injury or damage:

–If the battery leaks, avoid contact with the battery fluid.

–If battery fluid gets into your eyes, immediately rinse your eyes with clean water and seek medical attention. Do not rub your eyes!

–If battery fluid gets onto your skin or clothing, immediately use clean water to wash off the battery fluid.

vi Total Station Nivo Series Instruction Manual

|

Safety |

|

|

C |

|

|

WARNING – Charge and use the rechargeable Lithium-ion battery only in strict accordance |

|

|

with the instructions. Charging or using the battery in unauthorized equipment can cause an |

|

|

explosion or fire, and can result in personal injury and/or equipment damage. |

|

|

To prevent injury or damage: |

|

|

– Do not charge or use the battery if it appears to be damaged or leaking. |

|

|

– Charge the Lithium-ion battery only in a product that is specified to charge it. Be sure to |

|

|

follow all instructions that are provided with the battery charger. |

|

|

– Discontinue charging a battery that gives off extreme heat or a burning odor. |

|

|

– Use the battery only in equipment that is specified to use it. |

|

|

– Use the battery only for its intended use and according to the instructions in the product |

|

|

documentation. |

|

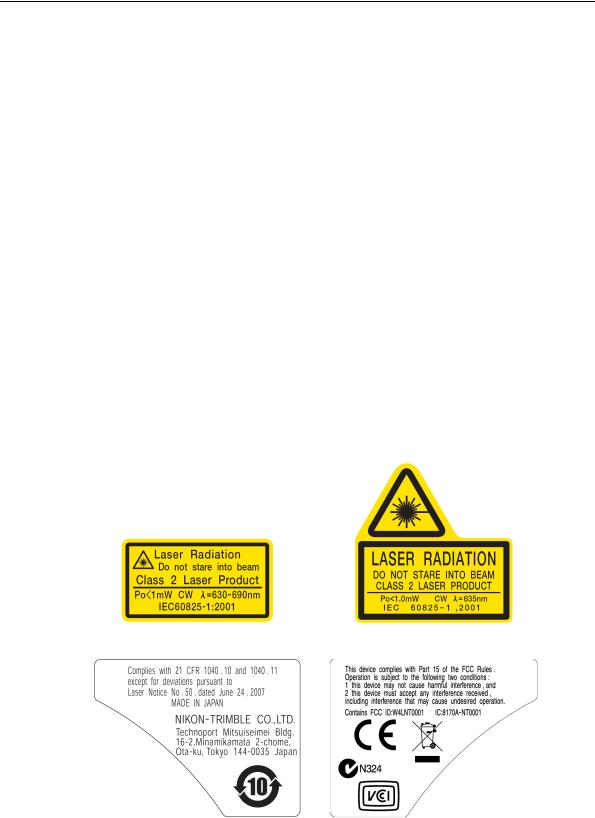

Laser Safety

|

The Nivo series is a Class 2 laser instrument. |

|

|

Nivo Series is a Class 2 Laser Product in accordance with: IEC60825-1, Am2 (2001): |

|

|

“Safety of Laser Products” |

|

|

Precautions: To counteract hazards, it is essential for all users to pay careful attention |

|

|

to the safety precautions and control measures specified in the standard IEC60825-1 |

|

|

(2001-08) resp. EN60825-1:1994 + A11:1996 + A2:2001, within the hazard |

|

|

distance *); particularly on to “User’s Guide”. |

|

|

C |

|

|

WARNING – Only qualified and trained persons should be assigned to install, adjust and |

|

|

operate the laser equipment. |

|

|

C |

|

|

WARNING – Precautions should be taken to ensure that persons do not look directly, with or |

|

|

without an optical instrument, into the beam. |

|

|

C |

|

|

WARNING – Laser beam path should be located well above or below eye level wherever |

|

|

practicable. |

|

Total Station Nivo Series Instruction Manual vii

Safety

|

Table 1.1 |

Specifications for laser emission |

||

|

Laser pointer |

|||

|

Wave length |

630-680 nm |

||

|

Output power |

CW |

Po ≤ 1 mW |

|

|

Disatance meter |

|||

|

Wave length |

850-890 nm |

||

|

Output power |

Pulse |

Po ≤ 6.4 W |

|

|

Pulse width |

< 5 ns |

||

|

Laser plummet (Option) |

|||

|

Wave length |

635 nm |

||

|

Output power |

CW |

Po < 1.0 mW |

|

|

Table 1.2 |

Conforming standards |

|

E.U. |

EN60825-1/Am.2 : 2001 (IEC60825-1/Am.2 : 2001) |

|

Laser Pointer: Class 2 |

|

|

Distance Meter: Class 1 |

|

|

Laser plummet: Class 2 (Option) |

|

|

USA |

FDA21CFR Part 1040 Sec.1040.10 and 1040.11 |

|

(except for deviations pursuant to Laser Notice No.50, dated June |

|

|

24, 2007) |

|

|

Laser pointer |

Laser plummet (Option) |

viii Total Station Nivo Series Instruction Manual

Contents

|

Safety . . . . . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . . |

. . . . |

. . |

. |

iii |

|

Introduction . . . . . . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. . |

iv |

|

Warnings and Cautions . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. . |

iv |

|

Warnings . . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

iv |

|

Cautions . . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

v |

|

Rechargeable Lithium-ion (Li-ion) batteries |

. . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. . |

vi |

|

Laser Safety. . . . . . . . . . . . . . . |

. . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. . vii |

|

1 |

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

Parts of the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

|

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

2 |

Preparation . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

. . . . |

. . |

. |

7 |

|

Unpacking and Packing the Instrument . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

8 |

|

|

Unpacking . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. |

8 |

|

|

Packing . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. |

8 |

|

|

Charging the Battery Pack . . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

8 |

|

|

Detaching and Re-Attaching the Battery Pack. . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. 12 |

||

|

Setting Up the Tripod . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

13 |

|

|

Centering . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

13 |

|

|

Centering using the optical plummet . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 13 |

||

|

Centering using the laser plummet . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 14 |

||

|

Centering using a plumb bob . . . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 15 |

||

|

Leveling . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

15 |

|

|

Sighting . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

16 |

|

|

Setting the Measurement Mode and Preparing the Target |

. . . . . . . . . . . . |

. . . . |

. . . |

. 17 |

||

|

Measurement with a prism . . . . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 17 |

||

|

Measurement in Reflectorless mode . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. 18 |

||

|

Preparing the Reflector Sheet . . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

19 |

|

|

Setting Up the Prism Reflector . . . . . . . . . . . . |

. . . . . . . . . . . . |

. . . . |

. . . |

. |

20 |

|

|

Adjusting the height of the tribrach adapter . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 21 |

||

|

Changing the direction of the prism . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 21 |

||

|

Setting the prism constant . . . . . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 21 |

||

|

Setting the position of the target plate . . . . . . |

. . . . . . . . . . |

. . . . |

. . |

. 22 |

|

3 |

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

23 |

|

Turning the Instrument On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

||

|

Turning on the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

||

|

Turning off the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

||

|

Changing Regional Configuration Pre-sets . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 25 |

||

|

Display and Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

26 |

|

|

Status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 28 |

||

|

LCD backlight, Laser pointer, Beep sound and Contrast adjustment . . . . . . . . . . |

. 30 |

||

|

[DSP] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 31 |

||

|

[MODE] key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 32 |

||

|

[COD] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 33 |

||

|

[HOT] key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 34 |

||

|

Total Station Nivo Series Instruction Manual |

ix |

Contents

|

Bubble indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 36 |

||

|

Laser plummet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 36 |

||

|

[USR] keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 37 |

||

|

[DAT] key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 38 |

||

|

List Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

39 |

|

|

Inputting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

39 |

|

|

Entering a point name or number . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 39 |

||

|

Entering a code . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 43 |

||

|

Advanced feature: Searching for a code by using the first character . . |

. . |

. 44 |

||

|

Entering values in feet and inches . . . . . . . . . . . . . . . . . . . . . |

. . |

. 45 |

||

|

Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

45 |

|

|

Creating a new job . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 46 |

||

|

Measuring Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

47 |

|

|

Sighting a prism reflector . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 47 |

||

|

Measuring distances. . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 47 |

||

|

Measurement settings . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 48 |

||

|

4 |

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

51 |

|

HA Reset and Angle Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. 52 |

||

|

Setting the horizontal angle to 0 . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 52 |

||

|

Entering the horizontal angle . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 52 |

||

|

Recording a foresight point after repeat angle measurement . . . . . . . . . . . |

. . |

. 52 |

||

|

Horizontal angle hold . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 53 |

||

|

Station Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

53 |

|

|

Setting up a station with known coordinates or azimuth . . . . . . . . . . . . . |

. . |

. 54 |

||

|

Setting up a station using multiple point resection . . . . . . . . . . . . . . . |

. . |

. 57 |

||

|

Advanced feature: Viewing and deleting a measurement in resection . . . . . 59 |

||||

|

Setting up the station quickly without coordinates . . . . . . . . . . . . . . . |

. . |

. 60 |

||

|

Determining station elevation . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 60 |

||

|

Checking and resetting the backsight direction . . . . . . . . . . . . . . . . |

. . |

. 61 |

||

|

Two-point resection along a known line . . . . . . . . . . . . . . . . . . . |

. . |

. 62 |

||

|

Stakeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

64 |

|

|

Specifying the stakeout point by angle and distance . . . . . . . . . . . . . . |

. . |

. 65 |

||

|

Specifying the stakeout point by coordinates . . . . . . . . . . . . . . . . . |

. . |

. 66 |

||

|

Advanced feature: Specifying a stakeout list by range input . . . . . |

. . |

. 68 |

||

|

DivLine S-O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 68 |

||

|

RefLine S-O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 69 |

||

|

Program Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

71 |

|

|

Measuring distance and offset values along a specified line . . . . . . . . . . . |

. . |

. 71 |

||

|

Measuring distance and offset values on the arc-curve . . . . . . . . . . . . . |

. . |

. 73 |

||

|

Remote distance measurement. . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 75 |

||

|

Measuring remote elevation . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 77 |

||

|

Measuring distance and offset values on the vertical plane . . . . . . . . . . . . |

. . |

. 78 |

||

|

Measuring distance and offset values on the slope . . . . . . . . . . . . . . . |

. . |

. 80 |

||

|

Recording Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. 81 |

||

|

Recording data from any observation screen . . . . . . . . . . . . . . . . . |

. . |

. 81 |

||

|

Outputting data to the COM port . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 82 |

||

|

Measuring Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

83 |

xTotal Station Nivo Series Instruction Manual

Contents

|

Measuring taped offsets . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 83 |

||

|

Measuring angle offsets . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 84 |

||

|

Two-prism pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 85 |

||

|

Extending a line by horizontal angle offset . . . . . . . . . . . . . . . . . . |

. . |

. 86 |

||

|

Entering a horizontal distance after an angle-only shot . . . . . . . . . . . . . |

. . |

. 87 |

||

|

Calculating a corner point . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 88 |

||

|

Measuring circle offsets . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 89 |

||

|

Extending the slope distance. . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 90 |

||

|

5 |

Menu Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

91 |

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

92 |

|

|

Job Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

92 |

|

|

Opening an existing job . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 92 |

||

|

Creating a new job . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 93 |

||

|

Deleting a job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 94 |

||

|

Setting the control job . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 94 |

||

|

Displaying job Information . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 95 |

||

|

Cogo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

96 |

|

|

Calculating angle and distance between two coordinates . . . . . . . . . . . . |

. . |

. 96 |

||

|

Calculating and manually inputting coordinates . . . . . . . . . . . . . . . . |

. . |

. 98 |

||

|

Calculating area and perimeter . . . . . . . . . . . . . . . . . . . . . . |

. . |

100 |

||

|

Advanced feature: Entering a range of points . . . . . . . . . . . |

. . |

101 |

||

|

Calculating coordinates from line and offset . . . . . . . . . . . . . . . . . |

. . |

102 |

||

|

Calculating coordinates using intersection functions . . . . . . . . . . . . . . |

. . |

103 |

||

|

Advanced feature: Entering angle and distance offsets . . . . . . . |

. . |

107 |

||

|

Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

108 |

||

|

Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

108 |

||

|

Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

109 |

||

|

Coordinate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

110 |

||

|

Power saving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

110 |

||

|

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

111 |

||

|

Stakeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

111 |

||

|

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

111 |

||

|

Recording. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

112 |

||

|

Others settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

112 |

||

|

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

114 |

||

|

Viewing records . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

114 |

||

|

Deleting records . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

117 |

||

|

Editing records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

119 |

||

|

Searching records . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

122 |

||

|

Entering coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

124 |

||

|

Point name list and code list . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

124 |

||

|

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

128 |

||

|

Downloading data . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

128 |

||

|

Uploading coordinate data . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

129 |

||

|

Advanced feature: Editing the data order for upload . . . . . . . . |

. . |

130 |

||

|

Uploading a point name list or code list . . . . . . . . . . . . . . . . . . . |

. . |

131 |

||

|

1sec-Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

131 |

Total Station Nivo Series Instruction Manual xi

Contents

|

[MSR] key settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

132 |

||

|

[DSP] key settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

132 |

||

|

[USR] key settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

132 |

||

|

[S-O] key settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

133 |

||

|

[DAT] key settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

133 |

||

|

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

134 |

|

|

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

134 |

|

|

6 |

Checking and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

135 |

|

|

Adjusting the Electronic Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

136 |

|

|

Checking and Adjusting the Circular Level. . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

136 |

|

|

Checking and Adjusting the Optical/Laser Plummet. . . . . . . . . . . . . . . . . . . |

. . |

. |

136 |

|

|

Zero Point Errors of Vertical Scale and Horizontal Angle Corrections . . . . . . . . . . . |

. . |

. |

137 |

|

|

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

137 |

||

|

Adjusting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

138 |

||

|

Checking the Instrument Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

139 |

|

|

Checking the Laser Pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

140 |

|

|

7 |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

141 |

|

|

Main Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

142 |

|

|

Telescope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

142 |

||

|

Measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

142 |

||

|

Distance precision . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

142 |

||

|

Measurement intervals . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

143 |

||

|

Angle measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

143 |

||

|

Tilt sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

143 |

||

|

Tangent screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

143 |

||

|

Tribrach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

143 |

||

|

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

144 |

||

|

Optical plummet . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

144 |

||

|

Optional laser plummet. . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

144 |

||

|

Display and keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

144 |

||

|

Connections in the base of instrument . . . . . . . . . . . . . . . . . . . . |

. . |

144 |

||

|

Battery pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

145 |

||

|

Environmental performance . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

145 |

||

|

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

145 |

||

|

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

145 |

||

|

Environmental protection . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

145 |

||

|

Standard Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

146 |

|

|

External Device Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. |

146 |

8System Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Uploading Coordinate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

|

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

154 |

|

Record format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

154 |

|

Uploading Point Lists and Code Lists . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 156 |

|

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

156 |

xii Total Station Nivo Series Instruction Manual

Contents

|

File format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

156 |

|

Data example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

157 |

|

Downloading Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 158 |

|

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

158 |

|

Nikon raw record formats . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

158 |

|

SDR2x and SDR33 record formats . . . . . . . . . . . . . . . . . . . . . |

. . |

161 |

|

Data examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

165 |

10Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Cogo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

|

Communications |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

170 |

|

Data . . . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

171 |

|

Job Manager . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

172 |

|

Programs . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

172 |

|

Recording Data . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

173 |

|

Searching . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

174 |

|

Settings. . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

174 |

|

Stakeout . . . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

174 |

|

Station Setup . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

175 |

|

System Error . . |

. . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . . . |

. . . . |

. . |

. |

176 |

Total Station Nivo Series Instruction Manual xiii

Contents

xiv Total Station Nivo Series Instruction Manual

C H A P T E R

1

Introduction

In this chapter:

QWelcome

QParts of the Instrument

QMaintenance

Total Station Nivo Series Instruction Manual 1

1 Introduction

Welcome

Thank you for purchasing this Nikon product.

This instruction manual was written for the users of Total Station Nivo series instruments. Before you operate a Nivo series instrument, read this manual carefully. In particular, pay attention to the warnings and cautions that appear in the Safety section at the front of the manual. Before you begin, you should also read the maintenance instructions. For more information, see Maintenance, page 5.

2 Total Station Nivo Series Instruction Manual

Introduction 1

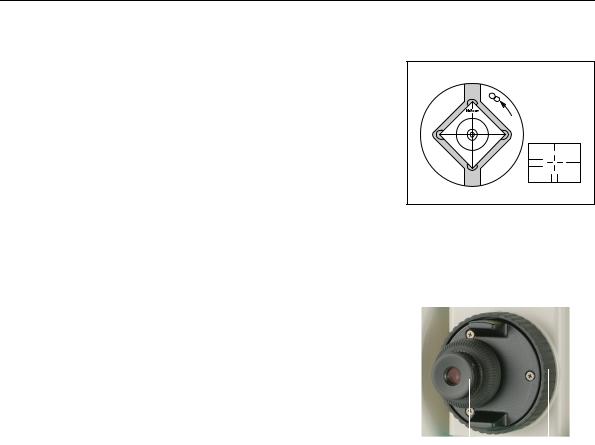

Parts of the Instrument

Figure 1.1 and Figure 1.2 show the main parts of the Nivo series instrument.

Carrying handle

Optical sight (Finder)

Telescope focusing ring

Telescope

eyepiece

Diopter ring

Reticle plate cover

Face-1 display / keyboard

The label shown below is attached to the underside of the keyboard.

Horizontal axis indication mark

Vertical tangent screw

Battery box

Battery box release knob

Upper plate tangent screw

The Laser Safety Label shown below is attached to the underside of the keyboard

Tribrach clamp knob

Figure 1.1 Total Station Nivo series – Face-1

Total Station Nivo Series Instruction Manual 3

1 Introduction

The Laser Safety label shown below is attached to the telescope.

Objective

LASER LIGHT IS

EMITTED FROM

THIS PART.

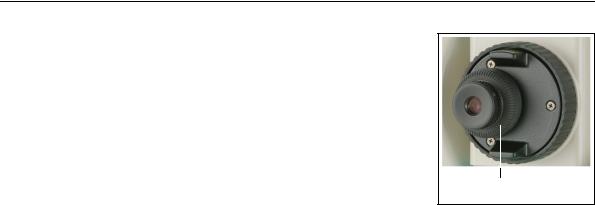

Optical or optional laser plummet (This picture shows the optical plummet.)

Circular level

Leveling screw

Tribrach

The Laser Safety label shown below is attached to

the telescope.

.

Horizontal axis indication mark

Battery box

Battery box release knob

Data output / external power input connector

Input voltage shall be 4.5-5.2 V DC

The Laser Safety label shown below will be attached here (underside) when the optional laser plummet is used.

Figure 1.2 Total Station Nivo series – Face-2

4 Total Station Nivo Series Instruction Manual

Introduction 1

Maintenance

Before using the instrument, read and follow the following maintenance instructions:

•Do not leave the instrument in direct sunlight or in a closed vehicle for prolonged periods. Overheating the instrument may reduce its efficiency.

•If the Nivo series instrument has been used in wet conditions, immediately wipe off any moisture and dry the instrument completely before returning the instrument to the carrying case. The instrument contains sensitive electronic assemblies which have been well protected against dust and moisture. However, if dust or moisture gets into the instrument, severe damage could result.

•Sudden changes in temperature may cloud the lenses and drastically reduce the measurable distance, or cause an electrical system failure. If there has been a sudden change in temperature, leave the instrument in a closed carrying case in a warm location until the temperature of the instrument returns to room temperature.

•Do not store the Nivo series instrument in hot or humid locations. In particular, you must store the battery pack in a dry location at a temperature of less than 30 °C (86 °F). High temperature or excessive humidity can cause mold to grow on the lenses. It can also cause the electronic assemblies to deteriorate, and so lead to instrument failure.

•Store the battery pack with the battery discharged.

•When storing the instrument in areas subject to extremely low temperatures, leave the carrying case open.

•When adjusting the leveling screws, stay as close as possible to the center of each screw’s range. The center is indicated by a line on the screw.

•If the tribrach will not be used for an extended period, lock down the tribrach clamp knob and tighten its safety screw.

•Do not use organic solvents (such as ether or paint thinner) to clean the non-metallic parts of the instrument (such as the keyboard) or the painted or printed surfaces. Doing so could result in discoloration of the surface, or in peeling of printed characters. Clean these parts only with a soft cloth or a tissue, lightly moistened with water or a mild detergent.

•To clean the optical lenses, lightly wipe them with a soft cloth or a lens tissue that is moistened with alcohol.

Total Station Nivo Series Instruction Manual 5

1 Introduction

•The reticle plate cover has been correctly mounted. Do not release it or subject it to excessive force to make it watertight.

•Before attaching the battery pack, check that the contact surfaces on the battery and instrument are clean.

•Securely press the cap that covers the data

output/external power input connector terminal.

The instrument is not watertight if the cap is not Reticle plate cover attached securely, or when the data output/external

power input connector is used.

•The carrying case is designed to be watertight, but you should not leave it exposed to rain for an extended period. If exposure to rain is unavoidable, make sure that the carrying case is placed with the Nikon nameplate facing upward.

•The battery pack contains a Lithium-ion battery. When disposing of the battery pack, follow the laws or rules of your municipal waste system.

•The instrument can be damaged by static electricity from the human body discharged through the data output/external power input connector. Before handling the instrument, touch any other conductive material once to remove static electricity.

•Be careful not to pinch your finger between the telescope and trunnion of the instrument.

6 Total Station Nivo Series Instruction Manual

C H A P T E R

2

Preparation

In this chapter:

QUnpacking and Packing the Instrument

QCharging the Battery Pack

QDetaching and Re-Attaching the Battery Pack

QSetting Up the Tripod

QCentering

QLeveling

QSighting

QSetting the Measurement Mode and Preparing the Target

QMeasurement in Reflectorless mode

QPreparing the Reflector Sheet

QSetting Up the Prism Reflector

Total Station Nivo Series Instruction Manual 7

2 Preparation

Unpacking and Packing the Instrument

Note – Handle the Nivo series instrument gently to protect it from shocks and excessive vibration.

Unpacking

To unpack the instrument, grip the carrying handle and gently remove the instrument from the carrying case.

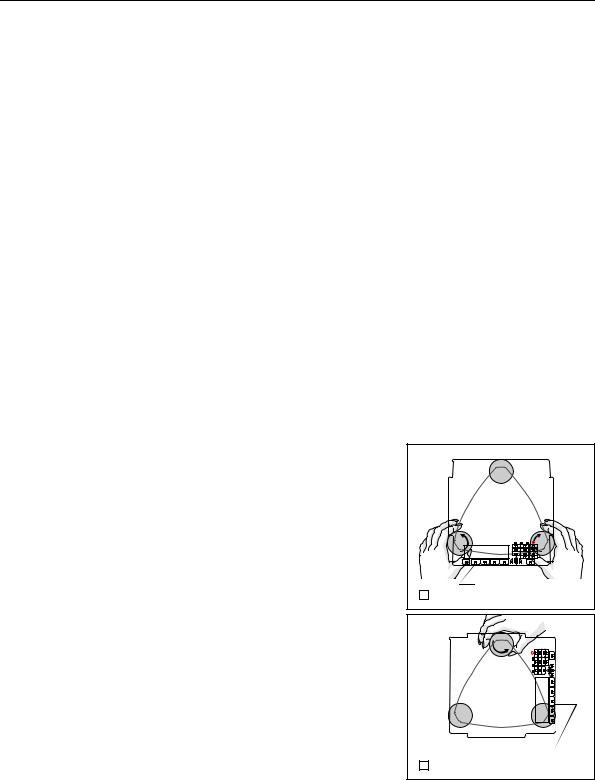

Packing

To pack the instrument back into the carrying case, please refer to the figure on the right.

Charging the Battery Pack

Before charging the battery pack, read the warnings (also listed in the Safety section at the front of this manual) and the following notes.

|

C |

WARNING – Do not damage the rechargeable Lithium-ion battery. A damaged battery can |

|

cause an explosion or fire, and can result in personal injury and/or property damage. |

|

|

To prevent injury or damage: |

|

|

– Do not use or charge the battery if it appears to be damaged. Signs of damage include, but |

|

|

are not limited to, discoloration, warping, and leaking battery fluid. |

|

|

– Do not expose the battery to fire, high temperature, or direct sunlight. |

|

|

– Do not immerse the battery in water. |

|

|

– Do not use or store the battery inside a vehicle during hot weather. |

|

|

– Do not drop or puncture the battery. |

|

|

– Do not open the battery or short-circuit its contacts. |

|

|

C |

|

|

WARNING – Avoid contact with the rechargeable Lithium-ion battery if it appears to be leaking. |

|

|

Battery fluid is corrosive, and contact with it can result in personal injury and/or property |

|

|

damage. |

|

|

To prevent injury or damage: |

|

|

– If the battery leaks, avoid contact with the battery fluid. |

|

|

– If battery fluid gets into your eyes, immediately rinse your eyes with clean water and seek |

|

|

medical attention. Do not rub your eyes! |

|

|

– If battery fluid gets onto your skin or clothing, immediately use clean water to wash off the |

|

|

battery fluid. |

|

8 Total Station Nivo Series Instruction Manual

|

Preparation 2 |

|

|

C |

|

|

WARNING – Charge and use the rechargeable Lithium-ion battery only in strict accordance |

|

|

with the instructions. Charging or using the battery in unauthorized equipment can cause an |

|

|

explosion or fire, and can result in personal injury and/or equipment damage. |

|

|

To prevent injury or damage: |

|

|

– Do not charge or use the battery if it appears to be damaged or leaking. |

|

|

– Charge the Lithium-ion battery only in a product that is specified to charge it. Be sure to |

|

|

follow all instructions that are provided with the battery charger. |

|

|

– Discontinue charging a battery that gives off extreme heat or a burning odor. |

|

|

– Use the battery only in equipment that is specified to use it. |

|

|

– Use the battery only for its intended use and according to the instructions in the product |

|

|

documentation. |

|

|

C |

|

|

WARNING – To charge the battery pack, use only the battery charger and AC adapter that are |

|

|

supplied with the instrument. Do NOT use any other charger or you may cause the battery pack |

|

|

to catch fire or rupture. The enclosed battery pack cannot be used with other chargers. |

|

|

C |

|

|

WARNING – Do not cover the battery charger and AC adapter while the battery pack is being |

|

|

recharged. The charger must be able to dissipate heat adequately. Coverings such as blankets |

|

|

or clothing can cause the charger to overheat. |

|

|

C |

|

|

WARNING – Avoid recharging the battery pack in humid or dusty places, in direct sunlight, or |

|

|

near heat sources. Do not recharge the battery pack when it is wet. If you do, you may receive |

|

|

electric shocks or burns, or the battery pack may overheat or catch fire. |

|

|

C |

|

|

WARNING – Although the battery pack has an auto-reset circuit breaker, you should take care |

|

|

not to short circuit the contacts. Short circuits can cause the battery pack to catch fire or burn |

|

|

you. |

|

C C

WARNING – Never burn or heat the battery. Doing so may cause the battery to leak or rupture. A leaking or ruptured battery can cause serious injury.

WARNING – Before storing the battery pack or battery charger, cover the contact points with insulation tape. If you do not cover the contact points, the battery pack or charger may short circuit, causing fire, burns, or damage to the instrument.

|

C |

WARNING – The battery is not itself waterproof. Do not get the battery wet when it is removed |

|

from the instrument. If water seeps into the battery, it may cause a fire or burns. |

|

Total Station Nivo Series Instruction Manual 9

2 Preparation

|

Power jack |

Charge indicator 0 |

||||||||

|

This will read |

Calibration |

||||||||

|

5V, 4A |

indicator 0 |

||||||||

|

Calibration button |

|||||||||

|

Case |

|||||||||

|

“Top” edge |

|||||||||

|

Calibration |

|||||||||

|

indicator 1 |

|||||||||

|

Battery Slot |

Charge indicator 1 |

||||||||

|

0 |

Battery Slot |

||||||||

|

1 |

Applying Power

•Plug in the charger to the supplied AC adapter to turn the unit on. The power input must be 5 V with at least 4 A of current capability. Each battery may take up to 2 A while charging.

Charging a battery

•Simply slide a battery into either battery slot to begin charging. The adjacent charge indicator will illuminate yellow when charging is in progress. The charge indicator will change to green when charging is complete.

•Charger slots are completely independent so a battery may be inserted regardless of the state of the other battery slot.

•Charging may take 2-4 hours if the battery was normally discharged.

•Charging may take up to 5 hours with a completely drained battery which has been stored for several months without use.

•By design Li-Ion batteries should not be charged above 40 °C-45 °C so a blinking charge light may mean the batteries are too hot for charging. Charging will resume after the batteries cool down. The charging time will be longer due to the batteries cool down when charging batteries above 40 °C-45 °C.

1 0 Total Station Nivo Series Instruction Manual

Preparation 2

•If the charge indicator(s) are blinking and the batteries feel cool, it may indicate a problem with the battery or the charger. If the charge light is still blinking after trying several batteries which are not warm, there is a problem with the unit or the batteries themselves.

Conditioning / calibrating a battery

•Battery calibration is necessary about once every 6 months or more often if desired. Calibration insures the reported battery charge remaining is accurate.

•Hold down the calibration button on the unit and then insert a battery while holding the calibration button to begin a battery calibration. Only the battery which was inserted while the button was depressed will begin calibration.

During a battery calibration the battery will be charged, discharged completely, and then recharged before finishing. Calibration should complete in roughly 17 hours and the charger vents should not be covered during a calibration cycle.

•The blue calibration indicator light(s) will blink slowly (on 1.5 sec, off 2 sec) while a calibration is in progress and the charge light(s) may be on or off during the calibration cycle.

•When a calibration cycle is completed, the calibration light will stop blinking remain on until the corresponding battery is removed.

•The bottom case temperature may continue to climb up to approximately 43 °C before temperature regulation is enabled to keep the case from getting warmer. As the battery voltage drops, the case will cool down and the automatic temperature limiting will no longer be necessary which minimizes the time it takes to discharge a battery.

•If the case temperature continues to get too hot internally even after temperature regulation is enabled, there is a secondary failsafe which will abort the calibration completely. If an abort occurs, the calibration light(s) will blink rapidly and battery charging will be re-enabled.

Total Station Nivo Series Instruction Manual 11

2 Preparation

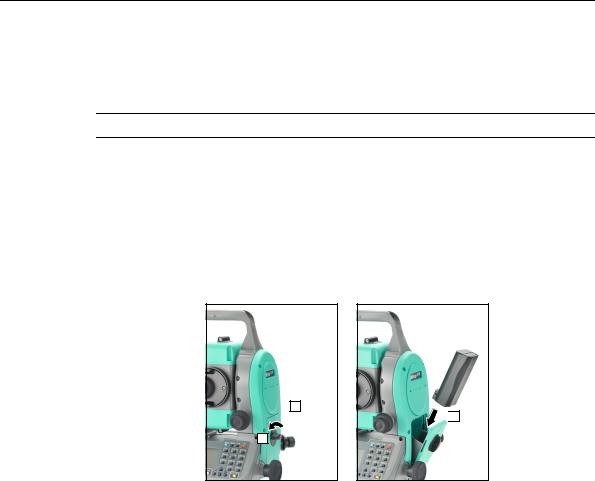

Detaching and Re-Attaching the Battery Pack

Detaching the battery pack

C CAUTION – Avoid touching the contacts on the battery pack.

1.If the instrument is turned on, press [PWR] to turn it off.

2.Turn the battery box release knob counterclockwise, open the battery box cover and remove the battery pack from the battery box.

Inserting the battery pack

Before inserting the battery pack, clear any dust or other foreign particles from the battery contacts.

2

1

1.Turn the battery box release knob counterclockwise and open the battery box cover.

2.Put the battery pack into the battery box. Insert the battery pack with the connectors bottom first, facing inside.

3.Close the battery box cover and turn the knob clockwise until the secure click sound is heard.

|

C |

CAUTION – If the battery box cover is not closed, this could adversely affect the watertightness |

|

of the instrument. |

|

1 2 Total Station Nivo Series Instruction Manual

|

Preparation 2 |

|

Setting Up the Tripod |

|

|

C |

|

|

CAUTION – The tops of the tripod ferrules are very sharp. When handling or carrying the |

|

|

tripod, take care to avoid injuring yourself on the ferrules. |

|

1.Open the tripod legs enough to for the instrument to be stable.

2.Locate the tripod directly over the station point. To check the tripod’s position, look through the center hole in the tripod head.

3.Firmly press the tripod ferrules into the ground.

4.Level the top surface of the tripod head.

5.Securely fasten the thumb screws on the tripod legs.

6.Place the instrument on the tripod head.

7.Insert the tripod mounting screw into the center hole of the base plate of the instrument.

8.Tighten the tripod mounting screw.